Page 1

OWNER'S

MANUAL

MODEL NO.

580.751500

_®

5 HORSEPOWER

1800 PS! 2.5 GPM

HOURS:

Mon.- Frl. 8 a,m. to 5 p.m

(CST)

CAUTION:

Read and Follow

all Safety Rules

and Instructions

Before Operating

This Equipment

SEARS, ROEBUCK

HiGH PRESSURE WASHER

o Assembly

= Operation

. Customer Responsibilities

• Service and Adjustment

o Repair Parts

and CO., HoffmanEstates,' IL 60179 U.S.A.

Page 2

SAFETY RULES

CAUTION: ALWAYS DISCONNECT SP/_K PLUG WIRE AND PLACE WIRE WHERE IT CANNOT CON-

TACT SPARK PLUG, TO PREVENT ACCIDENTAL STARTING WHEN SETTING UP, TRANSPORTING,

ADJUSTING OR MAKING REPAIRS TO YOUR HIGH PRESSURE WASHER,

TRAINING:

Engine exhaust gases contain DEADLY carbon mon-

oxide gas. l_is dangerous gas, if breathed in suffi-

cient concentrations, can cause unconsciousness or

even death. Operate this equipment only in the open

air where adequate ventilation is availabteo

= Gasoline is highly FIJ_M_L&.BLE and its vapors are

EXPLOSIVE. Do not permit smoking, open flames,

sparks or heat in the vicinity while handling gasoline.

Avoid spilling gasoline on a hot engine. Allow unit to

cool for 2 minutes before refueling. Comply with all

laws regulating storage and handhng of gasoline_

= Locate this pressure washer in areas away from com-

bustible materials, combustible fumes or dust=

= The high pressure equipment is designed to be used

with Sears authorized parts only. If you use this

equipment with parts that do not comply with minimum

specifications, the user assumes all nsks and liabili-

ties.

• Some chemP-.ats or detergents may be harmful if

inhaled or ingested, causing severe nausea, fainting

or poisoning. The harrr_,_! elements may cause prop.

erty damage or severe injury.

• Do not allow CHILDREN to operate the Pressure

Washer at any time.

PREPARATION:

• Operate engine only at governed speed. Running the

engine at excessive speeds increases the hazard of

personal injury. Do not tamper with parts which may

increase or decrease the governed speed.

= Do not wear loose clothing, jewelry or anything that

may be caught in the starter or other rotating parts.

" Before starting the Pressure Washer in cold weather,

check al! parts of the equipment and be sure ice has

not formed there.

• Units with broken or missing parts, or without protec-

tive housing or covers should NEVER be operated°

" The muffler and air cleaner must be installed and in

j_ood condition before operating the Pressure Washer.

hese components act as spark arrestors if the engine

backfires.

• Check the fuel system for leaks or signs of deteriora-

tion such as chafed or spongy hose, loose or missing

clamps or damaged tank or cap. Correct all defects

before operating the Pressure Washer.

OPERATION:

" Do not spray flammable liquids.

• Never aim the gun at people, animals or plants.

• Never allow any part of the body to come in contact

with the fluid stream. DO NOT come in contact with a

fluid stream created by a leak in the high pressure

hose_

o High pressure stream of fluid that this equipment can

produce can pieme skin and its undertying tissues,

leading to sedous injury and possible amputation.

° High pressure spray can cause paint chips or other

particles to become airborne and fly at high speeds.

LOOK FOR THIS SYMBOL TO POINT OUT IMPORI"ANT

SAFETY PRECAUTIONS. IT MEANS "ATTENTIONH! BE-

COME ALERT!!! YOUR SAFETY IS INVOLVED."

_' Always wear' eye protection when you use this equip-

ment or when you are in the vicinity where the equip-

ment is in use.

• Operate the pressure at no more than the PSI fluid

pressure rated for your pressure washer.

= Never move the machine by putling on the high pres-

sure hose. Use the handle provided on the top of the

uniL

= Always be certain the spray gun, nozzles and acces-

sories are correctly attached.

_' Never use a spray gun which does not have a trigger

lock or trigger guard in place and in working order.

=' Use a respirator or mask whenever there is a chance

that vapors may be inhaled. Read all instructions with

the mask so you are certain the mask will provide the

necessary protection against inhaling harmful vapors_

= High pressure spray may damage fragile items includ-

ing glass. Do not point spray gun at glass when in the

jet spray mode.

" Keep the hose connected to machine or the spray gun

while the system is pressurized. Disconnecting the

hose while the unit is pressurized is dangerous,

q' Hold the spray gun firmly in your hand before you start

the uniL Failure to do so could result in an injury from

a whipping spray gun. Do not leave the spray gun

unattended while the machine is running.

" The cleaning area should have adequate slopes and

drainage to reduce the possibility of a fall due to

slippery surfaces°

= Keep water spray away from electric wiring or fatal

electric shock may resulL

_, DO not adjust unloader valve to a pressure in excess

of machine rating°

_' Do not secure trigger gun in the pull-back (open)

position.

=' Do not by@ass any safety device on this machine°

o DO not leave trigger closed for more than 5 minutes

with engine running. This could damage the pump.

• The muffler and engine heat up during operation and

remain hot immediately after shutting it down° Avoid

contact with a hot muffler or engine or you could be

severely bumed.

MAINTENANCE AND STORAGE:

=' Operate and store this unit on a stable surface.

=' High pressure hose can develop leaks from wear,

kinking, abuse, etc. Water spraying! from a leak is

capable of injecting material into skin. inspect hose

each time before using it. Check all hoses for cuts,

leaks, abrasions or bulging of cover, or dama_]e or

movement of couplings. If any of these conditions

exist, replace hose immediately. Never repair high

pressure hose. Replace it with another hose that

meets minimum pressure rating of your pressure

washer.

J

2

Page 3

CONGRATULATIONS on your purchase of a Sears Crafts-

man high pressure washer. It has been designed, engi-

neered and manufactured to give you the best possible

dependability and performance.

Should you experience any problem you cannot easily

remedy, please contact your nearest Sears Service Cen-

tedDepartment or call the 1-800 number listed on the front

of this manual. We have competent, welt-trained techni.

clans and the proper tools to service or repair this uniL

Please read and retain this manual. The instructions wilt

enable you to assemble and maintain your high pressure

washer properly. Always observe the =SAFETY RULES."

MODEL

NUMBER 580,751500

SERIAL

NUMBER

PRODUCT S PECIFICATIONS

Pressure Washer Specifications

PUMP PRESSURE

FLOW RATE

DETERGENT MIX

DETERGENT RATIO

WATER SUPPLY

TEMPERATURE

SUCTION HEIGHT

Engine Specifications

RATED HORSEPOWER

DISPLACEMENT

Adjustable to 1800 ps!

2.5 gpm

Use undiluted detergent

Adjustable to 66:!

Not to exceed 140°F

3 FT'. maximum

5

12.6 cu. inches

DATE OF

PURCHASE ....

THE MODEl.. AND SERIAL NUMBERS WILL BE

FOUND ON A DECAL ATTACHED TO THE PRES-

SURE WASHER,,

YOU SHOULD RECORD BOTH SERIAL NUMBER

AND DATE OF PURCHASE AND KEEP IN A SAFE

PLACE FOR FUTURE REFERENCE,,

MAINTENANCE AGREEMENT

A Sears Maintenance Agreement is available on this prod-

ucto Contact your nearest Sears store for details,

CUSTOMER RESPONSIBILITIES

{, Read and observe the safety rules_

= Follow regular schedule in maintaining, caring for and

using your high pressure washer,

=, Follow the instructions under "Customer Responsibili-

ties" and "Storage" sections of this Owner's Manual

SPARK PLUG: Type:

Set Gap To.

GASOLINE CAPACITY

OIL (20 oz. capac!ty) ....

SOLID STATE IGNITION

AIR GAP

In the State of California a spark arrestor is required by law

(Section 4442 of the California Public Resources Code),

Other states may have similar laws_ Federal laws apply on

federal lands.

NOTE: If you equip the engine of your pressure washer with

a spark arrestor muffler, the spark arrestor must be main-

tained in effective working order by the owner operator_

You can order a spark arrestor through your Sears Service

Center, See Repair Parts section of engine for part num-

berso

Champion RCJ8

or equivalent

0.030 inch (O.76mm)

2 U.S. quarts

SAE 30 weight

0o0125 inch

Page 4

TABLE OF CONTENTS

SAFETY RULES ............................................................ 2

PRODUCT SPECIFICATIONS ...................................... 3

ACCESSORIES AND ATTACHMENTS .......................... 5

CONTENTS OF HARDWARE PACK .................................. 6

ASSEMBLY ....................................................................... 7-8

OPERATION ................................................................ 9-13

INDEX

-A-

Accessories ............... 5

Air Cleaner ............. 9,15

Assembly

Chet".,_Jist ................................. 8

Removing from Carton ............... 7

Tools Required ................ 7

Set Up ......................... 7-8

-B-

Before Starting the Engine .. _ 11

Hardware Pack ............. 6

High Pressure Hose ....... 8, 9

Maintenance

Agreement .......................... 3

Engine ............................... 15

Pressure Washer ................ 14

Pump ......................... 16

-C-

No_le, Adjustable ......... 10

Carburetor, ............... 16

Cleaning Tips ............. !3

Customer Responsibilities. 3,14

Changing Oil, engine .............. 15

Changing Oil, pump ................. 16

Checking Oil Level ................. 15

General Recommendations ..... 14

Pressure Washer .................. t4

Replace Spark Plug .............. t 5

Service Ait Cleaner. ............... 15

-E-

Engine Speed ............... 16

No_le, Optional Turbo ..... 11

Oil

Engine ............................ 12

Pump ............................. 16

Operation

Detergent Application ........... 11

Know Your Pressure Washer ...o. 9

Stopping .......................... 10

To Start Engine ...................... 13

ToTum on Washer ................. 12

Using Adjustable Nozzle .......... 10

Order Parts ........... back page

-G-

CUSTOMER RESPONSIBILITIES .......................... _ 4-15

SERVICE AND ADJUSTMENTS .................................. 16

STORAGE .................................................................... 17

TROUBLESHOOTING ......................... _ ......................... 18

REPLACEMENT PARTS ......................................... 19-29

WARRANTY ................................................................. 29

m H --

-p-

Pressure Regulator ......... 10

-R-

-M-

Replacement Parts ...... 19-29

-S-

Safety Latch .............. 13

Safety Rules .............. 2

Service and Adjustments o.. 16

-N-

Siphoning ............... 13

Specifications ............. 3

Storage

Engine ........................... 17

Pressure Washer Pump ......... 17

-T-

Troubleshooting .......... 18

-W-

Warranty ................. 29

Gun and Wand Assembly., ._ 8, 9

4

Page 5

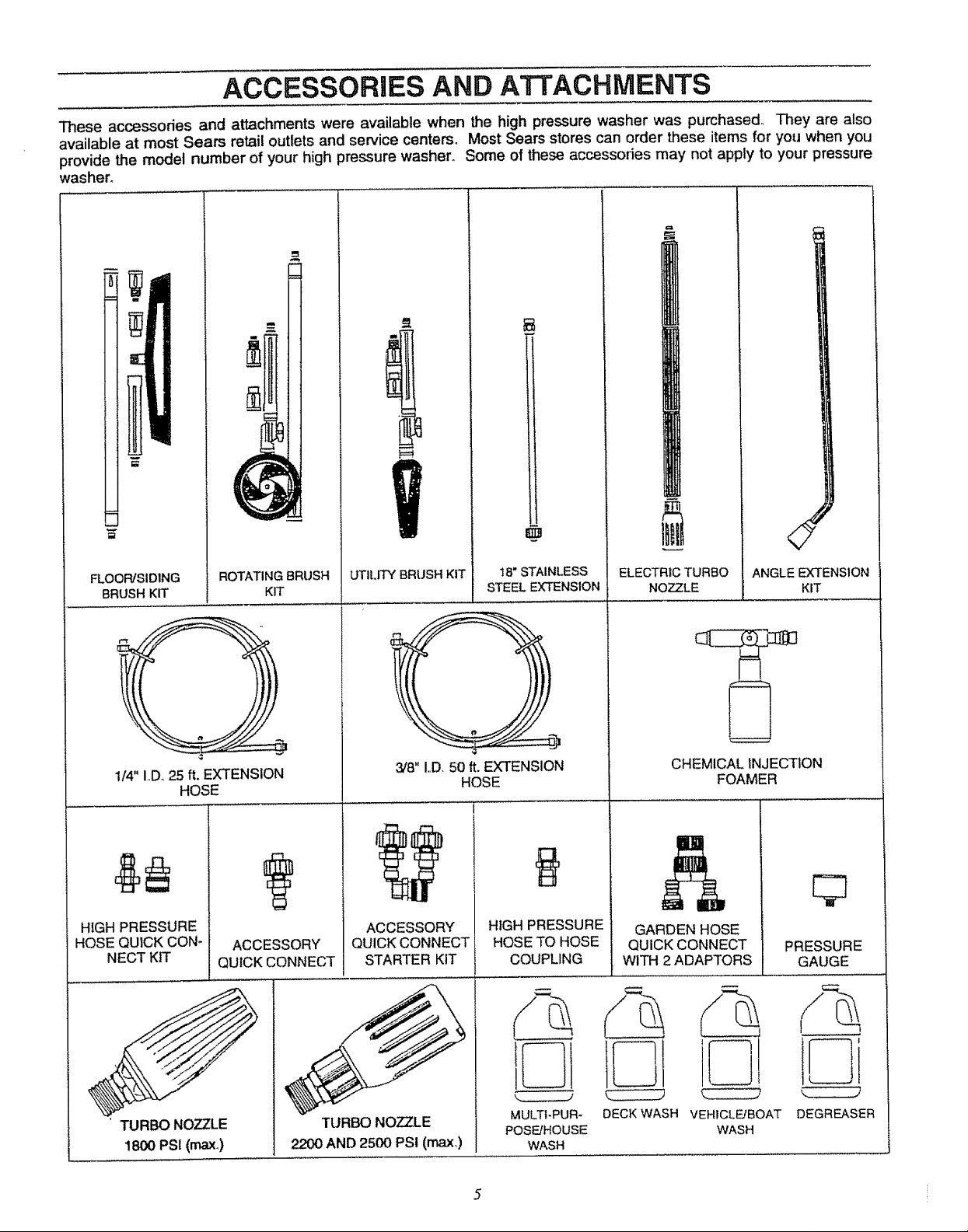

ACCESSORIES AND ATTACHMENTS

These accessories and attachments were available when the high pressure washer was purchased,, They are also

available at most Sears retail outlets and service centers. Most Sears stores can order these items for you when you

provide the model number of your high pressure washer. Some of these accessories may not apply to your pressure

washer°

®

u

FLOOR/SIDING

BRUSH KIT

1/4" ID., 25 ft. EXTENSION

HOSE

HIGH PRESSURE

HOSE QUICK. CON-

NECT KIT

ROTATING BRUSH

KIT

ACCESSORY

QUICK CONNECT

UTILITY BRUSH KIT

3/8" I,,D, 50 It. EXTENSION

ACCESSORY

QUICK CONNECT

STARTER KIT

18" STAINLESS

STEEL EXTENSION

HOSE

HIGH PRESSURE

HOSE TO HOSE

COUPLING

ELECTRIC TURBO

NOZZLE

CHEMICAL INJECTION

FOAMER

GARDEN HOSE

QUICK CONNECT

WITH 2 ADAPTORS

ANGLE EXTENSION

KIT

PRESSURE

GAUGE

' TURBO NOZZLE

1800 PS! (max,)

TURBO NOZZLE

2200 AND 2500 PSI (max,)

MULTI-PUR-

POSE/HOUSE

WASH

tC;

DECK WASH

VEHiCLE/BOAT

WASH

DEGREASER

Page 6

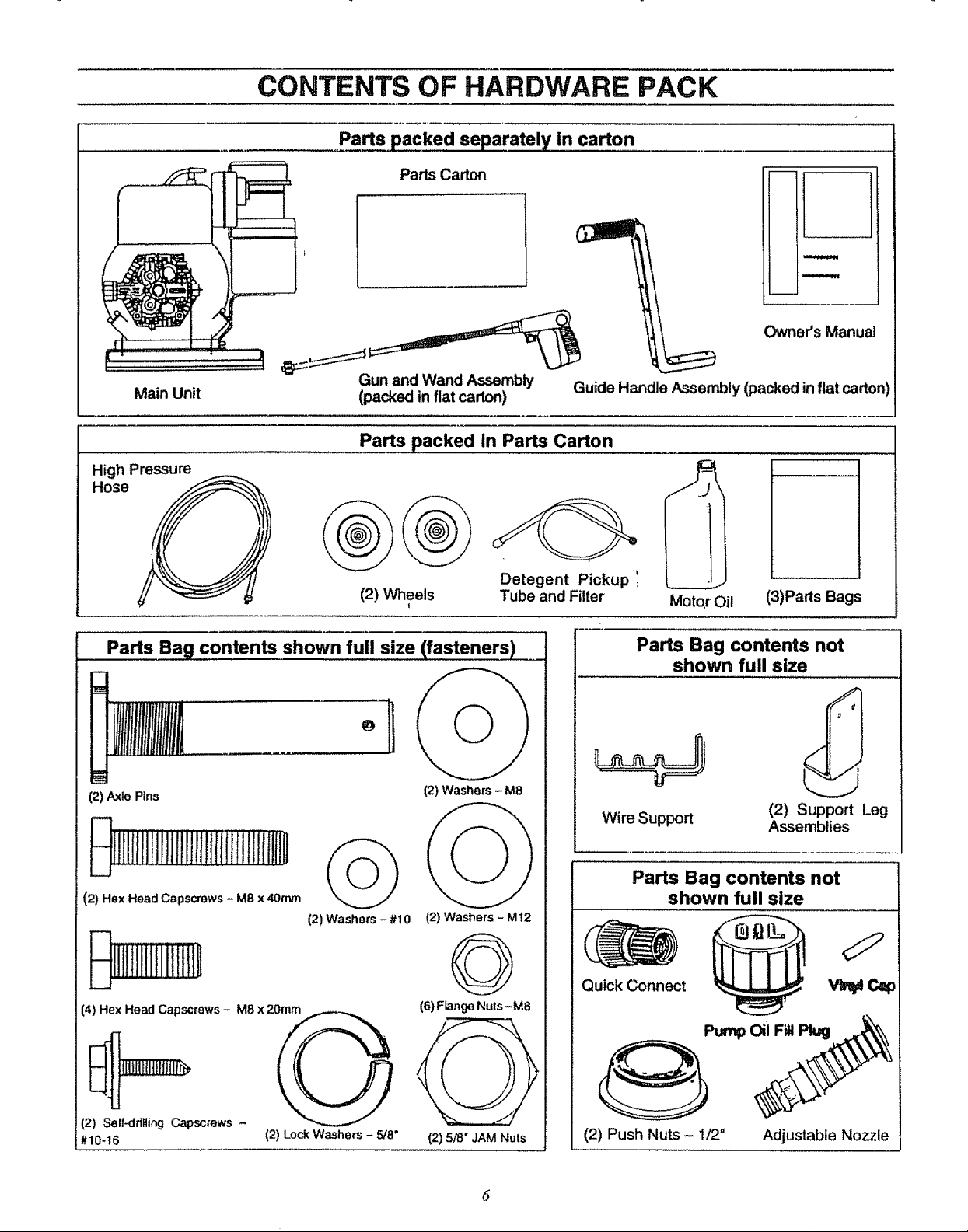

CONTENTS OF HARDWARE PACK

Parts packed separately in carton

Parts Carton

m

!

Owner's Manual

Main Unit

High Pressure

Hose

Pads Bag contents shown full size ,(fasteners) _

(2) Axle Pins

Gun and Wand Assembly

(packed in flat carton)

Parts packed In Parts Carton

(2) Wheels

!

(2) Washers - M8

Guide Handle Assembly (packed in flat carton)

Detegent Pickup ':

Tube and Filter'

Wire Support

MotQr Oit (3)Parts Bags

Pads Bag contents not

shown full size

(2) Support Leg

Assemblies

!l[ifiJliirlliiFllIl![fltiiJllr!!tlU

(2) Hex Head Capscrews - M8 x 40tT_

(2) Washers - #10

(2) Washers - M 12

0

(6) Flange Nuts-M8

(2) Lock Washers - 5/8"

(2) 5/8" JAM Nuts

Parts Bag contents not

shown full size

Quick Connect

(2) Push Nuts - i/2" Adjustable Nozzle

Page 7

ASSEMBLY

Read these iv, sttuctions and Operator's Manual in its en-

tirety before you attempt to assemble or operate your new

high pressure washer° Your high pressure washer has, for

the most part, been asserr_ed at the factory, except those

parts left unassembted. Before you can operate your new

high pressure washer, you must assemble the wheel kit and

property connect the high pressure hose.

IF YOU HAVE ANY PROBLEMS WITH THE ASSEMBLY

OF YOUR PRESSURE WASHER, PLEASE CALL THE

PRESSURE WASHER HELPLINE AT 1-800-_-3136.

TOOLS REQUIRED FOR ASSEMBLY

o Mallet

= 2 adjustable wrenches OR the following wrenches:

=, 5/16" (8mm) combination wrench

= 1/2" (13mm) combination wrench

- 5/8' (16mm) combination wrench

= 11/16" (18mm) combination wrench

= 7/8" (22ram) combination wrench

= 15/16" (24mm) combination wrench

TO REMOVE PRESSURE WASHER FROM

CARTON

=, Remove two boxes marked "PARTS INSIDE" and re-

move the parts contained in both boxes.

= Remove unit with one hand under pump and one hand

under recoil starter.

Refer to Page 6, "Contents of Hardware Pack" for an

illustrated listing of all the items included with your pressure

washer, Become familiar with each piece before assem-

bling the pressure washer,, Check all contents against the

illustrations on Page & If any parts are missing or dam-

aged, call the Pressure Washer Helpline at 1-800-222-

3136,

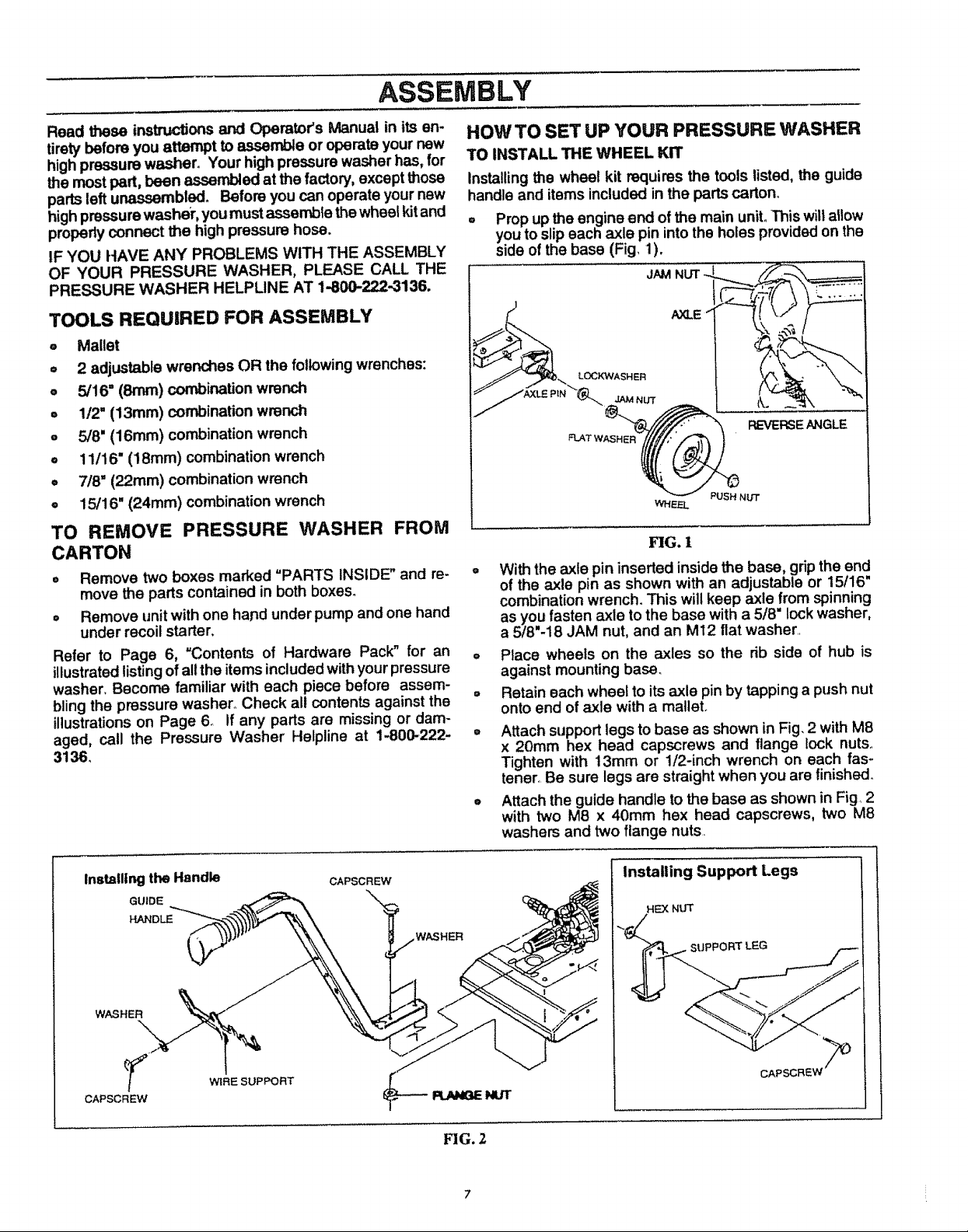

HOW TO SET UP YOUR PRESSURE WASHER

TO INSTALL THE WHEEL KIT

Installing the wheel kit requires the tools listed, the guide

handle and items included in the parts carton°

° Prop up the engine end of the main unit. This will allow

you to slip each axle pin into the holes provided on the

side of the base (Fig 1 ).

JAM

LOGK1NASHER

JAM NUT

FLAT v

FIG. 1

With the axle pin inserted inside the base, grip the end

of the axle pin as shown with an adjustable or 15/16"

combination wrench. This will keep axle from spinning

as you fasten axle to the base with a 5/8 lock washer,

a 5/8"-18 JAM nut, and an M12 flat washer..

o Place wheels on the axles so the rib side of hub is

against mounting base.

= Retain each wheel to its axle pin by tapping a push nut

onto end of axle with a mallet.

° Attach support legs to base as shown in Fig, 2 with M8

x 20mm hex head capscrews and flange lock nuts,.

Tighten with 13mm or 1/2-inch wrench on each fas-

tener.. Be sure legs are straight when you are tinished_

• Attach the guide handle to the base as shown in Fig, 2

with two M8 x 40mm hex head capscrews, two M8

washers and two flange nuts.

_L

REVERSE ANGLE

Installing the Handle

GUIDE

HANDLE

WASHER

\

CAPSCREW

WIRE SUPPORT

CAPSCREW

Installing Support Legs

CAPSC

_NUT

FIG. 2

Page 8

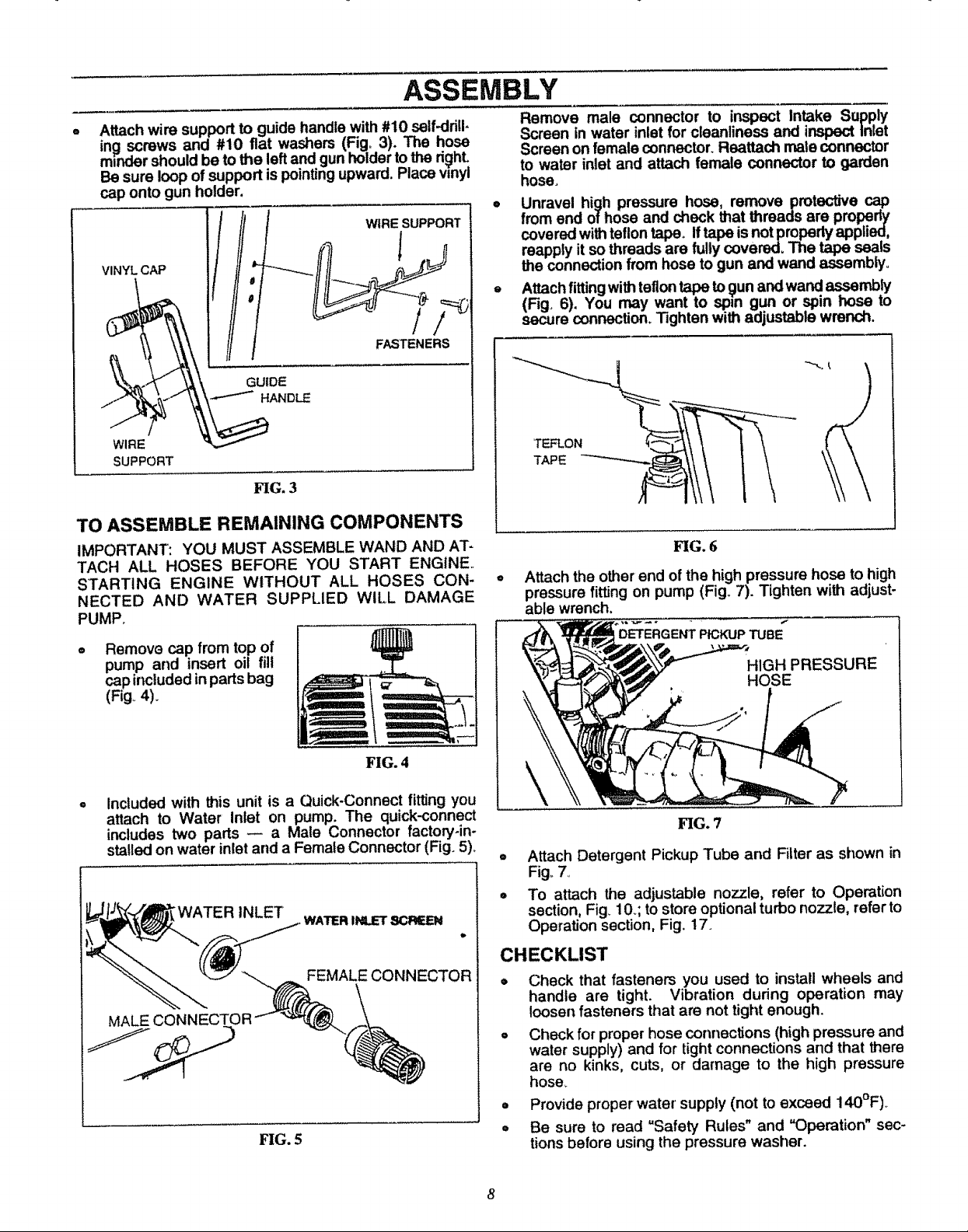

ASSEMBLY

o Attach wire support to guide handle with #10 self-dd!l-

in_! screws and #10 fiat washers (Fig° 3). The hose

mlnder should be to the left and gun holder to the d_tht.

Be sure loop of support is pointing upward. Place vinyl

cap onto gun holder.

WIRE SUPPORT

VINYL CAP i /

t

/

FASTENERS

SUPPORT

FIG. 3

TO ASSEMBLE REMAINING COMPONENTS

IMPORTANT: YOU MUST ASSEMBLE WAND AND AT-

TACH ALL HOSES BEFORE YOU START ENGINE,.

STARTING ENGINE WITHOUT ALL HOSES CON-

NECTED AND WATER SUPPLIED WILL DAMAGE

PUMP°

Remove cap from top of

pump and insert oil fill

cap included in parts bag

(Fig 4).

Remove male connector to inspect Intake Supply

Screen in water inlet for cleanliness and inspect Inlet

Screen on female connector. Reattach male connector

to water inlet and attach female connector to garden

hose.

o Unravel high pressure hose, remove protective cap

from end of hose and check that threads are properly

covered with teflon tape° If tape is not properly applied,

reapply it so threads are fully covered. The tape seals

the connection from hose to gun and wand assembly°

. Attach fitting with teflon tape to gun andwand assembly

(Fig° 6). You may want to spin gun or spin hose to

secure connection. Tighten with adjustable wrench.

FIG. 6

Attach the other end of the high pressure hose to high

pressure fitting on pump (Fig° 7). Tighten with adjust-

able wrench.

DETERGENT PICKUP TUBE

HIGH PRESSURE

HOSE

FIG. 4

Included with this unit is a Quick-Connect fitting you

attach to Water Inlet on pump. The quick-connect

includes two parts -- a Male Connector factory-in-

sta!led on water inlet and a Female Connector (Fig. 5).

WATER INLET

FEMALE CONNECTOR

MALE CONNECTOR

FIG. 5

FIG. 7

= Attach Detergent Pickup Tube and Filter as shown in

Fig. 7.

= To attach the adjustable nozzle, refer to Operation

section, Fig. 10o; to store optional turbo nozzle, refer to

Operation section, Fig. 17.

CHECKLIST

* Check that fasteners you used to install wheels and

handle are tight. Vibration during operation may

loosen fasteners that are not tight enough.

° Check for proper hose connections (high pressure and

water supply) and for tight connections and that there

are no kinks, cuts, or damage to the high pressure

hose_

. Provide proper water supply (not to exceed 140°F)_

,, Be sure to read "Safety Rules" and "Operation" sec-

tions before using the pressure washer.

Page 9

OPERATION

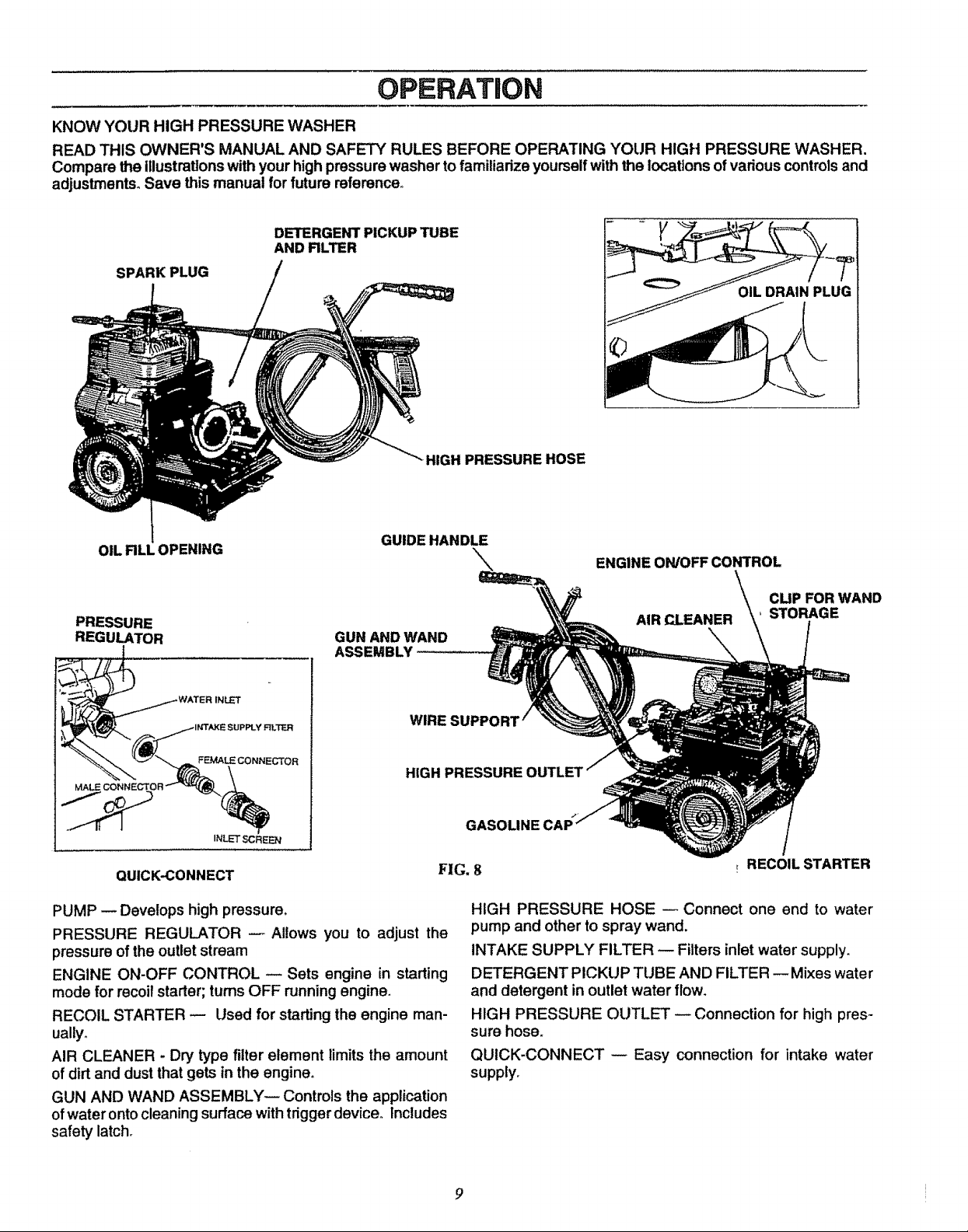

KNOW YOUR HIGH PRESSURE WASHER

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR HIGH PRESSURE WASHER.

Compare the illustrations with your high pressure washer to familiarize yourself with the locations of various controls and

adjustments. Save this manual for future reference,_

DETERGENT PICKUP TUBE

AND RLTER

SPARK PLUG

HIGH PRESSURE HOSE

OIL RLL OPENING

PRESSURE

REGULATOR

INLET

FEMALE CONNECTOR

QUICK-CONNECT

GUIDE HANDLE

GUN AND WAND

ASSEMBLY

WIRE SUPPORT t

HIGH PRESSURE €

PUMP -- Develops high pressure,

PRESSURE REGULATOR -- Allows you to adjust the

pressure of the outlet stream

ENGINE ON-OFF CONTROL -- Sets engine in starting

mode for recoil starter; turns OFF running engine.

RECOIL STARTER -- Used for starting the engine man-

uallyo

AIR CLEANER - Dry type filter element limits the amount

of dirt and dust that gets in the engine.

GUN AND WAND ASSEMBLY-- Controls the application

of water onto cleaning surface with trigger device° Includes

safety latch.

ENGINE ON/OFF CONTROL

CUP FOR WAND

GASOLINE CA!

FIG. 8

RECOIL STARTER

HIGH PRESSURE HOSE -- Connect one end to water

pump and other to spray wand.

INTAKE SUPPLY FILTER -- Filters inlet water supply.

DETERGENT PICKUP TUBE AND FILTER --Mixes water

and detergent in outlet water flow.

HIGH PRESSURE OUTLET -- Connection for high pres-

sure hose.

QUICK-CONNECT -- Easy connection for intake water

supply.

Page 10

OPERATION

HOW TO USE YOUR WASHER

IF YOU HAVE ANY PROBLEMS OPERATING YOUF..

PRESSURE WASHER, PLEASE CALL THE PRESSURE

WASHER HELPLINE AT 1-800-222-3136.

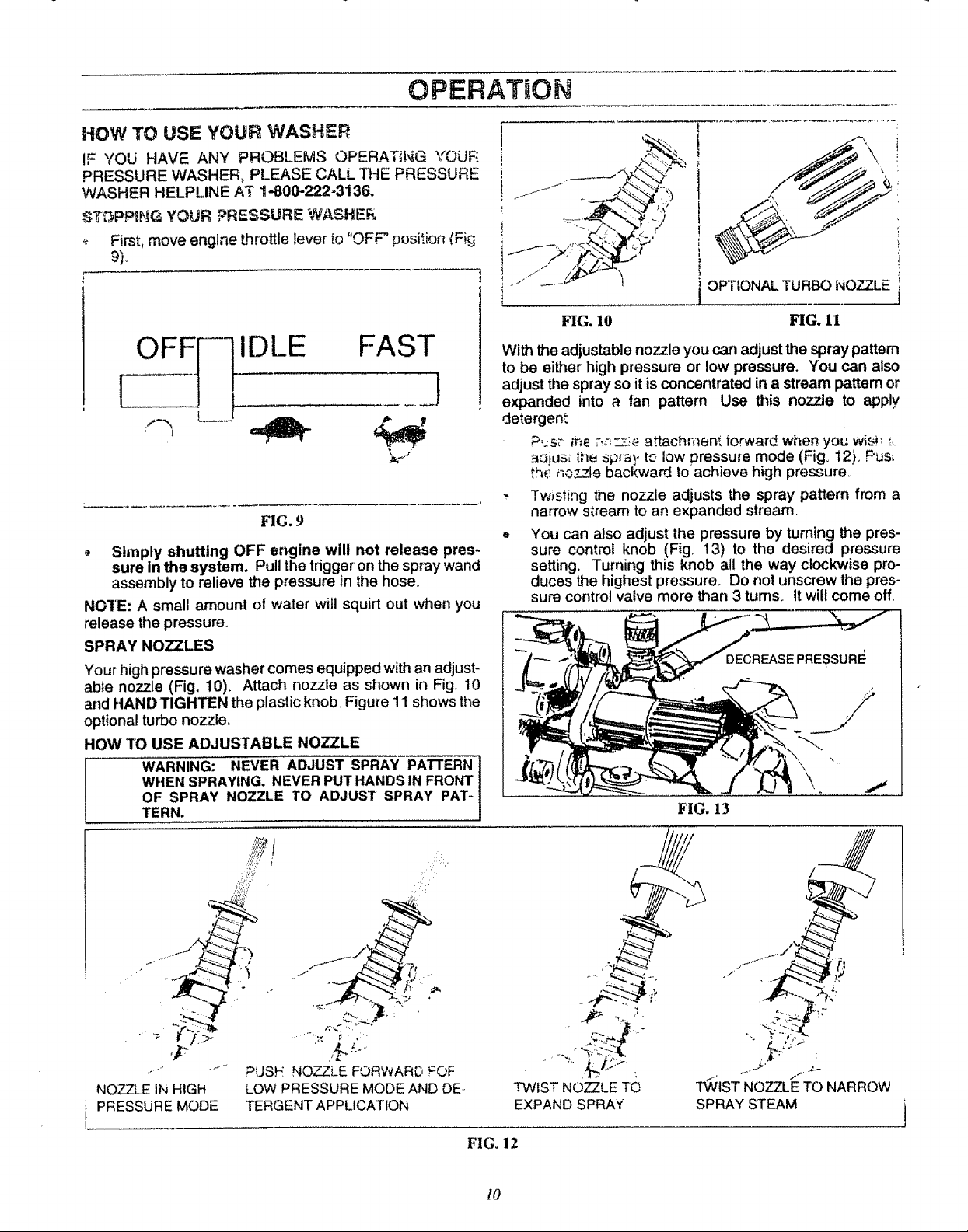

STOPPING YOUR PRESSURE WASHEF_

_; First, move engine throttle lever to °OEW position (Fig

9).

, _=." _, _;_:

" OPTIONAL TURBO NOZZLE

OFFr-]IDLE FAST

I

FIG. 9

Simply shutttng OFF engine will not release pres-

sure in the system. Pull the trigger on the spray wand

assembly to relieve the pressure in the hose.

NOTE: A small amount of water will squirt out when you

release the pressure,

SPRAY NO77LES

Your high pressure washer comes equipped with an adjust-

able nozzle (Fig. 10). Attach nozzle as shown in Fig. 10

and HAND TIGHTEN the plastic knob Figure 11 shows the

optional turbo nozzle.

HOW 'TO USE ADJUSTABLE NOZZLE

WARNING: NEVER ADJUST SPRAY PATTERN

WHEN SPRAYING. NEVER PUT HANDS IN FRONT

OF SPRAY NOZZLE TO ADJUST SPRAY PAT-

TERN,

-J

FIG. 10

With the adjustable nozzle you can adjust the spray pattem

to be either high pressure or low pressure, You can also

adjust the spray so it is concentrated in a stream pattern or

expanded into a fan pattern Use this nozzle to apply

detergent

_:sr _'_e ..-_,-, zz_ attachment torward when you wis!_ :.

a_jusi the spray to low _ressure mode (Fig° 12). Pus_

the _ozzle backwa_ toachieve high pressure.

,, "rwistir_g the nozzle adjusts the spray pattern from a

narrow stream to an expanded stream.

,, You can also adjust the pressure by turning the pres-

sure control knob (Fig., 13) to the desired pressure

setting. Turning this knob all the way clockwise pro-

duces the highest pressure. Do not unscrew the pres-

sure control valve more than 3 tunis. It will come off

FIG. 13

FIG. 11

NOZZLE IN HIGH

PRESSURE MODE

}:. •

t'-.. '- ' '

P_,JSH NOZZLE FORWARD gOF

LOW PRESSURE MODE AND DE-

TERGENT APPLICATION

FIG_ 12

10

._WIST NOZZLE TO

EXPAND SPRAY

T_;IST /

SPRAY STEAM

NOZZLE TO NARROW

Page 11

OPERATION

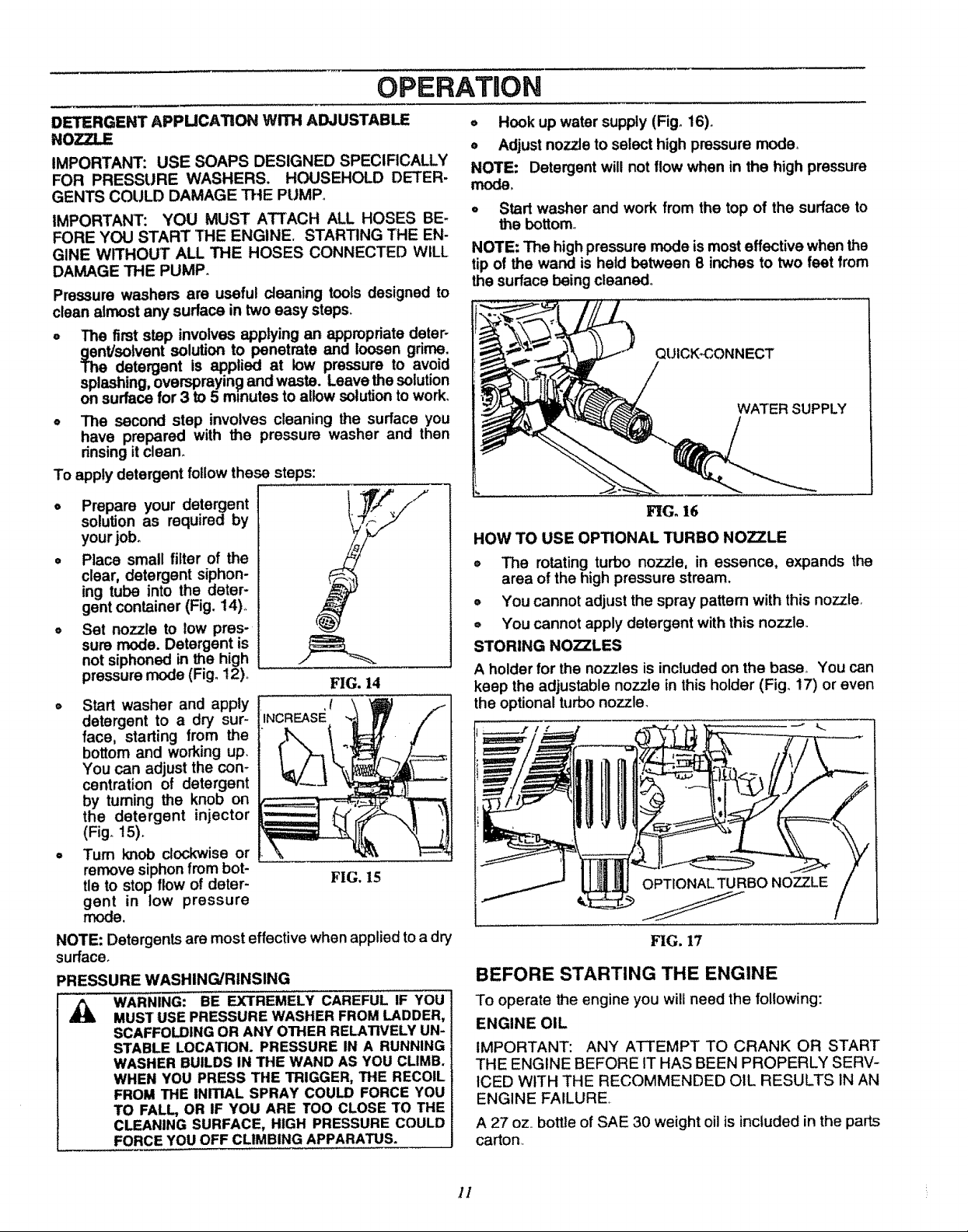

DETERGENT APPUCATION WITH ADJUSTABLE

NOZ21JE

IMPORTANT: USE SOAPS DESIGNED SPECIFICALLY

FOR PRESSURE WASHERS. HOUSEHOLD DETER-

GENTS COULD DAMAGE THE PUMP°

IMPORTANT: YOU MUST ATTACH ALL HOSES BE-

FORE YOU START THE ENGINE, STARTING THE EN-

GINE WITHOUT ALL THE HOSES CONNECTED WILL

DAMAGE THE PUMP.

Pressure washers are useful cteaning tools designed to

clean almost any surface in two easy steps+

= The flint step involves applying an appropriate deter-

t/€_etVent solution to penetrate and loosen grime.

tergent is applied at low pressure to avoid

splashing, overspraying and was tp.. Leaveme .soButton

on surface for 3 to 5 minutes to allow somtion to WORK.

o The second step involves cleaning the surface you

have prepared with the pressure washer and then

rinsing it clean+

To apply detergent follow these steps:

,, Prepare your detergent

soluUon as required by

your job.

,, Place small filter of the

clear, detergent siphon-

ing tube into the deter-

gent container (Fig. 14)+

o Set nozzle to tow pres-

sure mode. Detergent is

not siphoned in the high

pressure mode (Fig° t2)..

o Start washer and apply

detergent to a dry' sur-

INCREASE_

FIG. 14

l

face, starting from the

bottom and working up.

You can adjust the con-

centration of detergent

by tuming the knob on

the detergent injector

(Fig_ 15).

• Turn knob clockwise or

remove siphon from bot-

tle to stop flow of deter- FIG. 15

gent in tow pressure

mode.

NOTE: Detergents are most effective when applied to a dr,/

surface+

PRESSURE WASHING/RINSING

WARNING: BE EXTREMELY CAREFUL IF YOU

MUST USE PRESSURE WAStiER FROM LADDER,

SCAFFOLDING OR ANY OTHER RELATIVELY UN-

STABLE LOCATION. PRESSURE IN A RUNNING

WASHER BUILDS IN THE WAND AS YOU CLIMB.

WHEN YOU PRESS THE TRIGGER, THE RECOIL

FROM THE INITIAL SPRAY COULD FORCE YOU

TO FALL, OR IF YOU ARE TOO CLOSE TO THE

CLEANING SURFACE, HIGH PRESSURE COULD

FORCE YOU OFF CLIMBING APPARATUS.

o Hook up water supply (Fig° 16).

o Adjust nozzle to select high pressure mode_

NOTE: Detergent will not flow when in the high pressure

mode_

o Start washer and work from the top of the surface to

the bottom+

NOTE: The high pressure mode is most effective when the

tip of the wand is held between 8 inches to two feet from

the surface being cleaned.

QUICK+CONNECT

WATER SUPPLY

FIGo 16

HOW TO USE OPTIONAL TURBO NOZZLE

o The rotating turbo nozzle, in essence, expands the

area of the high pressure stream.

e You cannot adjust the spray pattem with this nozzle,

o You cannot apply detergent with this nozzle,,

STORING NOZZLES

A holder for the nozzles is included on the base,+ You can

keep the adjustable nozzle in this holder (Fig. 17) or even

the optional turbo nozzle.

OPTIONAL TURBO NOZZLE

FIG. 17

BEFORE STARTING THE ENGINE

To operate the engine you will need the following:

ENGINE OIL

IMPORTANT: ANY ATTEMPT TO CRANK OR START

THE ENGINE BEFORE iT HAS BEEN PROPERLY SERV-

ICED WITH THE RECOMMENDED OIL RESULTS IN AN

ENGINE FAILURE,

A 27 oz., bottle of SAE 30 weight oil is included in the parts

carton,,

Page 12

OPERATION

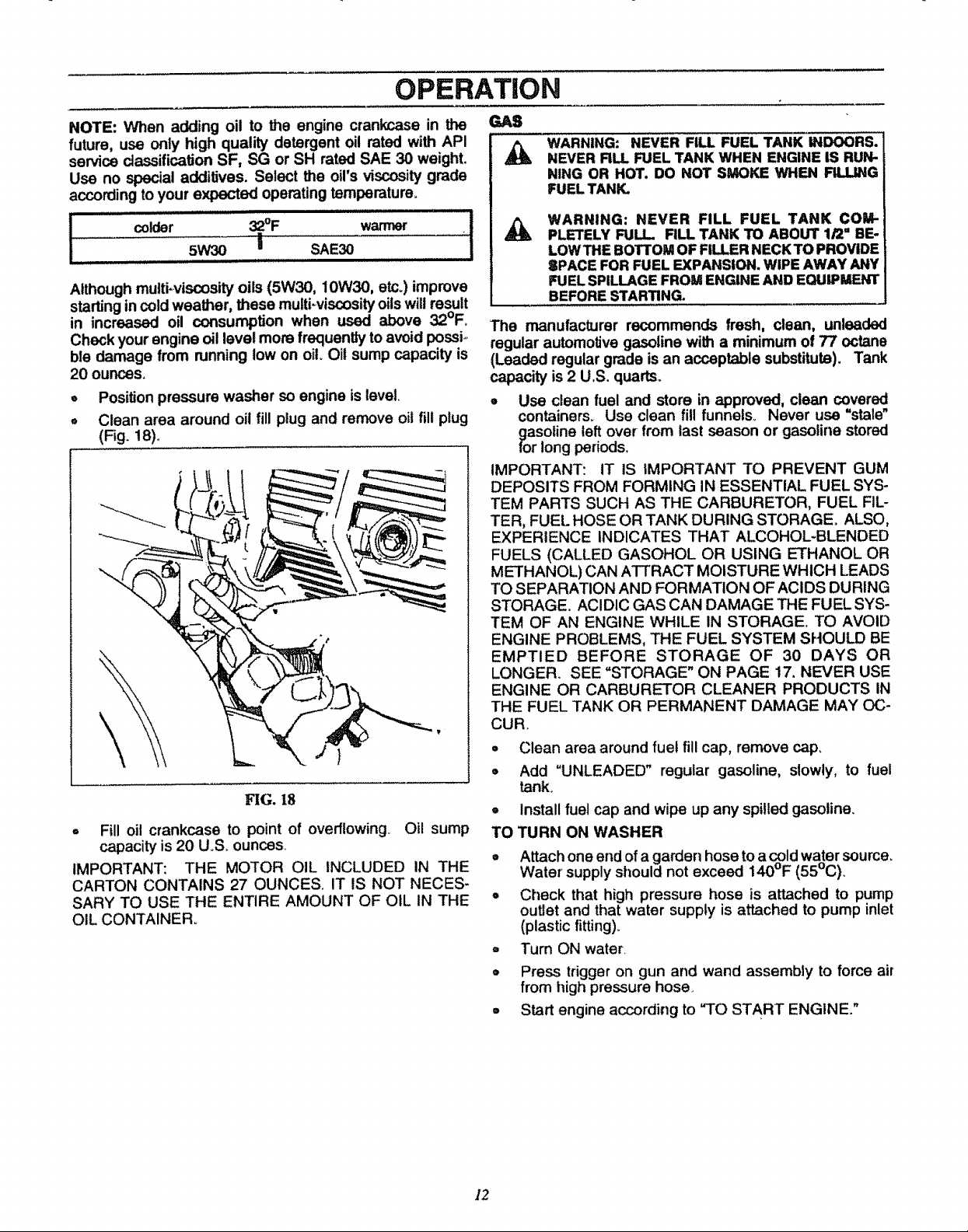

NOTE: When adding oil to the engine crankcase in the

future, use only high quality detergent oil rated with API

service classification SF, SG or SH rated SAE 30 weight.

Use no special additives. Select the oil's viscosity grade

according to your expected operating temperature.

Although mutti-viscosity oils (5W30, 10W30, etc.) improve

starting in cold weather, these multi-viscosity oils will result

in increased oil consumption when used above 32°F.

Check your engine oil level more frequently to avoid possi-

ble damage from running low on oilo Oil sump capacity is

20 ounces.

• Position pressure washer so engine is level.

. Clean area around oil fill plug and remove oil fill plug

(Fig. 18)_.

I_G. 18

° Fill oil crankcase to point of overflowing. Oil sump

capacity is 20 U.S_ ounces..

IMPORTANT: THE MOTOR OIL INCLUDED IN THE

CARTON CONTAINS 27 OUNCES. IT IS NOT NECES-

SARY TO USE THE ENTIRE AMOUNT OF OIL IN THE

OIL CONTAINER°

GAS

WARNING: NEVER FILL FUEL TANK INDOORS.

A

NEVER RLL FUEL TANK WHEN ENGINE IS RUN-

NING OR HOT. DO NOT SMOKE WHEN FILLING

FUEL TANK.

WARNING: NEVER FILL FUEL TANK COM-

a,

PLETELY FIJLL FILL TANK TO ABOUT 1/2" BE-

LOWTHE BOTTOM OF FILLER NECKTO PROVIDE

SPACE FOR FUEL EXPANSION. WIPE AWAY ANY

FUEL SPILLAGE FROM ENGINE AND EQUIPMENT

BEFORE STARTING.

The manufacturer recommends fresh, clean, unleaded

regular automotive gasoline with a minimum of 77 octane

(Leaded regular grade is an acceptable substitute). Tank

capacity is 2 U,S. quarts.

* Use clean fuel and store in approved, clean covered

containers_ Use clean fill funnets_ Never use "stale"

asoline left over from last season or gasoline stored

r long periods.

IMPORTANT: IT IS IMPORTANT TO PREVENT GUM

DEPOSITS FROM FORMING IN ESSENTIAL FUEL SYS-

TEM PARTS SUCH AS THE CARBURETOR, FUEL FIL-

TER, FUEL HOSE OR TANK DURING STORAGE. ALSO,

EXPERIENCE INDICATES THAT ALCOHOL-BLENDED

FUELS (CALLED GASOHOL OR USING ETHANOL OR

METHANOL) CAN ATTRACT MOISTURE WHICH LEADS

TO SEPARATION AND FORMATION OF ACIDS DURING

STORAGE. ACIDIC GAS CAN DAMAGE THE FUEL SYS-

TEM OF AN ENGINE WHILE IN STORAGE. TO AVOID

ENGINE PROBLEMS, THE FUEL SYSTEM SHOULD BE

EMPTIED BEFORE STORAGE OF 30 DAYS OR

LONGER. SEE "STORAGE" ON PAGE 17. NEVER USE

ENGINE OR CARBURETOR CLEANER PRODUCTS IN

THE FUEL TANK OR PERMANENT DAMAGE MAY OC-

CUR.

,, Clean area around fuel fill cap, remove cap.

. Add "UNLEADED" regular gasoline, slowly, to fuel

tank.

* Install fuel cap and wipe up any spilled gasoline.

TO TURN ON WASHER

* Attach one end of a garden hose to a cold water source=

Water supply should not exceed 140°F (55°C)_

= Check that high pressure hose is attached to pump

outlet and that water supply is attached to pump inlet

(plastic fitting)_

= Turn ONwater_

* Press trigger on gun and wand assembly to force air

from high pressure hose.

= Start engine according to "TO START ENGINE."

12

Page 13

OPERATION

TO START ENGINE

IMPORTANT: DO NOT RUN PUMP WITHOUT THE

WATER SUPPLY CONNECTED AND TURNED ON. YOU

MUST FOLLOW THiS CAUTION OR THE PUMP WILL, BE

DAMAGED_

o Press trigger on pressure washer wand to relieve high

pressure and/or purge the inlet hose of air°

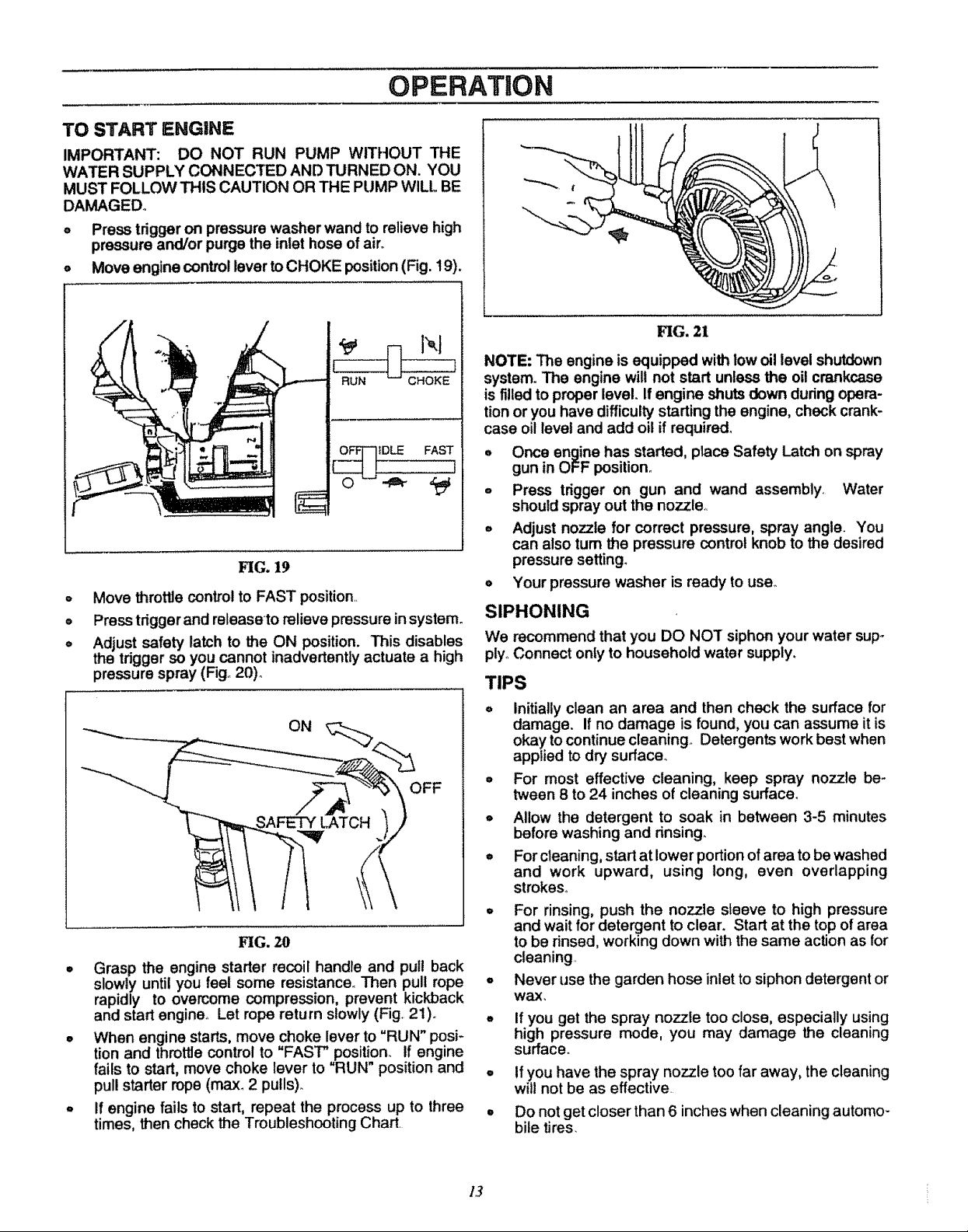

o Move engine control lever to CHOKE position (Fig. 19).

IDLE FAST

FIG. 19

o

Move throttle control to FAST position.

o

Press tdgger and releaseto relieve pressure in system.

@

Adjust safety latch to the ON position. This disables

the trigger so you cannot inadvertently actuate a high

pressure spray (Fig° 20)°

FIG. 21

NOTE: The engine is equipped with low oi! level shutdown

system. The engine will not start unless the oil crankcase

is filled to proper level. If engine shuts down during opera-

tion or you have difficulty starting the engine, check crank-

case oil level and add oil if required°

= Once engine has started, place Safety Latch on spray

]

gun in OFF position_

,, Press trigger on gun and wand assembly. Water

should spray out the nozzle.

= Adjust no_le for correct pressure, spray angle. You

can also turn the pressure control knob to the desired

pressure setting_

o Your pressure washer is ready to user

SIPHONING

We recommend that you DO NOT siphon your water sup-

plyo Connect only to household water supply.

TIPS

= Initially clean an area and then check the surface for

,, For most effective cleaning, keep spray nozzle be-

o Allow the detergent to soak in between 3-5 minutes

= For cleaning, start at lower portion of area to be washed

= For rinsing, push the nozzle sleeve to high pressure

FIG. 20

• Grasp the engine starter recoil handle and pul! back

slowly until you feel some resistance. Then pull rope

o Never use the garden hose inlet to siphon detergent or

rapidly to overcome compression, prevent kickback

and start engine° Let rope return slowly (Fig. 21)_ °

° When engine starts, move choke lever to "RUN" posi-

tion and throttle control to "FAST" position. If engine

fails to start, move choke lever to "RUN" position and °

pull starter rope (max. 2 pulls)_

° if engine fails to start, repeat the process up to three ,_

times, then check the Troubleshooting Chart.

damage, if no damage is found, you can assume it is

okay to continue cleaning Detergents work best when

applied to dry surface,

tween 8 to 24 inches of cleaning surface.

before washing and rinsing

and work upward, using long, even overlapping

strokes.

and wait for detergent to clear. Start at the top of area

to be rinsed, working down with the same action as for

cleaning..

wax,

If you get the spray nozzle too close, especially using

high pressure mode, you may damage the cleaning

surface_

if you have the spray nozzle too far away, the cleaning

will not be as effective.

Do not get closer than 6 inches when cleaning automo -

bite tires.

13

Page 14

CUSTOMER RESPONSiBiLiTiES

, i i ii ,,Jiiiiiiil,,,, Jl,i

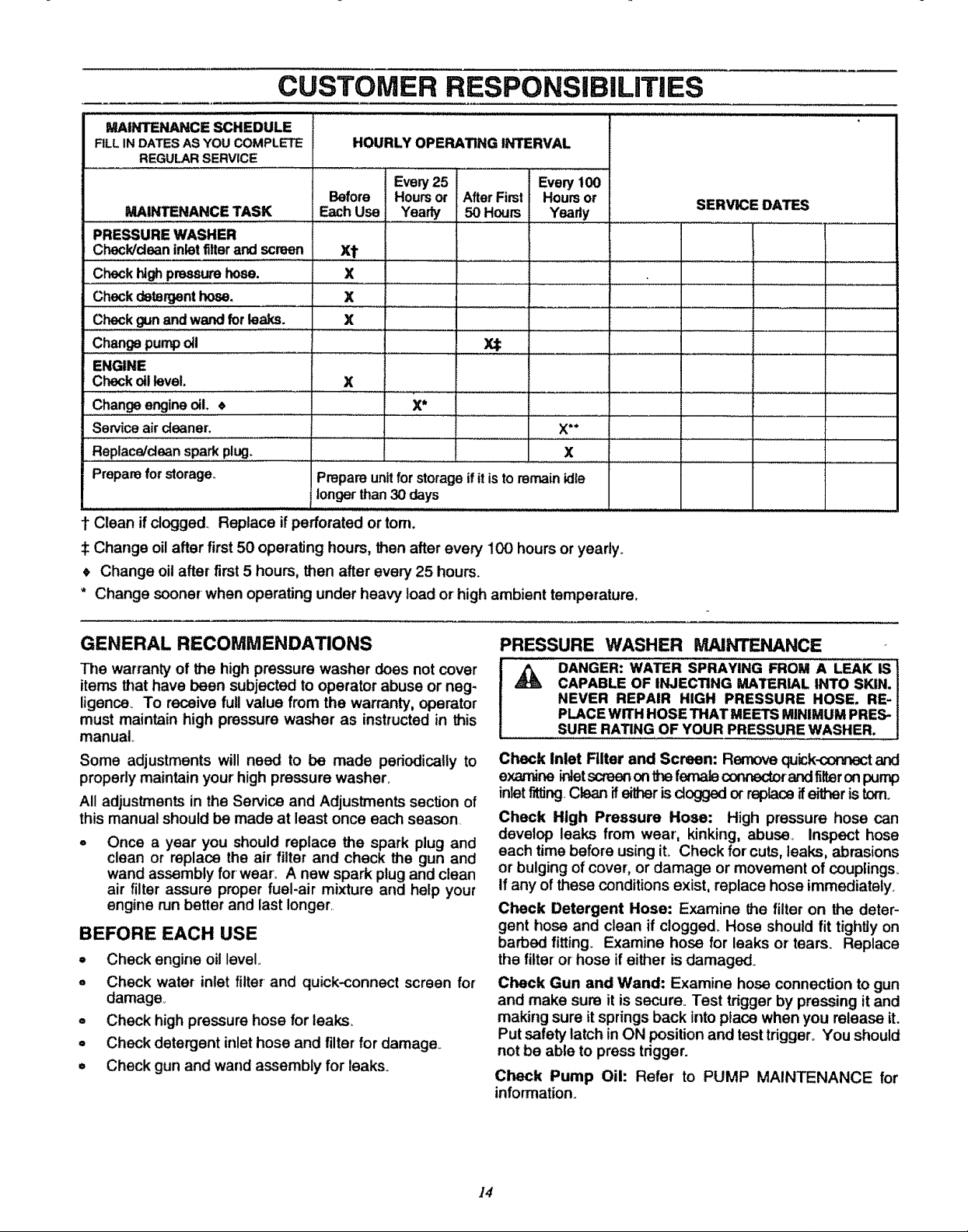

MAINTENANCE SCHEDULE

FILL IN DATES AS YOU COMPLETE

REGULAR SERVICE

MAINTENANCE TASK .... Each Use ....... Yearly

PRESSURE WASHER

Check/dean inlet filler and screen _ Xt ..................

Check high pressure hose. X

,, ,,,, ,, ......

Check detergent hose. X

Check gun and wand for leaks. X

Change pump oil X:I:

ENGINE

Check oil level. X

Change engine oil. _ X*

Service air cleaner. X "°

Replace/dean spark plug. _ X

Prepare for storage= Prepare unit for storage if it is to remain idle

1" Clean if clogged.. Replace if perforated or torn.

:1: Change oil after first 50 operating hours, then after every 100 hours or yearly.

Change oil after first 5 hours, then after evePj 25 hours.

* Change sooner = when operating under heavy load or high ambient temperature.

HOURLY OPERATING INTERVAL

Every 25

Before Hours or

After First Hours or SERVICE

50 Hours Yearly

J longer than 30 days

Every 100

............ r ........

DATES

........ ; ............... i,,

GENERAL RECOMMENDATIONS

The warranty of the high pressure washer does not cover

items that have been subjected to operator abuse or neg-

ligence_ To receive full value from the warranty, operator

must maintain high pressure washer as instructed in this

manual,.

Some adjustments will need to be made pefiodicaUy to

properly maintain your' high pressure washer,

All adjustments in the Service and Adjustments section of

this manual should be made at least once each season.

Once a year you should replace the spark plug and

clean or replace the air falter and check the gun and

wand assembly for wear_ A new spark plug and clean

air filter assure proper fuel-air mixture and help your

engine run better and last longer..

BEFORE EACH USE

,, Check engine oil level.

° Check water inlet filter and quick-connect screen for

damage...

° Check high pressure hose for leaks_

° Check detergent inlet hose and filter for damager

,, Check gun and wand assembly for leaks_

PRESSURE WASHER MAINTENANCE

,_ DANGER: WATER SPRAYING FROM A LEAK iS t

CAPABLE OF INJECTING MATERIAL INTO SKIN. I

NEVER REPAIR HIGH PRESSURE HOSE. RE-I

PLACE WITH HOSE THAT MEETS MINIMUM PRES- I

SURE RATING OF YOUR PRESSURE WASHER. j

Check Inlet Filter and Screen: Remove quick-correct and

examine inlet screen on the female o0nnectorand filter or1 pump

inlet fit_ng, Clean if either is dogged or replace if either is tom.

Check High Pressure Hose: High pressure hose can

develop leaks from wear', kinking, abuse., Inspect hose

each time before using it, Check for cuts, leaks, abrasions

or bulging of cover, or damage or movement of coupfings_

If any of these conditions exist, replace hose immediately°

Check Detergent Hose: Examine the filter on the deter-

gent hose and clean if clogged. Hose should fit tightly on

barbed fitting. Examine hose for leaks or tears. Replace

the filter or hose if either is damaged_

Check Gun and Wand: Examine hose connection to gun

and make sure it is secure_ Test trigger by pressing it and

making sure it springs back into place when you release it.

Put safety latch in ON position and test trigger° You should

not be able to press trigger.

Check Pump Oil: Refer to PUMP MAINTENANCE for

information.,

]4

Page 15

CUSTOMER RESPONSNBHUTY

PUMP MAINTENANCE

THE PUMP. WITHOUT THE PROPER TECHNIQUE,

ATTEMPTING TO DISASSEMBLE PUMP MAY

CAUSE PERSONAL INJURY. FOR SERVICE, CON-

I: WARNING: DO NOT ATTEMPT TO DISASSEMBLE

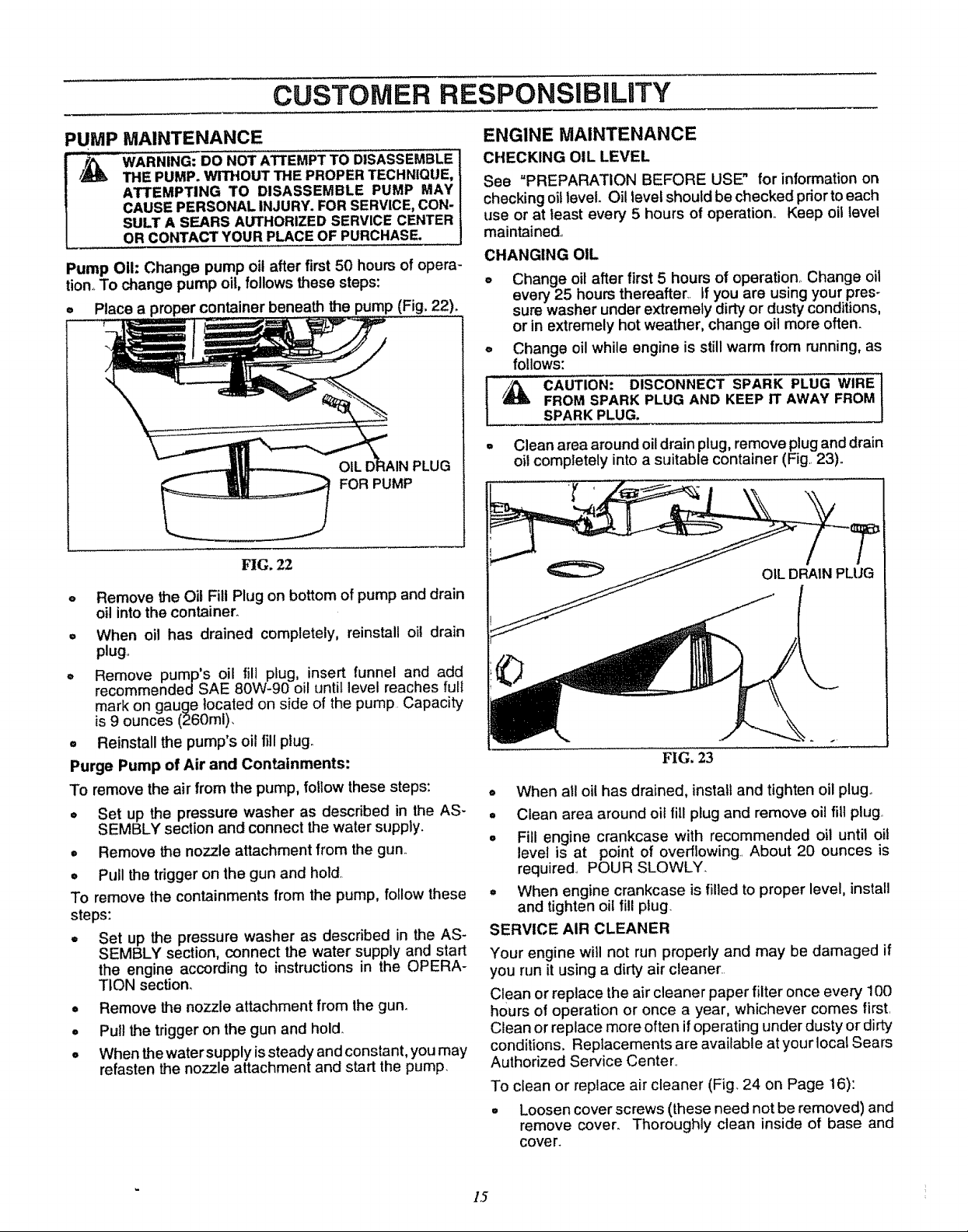

Pump Oih Change pump oil after first 50 hours of opera-

tion. To change pump oil, follows these steps:

o Place a proper container beneath the pump (Fig, 22).

SULT A SEARS AUTHORIZED SERVICE CENTER

OR CONTACT YOUR PLACE OF PURCHASE.

OIL D_RAIN PLUG

FOR PUMP

FIG. 22

ENGINE MAINTENANCE

CHECKING OIL LEVEL

See "PREPARATION BEFORE USE" for information on

checking oil level Oil level should be checked prior to each

use or at least ever]/5 hours of operation,. Keep oil level

maintained..

CHANGING OIL

Change oil after first 5 hours of operation,. Change oil

every 25 hours thereafter,. If you are using your pres*

sure washer under extremely dirty or dusty conditions,

or in extremely hot weather, change oil more often.

O

Change oil while engine is still warm from running, as

follows:

FROM SPARK PLUG AND KEEP IT AWAY FROM

/_ CAUTION: DISCONNECT SPARK PLUG WIRE 1

SPARK PLUG.

°

Clean area around oil drain plug, remove plug and drain

oil completely into a suitable container (Fig.. 23).

o Remove the Oil Fill Plug on bottom of pump and drain

oil into the container.

= When oil has drained completely, reinstall oil drain

plugo

o Remove pump's oil fill plug, insert funnel and add

recommended SAE 80W-90 oil until level reaches full

mark on gauge located on side of the pump Capacity

is 9 ounces (260ml)_

= Reinstall the pump's oil fill plug.

Purge Pump of Air and Containments:

To remove the air from the pump, follow these steps:

o Set up the pressure washer as described in the AS-

SEMBLY section and connect the water supply.

o Remove the nozzle attachment from the gun°

o Pull the trigger on the gun and hold

To remove the containments from the pump, follow these

steps:

= Set up the pressure washer as described in the AS-

SEMBLY section, connect the water supply and start

the engine according to instructions in the OPERA-

TION section.

= Remove the nozzle attachment from the gun_

= Pull the trigger on the gun and holdo

o When the water supply is steady and constant, you may

refasten the nozzle attachment and start the pump.

FIG. 23

o When all oil has drained, install and tighten oil plug..

= Clean area around oil fill plug and remove oil fill plug..

° Fill engine crankcase with recommended oil until oil

level is at point of overflowing. About 20 ounces is

required, POUR SLOWLY.

° When engine crankcase is filled to proper level, install

and tighten oil fill plug.

SERVICE AIR CLEANER

Your engine will not run properly and may be damaged if

you run it using a dirty air cleaner.

Clean or replace the air cleaner paper filter once every 100

hours of operation or once a year, whichever comes first.

Clean or replace more often if operating under dusty or dirty

conditions. Replacements are available at your local Sears

Authorized Service Center.

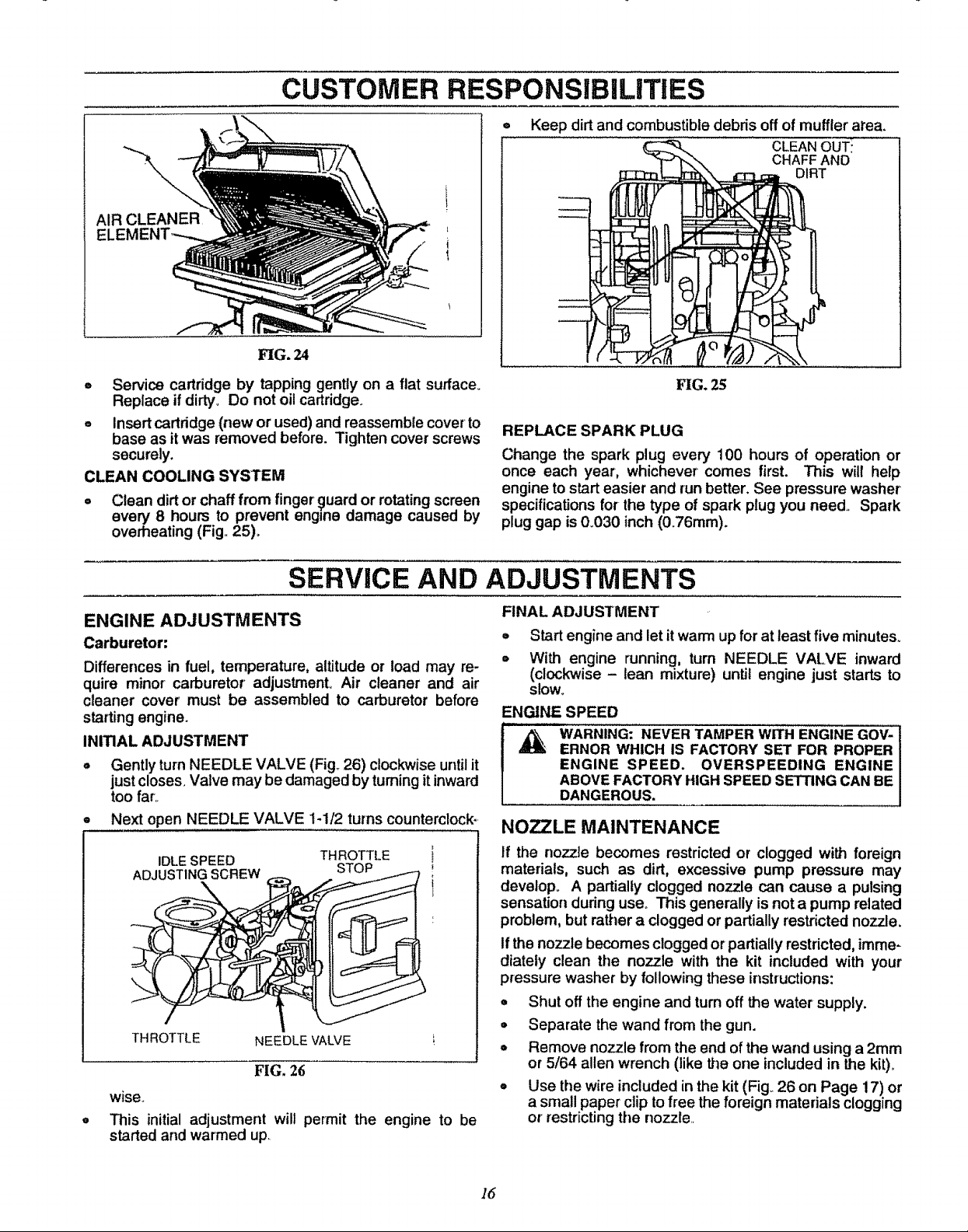

To clean or replace air cleaner (Fig. 24 on Page t6):

= Loosen cover screws (these need not be removed) and

remove cover. Thoroughly clean inside of base and

cover.

15

Page 16

AIR CLEANER

E[

CUSTOMER RESPONSIBiLiTiES

e

Keep dirt and combustible debris off of muffler area,

FIG. 24

CLEAN OUT:

CHAFF AND

DIRT

o Service cartridge by tapping gently on a flat surface.

Replace if dirty° Do not oil cartridge.

o Insert cartridge (new or used) and reassemble cover to

base as it was removed before. Tighten cover screws

securely.

CLEAN COOLING SYSTEM

= Clean dirt or chaff from finger' _luard or rotating screen

every 8 hours to prevent engine damage caused by

overheating (Fig.. 25)°

SERVICE AND ADJUSTMENTS

ENGINE ADJUSTMENTS

Carburetor=

Differences in fuel, temperature, altitude or load may re-

quire minor carburetor' adjustment. Air cleaner and air

cleaner cover must be assembled to carburetor before

starting engine.

INmAL ADJUSTMENT

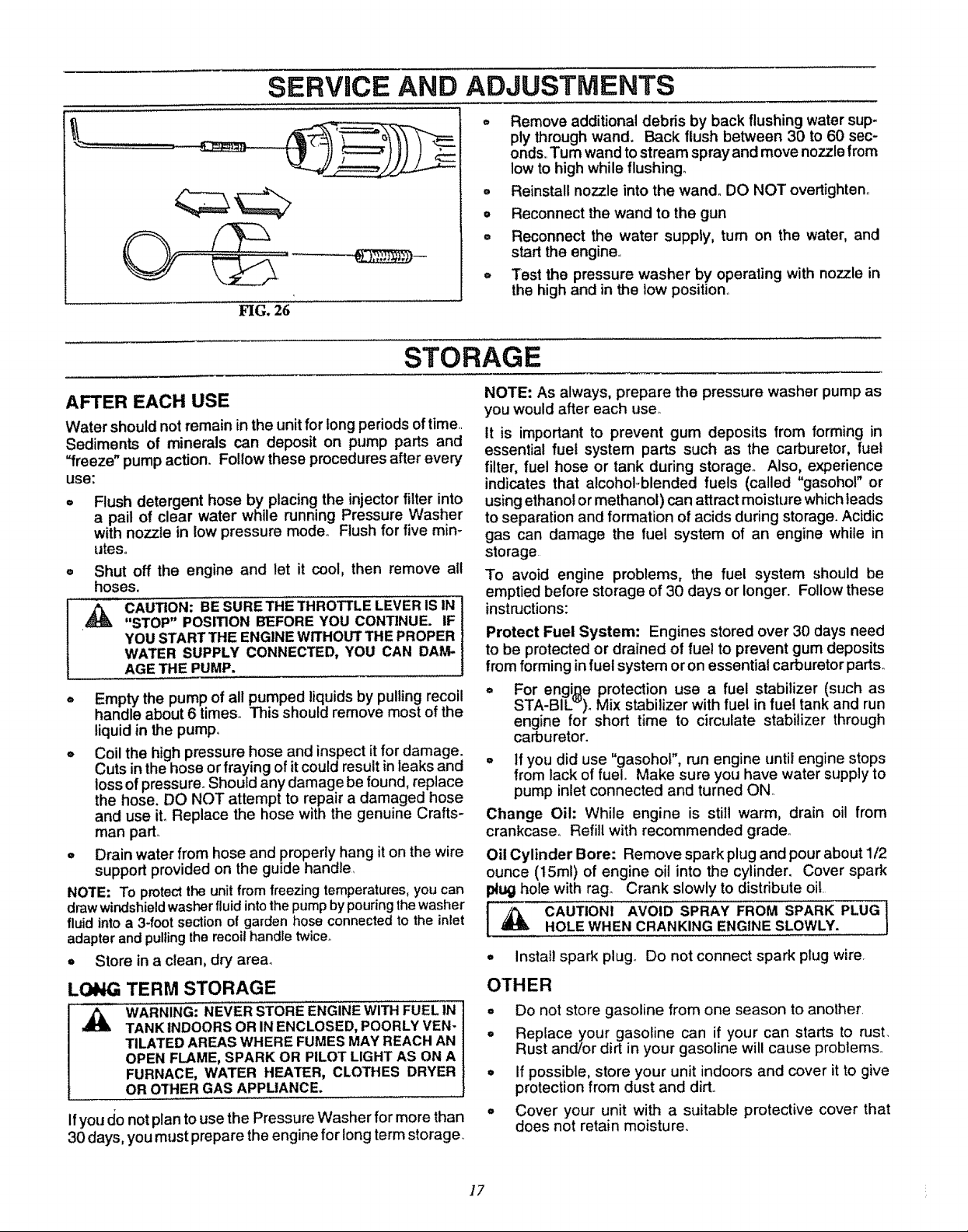

= Gently turn NEEDLE VALVE (Fig,, 26) clockwise until it

just closes_ Valve may be damaged by turning it inward

too far..

° Next open NEEDLE VALVE I-1/2 turns counterclock-.

FIG. 25

REPLACE SPARK PLUG

Change the spark plug every 100 hours of operation or

once each year, whichever comes first. This will help

engine to start easier and run better. See pressure washer

specifications for the type of spark plug you need,. Spark

plug gap is 0.030 inch (0.76ram).

FINAL ADJUSTMENT

o

Start engine and let it warm up for at least five minutes_

o

With engine running, turn NEEDLE VALVE inward

(clocle_ise - lean mixture) until engine just starts to

slow.

ENGINE SPEED

_" ERNOR WHICH IS FACTORY SET FOR PROPER

ENGINE SPEED. OVERSPEEDING ENGINE

i WARNING: NEVER TAMPER WITH ENGINE GOV-

ABOVE FACTORY HIGH SPEED SETTING CAN BE

DANGEROUS.

NOZZLE MAINTENANCE

IDLE SPEED THROTTLE

ADJUSTING SCREW STOP

\

i

THROTTLE NEEDLE VALVE

FIG. 26

wise,.

This initial adjustment will permit the engine to be

started and warmed up

If the nozzle becomes restricted or clogged with foreign

materials, such as dirt, excessive pump pressure may

develop. A partially clogged nozzle can cause a pulsing

sensation during use° This generally is not a pump related

problem, but rather a clogged or partially restricted nozzle,

If the nozzle becomes clogged or partially restricted, imme-

diately clean the nozzle with the kit included with your

pressure washer by following these instructions:

, Shut off the engine and turn off the water supply,

° Separate the wand from the gun.

° Remove nozzle from the end of the wand using a 2mm

or 5/64 allen wrench (like the one included in the kit).

,, Use ttle wire included in the kit (Fig° 26 on Page 17) or

a small paper clip to free the foreign materials clogging

or restricting the nozzle..

]6

Page 17

SERVICE AND ADJUSTMENTS

O

Remove additional debris by back flushing water sup-

ply through wand. Back flush between 30 to 60 sec-

onds,. Turn wand to stream spray and move nozzle from

low to high while flushing.

0

Reinstall nozzle into the wand,, DO NOT overtighten,

0

Reconnect the wand to the gun

o

Reconnect the water supply, turn on the water, and

start the engine..

Test the pressure washer by operating with nozzle in

the high and in the low position.

FIG. 26

STORAGE

AFTER EACH USE

Water should not remain in the unit for long periods of time..

Sediments of minerals can deposit on pump parts and

"freeze" pump action. Follow these procedures after every

use:

Flush detergent hose by placing, the injector filter into

a pail of clear water while running Pressure Washer

with nozzle in low pressure mode° Flush for five min-

utes,,

Shut off the engine and let it cool, then remove awl

hoses.

A CAUTION; BE SURE THE THROTTLE LEVER IS IN

. "STOP" POSITION BEFORE YOU CONTINUE. IF

YOU START THE ENGINE WITHOUT THE PROPER

WATER SUPPLY CONNECTED, YOU CAN DAM-

AGE THE PUMP.

o Empty the pump of all pumped liquids by pulling recoil

handle about 6 times, This should remove most of the

liquid in the pump.

o Coil the high pressure hose and inspect it for damage.

Cuts in the hose or fraying of it could result in leaks and

loss of pressure° Should any damage be found, replace

the hose. DO NOT attempt to repair a damaged hose

and use it. Replace the hose with the genuine Crafts-

man part_

,, Drain water from hose and properly hang it on the wire

support provided on the guide handle,

NOTE: To protect the unit from freezing temperatures, you can

draw windshield washer fluid into the pump by pouring the washer

fluid into a 3-foot section of garden hose connected to the inlet

adapter and pulling the recoil handle twice..

° Store in a clean, dry area°

LONG TERM STORAGE

WARNING: NEVER STORE ENGINE WITH FUEL IN

TANK INDOORS OR IN ENCLOSED, POORLY VEN-

TILATED AREAS WHERE FUMES MAY REACH AN

OPEN FLAME, SPARK OR PILOT LIGHT AS ON A

FURNACE, WATER HEATER, CLOTHES DRYER

OR OTHER GAS APPLIANCE.

If you do not plan to use the Pressure Washer for more than

30 days, you must prepare the engine for long term storage..

NOTE: As always, prepare the pressure washer pump as

you would after each use_

It is important to prevent gum deposits from forming in

essential fuel system parts such as the carburetor, fuel

filter, fuel hose or tank during storage° Also, experience

indicates that alcohol..blended fuels (called "gasohol" or

using ethanol or methanol) can attract moisture which leads

to separation and formation of acids during storage. Acidic

gas can damage the fuel system of an engine while in

storage

To avoid engine problems, the fuel system should be

emptied before storage of 30 days or longer. Follow these

instructions:

Protect Fuel System: Engines stored over 30 days need

to be protected or drained of fuel to prevent gum deposits

from forming in fuel system or on essential carburetor parts°

,, For engi,_e protection use a fuel stabilizer (such as

STA-BIL'_')o Mix stabilizer with fuel in fuel tank and run

engine for short time to circulate stabilizer through

carburetor.

,_ If you did use "gasohot", run engine until engine stops

from lack of fuelo Make sure you have water supply to

pump inlet connected and turned ON,.

Change Oil: While engine is still warm, drain oil from

crankcase. Refill with recommended grade°

Oil Cylinder Bore: Remove spark plug and pour about 1/2

ounce (15ml) of engine oil into the cylinder. Cover spark

plug hole with rag_ Crank slowly to distribute oil.

i _ CAUTION, AVOIDSPRAYFROM SPARKPLUG I

HOLE WHEN CRANKING ENGINE SLOWLY.

° Install spark plugo Do not connect spark plug wire.

OTHER

,_ Do not store gasoline from one season to another.

o Replace your gasoline can if your can starts to rusL

Rust and/or dirt in your gasoline will cause problems°

= If possible, store your unit indoors and cover it to give

protection from dust and dirt..

o Cover your unit with a suitable protective cover that

does not retain moisture°

17

Page 18

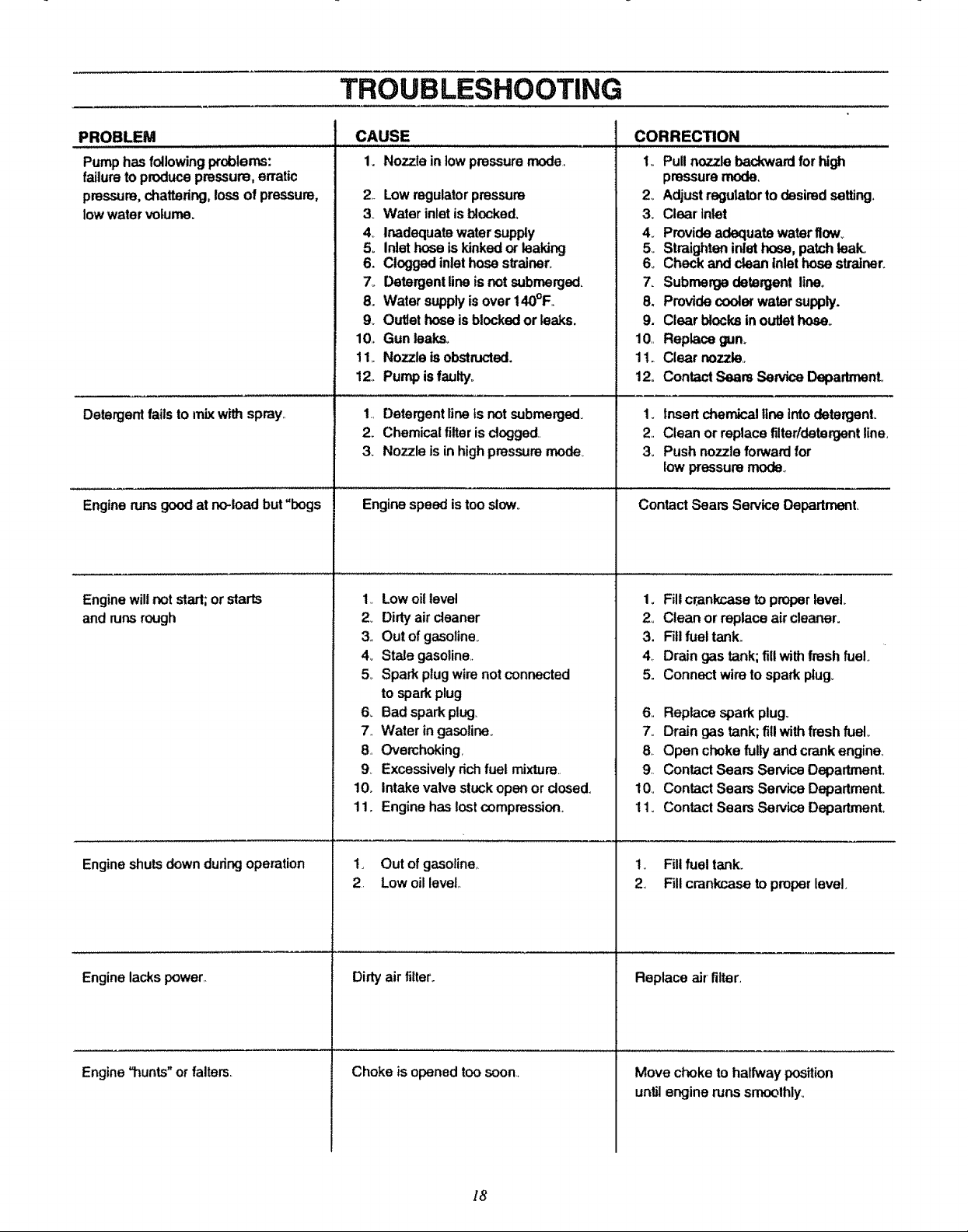

TROUBLESHOOTING

PROBLEM

CAUSE CORRECTION

Pump has following p_oblems: 1.

failure to pn_uce pressure, erratic

pressure, chattering, loss of pressure, 2_

low water volume. 3.

10,

11_

12.

Detergent fails to mix with spray, 1.

Engine runs good at no-load but "bogs

Nozzle in low pressure mode, 1,,

Low regulator pressure

Water inlet is blocked.

4o

Inadequate water supply

5o

inlet hose is kinked or leaking

6.

Clogged inlet hose strainer.

7_

Detergent line is not submerged.

8.

Water supply is over t40°F.

9_

Outlet hose is blocked or leaks.

Gun leaks.,

Nozzle is obstructed.

Pump is faulty°

Detergent line Is not submerged.

2.

Chemical filter is clogged

3.

Nozzle is in high pressure mode

Engine speed is too slowo

Pull nozzle backward for high

pressure mode.

2_ Adjust rogutatorto desired setting,

3. Clear inlet

4. Provide adequate water flow.

5o Straighten inlet hose, patch leak.

6o Check and clean Inlet hose strainer.

7. Submerge detergent line.

8. Provide cooler water supply.

9. Clear blocks in outlet hose_

10 Replace gun.

11_ Clear _],

12, Contact Sears Service Department,

1. Insert chemical line into detergent,.

2, Clean or replace filter/deteq;tent line.

& Push nozzle forward for

low pressure mode,

Contact Sears Service DepadrnenL

Engine will not start; or starts

and runs rough

Engine shuts down during operation

Engine lacks power,_

1. Low oil level

2. Dirty air cleaner

3. Out of gasoline.

4. Stale gasoline,,

5,_ Spark plug wire not connected

to spark plug

6_ Bad spark plug.

7,, Water in gasotine_

80vemhoking

9 Excessively rich fuel mixture.

10o Intake valve stuck open or closed.

11o Engine has lost compression.

1, Out of gasoline,,

2. Low oil level,.

Dirty air filter.

1. Fill crankcase to proper level.

2, Clean or replace air cleaner.

3. Fill fuel tank.

4, Drain gas tank; fill with fresh fuel.

5. Connect wire to spark plug.

6,, Replace spark plug.

7,, Drain gas tank; fill with fresh fuel.

8 Open choke full'>, and crank engine_

9 Contact Sears Service Department.

10o Contact Sears Service Department,

11. Contact Sears Service Department,

1. Fill fuel tank.

2o Fill crankcase to proper level.

Replace air filter,

Engine "hunts" or falters.

Choke is opened too soon.,

18

Move choke to halfway posffion

until engine runs smoolhly_

Page 19

CRAFTSMAN 1800 PSi HIGH PRESSURE WASHER 580.751500 REPAIR PARTS

\

\

\,

/

L

N

\

Parts List for this drawing and for drawing on Page 20

can be found on Page 21.

19 Drawing No,, 95087

Page 20

CRAFTSMAN 1800 PSi HIGH PRESSURE WASHER 580.751500 REPAIR PARTS

Drawing No, 95087 20

\

.<

!

Page 21

CRAFTSMAN 1800 PSi HiGH PRESSURE WASHER 580.751500 REPAIR PARTS

ITEM PART NO.

1 9.3871

2

3

4

S 96185

6 S6437

7 93869

8 93790

9 95386

10 95217

11 964O0

12 92479

13 93873

!4 40945

15 94404

16 93680

17 93668

18 93667

19 96015

20 95454

2t 95895

22 96O52

23 955O4

24 95503

25 96005

26 95896

27 95531

28 93652

29 95416

3O 944O2

31 93873

32 93678

3.3 93645

34 93644

35 95`320

36 96525

37 95382

38 93722

39 93874

DESCRIPTION ITEM PART NO.

Engine Adaptor Gasket (1 req.) 40 95373

Engine Adaptor (1 req_) 41 95367

Thrust Ball Bearing (1 mq_) 42 95.372

Washer Retainer (1 req.) 43 95378

Engine Adaptor (1 req_) 44 95377

Axial Cam (1 req.) 45 93788

Thrust Roller Bearing (t req.,) 46 93787

114 x 119 x 2o60_ring (1 mq,) 47 95376

Piston Spring Retainer (3 req,) 48 95374

Piston, D15 S So (3 req) 49 95375

Piston Retum Spring (3 req_) 50 95365

M8 Ribbed Lock Washer (10 req.) 51 95364-A

M6 Ribbed Lock Washer (9 req.)

M6 x 1_0 x 20ram Capscmw (7 req) 52 95381-A

Aluminun Crankcase (1 req) 53 96137

Pistion Oil Seal (3 req,) 54 93723

Pilot Spacer (3 req) 55 95216

Seat (3 req_) 56 95369

Beadng Ring Seal (3 req) 57 95368

Oil Fi!l/Breather (1 reqo) 58 95370

High Pressure Port Tower (3 req) 59 95363

High Pressure Seal [black] (3 reqo) 60 96069

Back-up Ring (1 req.) 61 95506

O-Ring 2°62 x 1712mm (6 req.) 62 95453

Valve Check Kit (6 req) 63 57163

Check Valve Seat Support (3 req,,) 64 95371

5/16"-24 x 3/4" Bolt (4 req,) 65 95380

Thermal By-pass Spring (t req,) 66 94738

By-pass Piston (1 req,,) 68 95366

Spacer Plate (1 req.) 70 95434

O-dng 4,,5 x 8 x 1.8 (2 req) 71 94944

M5-0.,8 x 20 Truss Head Bolt (2 req) 72 94284

Head Gasket (1 req.) 73 93876

Thermal By-pass Actuator (1 req,) 74 95379

Garden Hose Connector (! req,) 75 93656

Cylinder Head (1 mq ,) 76 93657

Spindle Seat (1 req) 77 95212-A

O_Ring, 1 °78 x 172 (2 req) 78 46580

M8-1 .,25 x 75mm Capscrew (6 req.)

DESCRIPTION

Unk_ader Assembly Spindle (1 req)

Unloader Piston Guide (1 req.)

O-nng 1.78 x 14ram (1 reqo)

Chemical Injector Fitting (1 req.)

High Pressure Ob_et Adaptor (1 reqo)

O_dng 1.78 x 12Amm (1 mq)

O-ring 1.78x 156mm (1 req_)

spring (1 req,)

High Pressure Outlet Piston (I re(] )

O-ring, #2A x 4.3 (1 req.)

Pressure Adjust Spring (1 req)

Pressure Adjust Adaptor with groove

(1 mq.)

Pressure Adjust Handle [red] (1 reqo)

1/8" NPT Pipe Plug (1 req,)

=O" Ring 2,,6 x 202 (1 req,)

Pressure Relief Valve Body (1 req)

Back-up O-ring 11 x 12A (1 reqo)

Unloader Piston (1 req.)

O-ring 1,78 x 7.65 (1 req)

Spring Support (1 req_)

Quad-Ring 0.09 x 1.06" (3 req.)

Beck-up Ring (3 req.)

Sight Gauge Assembly

3/8" NPT Magnetic Plug (1 req)

Piston Support (1 req.)

Chemical Injector Spring (1 req.)

Bellevilte Washer (1 req.)

M18 x 1_0 Nut (1 req)

Thrust Washer (1 req )

Piston Pivot Shoe (1 req)

"C" Ring Retainer (3 req_)

O-Ring 1_78 x 29 (1 req)

Ball (1 req.)

O-Ring 1.78 x 607 (1 req)

Back-up Ring 1o24 x 67 (1 mq.)

Unloader Assembly (1 re<!)

M6-10 x 45ram Cap.screw (2 req.)

21 Drawing No,, 95087 :

Page 22

CRAFTSMAN 1800 PSI HIGH PRESSURE WASHER 580.751500 REPAIR PARTS

\

\

"'i ..... @ _r. ' .....

xt

" i

Drawing No. 94720 22

Page 23

CRAFTSMAN 1800 PSi HIGH PRESSURE WASHER 580.751500 REPAIR PARTS

ITEM PART NO.

1 95998

2 95319B

3 51767

4 96016

5 95456

6 93790

7 93869

8 95437

9 95435

10 95434

11 95524

12 57108

13 95531

14 96430(3

15 93871

16 92479

18 39414

19 95902

20 75402

21 91094

22 _46

23 25391

24 93278

25 39253

26 52858

27 92235

28 91092

29 87841

30 57821

31 50190

32 91093

33 92067

34 95908

35 96633

36 86292

37 77584

38 96168

39 95587B

40 91630

41 95567

42 93873

44 92659

45 658.52

46 94944

47 _47!

48 91842A

49 23365

50 88977

51 91841

52 24679

53 95454

54 40945

55 93873

56 96581C

57 93723

58 40945

59 49808

DESCRIPTION

5 HP BRIGGS & STRATTON ENGINE (1 REQ)

2.5 GPM PUMP (1 REQ.)

M6-1.0 x 45ram CAPSCREW (2 REQ.)

QUICK.CONNECT, FEMALE (1 REQ.)

QUICK-CONNECT, MALE (1 REQ.)

O-RING, 2.6x 114 (1 REQ.)

THRUST BEARING (1 REQ.)

2.5 PGM AXIAL CAM (1 REQ.)

ENGINE ADAPTOR SHAFT (1 REQo)

THRUST WASHER (1 REQ.)

WASHER RETAINER (1 REQ.)

BEARING (1 REQ°) ....

5/16"-24 x 3/4" SL)Ut',_= HEAD BOLT (4 REQ,)

ENGINE ADAPTOR (1 REQ.)

ENGINE ADAPTOR GASKET (1 REQ.)

M8 RIBBED LOCK WASHER (4 REQ.)

M8-1,25 x 35mm HEX HEAD CAPSCREW (4 REQ,)

MOUNTING BASE (1 REQ,)

1/2 dia, PUSH NUT (2 REQ.)

2-I/4" x 8" WHEEL (2 REQ.)

5/8" LOCK WASHER (2 REQ_)

JAM NUT (2 REQ,)

WHEEL AXLE (2 REQ.)

M8-1,25 x 20ram HEX HEAD CAPSCREW (6 REQ)

M8-1.25 FLANGE NUT (12 REQ,)

RUBBER GROMMET (1 REQ,)

SUPPORT LEG (2 REQ.)

M8-1.25 x 40mm HE SCREW (2 REQ,)

M8 x 25 FLAT WASHER (2 REQ,)

GUIDE HANDLE (1 REQ)

VINYL CAP (1 RETD,)

GUN AND HOSE HOLDER (1 REQ,)

#10 FLAT WASHER (2 REQ)

#10 SELF-DRILLING SCR:_EW (3 REQo)

HANDLE GRIP (1 REQo)

CHEMICAL INJECTOR HOSE(1 REQ)

ADJUSTABLE NOZZLE (1 REQo)

3/8 LD, x 25 FT, HOSE ASSEMBLY (1 REQ)

GUN AND WAND ASSEMBLY (1 REQ)

M6 RIBBED LOCK WASHER (6 REQo)

REPLACEMENT NOZZLE [RED] (1 REQ)

SPR NG CUP 1REQ.

PISTON P,VO1 (SHOE Ca REe. rnb I 2 REQ

#8-32 NU[!ow oil shut down ass y] ( _)

LOW OIL SHUTDOWN WIRE (1 REQ.)

#8 SHAKEPROOF LOCKWASHER (1 REQ.)

LOW O!L SHUTDOWN (1 REQ,)

LOW OIL SHUTDOWN GASKET (1 REQ.)

#10-32 x 3/4" TAPTtTE SCREW (2 REQ.)

OIL CAP/BREATHER (1 REQ.)

M6-1.0 x 20ram SOCKET HEAD CAPSCREW (3 REQ.)

M6 RIBBED LOCK WASHER (3 REQo)

UNLOADER ASSEMBLY (1 REQ.)

SPINDLE SEAT"O RING (1 REQ.)

M6-1,0 x 20ram SOCKET HEAD SCREW (4 REQo)

M12 FLAT WASHER (2 REQ)

23 Drawling No. 94720

Page 24

CRAFTSMAN 1800 PSI HIGH PRESSURE WASHER 580.751500

BRIGGS & STRATTON 4-CYCLE ENGINE 133212-0159-01

346

306

357

10

! 741

REPAIR PARTS

13A

635

337

308

5

N!

I 2o1.1

,......

0

11

15

26

12

615

616

45

i

220

24

\" _ _ t N,O

219

11o19 LABEL KITI

"h" REQUIRES SPECIAL TOOLS

TO INSTALL. SEE REPAIR

INSTRUCTION MANUAL.

Page 25

CRAFTSMAN 1800 PSi HIGH PRESSURE WASHER 580.751500

BRIGGS & STRATTON 4-CYCLE ENGINE 133212-0159-01

634 97

REPAIR PARTS

394

4

392

127

217

127A

124[153 _1012

542 779 414 153

3 ,__--_ 978 163

149

256

187 433

!__!_\ _ 435

52 _ 611

52!_ _ 394_

191 _

J

414A

! 121 CARBURETOR KIT

(9 52

7

9

35B GASKET SET

232

25

216

201

621

467

Page 26

CRAFTSMAN 1800 PSI HIGH PRESSURE WASHER 580.751500

BRIGGS & STRATTON 4-CYCLE ENGINE 133212-0159-01

REPAIR PARTS

2O9

190 190A 208

,_.__ o o

223

280

®_

2O7'

269

206

271

268 _,

270

985

353 _

520 (_

354

969

L_ ..... _J

967

971

163

] 966 ......

26

Page 27

CRAFTSMAN 1800 PSg HiGH PRESSURE WASHER 580.751500

BRIGGS & STRATTON 4-CYCLE ENGINE 133212..0159-01

REPAIR PARTS

55

1016

57

59

305

Y

,)

/

69 456

24

0

I

461

69A

515

23

613A

...... 1676 _-

346A

81

t

346

332 (_

73

304

670

©

334

455

8_

75

335

356

27

Page 28

CRAFTSMAN 1800 PSI HIGH PRESSURE WASHER 580.751500

BRIGGS & STRATTON 4-CYCLE ENGINE 133212-0159-01

REPAIR PARTS

I0. I

1

11

12

13

13A

14

lS

16 ,

17

18

19

21

24

26

27

28

37

48

41

45

46

55

56

57

95

_A

75

81

108

118

t21

124

I_A

149

153

Part

No.

495133

*299819

214040

"272157

294178

'27459

94621

68578

"27O080

94221

94733

94679

94387

495648

494874

495641

495660

%95387

66768

94682

267229

222698

393819

399687

26026

2969O9

299430

221890

94745

262464

281044

268552

262750

222443

93312

491 442

280642

212733

• $_t935

464846

493824

262594

280406

395892

393152

94686

280973

224322

224633

224061

222263

495426

93499

223793

49OO48

491177

231533

495606

94616

226352

223789

26336

268575

490569

93527

Part Name

Cylinder Assembly

Oil Seal

Cylinder Itead

Cylinder Head Gasket

Breather - Valve Chamber

Valve Cover Gasket

Screw - Breather Mounting Sam

Breather Tube Grommt

Cylinder Head Screw -- 2_3/32"

Cylinder Head Stud

Cylinder Head Screw

Oil Drain Plug (magnetic)

Cmrd_simft

NOTE: To replace crard_ahaft pin,

order Part No. 230978

Ball Beadng (PTO side)

Crankcase Cover Assembly

Bushing -- oil Seal

Oil Se ed

Oil Filler Plug

t-lax i-kind Screw

Flywheel

Flywheel Key

Piston Assembly

Ring Set

Pleton Pin Lock

Platen Pin Assembly

Connecting Rod Assembly

Connecting Rod Dipper

Connecting Rod Screw

Exl_ua! Valve

intake Valve

intake Valve Spring

Exhaust Vedve Spdng

Rywhsel Guard

Valve Spring Retainer

Retatnor Valve

Valve Tappet

Cam Gear

Carburetor Mounting Gasket

Rewind Starting Housing

Rewind Starter Pulley

Rewind Starter Swing

RewirKI Starter Rope (cut to length

Starter Handle Insert

Rewind Starter Handle

Housing Mounting Screw

Washer

Washer

Rotating Screen

Flywheel Washer

Screw Lock

Carburetor Assembly

ThretUe_Velvo-to-Sha ft Screw

Carburetor ThretUa

Throttle Shaft and Lovm"

Choke Valve Group

Needle Valve

Carburetor Kit

Flex Head Screw

Welch Plug

Welch Plug (Mixing Chamber)

Needle Valve Spdng

Throttle Adjustment Spring

Screw end Collar

Round Head Screw 5-40 x 5/8"

F_eL _ Part

_1o. No.

163

180

181

187

190

190A

191

Z01

Z02

203

2O4

Z05

Z06

Z07

298

2O9

216

217

219

22O

222

223

224

227

23O

232

256

265

267

268

269

27O

271

280

300A

304

305

305

306

332

333

334

335

337

346

346A

353

354

356

356

363

373

392

394

*271935

495405

404556

231068

94712

94077

¥272489

26228O

262270

266720

222962

231520

94081

26855

262323

262282

262359

262281

391737

221551

490549

223455

93491

490374

222450

262310

223813

221535

93496

66968

26O99

63426

29O568

223798

393615

495795

94619

22482O

224738

92284

397358

93613

93414

492167

9468O

93705

92791

9O576

3988O8

495603

19069

92967

262328

t272538

* Included in Gasket Set _ Part Noo 495603

Included in Carburetor Kit _ Part No. 495606

Part Name

Air Cleenor Mounting GHked

Fuel Tank Assembly

Fuel Tank Cap

Fuel Pipe

Screw - S_m

Screw- Sam

Fuel Tank Mo*.mUng Gasket

Govem_,r Unk

Thmttia Link

Bell Crank

Control Lover Bushlng

Shoulder Screw

Stop Nut

Control Rod Spdng

Speed Control ROd

Governor Spdng

Choke Mink

Choke Spdng

Governor Gear

TnPJs t Washer

Control Brecka!

Governor Control Lever

Governor Control Lever Rivet

Governor Lever A_embly

Governor Lever Washer

Return Spdng

Bell Crank

Casing Clamp

Screw

Control Wire Casing N 48= long

ff longer casing Is needed, specify

lenght in Inches; if shortor casing

needed, order NO. 66986 and cut to

required length.

Control Wire

Casing Locknut

Control Laver

Control Rod Bracket

Exhaust Muffler.

Blower Housing

Blower Housing Mounting Screw

Cyllnder Shield

Cylinder Head Cover

Rywl_el Nut

Armature Assembly

Sam Screw

Am,alum Mounting Screw

Spark Plug _ 1_7/8" high, 48ram

Screw

Screw

Lock Washer

Hex Hut

Ground Wire

Gasket eel

Flywheel Puller

Hex Nut

Dlephregm Spdng

Diaphragm

28

Page 29

CRAFTSMAN 1800 PSi HIGH PRESSURE WASHER 580.751500

BRIGGS & STRATTON 4-CYCLE ENGINE 133212.4)159-01

REPAIR PARTS

Ref.

NO.

414

414A

432

=

456

467

515

520

5_

527

529

_6

sr_

5_

6o8

613A

814

615

Part

NO,

22olw2

2211_

221377

93266

214(_1

93141

49477O

224321

492ga3

262626

280715

262935

93722

94659

223788

231560

67838

491435

494279

93572

231079

92613

231082

298406

93035

93306

93307

Part Name

We=her

Wseher

sp._ cep

Diaphr_m Cover Pin

o_t..,_n Cowr

O_hr_m Cover SCn_

Ry_l Cup

_ln_r S_ktg

Rmchel P_

Spd_ Pin

ConLrot Knob

Tl_rmlnal

84wn _mw

B_ Tube Clamp

BmMher Tube

NOTE: 231550 -- Breather Tube

Breeffler Tube Grommet

Air Filter

Air Cleaner Aseebmly

Screw

Governor Crank Bushing

Governor Lever Bolt

No. 10-24 Hex Nut

Rewind Starter Assembly

Hex Head Shoulder Screw

H_dr Pin Cottar

E-Ring Retainer

Ref.

NO.

618

621

S34

635

655

670

676A

679

680

741

851

659

670

871

883

916

966

967

968

969

971

978

gas

987

1012

1016

1010

Part

NO.

231077

396847

271853

66538

222598

261o66

395700

27o832

221839

261696

221798

211787

211438

252o01

2723o9

250321

492797

491588

495357

490073

94018

271738

396525

398970

496507

490817

491100

Part Name

Governor Crank (114" dta.) ....

Stop Sv_ tc.h

Throttle Shaft Wseh_ (fomn)

Spark Plug Bbow

Anchor Spdng

Armature Sp=:er

E._aust Deflector

Windier (foam)

Ws=t_r (brae=)

Timing Gear (l:Hain bearing)

tgniUon Cable Tc_mkml

Intalm Valve Seal

Exhexmt Val'_ _et

Exhaust Valve Guide

"Muffler Gaske_

Governor Gear P.ack

Air Cleaner Base

Air Filter

Air Cleaner Cover

Cover Mounting Screw

Air Cleaner Screw

*Cover Ge=ket

tneulator

Throttle Sh=ft Scid

Retainer Link

Spacer

Dec=l (label) Kit

FULL ONE YEAR WARRANTY ON CRAFTSMAN HIGH PRESSURE WASHER

For one year from the date of purchase, when this Craftsman High Pressure Washer Is maintained and operated

according to the instructions in the owner's manual, Sears will repair, free of charge, any defect in material and

workmanship°

If this washer is used for commercial purposes, this warranty applies for only 90 days from the date of purchase.

If this high pressure washer is used for rental purposes, this warranty applies for only 30 days after date of

purchase,.

FULL TWO YEAR WARRANTY ON GASOLINE ENGINE

For two years from the date of purchase, when this gasoline engine is maintained and operated according to the

instructions in the owner's manual, Sears will repair, free of charge, any defect in material and workmanship.

if this gasoline engine is used for commercial or rental purposes, this warranty applies for only one year after

date of purchase°

If the Gasoline Engine is used for commercial or rental purposes, this warranty applies for only one year from the

date of purchase.

This warranty does not cover:

• Expendable items such as spark plugs and air filters, which become worn during normal use°

• Repairs necessary because of operator abuse or negligence, including damage resulting from no water being

supplied to pump or failure to maintain the equipment according to the instructions contained in the owner's

manual

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE HIGH PRESSURE WASHER TO THE NEAREST

SEARS SERVtCE CENTEPJDEPARTMENT THROUGHOUT THE UNITED STATES.

This warranty gives you specific legal rights and you may also have other rights, which vary from state to state°

SEARS, ROEBUCK AND CO. D/817 WA, Hoffman Estates, IL 60179

29

Page 30

CRRF rSMRN"

OWNER'S

MANUAL

MODEL NO.

580.751500

IF YOU NEED

REPAIR SERVICE

OR PARTS

FOR REPAIR SERVICE CALL

THIS TOLL FREE NUMBER

1-800-4,REPAIR

(1-800-473-7247)

5 HORSEPOWER

1800 PSi 2.5 GPM

HIGH PRESSURE WASHER

Each High Pressure Washer has its own model number. Each engine has

its own model number.

The model number for your pressure washer will be found on a decal

attached to the unit.

The model number for your engine will be found on the Blower Housing of

the engine adjacent to the spark plug.

All parts listed herein may be ordered through Sears, Roebuck and Co.

Service Centers and most Retail Stores,

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE THE FOL-

LOWING INFORMATION:

® PRODUCT m HIGH PRESSURE WASHER

• MODEL NUMBER I 580.751500

O ENGINE MODEL NO. _ 133212-0159-01

FOR REPLACEMENT PARTS

INFORMATION AND ORDER-

ING, CALL THIS TOLL FREE

NUMBER:

1-800-FON-PART

(1-800_366-7278)

• PART NUMBER

® PART DESCRIPTION

Your Sears merchandise has added value when you consider that Sears

has service units nationwide staffed with Sears trained technicians....pro-

fessional technicians specifically trained on Sears products, having the

parts, tools and the equipment to ensure that we meet our pledge to you,

we service what we sell.

SEARS, ROEBUCK and CO., HoffmanEstates, IL 60179 U.S.A.

Part No. 94719 Revision 4 (IQt16/95) Printed in U,.S.A.

Page 31

MANUAL DEL

PROPIETARIO

MODELO NO.

580.751500

UNEA DE AYUDA AL

cu_rEPA_ALA _E MAQUINA LAVADORA DE ALTA PRESION

MAO=.ALAVAOOP_A _ DE 5 CABALLOS

!®

"=____,_=== D EF U ERZA A, 800 PSI

HORAS:

Lun. - Vie. 8 a.m. a 5 p.m

(TCE)

PRECAUCION:

Lea y Stga tas Reglas de

Seguridad e Instrucciones

Antes de Operar Este

Equipo

SEARS, ROEBUCK and CO., HoffmanEstates, IL 60179 U.S.A.

. Ensamble

° Operaci6n

° Responsabilidades del Cliente

o Servicio y Ajuste

. Partes de Recambio

Page 32

REGLAS DE SEGURIDAD

PRECAUCION: StEMPRE DESCONECTE EL CABLE DE LA BUJIA Y COLOQUELO DONDE NO PUEDA HACEN

CON_ACTO CON LA BUJIA PARA EVITAR UN ENCENDIDO ACCIOENTAL CUANDO ESTE INSTALANDO,

TRANSPORTANDO, AJUSTANDO O HACIENDO REPARACIONES EN SU MAQUINA LAVADORA DE ALTA PRESIOt_L

ENTRENAMIENTO:

e Los gases de escape dal motor contienen gas de mon6xido de

carb6n MORTAL. Si este gas peligroso se respira en una

concentracf6n suftctente puede causer p_rdfda de ta conctencta

o tncluslve la muerte Opera este equlpo tir'dcamente en dines

ablertas donde hays dlspontble ventilactdn adecuada._

• La gasol|na el Wtamente tNFLAMABLE y sus vapores son

EXPLOSIVOS No permits que se rums,llamas abtedas, chispes

o ca!or an ta cercania cuando se mardpula gasolina. Evite regar

gasolina sobre un motor caUante., Permits qus la unided se anfY_e

por 2 minutos antes de volverta a cargar con combustible.

Cumpla con toda.s las leyes de mgutac_n de almasenamlento

y manaJo de gasottna,

e Ubique esta m_!zquina L_vadora a prmd6n en dines alejades de

matedates combustibles, vapoms combustibles o potvo.

e Et equips de alia presi6n estd dtsefiado pare set ussdo

dnicamente con las ptezas autortzadas de Sears, El usuado

asume todos los desgos y responsabilidadss si usted uttliza este

equips con piezas qua no cumplan las especifi, caciones mint-

mas

• Afgunos quimicos o detergantes pueden ser peligmsos si son

inhaiados o ingerldos, causando nausea severs, desmayo o

envenenamiento. Los elementos peligrosos pueden causar

dafio a la pmpiedad o tesk_n severs

e No permits qua NII_IO-S operen la Mdquina Lavadora a Presi6n

en ningdn momanto.

PREPARACION:

• Opera el motor r3ntcamente en la velocidad de mando. El hacer

funcionar el motor en velocidades excestvas aumenta el fiesgo

de lesi6n personal No manipule las partes qua puedan

aumentar o disminuir la velocidad de mando.

e No use mpas suettas, joyerta onada qua pueda quedar atrapado

an el arranque oen otras plazas en mtact_.

• Antes de encender la M_quina Lavadora a Presk_n an clima fdo

revise todas las piezas dal equips y aseg0rese qua no se ha

formado hlelo en elias,

e Las unidades con plazas dar'tadas o perdidas, o sin la caia o

cubiertas de protecci6n NUNCA deban set operadas.

e El silenciador y el depurador de aim deben astar instalados yen

buenas condiclonas antes de operara la M_quina Lavadora a

Presi6n, Estos componantes act0an coma recolectores de

chlspas si el motor produce fuego de retroceso..

e Revise si el sistema de combustible tJene fugas o stgnos de

deterioro corns ur'_ manguera fr_gil o esponjosa, abrazaderas

sueitas o inexistantes o tanque o taps dafiada Corrija todos los

defectos antes de operar la M_quina Lavadora a Presi(_n,

OPERACION:

• No rocle Gquides inflamables.

• Nunoa dirija la pistols de rociado a personas, an h'nWes o ptantas

e Nunca pennita qua Wguna parts de! cuerpo entre en contacts

con la corriente de! fluido_ NO entre an contacts con un corrtente

de fluids cmada pot una fuga en la manguera de aita pmsi6n.

• La corriente de alia pmst6n de fluids qua este equips puede

producir puede penatrar la piel y sus tejidos subyacentes,

tlevando a lesi_t saris y posibte amputacibn._

BUSQUE ESTE SIMBOLO PARA UBICAR IMPORTANTES PRECAUCIONES DE SEGURIDAD. ESTO I

I

SIGNIFICA "iATENClONll! |ESTE ALERTA!!! SU SEGURIDAD ESTA EN PELIGRO."

• El rociadode alta presi_n puede causar qua pertliculas de plntura

u otras parttculas sean aemtransportadas y qua vuelen a Wtas

veloddedes

e Stempre use pmtecck_ ocu_r cuande uttllce este equips o

cuando est_ cerca de donde el equips est_ siendo utJlizadQ.

e Opera la presi6n an un valor qus no sea mayor qua la presk_n

de Ituido an PSI ctastfk:ada pars su rn_qutna [avadonz a pFss_(_ff11_

• Nunoa mueva la m_:luina tirando de la manguem dealta pmsk_n.

Ut_tce ta manija co!scads an la parte superior de ta unidad

e Slempre este segum qua la pistota de mdado, embocaduras y

acoesodos estdn conectados correctamente_

• Nunca utitice una ptstota de rock, do qua no tenga un segum de