Page 1

OWNER'S

MANUAL

MODEL NO.

580.327060

CAUTION:

Read and Follow

CRRFTSMRNo

120-240 VOLT/4000 WATT A-C

PORTABLE A-C GENERATOR

with Automatic Idle Control

all Safety Rules

and Instructions

Before Operating

This Equipment

SEARS ROEBUCK AND Co., Chicago, IL 60684 U.S.A.

Assembly

Operation

Maintenance

Service and Adjustment

Repair Parts

o 36 6

PartNo. 80059GS_v3-1./11/90

Page 2

SAFETY RULES

& CAUTION: ALWAYS DISCONNECT SPARK PLUG WIRE AND PLACE WtRE WHERE IT CANNOT ACONTACT SPARK PLUG, TO PREVENT ACCIDENTAL STARTING WHEN SETTING UP,

TRANSPORTING, ADJUSTING OR MAKING REPAIRS TO YOUR GENERATOR.

IMPORTANT

THIS GENERATOR IS DESIGNED FOR OUTDOOR USE ONLY. USING THIS GENERATOR INSIDE ANY

BUILDING OR ENCLOSURE, INCLUDING THE GENERATOR COMPARTMENT OF A RECREATIONAL VEHICLE

(RV), IS DANGEROUS. FIRE OR AN EXPLOSION MAY RESULT. NO USER PERFORMED MODIFICATIONS,

INCLUDING VENTING OF EXHAUST ANDIOR COOLING VENTILATION, WILL ELIMINATE THE DANGER.

If this unit is used for backup power inthe event of a

utitity power failure, take the following steps: BEFORE

CONNECTING THE GENERATOR TO AN ELECTRI-

CAL SYSTEM OPEN THE MAIN CIRCUIT BREAKER

OR MAIN SWITCH SERVING THE SYSTEM TO ISO-

LATE THE GENERATOR SYSTEM FROM THE

ELECTRIC UTILITY. FAILURE TO ISOLATE THE

GENERATOR AND UTILITY SYSTEMS MAY

RESULT IN DAMAGE TO THE GENERATOR AND

MAY ALSO RESULT IN INJURY OR DEATH TO

ELECTRIC UTILITY WORKERS DUE TO BACK-

FEED OF ELECTRICAL ENERGY.

This generator supplies dangerously high electrica!

voltages. Use care to prevent extremely hazardous

and possibly lethal electrical shock. Never permit any

unqualified person(s) to operate or service the unit.

DO NOT operate this equipment in the rain, while

standing in water, while barefoot, or white hands or

feet are wet. Dangerous electrical shock will result.

Maintain all wiring, extension cords, etc., in good

condition. Worn, bare, frayed, or otherwise damaged

wiring and cord sets may cause dangerous electrical

shock and may also result in damage to equipment

and!or property.

The National Electrical Code requires that the gener-

ator be properly connected to an approved earth

ground. Local electrical codes may also require

proper grounding of the unit. See ASSEMBLY section

for more grounding information.

Wire gauge sizes of wiring and cord sets must be large

enough to handle the maximum electrical load to

which they will be subjected. Cord sets must be rated

125 a-c volts at 20 amperes or (or greater). Some

electrical devices, however, do not require that cord

rating. Refer to the Owner's manual of the electrciat

device for the manufacturer's recommendations.

The generator engine consumes oxygen and gives off

DEADLY carbon monoxide gas through its exhaust

system. This dangerous gas, if breathed in sufficient

concentrations, can cause unconsciousness or even

death. Operate this equipment outdoors only, in well

ventilated areas where exhaust gases cannot ac-

cumulate and endanger people or animals.

° Gasoline is extremely FLAMMABLE and its vapors are

EXPLOSIVE. Comply with all laws regulating the

storage and handling of gasoline. DO NOT permit

smoking, open flames, sparks or heat in the vicinity

while handling gasoline. Avoid spilling gasoJine on a

hot engine. DO NOT fill fuel tank while engine is

running or hot. Clean off any spilled gasoline before

starting engine.

• DO NOT fill fuel tank completely full. Allow room at

top of tank for fue! expansion or fuel may expand and

over/low onto a hot engine.

• Drain all gasoline from tank before transporting your

generator inside your car or other vehicle.

• DO NOT store the generator with fuel in tank where

gasoline vapors might reach an open flame, spark, or

pilot light, as on a furnace, water heater, dryer, etc.

FIRE or an EXPLOSION might result.

• DO NOT insert any object or tool through cooling air

slots or openings of the engine or generator, even if

the engine is not running. Damage to the unit or

personal injury may result.

• DO NOT attempt to change the engine governed

speed. Factory settings are correct when you receive

the unit. Excessively high engine speeds may result

in injury or damage to equipment.

" DO NOT use the unit if it has been damaged. Repair

or replace all damaged or defective components

before you run the unit.

• DO NOT permit children to operate or service the

generator.

Read your Owner's Manual carefully. Only persons

who are familiar with these safety rules and have been

properly instructed in the use of this product should be

permitted to use the product.

,_ LOOK FOR THIS SYMBOL TO POINT OUT IMPORTANT

SAFETY PRECAUTIONS. IT MEANS "ATTENTION!!I.

BECOME ALERT!H YOUR SAFETY IS INVOLVED."

Page 3

CONGRATULATIONS on your purchase of a Sears

Craftsman Generator. tt has been designed, engineered

and manufactured to give you the best possible depend-

ability and performance.

Shoul_you experience any problem you cannot easily

remedy, please contact your nearest Sears Service Cen-

ter/Department. We have competent, well-trained tech-

nicians and the proper tools to service or repair this unit.

Please read and retain this manual. The instructions will

enable you-to assemble and maintain your generator

prepedy. Always observe the 'SAFETY RULES."

MODEL

NUMBER 580.327060

PRODUCT SPECIFICATIONS

Generator Specifications

RATED MAXIMUM

POWER

RATED VOLTAGE

RATED MAXIMUM

LOAD CURRENT

RATED FREQUENCY

PHASE

Engine Specifications

4000 Watts (2.4 kW)

120/240 Volts a-c

33.3/16.7 a-c amperes

60 Hz at 3600 rpm

Single Phase

SERIAL

NUMBER

DATE OF

PURCHASE

THE MODEL AND SERIAL NUMBERS WILL BE

FOUND ON A DECAL AI-I-ACHED TO THE GENER-

ATOR STATOR CAN.

YOU SHOULD RECORD BOTH SERIAL NUMBER

AND DATE OF PURCHASE AND KEEP IN A SAFE

PLACE FOR FUTURE REFERENCE.

MAINTENANCE AGREEMENT

A Sears Maintenance Agreement is available on this

product. Contact your nearest Sears store for details.

CUSTOMER RESPONSIBILITIES

• Read and observe the safety rules.

RATED HORSEPOWER

DISPLACEMENT

SPARK PLUG: Type:

_ Set Gap to:

MAXIMUM (full tank)

OPERATING TIME (hrs)

GASOL1NE CAPACITY

OIL (1.5 U.S. pint capacity)

NOTE: This generator is equipped with a spark arrestor

muffler. The spark arrestor must be maintained ineffective

working order by the owner/operator.

In the State of California a spark arrestor is required by law

(Section 4442 of the California Public Resources Code).

Other states have similar laws. Federal laws apply on

federal lands.

8 at 3600 rpm

19.3 cubic inches

Champion RJ171Mor

equivalent

0.030 inch (0.76mm)

full load 3/4 1/2 1t4

1,0 1.25 t.5 t.5

1.0 U.S. gallon

SAE 30 Oil

(SAE 10W-30)

• Followregular schedule in maintaining, caring for and.

using your generator.

Follow the instructions under "Maintenance" and

"Storage" sections of this Owner's Manual.

FULL ONE YEAR WARRANTY

For one year from the date of purchase, Sears will repair any defect in material or workmanship in this generator

at no charge.

If the generator is used for commercial or rental purposes, this warranty applies for only ninety days from the

date of purchase.

Warranty service is available by returning to the nearest SEARS SERVICE CENTER/DEPARTMENT throughout

the United States.

This warranty gives you specific legal rights and you may also have other rights, which va,'y from state to state.

SEARS, ROEBUCK AND CO., Department 731CR-W, Sears Tower, Chicago, IL 60684

Page 4

TABLE OF CONTENTS

SAFETY RULES .............................. INSIDE COVER

MAINTENANCE AGREEMENT ............................... 1

CUSTOMER RESPONSIBILITIES ........................... 1

PRODUCT SPECIFICATIONS ................................ 1

WARRANTY ............................................................. 1

ASSEMBLY

To Remove Generator from Carton ...................... 3

Paris Shipped Loose with Unit ............................. 3

Cord Sets and Connector Plugs ........................... 3

Grounding the Generator ..................................... 3

OPERATION

Know Your Generator ........................................... 4

Before Starting Engine ......................................... 5

To Start Engine .................................................... 5

Connecting Electrical Loads ................................. 6

Stopping the Engine ............................................. 6

Don't Overload the Generator .............................. 7

Wattage Reference Guide .................................... 7

MAINTENANCE

General Recommendations ................................. 8

Generator Maintenance ....................................... 8

Engine Maintenance ............................................ 8-9

SERVICE AND ADJUSTMENTS

Engine Speed ...................................................... 10

Carburetor ............................................................ t 0

Check Compression ............................................. I0

Check Ignition ...................................................... 11

Check Carburetion ............................................... t 1

STORAGE

General ................................................................ 11

Storage Instructions .............................................. 11

TROUBLESHOOTING POINTS .............................. 12

WIRING DIAGRAM .................................................. 14

REPAIR PARTS ....................................................... 15-23

PARTS ORDERING ............................. BACK COVER

INDEX

-A-

Air Filter ................. 8

Assembly ................ 3

-B-

Battery

Charging ................... 6

Safety ..................... 6

Before Starting ............ 5

-C-

Carburetor ................ 11

Check Carburetion ......... 12

Check Compression ........ 11

Check lgnitition ............ 11

Circuit Breaker ............ 7

Connecting Electrical Load... 6

Cord Sets, 120 volts ........ 3

Customer Responsibilities ... 1

-E-

Engine

Maintenance ................ 8

Oil Level ................... 5

Speed ..................... 11

-G-

Generator Maintenance ..... 8

Grounding ................ 3

Gasoline ................. 5

-L-

Lubrication ............... 5, 8

-M-

Maintenance

Agreement .................. 1

Engine ..................... 8

Generator .................. 8

Recommendations ........... 8

Spark Arrestor ............... 9

Spark Plug .................. 9

-O-

Operation ................ 4-7

Overloads ................ 7

=p=

Parts, loose in carton ....... 3

Parts, repair .............. 15-23

-R-

Replace Foam Filter ........ 8

Replace Paper Element ..... 9

-S-

Safety Rules ........... inside cover

Service and Adjustments

Carburetor .................. 11

Carbutetion ................. 12

CheckingCompression........ 12

CheckingIgnition............. 11

EngineSpeed ............... 11

Service Recommendations .. 10

Specifications ............. 1

Starting Engine ............ 5

Stopping Engine ........... 6

Storage .................. 12

-T-

Troubleshooting ........... 13

-W-

Warranty ................. 1

Wattage Reference Guide ... 7

Wiring Diagram ............ 14

2

Page 5

ASSEMBLY

Your a-c generator was completely assembled at the fac-

tory. It is ready for use after it has been properly serviced

with the recommended lubricating oil and fuel.

IMPORTANT: ANY A]-I-EMPT TO RUN THE ENGINE

BEFORE IT HAS BEEN SERVICED WITH THE RECOM-

MENDED OIL WILL RESULT IN AN ENGINE FAILURE.

TO REMOVE GENERATOR FROM CARTON

• Set the carton on a flat rigid surface with "THIS SIDE

UP" arrows pointing upward.

• Carefully open the top flaps of shipping carton.

• Remove any loose parts shipped with the unit. These

are shipped in a brown manilla or plastic envelope.

° Cut down comers at one end of shipping carton and lay

that side of carton down flat.

Remove packing material, carton tillers, etc.

Remove generator from shipping carton.

Check carton carefully for any additional loose parts.

CORD SETS AND CONNECTOR PLUGS

120 VOLTS DUPLEX RECEPTACLE

Use only high quality, well-insulated, 3-wire grounded ex-

tension cords with the generator's 120-volt "duplex" type

electrical receptacles (Fig. t ). All cord sets used should be

rated 125 volts at 20 a-c amps or greater for most electrical

devices. Keep extension cords as short as possible,

preferably less than t 5 feet long to prevent voltage drop

and possible overheating of wires.

@

120 V. A.C.

.@

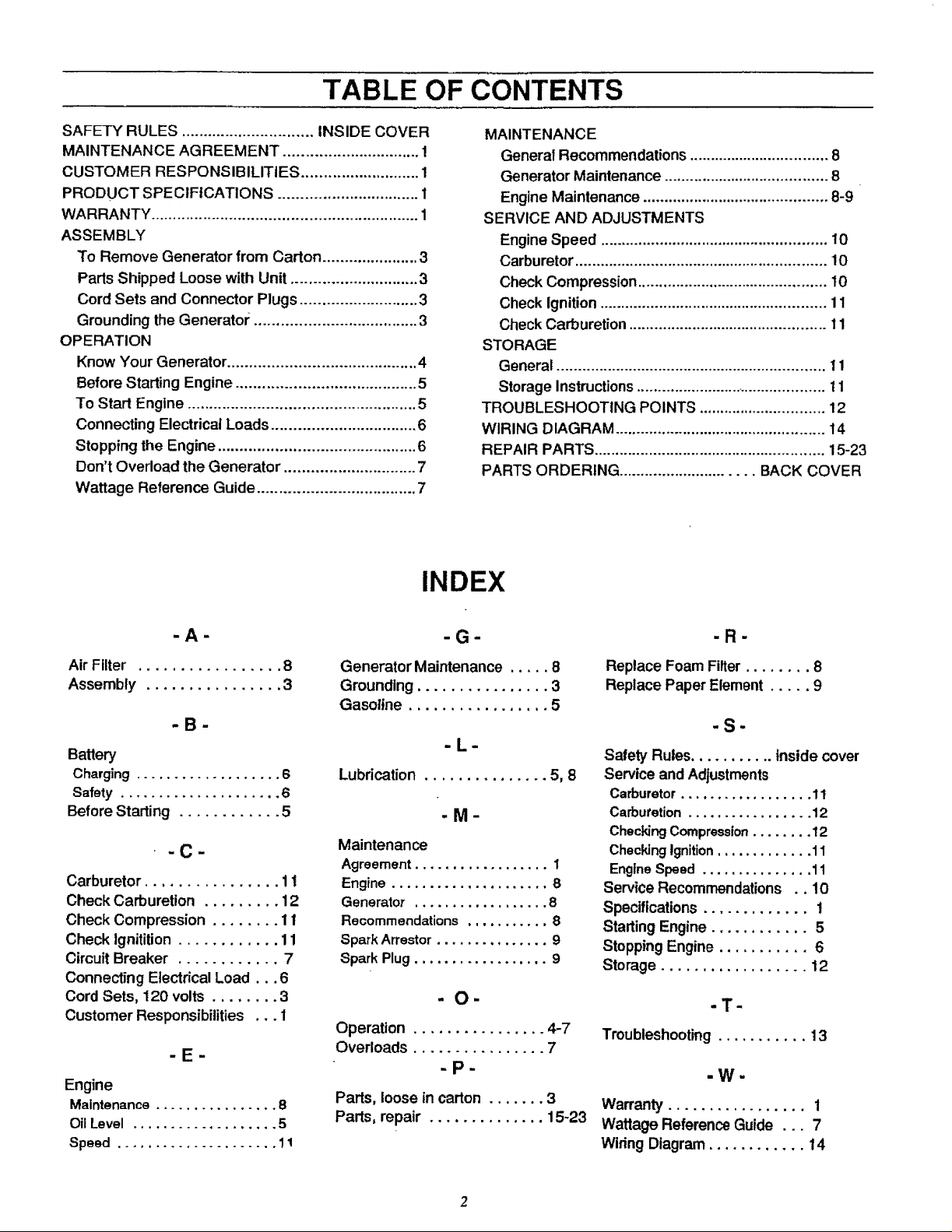

120/240 VOLTS RECEPTACLE:

A 240 volts, 20 amp, twistlock type mating connector plug

(Fig. 2) is required when using this receptacle. A 4-wire

cord set, rate 20 a-c amperes at 250 volts (or greater), is

required and must be connected to the plug and to the

desired load(s). To order additional connector plugs, see

REPAIR PARTS section of this manual. You may also

purchase plugs at a local electrical supply store, ordering

NEMA type L14-20P.

4-Wtre Cord Se!

O AMP

N E tvIA L14-2 OH

FIG. 2

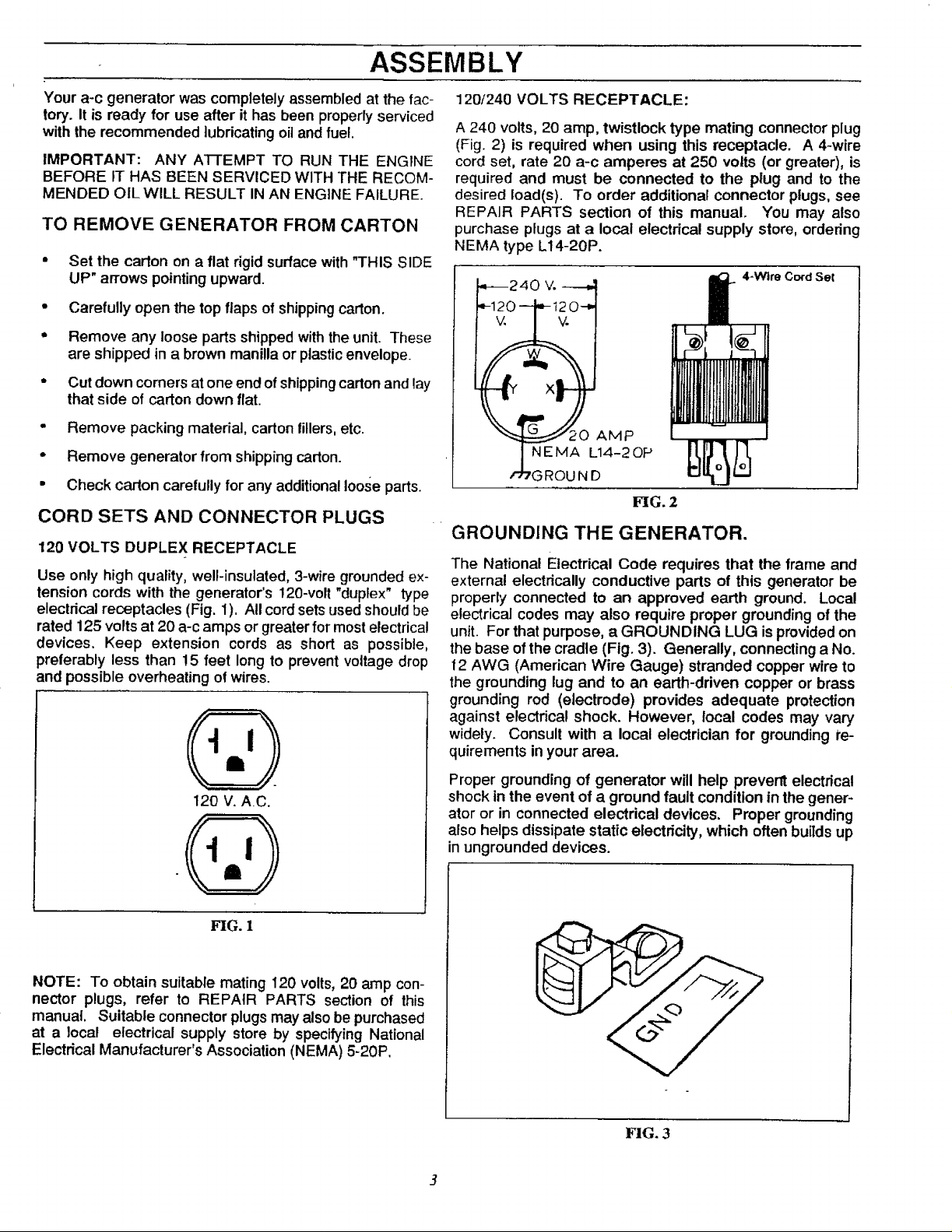

GROUNDING THE GENERATOR.

The National Electrical Code requires that the frame and

external electrically conductive parts of this generator be

properly connected to an approved earth ground. Local

electrical codes may also require proper grounding of the

unit. For that purpose, a GROUNDING LUG is provided on

the base of the cradle (Fig. 3). Generally, connecting a No.

t 2 AWG (American Wire Gauge) stranded copper wire to

the grounding lug and to an earth-driven copper or brass

grounding rod (electrode) provides adequate protection

against electrical shock. However, local codes may vary

widely. Consult with a local electrician for grounding re-

quirements in your area.

Proper grounding of generator will help prevent electrical

shock in the event of a ground fault condition in the gener-

ator or in connected electrical devices. Proper grounding

also helps dissipate static electricity, which often builds up

in ungrounded devices.

]FIG. !

NOTE: To obtain suitable mating 120 volts, 20 amp con-

nector plugs, refer to REPAIR PARTS section of this

manual. Suitable connector plugs may also be purchased

at a local electrical supply store by specifying National

Electrical Manufacturer's Association (NEMA) 5-20P.

]FIG. 3

3

Page 6

OPERATION

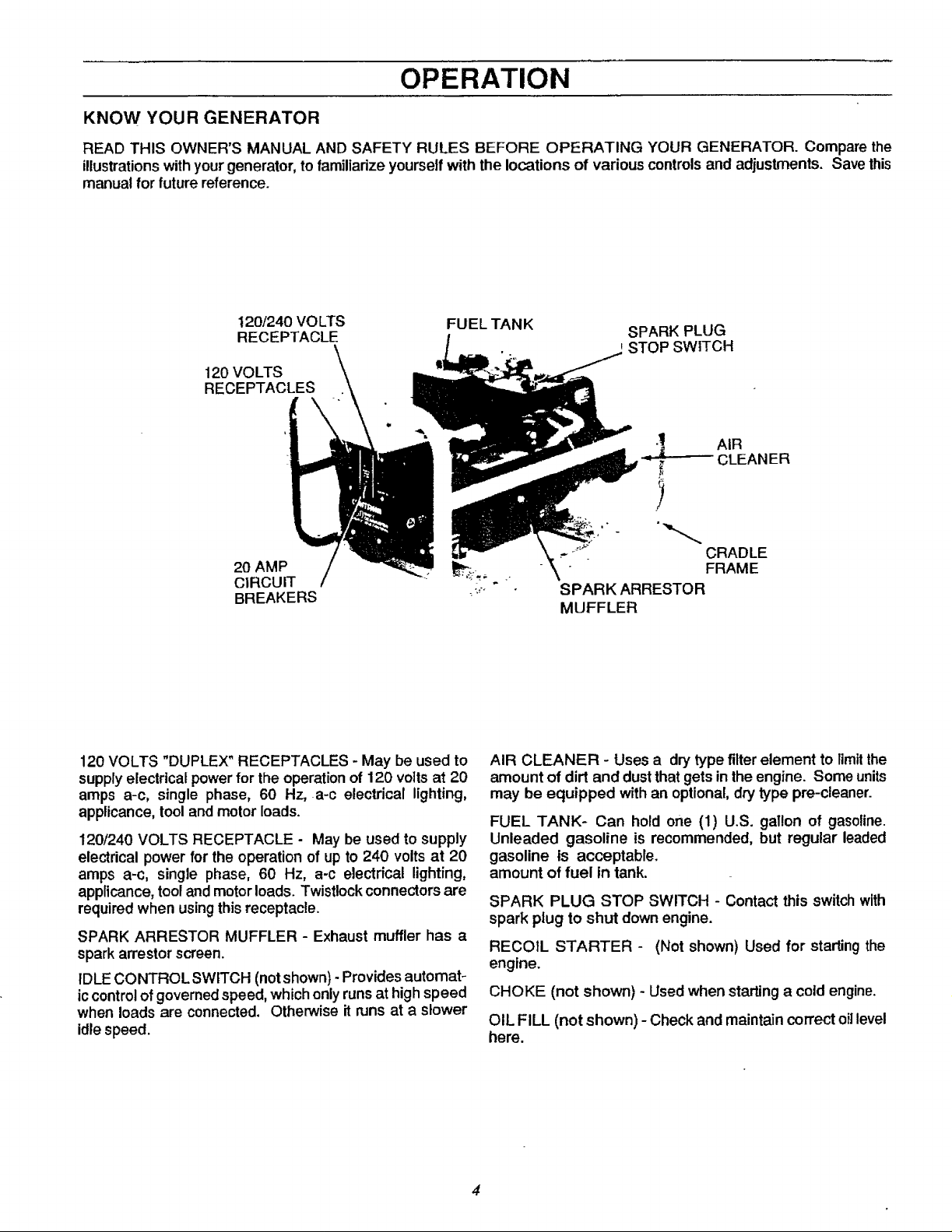

KNOW YOUR GENERATOR

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR GENERATOR. Compare the

illustrationswith your generator, to familiarize yourseff with the locations of various controls and adjustments. Save this

manual for future reference.

120/240 VO LTS

RECEPTACLE

120 VOLTS

RECEPTACLES

120 VOLTS "DUPLEX" RECEPTACLES - May be used to

supply electrical powerfor the operationof 120 volts at 20

amps a-c, single phase, 60 Hz, a-c electrical lighting,

applicance, tool and motor loads.

120/240 VOLTS RECEPTACLE - May be used to supply

electrical power for the operation of up to 240 volts at 20

amps a-c, single phase, 60 Hz, a-c electrical lighting,

applicance, tool and motor loads. Twistlock connectors are

required when using this receptacle.

SPARK ARRESTOR MUFFLER - Exhaust muffler has a

spark arrestor screen.

IDLE CONTROL SWITCH (not shown) - Provides automat-

iccontrol of governed speed, which only runs at high speed

when loads are connected. Otherwise it runs at a slower

idlespeed.

FUEL TANK

SPARK PLUG

i STOP SWITCH

.t AIR

CLEANER

SPARK ARRESTOR

MUFFLER

AIR CLEANER - Uses a dry type filter element to limit the

amount of dirt and dust that gets in the engine. Some units

may be equipped with an optional, dry type pre-cleaner.

FUEL TANK- Can hold one (1) U.S. gallon of gasoline.

Unleaded gasoline is recommended, but regular leaded

gasoline is acceptable.

amount of fuel in tank.

SPARK PLUG STOP SWITCH - Contact this switch with

spark plug to shut down engine.

RECOIL STARTER - (Not shown) Used for starting the

engine.

CHOKE (not shown) - Used when starting a cold engine.

OIL FILL (not shown) - Check and maintain correct oit level

here.

4

Page 7

OPERATION

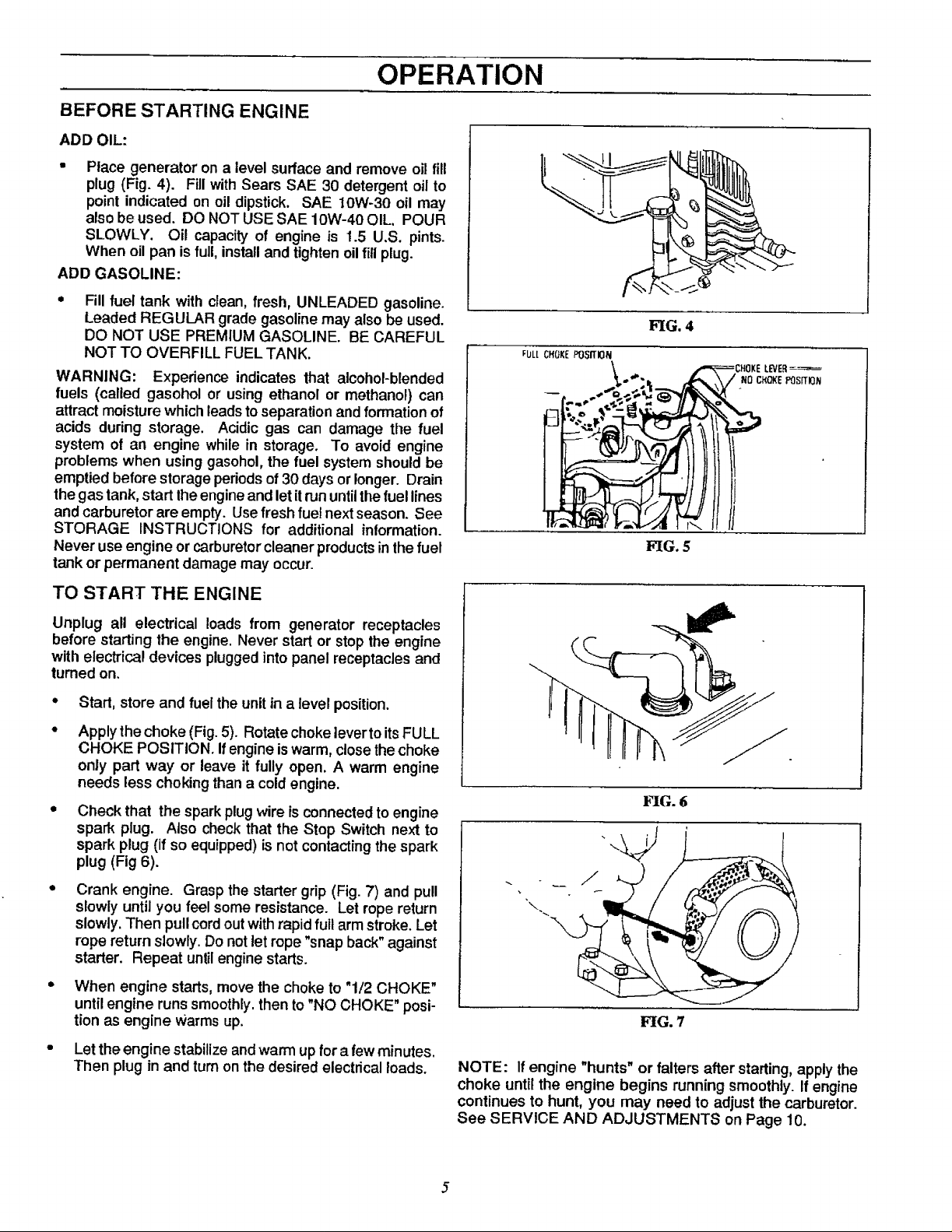

BEFORE STARTING ENGINE

ADD OIL:

• Place generator on a level surface and remove oil fill

plug (Fig. 4). Fill with Sears SAE 30 detergent oil to

point indicated on oil dipstick. SAE 10W-30 oil may

also beused. DO NOTUSESAE 10W-40OIL. POUR

SLOWLY. Oil capacity of engine is 1.5 U.S. pints.

When oil pan is full, install and tighten oil fill plug.

ADD GASOLINE:

Fill fuel tank with clean, fresh, UNLEADED gasoline.

Leaded REGULAR grade gasoline may also be used.

DO NOT USE PREMIUM GASOLINE. BE CAREFUL

NOT TO OVERFILL FUEL TANK.

WARNING: Experience indicates that alcohol-blended

fuels (called gasohol or using ethanol or methanol) can

attract moisture which leadsto separation and formation of

acids during storage. Acidic gas can damage the fuel

system of an engine while in storage. To avoid engine

problems when using gasohol,the fuel system should be

emptied before storage periodsof 30 days or longer. Drain

the gas tank, start theengineand letitrun untilthe fuel lines

and carburetor are empty. Use fresh fuelnextseason. See

STORAGE INSTRUCTIONS for additional information.

Never useengine or carburetorcleaner products in thefuel

tank or permanent damage may occur.

FIG. 4

FULt CHOKE POSITION

_, j-"_===CHOKE LEVER=_

,,'_"_. _%= _'_// NO Cf(C'KEPOSITION

]FIG, 5

TO START THE ENGINE

Unplug all electrical loads from generator receptacles

before starting the engine. Never start or stop the engine

with electrical devices plugged into panel receptacles and

turned on.

Start, store and fuel the unit in a level position.

Apply the choke (Fig. 5). Rotate choke lever to its FULL

CHOKE POSITION. If engine iswarm, close the choke

only part way or leave it fully open. A warm engine

needs less choking than a cold engine.

Check that the spark plug wire is connected to engine

spark plug. Also check that the Stop Switch next to

spark plug (if so equipped) isnot contacting the spark

plug (Fig 6).

Crank engine. Grasp the starter grip (Fig. 7) and pull

slowly until you feel some resistance. Let rope return

slowly. Then pull cord out with rapid full arm stroke. Let

rope return slowly. Do not let rope "snap back" against

starter. Repeat until engine starts.

When engine starts, move the choke to "1/2 CHOKE"

until engine runs smoothly, then to "NO CHOKE" posi-

tion as engine Warms up.

][_[G.6

FiG. 7

Letthe engine stabilize and warm upfor a few minutes.

Then plug in and turn on the desired electrical loads.

NOTE: Ifengine "hunts" or falters after starting, apply the

choke until the engine begins running smoothly. If engine

continues to hunt, you may need to adjust the carburetor.

See SERVICE AND ADJUSTMENTS on Page 10.

5

Page 8

OPERATION

CONNECTING ELECTRICAL LOADS

• Use this generator to operate 120_240 volts, single

phase, 60 Hz, a-c lighting, appliance, tool and motor

loads.

DO NOT connect 240 volts to the 120 volts duplex

receptacles.

DO NOT connect any 3-phase loads to panel recep-

tacles.

DO NOT connect any 50 Hz loads to the generator.

Add up the rated watts of all lights, tool, appliance and

motor loads you are powering at one time. This total

should NOT be greater than (a) the generator's rated

wattage capacity, or (b) the circuitbreaker rating of the

receptacle supplying power. See "Don't Ovedoad the

Generator" on Page 7.

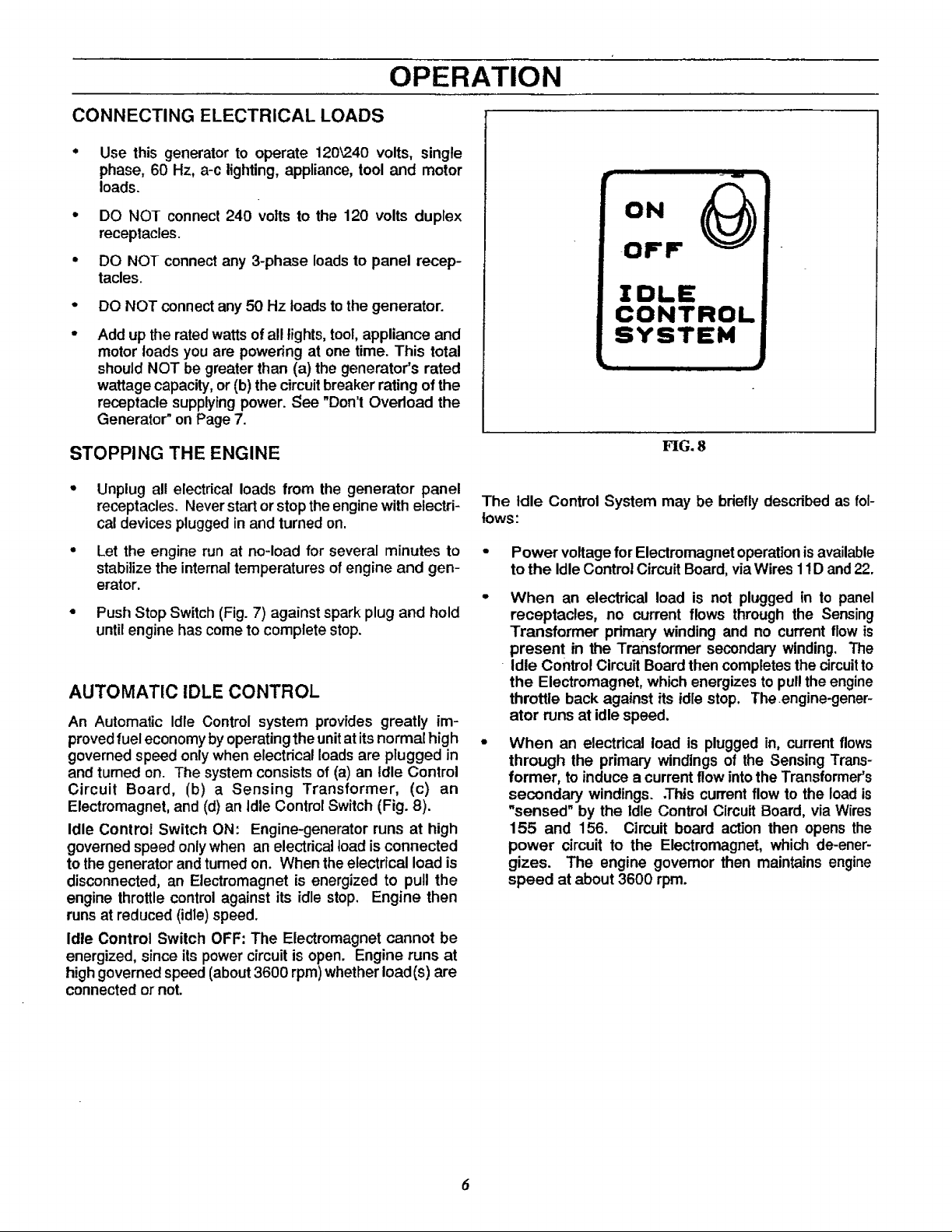

STOPPING THE ENGINE

ZDLE

CONTROL

SYSTEM

HG. 8

Unplug all electrical loads from the generator panel

receptacles. Never start or stop the engine with electri-

cal devices pluggedin and turned on.

Let the engine run at no-load for several minutes to

stabilize the internal temperatures of engine and gen-

erator.

Push Stop Switch (Fig. 7) against spark plug and hold

until engine has come to complete stop.

AUTOMATIC IDLE CONTROL

An Automatic Idle Control system provides greatly im-

provedluel economy by operating the unit at its normal high

governed speed only when electrical loads are plugged in

and turned on. The system consists of (a) an Idle Control

Circuit Board, (b) a Sensing Transformer, (c) an

Electromagnet, and (d) an Idle Control Switch (Fig. 8).

Idle Control Switch ON: Engine-generator runs at high

governed speed only when an electrical toad is connected

to the generator and turned on. When the electrical load is

disconnected, an Electromagnet is energized to pull the

engine throttle control against its idle stop. Engine then

runs at reduced (idle) speed.

Idle Control Switch OFF: The Electromagnet cannot be

energized, since its power circuit is open. Engine runs at

highgoverned speed (about 3600 rpm) whether load (s) are

connected or not.

The Idle Control System may be briefly described as fol-

tows:

Power voltage for Electromagnet operation is available

to the Idle Control Circuit Board, via Wires 11D and 22.

When an electrical load is not plugged in to panel

receptacles, no current flows through the Sensing

Transformer primary winding and no current flow is

present in the Transformer secondary winding. The

Idle Control Circuit Board then completes the circuitto

the Electromagnet, which energizes to pull the engine

throttle back against its idle stop. The .engine-gener-

ator runs at idle speed.

When an electrical load is plugged in, current flows

through the primary windings of the Sensing Trans-

former, to induce a current flow into the Transformer's

secondary windings..This current flow to the load is

"sensed" by the Idle Control Circuit Board, via Wires

155 and 156. Circuit board action then opens the

power circuit to the Electromagnet, which de-ener-

gizes. The engine governor then maintains engine

speed at about 3600 rpm.

Page 9

OPERATION

DON'T OVERLOAD THE GENERATOR

This generator is equipped with 20-amp circuit breakers,

which protect the unit against electrical overload. Over-

loading a generator in excess of itsrated wattage capacity

can result in damage to the generator to connected electri-

cal devices. Observe the following, to prevent overloading

the unit.

Add up the total wattage of all electrical devices to be

connected at one time. This total should NOT be

greater than the generator's wattage capacity.

The rated wattage of lights can be taken from light

bulbs. The rated wattage of tools, appliances and

motors can usually be found on a data plate or decal

affixed to the device.

If the appliance, tool or motor does not give wattage,

mulitply 120 volts times ampere rating to determine

watts (volts x amps = watts).

WATTAGE REFERENCE GUIDE

RUNNING

WATTS

*Air Conditioner (12,000 Btu) ................................... 1700

Battery Charger (20 amp) ......................................... 500

Belt Sander (3") ........................................................ 1000

Chain Saw ................................................................ t200

Circular Saw (6-12/") ...................................... 800 to 1000

Coffee Maker ............................................................ 1000

*Compressor (1 HP) ................................................. 2000

*Compressor (3/4 HP) .............................................. 1800

*Compressor (1/2 HP) .............................................. 1400

Curling Iron ................................................................ 700

*Deep Freeze ............................................................ 500

Disc Sander (9") ....................................................... 1200

Edge Trimmer ............................................................ 500

Electric Nail Gun ...................................................... 1200

Electric Range (one element) ................................... 1500

Electric Skillet ............................. .............................. 1250

*Furnace Fan (1/3 HP) ............................................. 1200

Hair Dryer ................................................................. 1200

Hand Drill (1") ........................................................... 1100

Hand Drill (1/2") ............................................. 750 to 1000

Hand Drill (3/8") ......................................................... 500

Hand Drill (1/4") ......................................................... 250

Hedge Trimmer ......................................................... 450

Impact Wrench .......................................................... 500

*Jet Pump .................................................................. 800

Some electric motors,such as induction types, require

about two and a halt times more watts of power for

starting than for running. This surge of power lasts only

a few seconds when starting such motors. Make sure

you allow for this high startingwattage when selecting

electrical devies to connect to your generator. First,

figure the watts needed to start the largest motor. Add

to that figure the running watts of all other connected

loads.

The GUIDE below is provided to assist you in deter-

mininghowmany items your generator can operate at

one time.

RUNNING

WATTS

Lawn Mower ............................................................. 1200

Ught Bulb .................................................................. 100

Microwave Oven ....................................................... 700

*Milk Cooler ...................... _....................................... 1100

Oil Burner on Furnace .............................................. 300

Oil Fired Space Heater (140,000 Btu)...................... 400

Oil Fired Space Heater (85,000 Btu)........................ 225

Oil Fired Space Heater (30,000 Btu)........................ 150

*Paint Sprayer, Airless (1/3 HP) ............................... 600

Paint Sprayer, Airless (handheld) ............................ 150

Radio................................................................. 50 to 200

*Refrigerator .............................................................. 600

Slow Cooker.............................................................. 200

*Submersible Pump (1-1/2 HP) ................................ 2800

*Submersible Pump (1 HP) ...................................... 2000

*Submersible Pump (1/2 HP) ................................... 1500

Sump Pump .............................................................. 600

*Table Saw (10")......................................... 1750 to 2000

Television ......................................................... 200 to 500

Weed Trimmer .......................................................... 500

* Allow 2-1/2 times the listed watts for starting these

devices.

Page 10

MAINTENANCE

GENERAL RECOMMENDATIONS ENGINE MAINTENANCE

The Owner/Operator isresponsible for making sure that all

periodic maintenance tasks are completed on a timely

basis; that all discrepancies are corrected; and that the unit

is kept clean and properly stored. Never operate a

damaged or defective generator. Follow the recommenda-

tions in the SERVICE RECOMMENDATIONS chart on

page 12.

CAUTION: DISCONNECT SPARK PLUG WIRE

FROM SPARK PLUG AND PLACE WIRE WHERE IT

CANNOT COME IN CONTACT WiTH YOUR SPARK

PLUG BEFORE WORKING ON YOUR GENER-

ATOR.

GENERATOR MAINTENANCE

Generator maintenance constists of keeping the unit clean

and dry. Operate and store the unit ina clean dry environ-

ment where it will not be exposed to excessive dust,dirt,

moisture or any corrosive vapors. Cooling air slots in the

generator must not become clogged with snow, leaves,or

any other foreign material.

Check the cleanliness ofthe generator frequently and clean

when dust, dirt, oil, moisture or other foreign substances

are visible on its exterior surface.

NOTE: We DO NOT recommend using a garden hose to

clean generator. Water can enter the engine fuel system

and cause problems. In addition, if water enters the gen-

erator through cooling air slots, some of the water will be

retained in voids and cracks of the rotor and stator winding

insulation. Water and dirt buildup on the generator internal

windings wilt eventually decrease the insulation resistance

of these windings.

TO CLEAN THE GENERATOR:

• Use a damp cloth to wipe exterior surfaces clean.

" A soft, bristle brush may be used to loosen caked on

dirt, oil, etc.

• A vacuum cleaner may be used to pick up loose dirt

and debris.

Low pressure air (not to exceed 25 psi) may be used

to-blow away dirt. Inspect cooling air slots and open-

ings on the generator. These openings must be kept

clean and unobstructed.

CAUTION: NEVER INSERTANY OBJECTORTOOL

THROUGH THE AIR COOLING SLOTS, EVEN IF

THE ENGINEIS NOT RUNNING. DAMAGETOTHE

UNIT OR PERSONAL INJURY MAY RESULT.

CHECKING OIL LEVEL

Oil level should be checked prior to each use or at least

every five hours of operation. See OPERATION section

for more information.

CHANGING OIL

Change oil after first five hours of operation. Change oil

every 50 hours thereafter. If you are using your generator

under dirty or dusty conditions, or in extremely hot weather,

change oil every 25 hours of operation.

Change oil while engine is still warm from running, as

follows:

• Remoye oildrain plug (Fig. 9) anddrain oil completely

intoa suitable container.

• When all oil has drained, install and tighten oil dry,in

plug.

Cooling Fin

o,, F

and Dipstick __ Drain Plugi

FIG. 9

• Remove oil filler plug/dipstick. Fill engine to point

indicated on oil dipstick. DO NOT fill above "FULL"

mark. You will need about 1.5 pints.

° When engine sump pump isfilled to proper point, install

and tighten oil tiller plug/dipstick.

SERVICE AIR CLEANER

Your engine will not run properly and may be damaged if

you run it using a dirty air cleaner.

Replace paper air cleaner element: If engine is equipped

with paper type cleaner (Fig. 10) clean or replace air filter

at least once each year. Replace more often if operating

under extremely dirty or dusty conditions DO NOT AT-

TEMPT TO CLEAN OR OIL THE PAPER FILTER. Install

a new paper filter as follows.

• Remove WING NUT, COVER and PAPER FILTER.

Discard the PAPER FILTER.

• Clean inside of BASE and COVER thoroughly.

• Position new PAPER FILTER on BASE.

• InstallCOVER and secure it to BASE with WING NUT.

8

Page 11

REPLACE SPARK PLUG

COW:-

BASE

PAPERFILTER

FIG. 10

CLEAN SPARK ARRESTOR

The engine exhaustmuffler has a spark arrestor screen.

The screen shouldbe inspected every 100 operating hours

or once each year, whichever comes first.

CAUTION: LET THE MUFFLER COOL BEFORE i

_k WORKING ON IT. CONTACT WITH A HOT MUF-

FLER ORENGINE CAN CAUSESEVERE BURNS.

NOTE: If you use your generator on any forest-covered,

brush-covered or grass-covered unimproved land, it must

have a spark arrestor. The spark arrestor must be cleaned

and maintained in good condition by the owner or operator.

The preceding is required by law in the State of California.

Other states my have similar laws. Federal laws apply on

federal lands.

t

WINGNU"

Change the spark plug every 100 hours of operation or

once each year, whichever comes first. This willhelp your

engine to start easier and run better. Set spark plug gap

(Fig. 12) to 0.030 inch (0.76mm). Remove spark plug

access cover to gain access to the spark plug.

.030" (#6 rnrn) _,_

FEELER GAUGE t

SPARK PLUG

FIG. 12

CLEAN ENGINE

Inspect the engine frequently and clean when its cooling

fins are dirty. Clean the engine cooling fins. Also cleanthe

air intake screen around the starter housing.

I

Clean and inspect the spark arrestor as follows (Fig. 11)

• Remove four screws, then remove the exhaust outlet

pipe and itsgasket.

• Clean the screen with a commercial cleaning solvent.

• Inspect the screen and replace if torn, performed or

otherwise damaged. DO NOT USE a defective

screen.

• Use a new gasket and install the exhaust outtet pipe.

Retain with four screws.

EXHAUST OUTLET

PIPE

SCREWS (4)

FIG. 11

SCREEN

9

Page 12

SERVICE RECOMMENDATIONS

Periodic Maintenance Chart

PERIODI(_"MAINTENANCE INTERVAL

After First EverY Every Every Once

Maintenance Task 2 Hours 5 Hours 20 Hours 25 Hours Annually Other

1, Check engine oil level X

2. Change engine oil* X X

3. Replace paper filter

type air cleaner** X

4. Clean & re-oil foam type

air cleaner (if so equipped) X

5. Check engine spark plug X

6. Inspect spark arrestor X

7, Inspect engine-generato_ X X

8 Prepare unil for storage I ....... I t X

]0

Page 13

ENGINE SPEED

SERVICE AND ADJUSTMENTS

Engine speed was properly adjusted at the factory and

should require no additional adjustment. Do not attempt to

change engine speed. If you believe the engine is running

too fast or too slow, take your generator to. an authorized

Sears Service Center for repair and adjustment.

Your generator engine runs at a constant speed. This

constant operating speed is maintained by a mechanical,

flyweight type, fixed speed govenor. DO NOT try to adjust

the governed speed setting for the following reasons:

High engine speeds are dangerous and increase the

risk of personal injury or damage to equipment.

Low engine speeds impose a heavy load on the engine

when sufficient engine power is not available and may

shorten engine life.

The generator will supply correct rated a-c frequency

and voltageonly at the proper speed. Some connected

electrical devices could be damaged by incorrect fre-

quency and/or voltage.

CARBURETOR

The engine carburetor was factory adjusted and, under

most normal conditions, should require no additional ad-

justment. However, some minor adjustment may be re-

quired to compensate for differences in fuel, temperature,

altitude, or load on the engine.

NOTE: DO NOT remove the air cleaner when running

engine. Operation without fully assembled air filter in-

stalled may cause engine damage.

INITIAL CARBURETOR ADJUSTMENT:

= Gently turn IDLE VALVE and NEEDLE vALVE (Fig.

14) clockwise until they just close. Valves may be

damaged by turning them in too far.

Rotate the THROTTLE counterclockwise and hold it

against the THRO-I-FLE STOP. While holding itin this

position, turn IDLE VALVE in slowly and then out

slowly. Set at midpoint between rich and lean.

Release THROTTLE. If engine does not accelerate

properly, readjust carburetor to a richer mixture.

IOLE AIR

SHUTTER

IDLE

ADJUSTMENT

MA_N NOZZLE

BLEED

_MAIN AJUSTMENT

FIG. 14

MAIN AIR

BLEED

INLET NEEDLE

AND SEAT

FLOAT

CHECK COMPRESSION

Remove spark plug and hold thumb over spark plug hole

while cranking engine. Compression should be sufficient

to push thumb off the opening. Ifcompression appears low,

check for the following:

• Open NEEDLE VALVE one and a half turns

counterclockwise.

• Open IDLE VALVE one turn counterclockwise.

FINAL ADJUSTMENT:

• Start engine and let it warm up at least five minutes.

• Turn NEEDLE VALVE in(clockwise-lean mixture) until

engine starts to slow down.

• Turn NEEDLE VALVE out (counterclockwise - rich

mixture) past the smooth operating point.

° Turn the needle valve in (lean mixture) to midpoint

between rich and lean.

• Loose cylinder head bolts.

• Blown head gasket

• Worn or damaged engine.

Department.

]]

Contact Sears Service

Page 14

SERVICE AND ADJUSTMENTS

CHECK CARBURETION

Make sure gas tank is filled with clean, fresh gasoline.

Make sure fuel shutoff valve is open. Make sure fuel flows

freely through fuel line between tankand carburetor. Crank

engine several times, then remove spark plug. If plug is

wet, look for the following:

• Overchoking

• Rich fuel mixture

• Water in fuel

• Intake Valve stuck open

STORAGE

GENERAL

The generator should be started at least once every seven

days and allowed to run at least 30 minutes. If this cannot

be done and you must store the unit for more than 30 days,

use the following information as a guide to prepare it for

storage.

STORAGE INSTR UCTIONS

ENGINE:

• Whileengine is stillwarm, drainoilfrom crankcase and

refillwith fresh oil.

if plug is dry, look for the following:

• Leaking carburetor gaskets

• Gummy or dirty carburetor

• Intake valve stuck closed

CHECK IGNITION

Remove spark plug wire from plug and hold metal terminal

end of wire near engine metal part. Crank engine. A spark

shouldjump the gap from wire to engine. If spark occurs,

try a new spark plug. If no spark occurs, contact Sears

Service Department.

GENERATOR:

• Clean the generator as outline on Page 8 ("Cleaning

the Generator").

• Check that cooling air slots and openings on generator

are open and unobstructed.

OTHER STORAGE TIPS:

• Do not store gasoline from one season to another.

• Replace your gasoline can if tt starts to rust. Rust

and!or dirt in your gasoline can cause problems when

you use it with this unit.

• Remove all fuel from fuel tank. Drain tank and run

engine until itstopsfrom lackof fuel.

IMPORTANT: 1T IS IMPORTANT TO PREVENT GUM

DEPOSITS FROM FORMING tN ESSEN-

TIAL FUEL SYSTEM PARTS SUCH AS

THE CARBURETOR, FUEL FILTER,

FUEL HOSE, OR TANK DURING

STORAGE. ALSO, EXPERIENCE INDI-

CATES THAT ALCOHOL BLENDED

FUELS (called gasoholor using ethanol

or methanol) CAN AI-rRACT MOISTURE

WHICH CAN FORM ACIDS THAT

SEPARATE DURING STORAGE.

ACIDIC GAS CAN DAMAGE THE FUEL

SYSTEM OF AN ENGINE WHILE IN

STORAGE.

Remove spark plug and pour about 0.5 ounce (15cc)

of engine oil into cylinder. Crank engine to distribute

oil. Install spark plug.

Clean dirt, oil, and grease from cylinder, cylinder head,

fins, blower housing, rotating screen and muffler area.

• Store generator indean, dry area.

Do not store the generator underany plastic cover. Plastic

cannot breathe, allowing condensation (moisture) to form.

This condensation can cause your generator to rust.

NOTE: Ifyou must store the generator with fuel in thefuel

tank, using a fuel additive such as STA-BIL®, or an

equivalent will prevent fuel gum deposits from forming.

]2

Page 15

TROUBLESHOOTING POINTS

PROBLEM

No a-c output.

Enginerunsgoodat no-loadbut"bogs down"

whenloadsarecon-ected.

Engine will not start or starts and runs rough.

CAUSE

1.20 amp circuit breaker open.

2. Fault in generator.

3. Poor connection or defective cord set.

4. Connected device is bad.

1. Short circuit in a connected electrical load.

2. Engine speed too slow.

3. Generator isoverloaded.

4. Shorted generator circuit,

1. Run/Stop Switch set to Stop.

2, Dirty air cleaner

3. Out of gasoline.

4. Stale gasoline.

5. Spark plug wire notconnected to spark plug.

6. Bad spark plug.

7. Water in gasoline.

8.0verchoking.

9. Excessively rich fuel mixture.

10. Intake valve stuck open orclosed.

1I. Engine Compression lost.

CORRECTION

1. Reset circuitbreaker.

2, Contact Sears Service Dept,

3. Check and repair,

4. Connect another device that is in good

conditon.

f. Disconnectshorted electrical load.

2. Contact Sears Service Dept.

3. See "Don't Overload the Generator on

Page 7.

4, Contact Sears Service Dept.

1. Set switch to RUN,

2. Clean or replace air cleaner,

3. Fill fuel tank.

4. Draingas tank; fill with fresh gasoline.

5, Connect wire to spark plug.

6. Replace spark piug,

7. Drain gas tank; fill with fresh gasoline.

8. Open choke fully E[ndcrank engine

9. Adjust carburetor (see Page 11)

10. Contact Sears Service Deptartment

11. Contact Sears Service Department.

Engine lacks power

Engtne'hunsts" or falters.

Other engine problems

1, Load is too high.

2. Dirty air filter.

1. Choke is openedtoosoon.

2. Carburetoris runningtoorichortoolean.

Check compression, ignition,carburetion, or a-c

generation.

1. See "Don't Overload the Generator on

Page 7

2.Replaco airfilter..

1. Move choke to ha_way position until en-

gine runssmoothly.

2. Adjust carburetor.

See informationin"Service andAdjustmenmts"

on Page 10.

]3

Page 16

SCH[MAnC

120/24,0 V I 120 V

I _ 2oA 11 .J-J../ eE_<EN Orr_;

::0

}>

"n

,--t

Z

o

Q

0

>

]_

I

[..)

m

z

m

J,",2o ,u_, _, _'_c..e.

HX 22 N.-Y..-. r 22

_Zo/24,o v

20 AkqP

t_t-;ilr I ' I !1

_'" L I I

I/1 IOL_" I

-- t_O'--'l 2,2 _ SENSING

[_1---°= 11 _1 I_A.sFo..<.

• IDL£ _k

J

lo CON'TROL _J

!

HOUSING

0

€0

r._

",.4

o

g_

0

:g

m

Z

13

:g

Page 17

CRAFTSMAN 4000 WATT A-C GENERATOR 580.327060

5

REPAIR PARTS

"_SUPPLIEDWiTH ENGINE

12

ITEM PART NO. QTY.

1 76236 1

2 75933 1

3 44624 4

4 22129 8

5 36223 4

6 33212 2

8 76220 1

9 70434 1

10 70433 1

11 70432 1

12 38150 3

13 22264 3

14 51718 2

15 22153 1

16 22473 1

17 23897 2

18 36261 2

19 70446 1

2o 77816 1

21 50923 1

22 22152 1

23 25105 2

DESCRIPTION

ENGtNE-TECUMSEH 8HR

CRADLE,,SEARS 4000

MOUNT, RUBBER

LOCKWASHER-5/16"

CAPSCREW, HEXHEAD-5i16"_18 x 3/4"

CAPSCREW, HEX HEAD-5/16"-18 x 1-1/4" LONG

IDLE CONTROL COIL

LEVER, I/C THROTTLE

BRACKET,COIL TO ENGINE

BRACKE'_,I/(3COIL

FLATWASHER-#8

LOCKWASHER-#8

CAPSCREW, HE)( HD.-M4.-0.70 x 10

MACHINE SCREW, ROUND HEAD-#8-32 x 1/2"

FLATWASHER-#10

FLATWASHER-#10

POP RIVET,STAINLESS STEEL 1/8"x .23

GOVERNOR LEVER

DECAL, CAUTION HOT

MACH. SCR., PP HD. #I0-24 x 5/8"

LOCK WASHER, NO. 10

SCR, ROUND HD.-MACH. WITH LOCK WASHER #6-32×1/4"

15 Drawing No. 70442

Page 18

0_

,\

23

2O

\

'1'1

.-/

13

12

03

Z

_>

,>

(..)

Q

m

Z

m

-4

0

(31

\

4

t

7

CO

0

PO

"..I

0

\

16

m

21

3

m

-a

,-4

Page 19

CRAFTSMAN 4000 WATT A-C GENERATOR 580.327060 REPAIR PARTS

ITEM PART NO.

1 24489

2 24944

3 76249

4 76460

5 68867

6 68759

7 66819

8 6.77632

9 22717-A

10 74769

11 75921

12 55869

13 76255

14 51715

15 22264

16 23365

17 75475

18 38150

19 70439

20 76278

* 43483

* 70438

21 25433

22 77818

23 77026

DESCRIPTION

SCREW (TAPTITE) - No. 10-32 x 3/8" (14 REQ.)

PLUG, BUTTON -- 1.25" DIAMETER (1 REQ.)

PANEL, END (1 REQ.)

BACK, PANEL SHROUD (1 REQ.)

RECEPTACLE- 120/240 VOLTS (1 REQ.)

RECEPTACLE - 120 VOLTS DUPLEX TYPE (1 REQ.)

BREAKER, CIRCUIT -- 20 AMP (2 REQ.)

BOARD, CIRCUIT - IDLE CONTROL (1 REQ.)

GROMMET (1 REQ.)

TRANSFORMER, IDLE CONTROL (1 REQ.)

DECAL, SEARS 4000 (1 REQ.)

SWITCH, IDLE CONTROL (t REQ.)

DECAL, IDLE CONTROL (1 REQ.}

NUT, HEX- M4-0.70 (8 REQ.)

LOCKWASHER- No. 8 (8 REQ.}

WASHER (SHAKEPROOF) - No. 8 (2 REQ.)

SCREW, PAN HD.- M4-0.7 X 10ram (6 REQ.)

FLAT WASHER - No. 8 (4 REQ.)

SCREW, PAN HD. - M4-0.7 X 20ram (2 REQ.)

SHROUD, PANEL (1 REQ.)

PLUG, CONNECTOR- NEMA L14-20P (1 REQ.)

MANUAL (I REQ.)

GROUND LUG (1 REQ.)

DECAL, DANGER (1 REQ.)

DECAL, NAMEPLATE (1 REQ.)

Drawing No. 70441 17

Page 20

0

'2_. 27._

SUPPLIED WITH ENGINE

o_

6

C_

/'11

16

oo

Z

m

--I

0

".4

m

,,_

_a

_o

Sl

Page 21

CRAFTSMAN 4000 WATT A-C GENERATOR 580.327060 REPAIR PARTS

ITEM PART NO.

1 60220-F

2 22O97

3 22129

4 43107

5 76256

6 7595O

7 28293

8 44395-H

9 22336

10 68397

11 24049

12 44943

13 A-24044-A

14 23877-D

15 25105

16 28092

17 50190

18 44357

19 44331

20 76236

21 72804

22 60706

23 52858

24 76299

25 22145

26 40976

27 77819

28 36223

29 70634

** 70438

30 75940

31 67210-A

35 52829

36 52858

DESCRIPTION

HOUSING ADAPTER (1 REQ.)

LOCKWASHER - 1/4" (4 REQ.)

LOCKWASHER - 5/16" (9 REQ.)

CAPSCREW, HEX HEAD M8-1.25 x 25ram LONG (2 REQ.)

STATOR ASSEMBLY (1 REQ.)

BAR, STATOR BOLT (2 REQ.)

RECTIFIER BRIDGE (1 REQ.)

BOLT, STATOR (4 REQ.)

SCREW - 5/16"-24 X 3/4" (4 REQ.)

ROTOR ASSEMBLY (1 REQ.)

BEARING, ROTOR (1 REQ.)

CARRIER, BEARING (1 REQ.)

BRUSH (2 REQ.)

HOLDER, BRUSH (1 REQ.)

SCREW - No. 6-32 X 1/4" (2 REQ.)

BOLT, ROTOR - 5/16"-24 X 9.25" (1 REQ.)

WASHER, FAN RETAINING (1 REQ.)

COVER, FAN (1 REQ.)

FAN, COOLING (1 REQ.)

ENGINE - 8HP. TECUMSEH (1 REQ.)

MUFFLER ASSEMBLY (1 REQ.)

CAPSCREW, SOCKET HD. - 5/16"-18 x 3/4" LONG (2 REQ.)

NUT, LOCKING FLANGE- M8-1.2514 REQ.)

SUPPORT, MUFFLER (1 REQ.)

FLAT WASHER - M8 (2 REQ.)

CAPSCREW, SOCKET HD. - M8-1.25 x 20ram (2 REQ.)

DECAL, START/STOP (1REQ.)

CAPSCREW, HEX HD. - 5/16"-18 x 1/2" LONG (2 REQ.)

SUPPORT, REAR ALTERNATOR (1REQ.)

MANUAL, OWNER'S (1 REQ.)

DECAL, SEARS (1 REQ.)

DECAL, GROUND (1 REQ.)

CAPSCREW, SOCKET HD. - M8-1.25 x 14mm (2 REQ.)

NUT, LOCKING FLANGE - M8-1.25 (4 REQ,)

** NOT SHOWN

Drawing No. 70440 19

Page 22

CRAFTSMAN4-CYCLEENGINE MODEL NUMBER" 143.796202

I

215

6O

58

I

I

'_178

56

24

MODELendSERIAL

NUMBERS HERE

I

I

7

20

213 /

196

i"

.i"

Page 23

CRAFTSMAN4-CYCLEENGINE

Ref.

No.

1

3

4

5

6

7

8

9

9A

9A

9A

1o

11

11

11

17

18

19

19A

2O

21

22

23

24

25

26

27

33

34

35

36

37

38

39

4O

41

42

43

49

5O

51

52

53

54

55

56

57

58

59

6O

62

66

66

67

Part

No.

35385

27642

35319

27652

35326

65O561

35425

34552

34553

34554

34329A

34330A

34331A

27888

34332

34333

34334

35373A

35374

65O9O8

6.5_882

34O34

35375

33273A

650128

"35262

35376

35377

35319

30699C

307OO

65O494

29642

31845

30588A

36479

29193

35378

33369

650836

29916

29826

29216

33454

29918

65O548

30322

650832

650833

35555

35499

35554

35540

27878A

27880A

34035

Part Name

Cylinder (Incl. Nos. 3, 4 Et5)

Plug, Pipe

Seal, Oil

Pin, Dowel

Baffle, Blower housing

Screw, Hex washer hd. Durlok, !/4-20

x 5/8

Crankshaft

Piston, Pin 8 Ring Assy. (Incl. Nos.

9A, 10 6" 11} (Std.)

Piston, Pin 8- Ring Assy. (Incl. Nos.

9A, 10 _ 1t) (.010 oversize)

Piston, Pin El" Ring Assy. (Incl. Nos.

9A, 10 _ 11) (.020 oversize)

Piston 8 Pin Assy. (Incl. No. 10} (Std.)

Piston 8 Pin Assy. (Incl. No. 10) (.010

oversize)

Piston EfPin Assy. (tncl. No. 10} [.020

oversize)

Ring, Piston pin retaining

Ring Set, Piston (Std.)

Ring Set, Piston (.010 oversize)

Ring Set, Piston [.020 oversize)

Rod Assy., Connecting [Incl. Nos. !8,

19 _ 19A)

Dipper, Oil

Bolt, Connecting rod

Bolt, Connecting rod

Lifter, Valve

Camshaft (Mechanical Compression

ReleaseJ

Extension, Blower housing

Screw, Hex hd. Seres, 10-24 x 1/2

Gasket, Cylinder cover

Cover Assy., Cylinder (Incl. Nos. 26,

27 _ 37)

Bushing, Cylinder cover

Seal, Oil

Rod Assy., Governor Ilncl. Nos. 34 8

35)

Yoke, Governor

Screw, Fil. hd. Sems, 6-40 x 5/16

Ring, Retaining

Shaft, Governor

Spool, Governor

Washer, Flat

Ring, Retaining

Gear, Governor (lncl. No. 39)

Bracket, Governor gear

Screw, Hex washer hd. thread form-

mg, 10-24 x I/2

Clamp, Governor lever

Screw, Hex washer hd., !0-32 x 3/4

Locknut, Hex "Keps", 10-32

Lever, Governor

Washer, E.T. Lock

Screw, Hex washer hd., 8-32 x 5/16

Locknut, Hex "Keps", 8-32

Screw, Hex washer hd. Powerlok,

1/4-20 x 1-11/16

Screw, Hex washer hd. Powerlok,

1/4-20 x I-3/16

Dipstick, Oil

"0" Ring

Tube, Oil fill

Clip, FilJtube

Valve, Exhaust (Incl. No. 70) {Std.)

Valve, Exhaust (InoL No. 70) (1132"

oversize)

Valve, Intake (Incl. No. 70) {Std.)

100

101

102

103

104

105

106

t07

108

109

110

111

112

114

115

117

118

119

120

130

140

143

144

145

146

147

148

155

156

157

158

159

160

161

168

169

170

171

172

173

174

Ref.

No.

67

68

68A

69

70

76

78

79

80

81

82

83

96

97

99

99A

MODEL NUMBER: 143.79620;

Part

No.

34O36

27882

34689

27881

32581

32589

611090

65O88O

650881

65O872

35135

65o814

"34041A

34030

34251

27276

650691

650727

65069o

650694A

"27896A

28423

28424

28425

35350

650t 28

30845A

3345O

30886A

29752

*33263

34707

30088A

650378

"27915A

33375C

338_

6507_

29747B

33013

650760

65O89O

30747

33267

28820

33266

"27272A

33268

33269A

65O513

33272.A

650802

341_

62713

34158

65O561

650665

Valve, Intake (Incl. No. 70) (1/32"

oversize)

Cap, Upper valve spring

SeatAssy., Intake valve

Spring, Valve

Cap, Lower valve spring

Key, Flywheel

Flywheel

Washer, Lock

Nut, Flywheel

Stud, Solidstate mounting

SolidState Assy.

Screw, Torx Hex washer hd. Sems,

t0-24 x 1

Gasket,Cylinderhead

Head, Cylinder

Resistor Spark plug (Champion RJ-

17LM or equivalent}

Cover, Spark plug

Washer, Flat

Screw, Speciat hex hd. tapped,

5/16-18 x 1-3/4

Washer, Flat

Screw

Gasket,Breather

Body, Breather

Element,Breather

Cover, Breather

Tube, Breather

Screw, Hex hd. Seres, 10-24 x 1/2

Bolt, Governorspring adjusting

Nut, Lock

Spring,Extension

Nut _ Lockwasher,1/4-28

Gasket,Carburetor

Pipe, Intake

Screw, Fil. hd. Sems, 1/4-28 x 1

Screw, Torx Fil. hd. Seres, 5/16-18 x

1-1/8

Gasket,Intake pipe

Housing, Blower

Link,Governor-to-throttle

Screw, Hex hd. spinlock thread form-

rag, 5/16-18 x 3/4

Screw, Hex hd. Seres,5/16-24 x 21/32

Cover, Starter hole

Screw, Pan hd. taptite, 8-32 x 3/8

Washer, Lock

Clip, Shorting

Bracket, Air cleaner

Screw, Fit. hd. Seres, 10-32 x 1/2

Bracket, Air cleaner

Gasket, Air cleaner

Element,Air cleaner

Cover, Air cleaner

Nut, Wing

Cover, Cylinder head

Screw, Hex washer hd. taptite, 1/4-20

x 5/8

Plate, Fueltank mounting

Screw, Hex hd., 5/'16-18 x 5/8

Bracket, Fuel tank

Screw, Hex washer hd. Durlok, 1/4-20

x 5/8

Screw, Hex washer hd. thread cutting,

1/4-15 x 7/8

*Indicates Parts Included in

Gasket Set, Ref. No. 2!5.

Part Name

2]

Page 24

CRAFTSMAN4"CYCLEENGINE MODELNUMBER"143.796202

Ref. Part

No. No.

175

176

177

178

186

194

195

196

199

210

34156A

35355

30705

2646O

27930A

35287

35446

29752

35392

34346

Part Name

Tank, Fuel(IncL Nos. 176 8 178)

Cap, Fueltank

Line, Fuel

Clamp, Fuel line

Gasket, Exhaust

Hub, Starter

Screen, Starter

"Nut 8 Lockwasher, 1/4-28

Plug, Starter

Decal, Instruction

Ref.

No.

212

2t3

215

Part

No.

632351

590633

33279G

Part Name

Carburetor {Incl. No. 115)

Starter, Rewind

Gasket Set (Incl. items marked "1

RPM Setting:

High Speed: 3750.

*Indicates Parts Included in

Gasket Set, Ref. No. 215.

CARBURETOR NO, 632351

"- 14

i

_-16

!Ref,

No,

I

2

3

4

5

7

8

9

10

11

12

13

14

15

16

17

18

23

24

25

26

28

29

3O

31

Part

No,

632351

631776

631970

631778

6505O6

63O768

63O738

65O417

631812

630735

631763

*630748

*631027

*631021

631022

632019

*631024

631867

631184

631183

27110

"632239

*630740

*632281

*631028

632164

632043

631971

630739

632347

Part Name

Carburetor

Shaft 8 Lever Assy., Throttle

Spring, Throttle return

Shutter, Throttle

Screw, Throttle Et Choke shutter

Spring, Idle regulating screw

Spring, Main adiustment screw

Screw, Idle regulating

Shaft Et Lever Assy., Choke

Spring, Choke positioning

Shutter, Choke

Plug, Welch

Plug, Welch

Inlet Needte, Seat Et Clip Assy.

(Incl. No. 13)

Clip, Inlet needle

Float, Carburetor

Shaft, Float

Bowl, Float

Washer, Fiat

Washer, Felt

Gasket, Bowl-to-body

Adjustment Screw Assy., Main

[tncl. Nos. 5A, 21, 23 6" 301

"0" Ring, Adjustment screw

Screw, Idle adiustment

Gasket, Rowl-to-body

Fitting, Fuel

Spring, Choke return

Seal, Dust

Washer, Flat

Repair Kit {IncI. items marked *)

22

Page 25

12

l_f. Part

No. No. Part Name

10

11

12

1

2

3

4

8

9

59O633

_Ai

58O60O

590861

59O627

59O641

59O6O1

59O632

5_451A

59O629

59O387

59O634

StaRer, Rewind

Pin, Spring (Inct. No. 7)

We=her

Spring A_y., Brake _t Dog

Retainer

Dog, Starter

Washer

Pulley

Rope, Starter

Spring _ Keeper A_y.

Handle Auy., Starter

Housing A_y., Starter

23

Page 26

SEA/R@

£RRFTSMRN °

OWNER'S

MANUAL

MODEL NO.

580.327060

120 VOLTS / 4000 WATT A-C

PORTABLE A-C GENERATOR

Each Generator has its own model number. Each engine has its own

model number.

The model number for your generator will be found on a decal

attached to the control panel shroud.

The model number for the engine willbefoundon the Blower Housing

of the engine adjacent to the spark plug.

All parts listed herein may be ordered through Sears, Roebuck and

Co. Service Centers and most Retail Stores.

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE THE

FOLLOWING INFORMATION:

• PRODUCT- PORTABLE A-C GENERATOR

HOW TO ORDER

REPAIR PARTS

• MODEL NUMBER-580.327060

• ENGINE MODEL NO.- 143.796202

• PART NUMBER

• PART DESCRIPTION

Your Sears merchandise has added value when you consider that

Sears has service units nationwide staffed with Sears trained tech-

nicians .... professional technicians specifically trained on Sears

products, having the parts, tools and the equipment to ensure that

we meet our pledge to you, we service what we sell.

Put No. 80059 R_vision 3 (1111/90) Printed in U.S.A.

Loading...

Loading...