Page 1

Installation Instructions

GENERAL

These instructions cover the installation of the accessory wall

mounting kit. The kit is provided for mounting cooling only,

multi-split, and heat pump units to a wall due to space

limitations.

IMPORTANT: Read these installation instructions thoroughly

BEFORE starting installation.

Refer to Table 1 for kit contents and usage.

Table I--KIT CONTENTS AND USAGE

MOUNTING

KIT PART USAGE KIT CONTENTS*

NUMBER

2 - Long Bracket

Section

2 - Horizontal Bracket

All 018,024 Sizes

53DS900077

53DS900078

*The contents for both kits are the same: however, the items are different

sizes for specific applications.

Installation of this equipment can be hazardous due to system

pressures, electrical components and equipment location. Only

trained, qualified installers and service technicians should install.

start up and service this equipment. Observe all applicable

precautions.

Improper installation, adjustment, alteration, service,

maintenance, or use can cause explosion, fire. electrical shock, or

other conditions which may cause personal injury or property

damage. Consult a qualified installer, service agency, or your

distributor or branch for information or assistance. The qualified

installer or agency must use factory-authorized kits or accessories

when modifying this product. Refer to the individual instructions

packaged with kits or accessories when installing.

Plus

38HDF/538E- F 030

38QRF/638Q- F030

AIIElse

030 - 060

SAFETY CONSIDERATIONS

Section

2 - Angled Bracket

Section

6 - Wall Lag Bolts

6 - Lag Bolt Washers

6 - Wall Lag Bolt

Shields (Anchors)

4 - Mounting Feet

Bolts (1 in.)

4 - Mounting Feet

Locknuts

10 - Bracket Assy.

Locknuts

10 - Bracket Assy.

Bolts (1/2 in.)

10 - Bracket Assy.

Lockwashers

Follow all safety codes. Wear safety glasses and work gloves. Use

quenching cloth for brazing operations. Have fire extinguisher

available. Read these instructions thoroughly and follow all

warnings or cautions attached to the unit. Consult local building

codes and National Electrical Code (NEC) for special

requirements.

Recognize safety information. This is the safety-alert symbol

Z_. When you see this symbol on the unit and in instruction

manuals, be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING,

CAUTION, and NOTE. These words are used with the

safety-alert symbol. DANGER identifies the most serious

hazards which will result in severe personal injury or death.

WARNING signifies hazards which could result in personal

injury or death. CAUTION is used to identify unsafe practices

which may result in minor personal injury or product and

property damage. NOTE is used to highlight suggestions which

will result in enhanced installation, reliability, or operation.

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Before installation, always check to be sure main power to

system is OFE

INSTALLATION

1. Unpack accessory from carton. Check to be sure contents

are not damaged or missing. See Table 1.

2. Select mounting location on the wall. The location must

allow for use of wall studs for mounting security. Check

local building codes and building construction to ensure

that there is adequate wall strength to support the mounted

unit. The location must also allow for condensate drainage

from the unit. Be sure this drainage does not cause a

problem for the area beneath the unit.

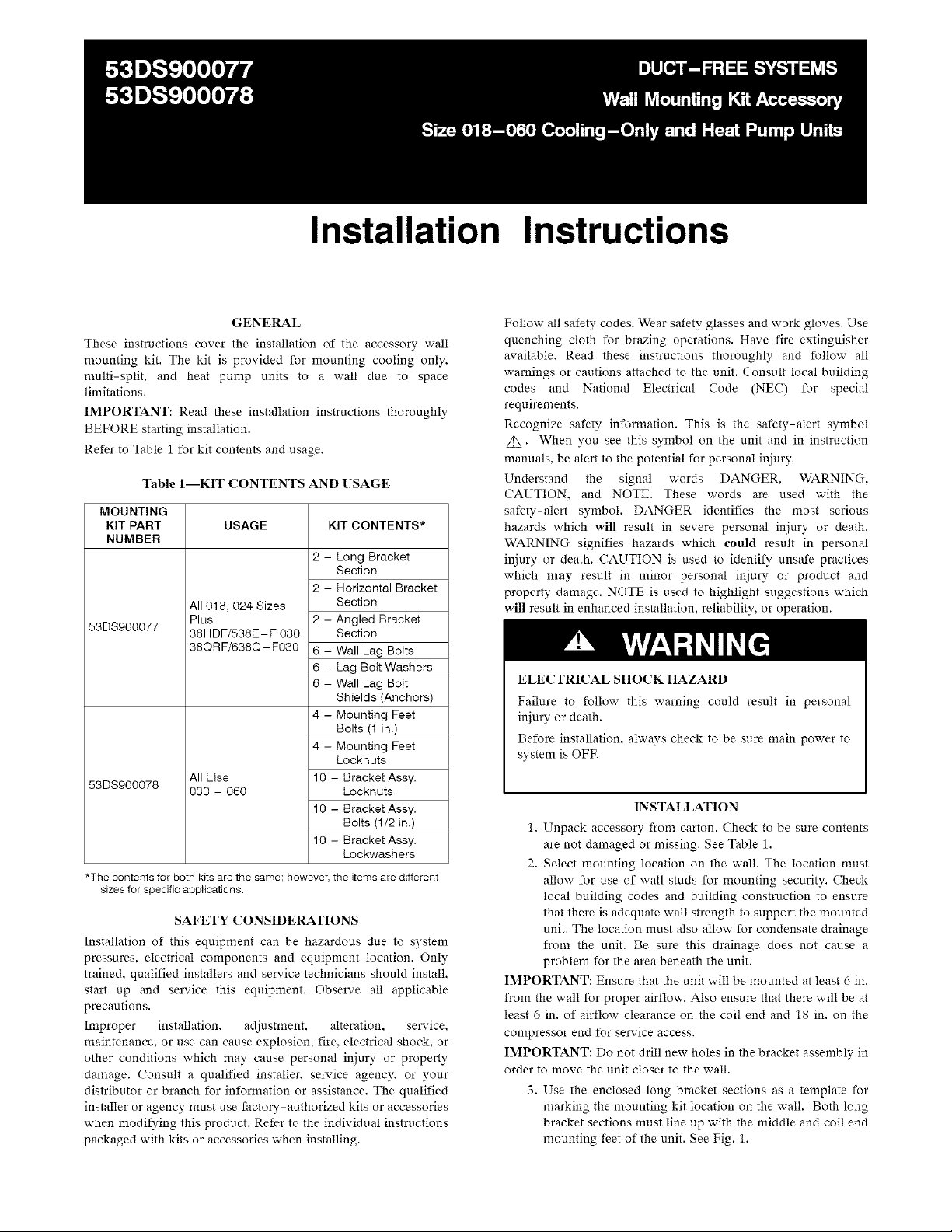

IMPORTANT: Ensure that the unit will be mounted at least 6 in.

from the wall for proper airflow. Also ensure that there will be at

least 6 in. of airflow clearance on the coil end and 18 in. on the

compressor end for service access.

IMPORTANT: Do not drill new holes in the bracket assembly in

order to move the unit closer to the wall.

3. Use the enclosed long bracket sections as a template for

marking the mounting kit location on the wall. Both long

bracket sections must line up with the middle and coil end

mounting feet of the unit. See Fig. 1.

Page 2

4.Drill6 mountingholesinmarked-offlocationsonthe

wall.Forwoodwallmounting,drill5/16-in.diameter

holes.Formasonrywallmounting,drill5/8-in.diameter

holesandinsert3/8-in.steelshields(anchors).

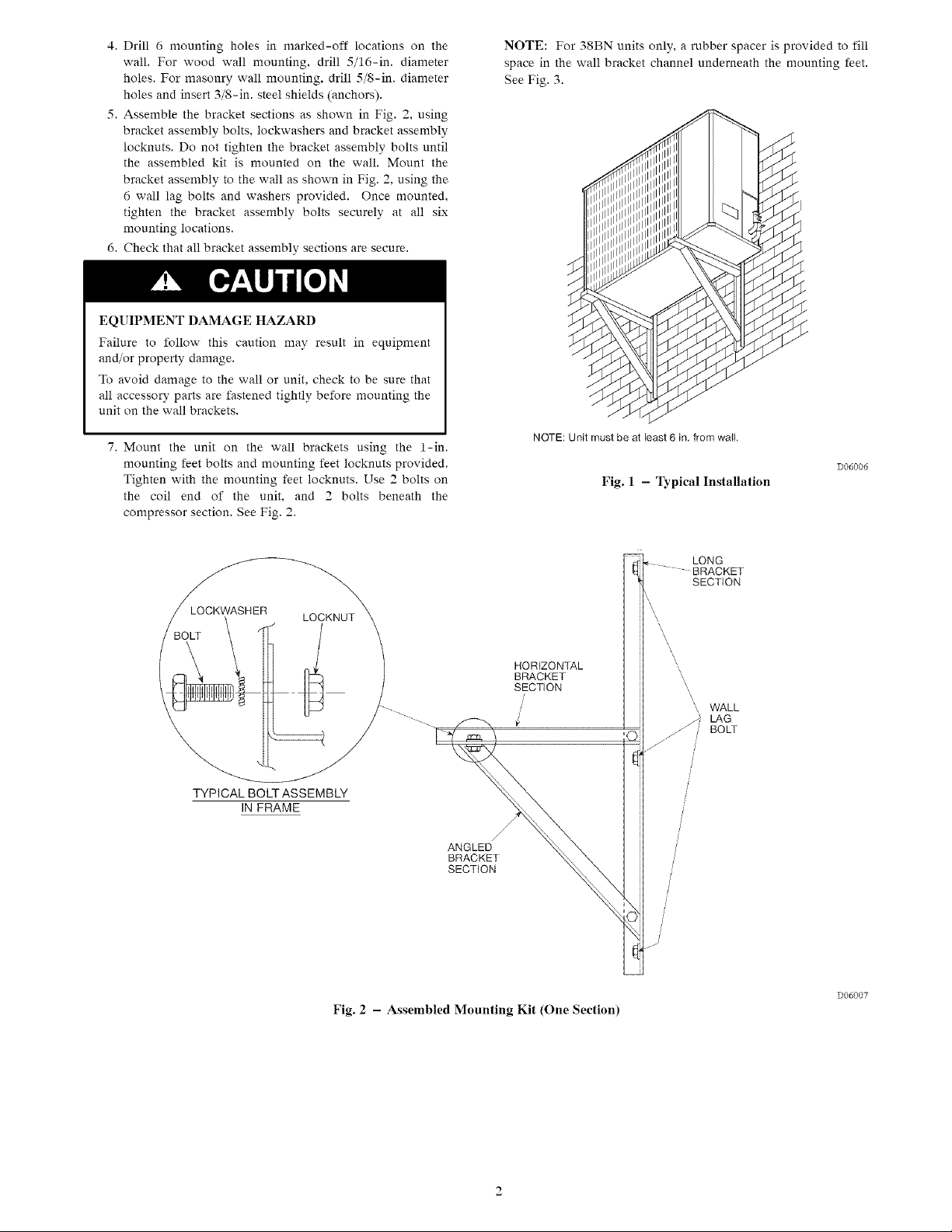

5.AssemblethebracketsectionsasshowninFig.2,using

bracketassemblybolts,lockwashersandbracketassembly

locknuts.Donottightenthebracketassemblyboltsuntil

theassembledkitis mountedonthewall.Mountthe

bracketassemblytothewallasshowninFig.2,usingthe

6walllagboltsandwashersprovided.Oncemounted,

tightenthebracketassemblyboltssecurelyatallsix

mountinglocations.

6.Checkthatallbracketassemblysectionsaresecure.

EQUIPMENTDAMAGEHAZARD

Failureto followthiscautionmayresultin equipment

and/orpropertydamage.

Toavoiddamagetothewallorunit.checktobesurethat

allaccessorypartsarefastenedtightlybeforemountingthe

unitonthewallbrackets.

NOTE:For38BNunitsonly,arubberspacerisprovidedtofill

spaceinthewallbracketchannelunderneaththemountingfeet.

SeeFig.3.

7.Mounttheunitonthewallbracketsusingthe1-in.

mountingfeetboltsandmountingfeetlocknutsprovided.

Tightenwiththemountingfeetlocknuts.Use2boltson

thecoilendof theunit,and2 boltsbeneaththe

compressorsection.SeeFig.2.

/

LOCKWASHER LOCKNUT

/BOLT\ /

TYPICAL BOLT ASSEMBLY

IN FRAME

ANGLED

BRACKET

SECTION

NOTE: Unit must be at least, ; in. from wail.

Fig. 1 - Typical Installation

HORIZONTAL

BRACKET

SECTION

/

j / BOLT

D06006

;KET

SECTION

', WALL

/_.} LAG

Fig. 2 - Assembled Mounting Kit (One Section)

D06007

Page 3

HOLE FOR

MOUNTING

FOOT

(_1" LONG BOLT

Fig. 3 - 38BN Units Only

HOLE FOR BOLT HEAD

ON DIAGONAL BRACE

INSTALL RUBBER PAD

(SHIPPED WITH 38BN UNIT)

SPACER IN WALL BRACKET

CHANNEL.

D06008

Page 4

Copyright 2006 CAC / BDP * 7310 W. Morris St. * indianapolis, IN 46231 Printed in USA. Edition Date: 05/06

Manufacturer reserves the right to change_ at any time_ specifications and designs without notice and without obligations.

Catalol_ No: IIK-53DS900-3

Replaces: 38-56Sl

Loading...

Loading...