Page 1

owner's

manual

MODEL NO.

536.918300

\\

CAUTION:

Read

INSTRUCTIONS

carefully

I

SEARS, ROEBUCK AND CO., Chicago, Illinois 60684 U.S.A.

OWE

• Assembly

• Operating

e Maintenance

• Repair Parts

Page 2

HAZARD TO OPERATOR, BYSTANDERS, PROPERTYOR UNIT MAY

Look for this symbol, It means -- ATTENTION! BECOME ALERT! A

EXIST,

Page

OWNERS INFORMATION ........................... 2

MAINTENANCE AGREEMENT ....... :. .............. 2

"WARRANTY ....................................... 2

OPERATIONAL PRECAUTIONS ...................... 3

Contents of Shipping Carton ...................... 4

Tools Required for Assembly ...................... 4

ASSEMBLY ...................................... 4-6

Handle Assembly ................................. 4

Controls Assembly .............................. 4,5

Skid and Gage Wheel (Height) Adjustment ......... 6

OPERATION ..................................... 6-8

Operating Controls .............................. 6,7

Snow Thrower Operation ......................... 7

Before Starting Engine .......................... 7,8

To Start Engine .................................. 8

ADJUSTMENTS ................................. 8-10

Drive Belt Adjustment ........................... 8,9

Chute Deflector Cable Adjustment ................. 9

Power Clutch Cable Adjustment ................... 9

Wheel Drive Control Adjustment ............... 9,10

Page

impeller/Auger Control Cable Adjustment ......... 10

Carburetor Adjustment .......................... 10

Spark Plug Adjustment .......................... 10

MAINTENANCE ................................ 10-!2

Drive Belt Replacement ....................... 10,11

Shear Bolt Replacement ......................... 11

Roller Chain Replacement ....................... 11

Transmission Replacement ....................... 1 t

Snow Chain Removal ............................ 11

Lubrication .................................. 11,12

Engine Service .................................. 12

STORAGE ........................................ 12

Engine Storage ................................. 12

Unit Storage .................................... 12

LUBRICATION CHART ............................. 13

UNIT REPAIR PARTS ........................... 14-2!

ENGINE REPAIR PARTS ........................ 22-25

TRANSMISSION REPAIR PARTS .................... 26

SERVICE HELPS CHART ........................... 27

HOW TO ORDER REPAIR PARTS ................... 28

Record the following information about your unit so that you will be able to provide it in case of loss or theft.

DATE PURCHASED: MODEL NO.: 536,918300 CODE NO.:

STORE WHERE PURCHASED: ADDRESS

CITY STATE TELEPHONE

The Craftsman Warranty, plus a Maintenance Agreement, provide maximum value for Sears products. Contact your

nearest Sears store for details.

t IIRFIrSNRN. WARRANTY

FULL ONE YEAR WARRANTY ON CRAFTSMAN SNOW THROWER

If this Snow Thrower fails to perform properly due to a defect in material or workmanship within one year

from the date of purchase, Sears wilt repair it, free of charge.

WARRANTY SERVICE IS AVAILABLE BY SIMPLY CONTACTING THE NEAREST SEARS STORE OR

SERVICE CENTER THROUGHOUT THE UNITED STATES.

This warranty gives you specific legal rights, and you may have other rights which vary from state to state.

SEARS, ROEBUCK AND CO. SEARS TOWER BSC 41-3 CHICAGO, IL 60684

--2--

Page 3

observed to prevent the possibility of injury or damage. Please read the following operational

It is imperative in operating and handling your Snow Thrower that certain normal precautions be _r_

precautions before you assemble or use your new Snow Thrower.

TRAINING

1. Wear safety glasses or eye shields when assmbling

or operating snow thrower.

2. Read the Owner's Manual carefully. Be thoroughly

familiar with the controls and the proper use of the

equipment. Know how to stop the unit and disengage

the controls quickly.

3. Never allow children or young teenagers to operate

equipment and instruct them to stay away from the unit

while it is operating. Never allow adults to operate equip-

ment without proper instruction.

4. Keep the area of operation clear of all persons,

especially small children and pets.

5, Exercise caution to avoid slipping or falling, espe_

cially when operating in reverse.

PREPARATION

I. Thoroughly inspect the area where the equipment

is to be used and remove all door mats, sleds, boards,

wires, and other foreign objects.

2. Disengage all clutches and shift into neutral before

starting engine or motor.

3, Do not operate equipment without wearing ade-

quate winter outer garments. Wear footwear which will

improve footing on slippery surfaces.

4. Handle gasoline with care - it is highly flammable.

A. Use only approved gasoline containers.

B, Never remove fuel tank cap or add gasoline to a

running or hot engine or fill fuel tank indoors.

C, Replace fuel tank cap securely and wipe any

spilled gasoline at once.

D. Check your fuel supply before each use, allow-

ing space for expansion as the heat of the engine

and/or sun can cause gasoline to expand.

5. Use a grounded three wire plug-in for all units with

electric starting motors.

6. Adjust auger housing height to clear gravel or

crushed rock surfaces.

7. Never attempt to make any adjustments, except

where required, while engine is running,

8. Let engine and machine adjust to outdoor tempera-

tures before starting to clear snow.

OPERATION

1. Do not put hands or feet near rotating parts. Keep

clear of discharge opening at all times.

2. Exercise extreme caution when operating on or

crossing a gravel drive, walks, or roads. Stay alert for

hidden hazards or traffic. Do not carry passengers.

3. After striking a foreign object, stop the engine,

remove wire from spark plug, thoroughly inspect the

snow thrower for any damage, and repair the damage

before restarting and operating the snow thrower.

4. If the u_nit should start to vibr_te___l[V_stop

the engine and check immediately for the cause. Vibra-"

tion is generally a warning of trouble,

_L

5. Stop engine whenever you leave the operating

position, before unclogging the auger/impeller housing

or dischargechute, and making any repairs, adjustments,

or inspections.

6. Take all possible precautions when leaving the

machine unattended. Disengage the auger/impeller,

shift into neutral, stop the engine, and remove the key.

7. When cleaning, repairing, or inspecting, make

certain auger/impeller and all moving parts have

stopped. Disconnect spark plug wire and keep wire away

from plug to prevent accidental starting.

8. Do not run engine indoors, except when starting

engine and for transporting snow thrower in or out of

building. If for some reason engine must be run indoors,

open outside doors. Exhaust fumes contain carbon

monoxide which is odorless and deadly poisonous.

9. Do not clear snow across the face of slopes. Exer-

cise extreme caution when changing direction on slopes.

Do not attempt to clear steep slopes.

10. Never operate snow thrower without guards,

plates or other safety protective devices in place.

11. Never operate snow thrower near glass enclosures,

automobiles, window wells, drop-off, etc. without

proper adjustment of snow discharge angle.

12. Do not overload machine capacity by attempting tc

clear snow at too fast a rate.

13. Do not change engine governor settings, The

governor controls the speed and protects the engine

from excessive, damaging speeds.

14. Never operate machine at high transport speeds on

slippery surfaces. Use care when backing.

15. Never direct discharge at bystanders or allow any-

one in front of unit.

16. Disengage power to auger/impeller when trans-

porting unit or when unit is not in use.

17. Use only accessories approved by manufacturer of

the snow thrower (such as tire chains, electric start kits,

etc).

18. Never operate the snow thrower without good

visibility or light. Always be sure of your footing and keep

a"firm hold on the handles and walk. never run.

MAINTENANCE AND STORAGE

1. Check shear bolts, engine mounting bolts, etc., at

frequent intervals for proper tightness to be sure equip-

ment is in safe working condition.

2. Run machine a few minutes after throwing snow to

prevent freeze up of auger/impeller.

3. Never store gasoline or equipment with gasoline in

the tank inside of a building where fumes may reach an

open flame or spark. Never store your snow thrower for

prolonged periods (more than 15 days) with gasoline in

the fuel tank. Store gasoline and your snow thrower in a

locked safe storage area secure from children and others.

--3--

Page 4

CONTENTS OF SHIPPING CARTON

1 - 24 inch Snow Thrower (completely assembled except for

handles, controls and headlight),

1 - Can of Engine Oil

1 - Upper Chute Control Rod

1 - Left Hand Handle Assembly

1 - Right Hand Handle Assembly (with clutch lever attached)

I - Control Pane_ Assembly

1 - Bag of Assembly Parts Containing:

I - 3A inch Flatwasher

2 - 5/16 inch Split Lockwasher

10 - Formed (curved) Washers

4 - No. 10 x 1/2 inch Hex Head Screws

4 - No. 10 Locknuts

2 - 5/16 x 5/8, inch Hex Head Screws

2 - 5/16 x 1 inch Hex Head Screws

8 - 5/16 x 13A inch Hex Head Screws

8 - 5/16 inch Locknuts

1 - 3/_ x 3A inch Hex Head'Screws

1 - 3_ inch Locknut

1 - Cable C_amp (meta!)

2 - Knobs (for Throttle and Impeller/Auger Drive Levers)

1 - Bag of Shear Bolt Replacement Parts (Not used in assem-

bly) Containing:

3 - 5/16 x 13/_ inch Shear Bolts

3 - 5/16 inch Locknuts

I - Instruction Sheet

TOOLS REQUIRED FOR ASSEMBLY

1 - 3/8 inch Wrench (or adjustable wrench)

1 - 5/16 inch Wrench (or adjustable wrench)

2 _ V2 inch Wrenches {or adjustable wrenches)

2 - 7/16 inch Wrenches (or adjustable wrenches)

2 - 9/16 inch Wrenches (or adjustable wrenches)

1 - Hammer (plastic or rawhide head recommended)

DANGER

The operation of any powered equipment can result

in foreign objects being thrown into the eyes, which

can result in severe eye damage. Always wear safety

glasses or eye shields while assembling or operating

Snow Thrower.

HANDLE ASSEMBLY

Right handle has a lever (power clutch) attached to upper

end. Nuts used to attach lower end of handles are attached to

inside of side frame.

1. Attach right lower handle to side of side frame as

shown in figure 2. Handle grip should be tilted down and out

when handle is properly installed. "-

2. Repeat step 1 for left handle.

RIGHT HANDLE

FORMED WASHER

5/16 x 1 INCH SCREW _

5/16 x % INCH SCREW L

5/,16 INCH SPLIT LOCKWASHER _

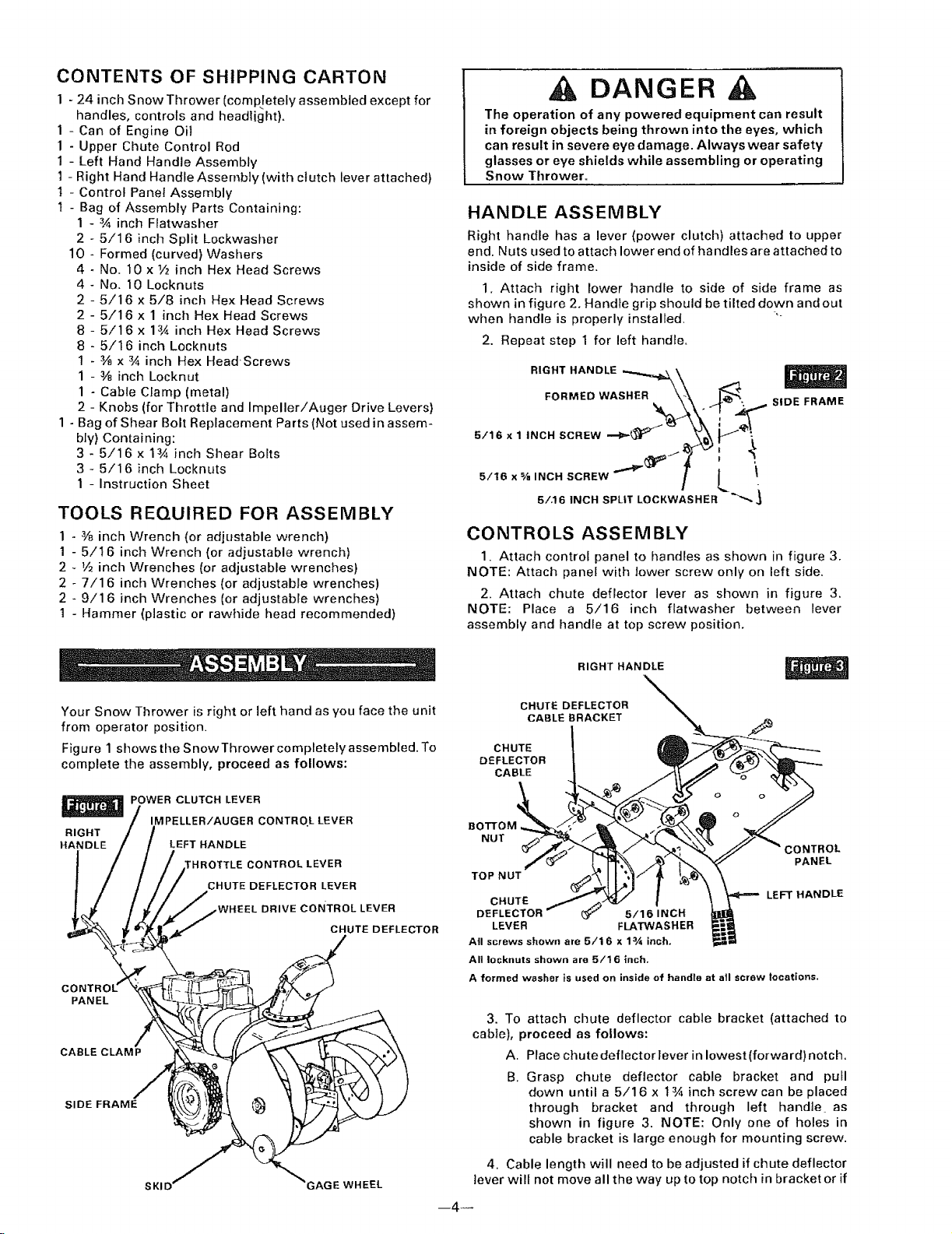

CONTROLS ASSEMBLY

1. Attach control panel to handles as shown in figure 3.

NOTE: Attach panel with lower screw only on left side.

2. Attach chute deflector lever as shown in figure 3.

NOTE: Place a 5/16 inch flatwasher between lever

assembly and handle at top screw position.

SIDE FRAME

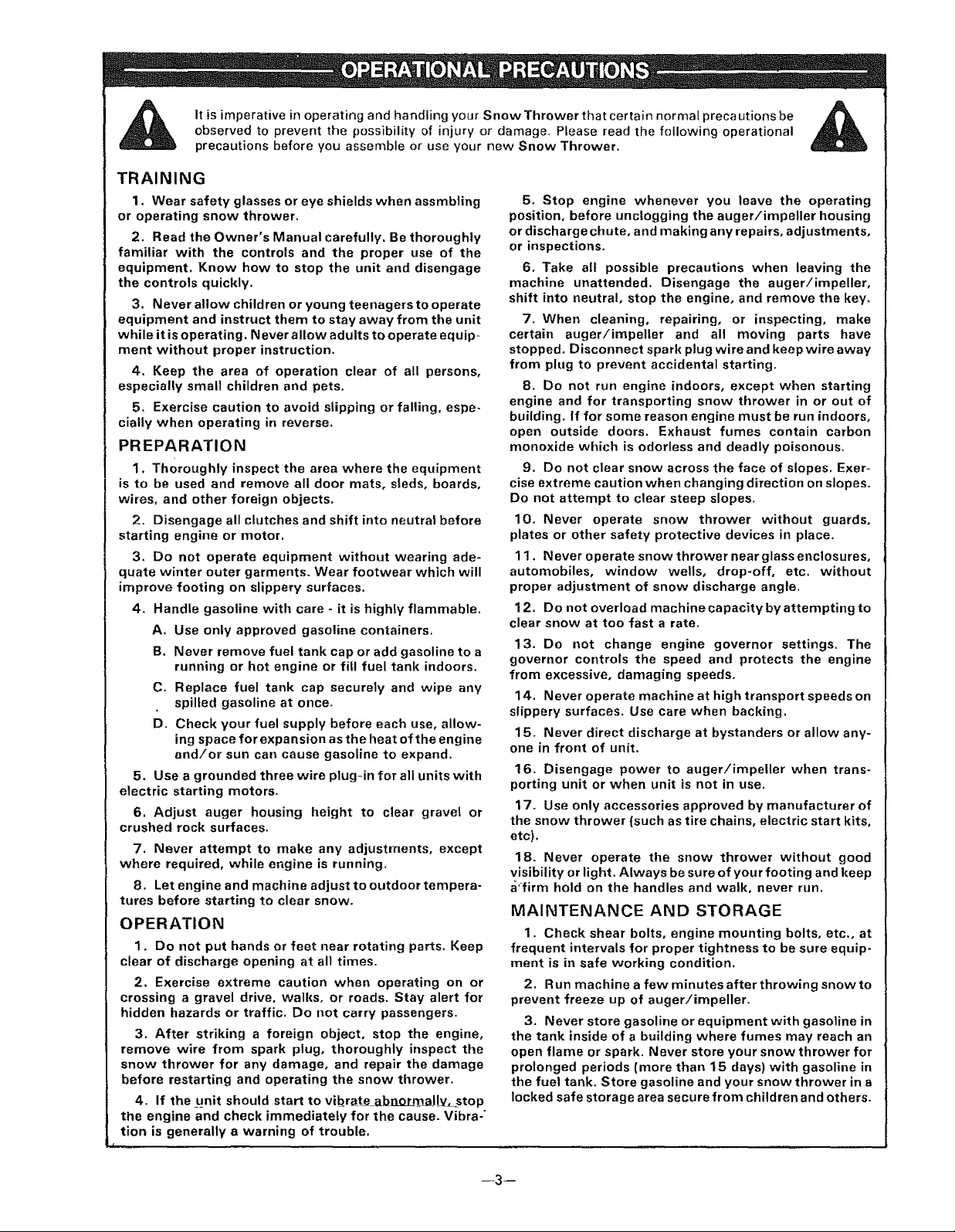

Your Snow Thrower is right or left hand as you face the unit

from operator position.

Figure 1 shows the Snow Thrower completely assembled. To

complete the assembly, proceed as follows:

POWER CLUTCH LEVER

RIGHT

HANDLE LEFT HANDLE

PANEL

CABLE CLAMP

SIDE FRAME

IMPELLER/AUGER CONTRO.L LEVER

,TTLE CONTROL LEVER

CHUTE DEFLECTOR LEVER

DRIVE coNTROL LEVER

CHUTE DEFLECTOR

_GAGE WHEEL

RIGHT HANDLE

CHUTE DEFLECTOR

CABLE BRACKET

CHUTE

DEFLECTOR

CABLE

BOTTOM

NUT

TOP NUT

CHUTE

r 5/16 INCH

LEVER FLATWASHER

All screws shown are 5/16 x 13,'_ inch.

All Iocknuts shown are 5/16 inch.

A formed washer is used on inside of handte at all screw locations.

3. To attach chute deflector cable bracket (attached to

cable), proceed as follows:

A. Place chute deflector Iever in lowest (forward) notch.

B. Grasp chute deflector cable bracket and pull

down until a 5/16 x 1_'_ inch screw can be placed

through bracket and through left handle as

shown in figure 3. NOTE: Only one of holes in

cable bracket is large enough for mounting screw.

4. Cable length will need to be adjusted if chute deflector

lever wilf not move all the way up to top notch in bracket or if

--4--

ONTROL

PANEL

LEFT HANDLE

Page 5

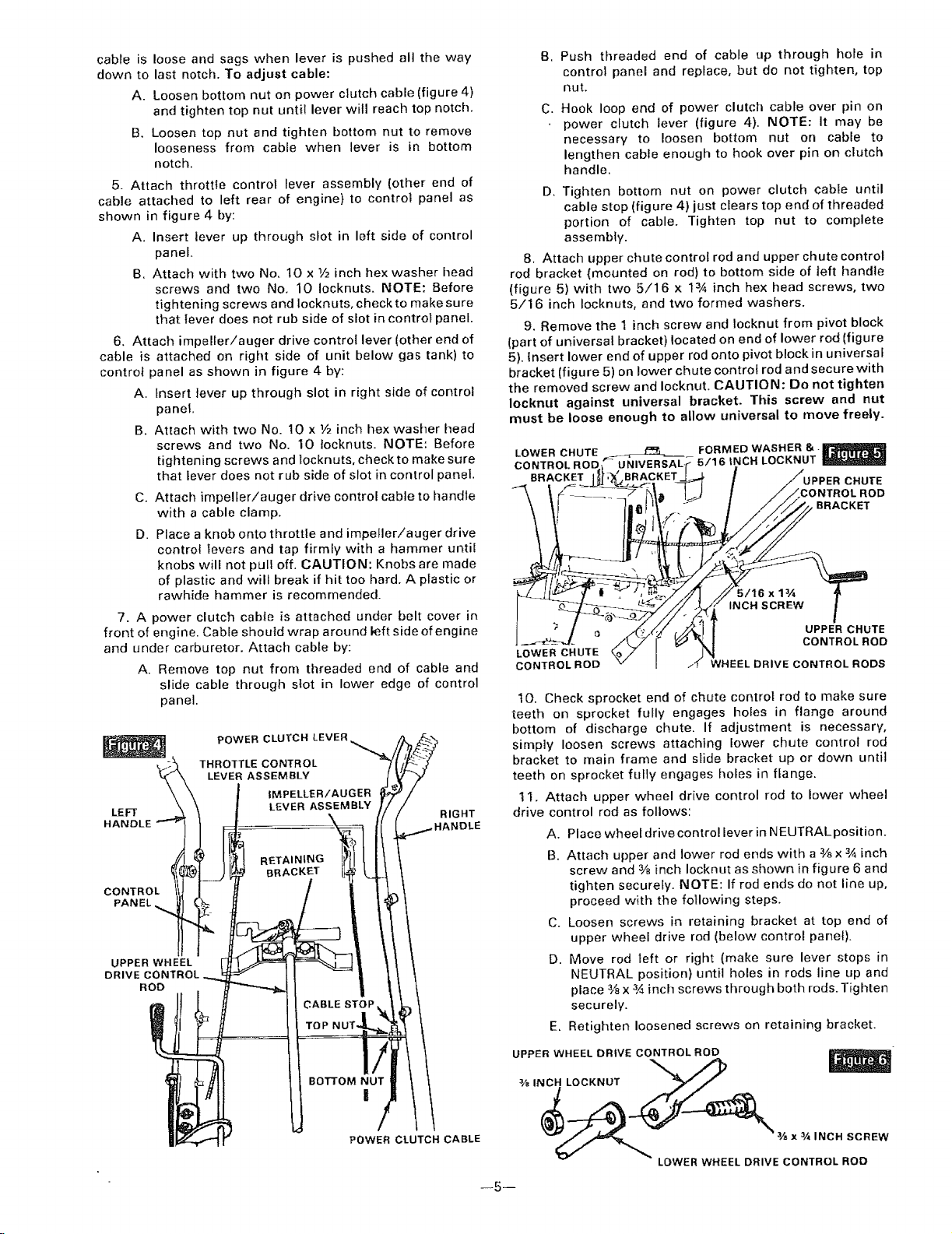

cable is loose and sags when lever is pushed all the way

down to last notch. To adjust cable:

A. Loosen bottom nut on power clutch cable (figure 4)

and tighten top nut until lever will reach top notch.

B. Loosen top nut and tighten bottom nut to remove

looseness from cable when lever is in bottom

notch.

5_ Attach throttte control lever assembly (other end of

cable attached to left rear of engine} to control panel as

shown in figure 4 by:

A. Insert lever up through slot in left side of control

panel.

B. Attach with two No. 10 x 1/2 inch hex washer t_ead

screws and two No. 10 Iocknuts. NOTE: Before

tightening screws and locknuts, check to make sure

that lever does not rub side of slot in control panel.

6. Attach impeller!auger drive control lever (other end of

cable is attached on right side of unit below gas tank) to

controt panel as shown in figure 4 by:

A. Insert lever up through slot in right side of control

panel

B. Attach with two No. 10 x 1/2 inch hex washer head

screws and two No. 10 {ocknuts. NOTE: Before

tightening screws and ]ocknuts, check to make sure

that lever does not rub side of slot in control panel.

C. Attach impeller/auger drive control cable to handle

with a cable clamp.

D. Place a knob onto throttle and impeller/auger drive

controi tevers and tap firmly with a hammer until

knobs will not pull off. CAUTION: Knobs are made

of plastic and will break if hit too hard. A plastic or

rawhide hammer is recommended.

7. A power clutch cabte is attached under belt cover in

front of engine. Cable shoutd wrap around left side of engine

and under carburetor. Attach cable by:

A. Remove top nut from threaded end of cable and

slide cable through slot in lower edge of control

panel.

B. Push threaded end of cable up through hole in

control panel and replace, but do not tighten, top

nut.

C, Hook loop end of power clutch cable over pin on

power clutch lever (figure 4). NOTE: It may be

necessary to loosen bottom nut on cable to

lengthen cable enough to hook over pin on clutch

handle.

D. Tighten bottom nut on power clutch cabEe until

cable stop (figure 4) just clears top end of threaded

portion of cable. Tighten top nut to complete

assembly.

8. Attach upper chute control rod and upper chute control

rod bracket (mounted on rod) to bottom side of left handle

(figure 5) with two 5/16 x 13/4 inch hex head screws, two

5/16 inch Iocknuts, and two formed washers.

9. Remove the 1 inch screw and locknut from pivot block

(part of universal bracket) located on end of lower rod (figure

5). insert lower end of upper rod onto pivot block in universal

bracket (figure 5) on lower chute control rod and securewith

the removed screw and Iocknut. CAUTION: Do not tighten

Iocknut against universal bracket. This screw and nut

must be loose enough to allow universal to move freely.

LOWER CHUTE _._._ 5/16 INCH LOCKNUT

CONTROL ROD

BRACKET BRACKET _ CHUTE

LOWER CHUTE

CONTROL ROD WHEEL DRIVE CONTROL RODS

10. Check sprocket end of chute control rod to make sure

teeth on sprocket fully engages holes in flange around

bottom of discharge chute. If adjustment is necessary,

simply loosen screws attaching lower chute control rod

bracket to main frame and sIide bracket up or down until

teeth on sprocket fully engages holes in flange.

1 I. Attach upper wheel drive control rod to lower wheel

drive control rod as follows:

A. Place wheel drive control lever in NEUTRALposition.

B. Attach upper and lower rod ends with a _ x 3,4 inch

screw and 3/8 inch Iocknut as shown in figure 6 and

tighten securely. NOTE: If rod ends do not line up,

proceed with the following steps.

C. Loosen screws in retaining bracket at top end of

upper wheel drive rod (below control panel).

D. Move rod left or right (make sure lever stops in

NEUTRAL position) until holes in rods line up and

place 3,_ x 3,4 inch screws through both rods. Tighten

securely.

E. Retighten loosened screws on retaining bracket.

UPPER WHEEL DRIVE CONTROL ROD

3/S _NCH LOCKNUT _

FORMED WASHER 8,. _jl_._

BRACKET

5/16x1¾

INCH SCREW

UPPER CHUTE

CONTROL ROD

--5 m

-- ox ,NcNscREw

LOWER WHEEL DRIVE CONTROL ROD

Page 6

SKID and GAGE WHEEL

(Height) ADJUSTMENT

A CAUTION A

For packing purposes, the gage wheels on this unit

were adjusted all the way up to lowest height

position, Adjust height as instructed below before

using snow thrower,

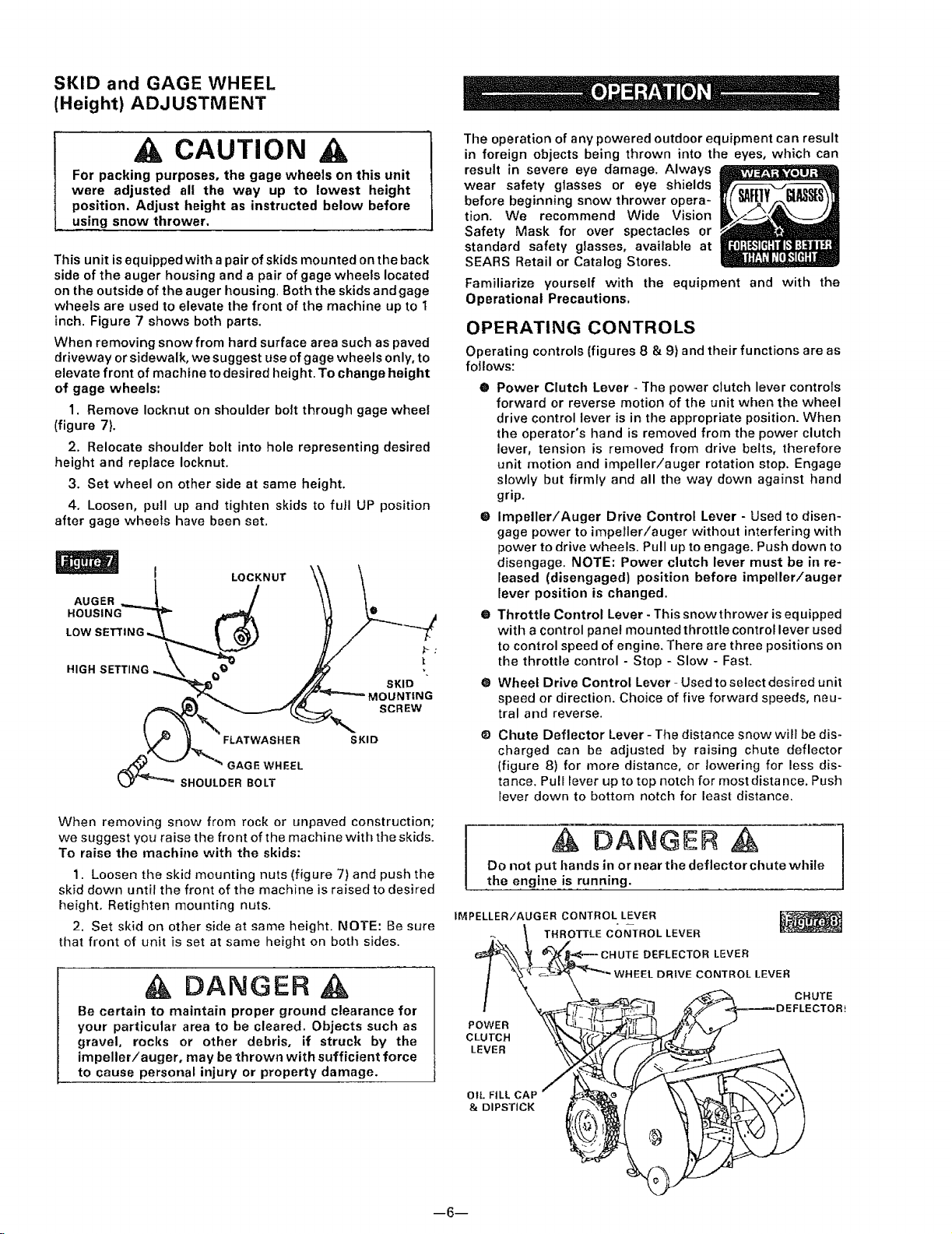

This unit is equipped with a pair of skids mounted on the back

side of the auger housing and a pair of gage wheels located

on the outside of the auger housing. Both the skids andgage

wheels are used to elevate the front of the machine up to 1

inch. Figure 7 shows both parts.

When removing snow from hard surface area such as paved

driveway or sidewalk, we suggest use of gage wheels only, to

elevate front of machine to desired height. To change height

of gage wheels:

1. Remove Iocknut on shoulder bolt through gage wheel

(figure 7).

2. Relocate shoulder bolt into hole representing desired

height and replace Iocknut.

3. Set wheel on other side at same height.

4. Loosen, pull up and tighten skids to full UP position

after gage wheels have been set.

LOCKNUT

AUGER

HOUSING

LOW SE'n'IN G

HIGH SETTING

FLATWASHER

GAGE WHEEL

SHOULDER BOLT

SKID

SKID

,INT|NG

SCREW

The operation of any powered outdoor equipment can result

in foreign objects being thrown into the eyes, which can

result in severe eye damage. Always

wear safety glasses or eye shields

before beginning snow thrower opera-

tion. We recommend Wide Vision

Safety Mask for over spectacles or

standard safety glasses, available at

SEARS Retail or Catalog Stores.

Familiarize yourself with the equipment and with the

Operational Precautions,

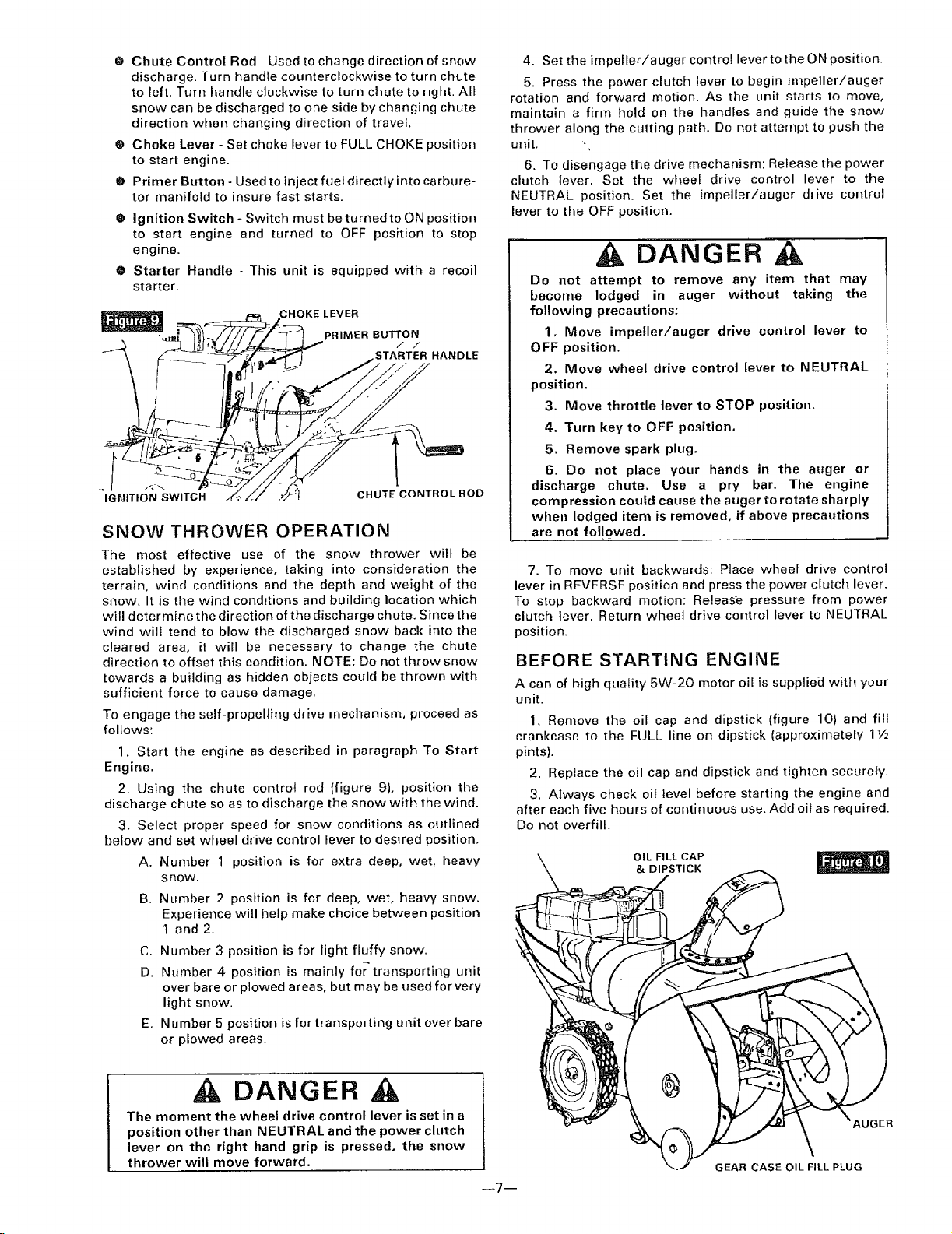

OPERATING CONTROLS

Operating controls (figures 8 & 9) and their functions are as

follows:

• Power Clutch Lever - The power clutch lever controls

forward or reverse motion of the unit when the wheel

drive control lever is in the appropriate position. When

the operator's hand is removed from the power clutch

lever, tension is removed from drive belts, therefore

unit motion and impeller/auger rotation stop. Engage

slowly but firmly and all the way down against hand

grip.

• Impeller/Auger Drive Control Lever - Used to disen-

gage power to impeller/auger without interfering with

power to drive wheels. Pull up to engage. Push down to

disengage. NOTE: Power clutch lever must be in re-

leased (disengaged) position before impeller/auger

lever position is changed.

e Throttle Control Lever - This snowthrower is equipped

with a control panel mountedthrottle control lever used

to control speed of engine, There are three positions on

the throttle control - Stop - Slow - Fast.

O Wheel Drive Control Lever - Used to select desired unit

speed or direction. Choice of five forward speeds, neu-

tral and reverse.

_) Chute Deflector Lever- The distance snow will be dis-

charged can be adjusted by raising chute deflector

(figure 8) for more distance, or lowering for less dis-

tance. Pull lever up to top notch for most distance. Push

lever down to bottom notch for least distance.

When removing snow from rock or unpaved construction;

we suggest you raise the front of the machine with the skids.

To raise the machine with the skids:

1. Loosen the skid mounting nuts (figure 7) and push the

skid down until the front of the machine is raised to desired

height. Retighten mounting nuts.

2. Set skid on other side at same height. NOTE: Be sure

that front of unit is set at same height on both sides.

DANGER

Be certain to maintain proper ground clearance for

your particular area to be cleared. Objects such as

gravel, rocks or other debris, if struck by the

impeller/auger, may be thrown with sufficient force

to cause personal injury or property damage.

Do not put hands in or near the deflector chute while

the engine is running.

IMPELLER/AUGER CONTROL LEVER

THROTTLE CONTROL LEVER

POWER

CLUTCH

LEVER

OIL FILL CAP

& DIPSTICK

--6--

DANGER

DEFLECTOR LEVER

CHUTE

L DRIVE CONTROL LEVER

%

Page 7

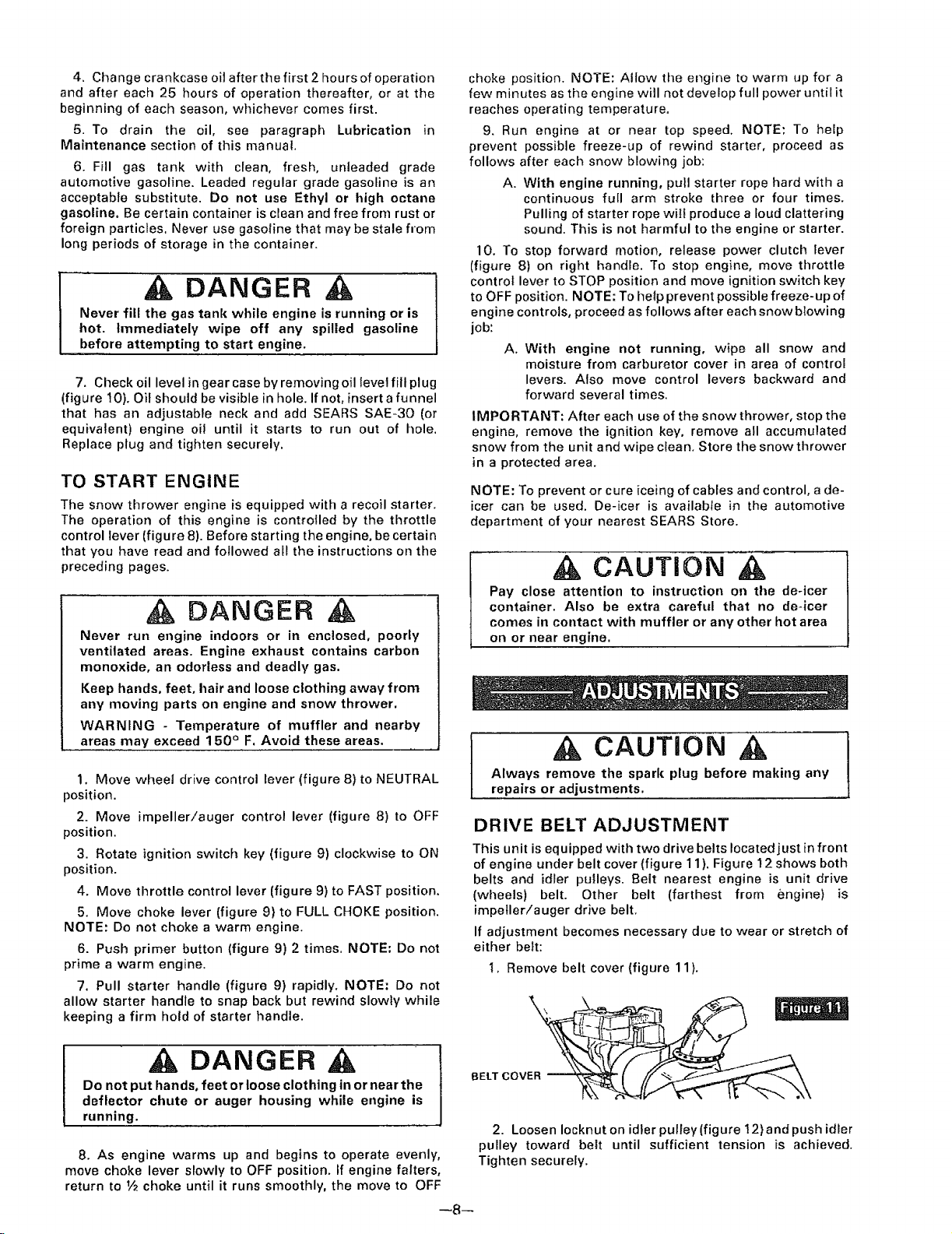

@ Chute Control Rod - Used to change direction of snow

discharge. Turn handle counterclockwise to turn chute

to left. Turn handle clockwise to turn chute to Hght. All

snow can be discharged to one side by changing chute

direction when changing direction of travel.

@ Choke Lever - Set choke lever to FULL CHOKE position

to start engine.

@ Primer Button - Used to inject fuel directly into carbure-

tor manifold to insure fast starts.

8 Ignition Switch - Switch must be turned to ON position

to start engine and turned to OFF position to stop

engine.

• Starter Handle - This unit is equipped with a recoil

starter.

_== CHOKE LEVER

_-- fl4/- x

IGNITION SWITCH 1( .I -"

CHUTE CONTROL ROD

SNOW THROWER OPERATION

The most effective use of the snow thrower wilt be

establishsd by experience, taking into consideration the

terrain, wind conditions and the depth and weight of the

snow. It is the wind conditions and building location which

will determine the direction of the discharge chute. Since the

wind will tend to blow the discharged snow back into the

cleared area, it wilt be necessary to change the chute

direction to offset this condition. NOTE: Do not throw snow

towards a building as hidden objects could be thrown with

sufficient force to cause damage.

To engage the self-propeINng drive mechanism, proceed as

follows:

1. Start the engine as described in paragraph To Start

Engine.

2. Using the chute control rod (figure 9), position the

discharge chute so as to discharge the snow with the wind.

3. Select proper speed for snow conditions as outlined

below and set wheel drive control lever to desired position.

A. Number 1 position is for extra deep, wet, heavy

SROW,

B. Number 2 position is for deep, wet, heavy snow.

Experience will help make choice between position

1 and 2.

C. Number 3 position is for light fluffy snow.

D. Number 4 position is mainly for transporting unit

over bare or plowed areas, but may be used for very

light snow.

E. Number 5 position is for transporting unit over bare

or plowed areas.

4. Set the impeller/auger control lever to the ON position.

5. Press the power clutch lever to begin impeller/auger

rotation and forward motion. As the unit starts to move,

maintain a firm hold on the bandies and guide the snow

thrower along the cutting path. Do not attempt to push the

unit. "-,

6. To disengage the drive mechanism: Release the power

clutch lever. Set the wheel drive control lever to the

NEUTRAL position. Set the impeller/auger drive control

lever to the OFF position.

A DANGER

Do not attempt to remove any item that may

become lodged in auger without taking the

following precautions"

1, Move impeller/auger drive control lever to

OFF position.

2. Move wheel drive control lever to NEUTRAL

position.

3. Move throttle lever to STOP position.

4. Turn key to OFF position.

5. Remove spark plug.

6. Do not place your hands in the auger or

discharge chute. Use a pry bar. The engine

compression could cause the auger to rotate sharply

when lodged item is removed, if above precautions

are not followed.

7. To move unit backwards: Place wheel drive control

lever in REVERSE position and press the power clutch lever.

To stop backward motion: Release pressure from power

clutch lever. Return wheel drive control lever to NEUTRAL

position.

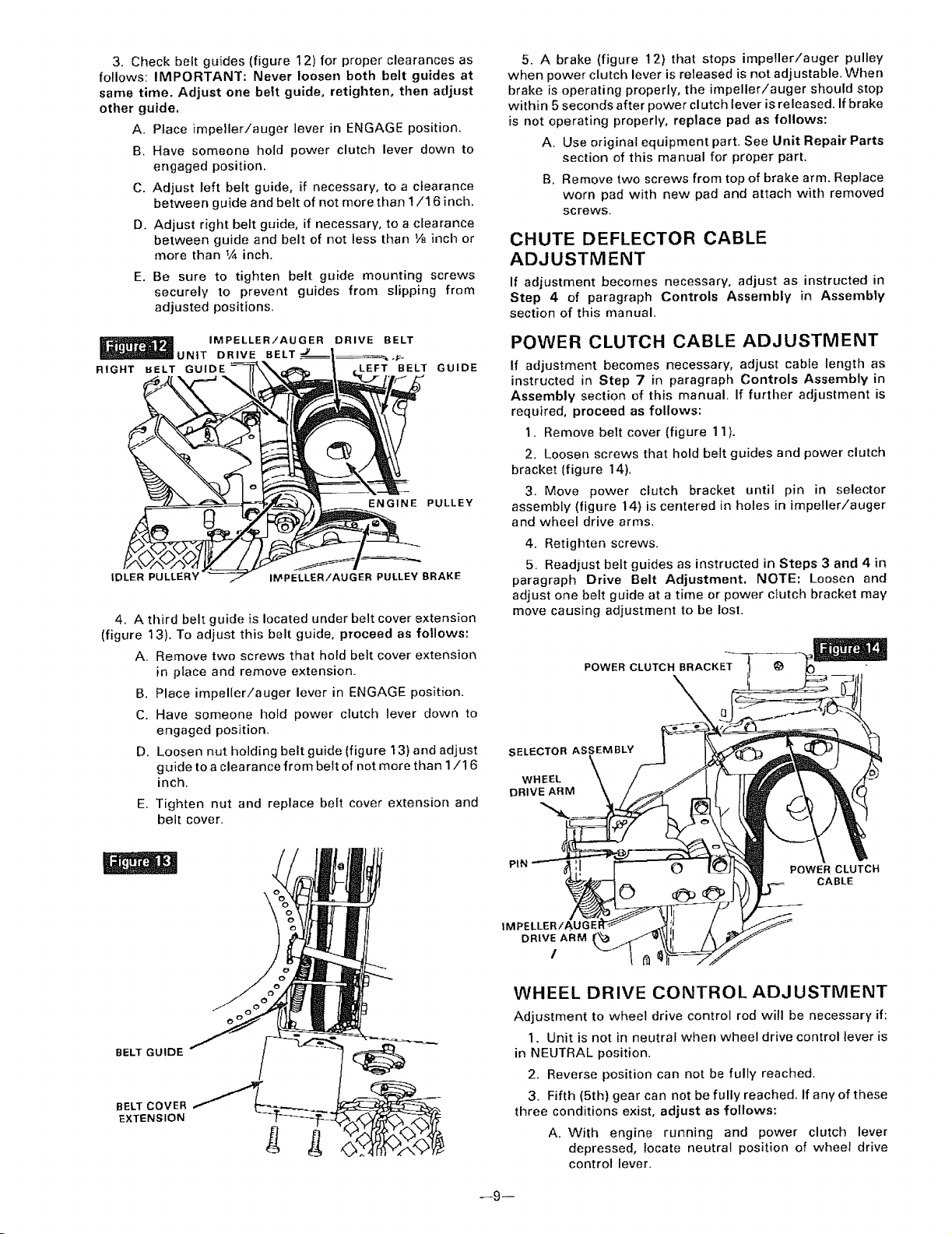

BEFORE STARTING ENGINE

A can of high quality 5W-20 motor oil is supplied with your

unit.

1. Remove the oil cap and dipstick (figure 10) and fill

crankcase to the FULL line on dipstick (approximately 1V2

pints),

2. Replace the oil cap and dipstick and tighten securely.

3. Always check oif level before starting the engine and

after each five hours of continuous use. Add oil as required.

Do not overfill.

OIL FILL CAP

& DIPSTICK

DANGER A

The moment the wheel drive control lever is set in a

position other than NEUTRAL and the power clutch

lever on the right hand grip is pressed, the snow

thrower will move forward.

IGER

GEAR CASE OIL FILL PLUG

--7--

Page 8

4. Change crankcase oil after the first 2 hours of operation

and after each 25 hours of operation thereafter, or at the

beginning of each season, whichever comes first.

5. To drain the oil, see paragraph Lubrication in

Maintenance section of this manual.

6. Fill gas tank with clean, fresh, unleaded grade

automotive gasoline. Leaded regular grade gasoline is an

acceptable substitute. Do not use Ethyl or high octane

gasoline, Be certain container is clean and free from rust or

foreign particles. Never use gasoline that may be stale fiom

long periods of storage in the container.

A DANGER

Never fill the gas tank while engine is running or is

hot. Immediately wipe off any spilled gasoline

before attempting to start engine.

7. Check oil level in gear case by removing oil leve! fill plug

(figure 10). Oil should be visible in hole. If not, insert a funnel

that has an adjustable neck and add SEARS SAE-30 (or

equivalent) engine oil until it starts to run out of hole.

Replace plug and tighten securely.

TO START ENGINE

The snow thrower engine is equipped with a recoil starter.

The operation of this engine is controlled by the throttle

control lever (figure 8). Before starting the engine, be certain

that you have read and followed all the instructions on the

preceding pages.

DANGER

Never run engine indoors or in enclosed, poorly

ventilated areas. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

Keep hands, feet, hair and loose clothing away from

any moving parts on engine and snow thrower.

WARNING - Temperature of muffler and nearby

areas may exceed 150 ° F, Avoid these areas,

1, Move wheel drive control lever (figure 8) to NEUTRAL

position.

2. Move impeller/auger control lever (figure 8) to OFF

position.

3. Rotate ignition switch key (figure 9) clockwise to ON

position.

4. Move throttle control lever (figure 9) to FAST position,

5. Move choke lever (figure 9) to FULL CHOKE position.

NOTE: Do not choke a warm engine.

6. Push primer button (figure 9) 2 times. NOTE; Do not

prime a warm engine.

7. Pull starter handle (figure 9) rapidly. NOTE: Do not

allow starter handle to snap back but rewind slowly while

keeping a firm hold of starter handle.

choke position. NOTE: Allow the engine to warm up for a

few minutes as the engine will not develop full power until it

reaches operating temperature,

9. Run engine at or near top speed. NOTE: To help

prevent possible freeze-up of rewind starter, proceed as

follows after each snow blowing job:

A. With engine running, pull starter rope hard with a

continuous fuil arm stroke three or four times.

Pulling of starter rope wilt produce a loud clattering

sound. This is not harmful to the engine or starter.

10. To stop forward motion, release power clutch lever

(figure 8) on right handle. To stop engine, move throttle

control lever to STOP position and move ignition switch key

to OFF position. NOTE: To help prevent possible freeze-up of

engine controls, proceed as follows after each snow blowing

job:

A. With engine not running, wipe all snow and

moisture from carburetor cover in area of control

levers. Also move control levers backward and

forward several times.

IMPORTANT: After each use of the snow thrower, stop the

engine, remove the ignition key, remove all accumulated

snow from the unit and wipe clean. Store the snow thrower

in a protected area.

NOTE: To prevent or cure iceing of cables and control, a de-

icer can be used. De-icer is available in the automotive

department of your nearest SEARS Store.

CAUTION

Pay close attention to instruction on the de-icer

container. Also be extra careful that no de-icer

comes in contact with muffler or any other hot area

on or near engine.

CAUTION

Always remove the spark plug before making any

repairs or adjustments,

DRIVE BELT ADJUSTMENT

This unit is equipped with two drive belts located just in front

of engine under belt cover (figure 11 ). Figure 12 shows both

belts and idler pulleys. Belt nearest engine is unit drive

(wheels) belt. Other belt (farthest from engine) is

impeller/auger drive belt.

If adjustment becomes necessary due to wear or stretch of

either belt:

1. Remove belt cover (figure 11 ).

DANGER

Do not put hands, feet or loose clothing in or near the

deflector chute or auger housing while engine is

running.

8. As engine warms up and begins to operate evenly,

move choke lever slowly to OFF position. If engine falters,

return to 1/2 choke until it runs smoothly, the move to OFF

2. Loosen Iocknut on idler pulley (figure 12) and push idler

pulley toward belt until sufficient tension is achieved.

Tighten securely.

--8--

Page 9

3. Check belt guides (figure 12) for proper clearances as

follows: IMPORTANT: Never loosen both belt guides at

same time. Adjust one belt guide, retighten, then adjust

other guide.

A, Ptace impeller!auger lever in ENGAGE position.

B. Have someone hold power clutch lever down to

engaged position.

C. Adjust left belt guide, if necessary, to a clearance

between guide and be}t of not more than 1/16 inch.

D. Adjust right belt guide, if necessary, to a clearance

between guide and belt of not less than V8 inch or

more than V_ inch.

E. Be sure to tighten belt guide mounting screws

securely to prevent guides from slipping from

adjusted positions.

5. A brake (figure 12) that stops impeller/auger pulley

when power clutch lever is released is not adjustable. When

brake is operating properly, the impeller/auger should stop

within 5 seconds after power clutch lever is released. If brake

is not operating properly, replace pad as follows:

A. Use original equipment part. See Unit Repair Parts

section of this manual for proper part.

B. Remove two screws from top of brake arm. Replace

worn pad with new pad and attach with removed

screws.

CHUTE DEFLECTOR CABLE

ADJUSTMENT

If adjustment becomes necessary, adjust as instructed in

Step 4 of paragraph Controls Assembly in Assembly

section of this manual.

IMPELLER/AUGER DRIVE BELT

RIGHT BELT GUIDE ,LEFT BELT GUIDE

IDLER PULLERY' IMPELLER/AUGER PULLEY BRAKE

4. A third belt guide is located under belt cover extension

(figure 13). To adjust this belt guide, proceed as follows:

UNIT DRIVE BELT .._.

ENGINE PULLEY

A. Remove two screws that hold belt cover extension

in place and remove extension.

B. Place impeller/auger lever in ENGAGE position.

C. Have someone hold power clutch lever down to

engaged position.

D. Loosen nut holding belt guide (figure 1 3) and adjust

guide to a clearance from belt of not more than 1/1 6

inch.

E. Tighten nut and replace belt cover extension and

belt cover.

POWER CLUTCH CABLE ADJUSTMENT

If adjustment becomes necessary, adjust cable length as

instructed in Step 7 in paragraph Controls Assembly in

Assembly section of this manual. If further adjustment is

required, proceed as follows:

1. Remove belt cover (figure 1 1).

2. Loosen screws that hold belt guides and power clutch

bracket (figure 14).

3. Move power clutch bracket until pin in selector

assembly (figure 14) is centered in holes in impeller/auger

and wheel drive arms.

4. Retighten screws.

5. Readjust belt guides as instructed in Steps 3 and 4 in

paragraph Drive Belt Adjustment. NOTE: Loosen and

adjust one belt guide at a time or power clutch bracket may

move causing adjustment to be lost.

POWER CLUTCH BRACKET

\

SELECTOR ASSEMBLY

wHEEL

DRIVE ARM

BELT GUIDE

BELT COVER

EXTENSION

POWER CLUTCH

IMPELLER/AUGEF

DRIVE ARM

/

WHEEL DRIVE CONTROL ADJUSTMENT

Adjustment to wheel drive controf rod will be necessary if:

1. Unit is not in neutral when wheel drive control lever is

in NEUTRAL position.

2. Reverse position can not be fully reached.

3. Fifth (5th) gear can not be fully reached. If any of these

three conditions exist, adjust as follows:

A. With engine running and power clutch lever

depressed, locate neutral position of wheel drive

control lever.

--9--

CABLE

Page 10

B. Leave wheel drive control lever in position where

neutral was obtained and release power cutch

lever. Shut off engine.

C. Loosen screws in retaining bracket (figure 15)at top

end of wheel drive control rod (under control panel).

D. Slide retaining bracket and rod left or right until

wheel drive control lever is in proper neutral

position. Tighten screws in retaining bracket.

E. Start engine and check adjustment by moving lever

to each position, NOTE: Be sure to check to see that

NEUTRAL is properly reached from both directions

(from reverse and from forward gear).

POWER CLUTCH LEVER

RETAINING BRACKET

pin through selector arm should engage wheel drive arm

only and clear impeller/auger drive arm by at least +/8 inch.

To adjust to these positions:

A. Loosen screw that clamps impeller!auger control

cable to cable bracket (figure 16).

B. Move cable forward or backward in clamp to obtain

proper position mentioned above.

C. Reclamp cable by tightening loosened screw.

I DANGER A I

Never attempt to manually stop auger from turning,

CARBURETOR ADJUSTMENT

HIGH SPEED and IDLE ADJUST NEEDLES are pre+set at the

factory and re-adjustment should notbe necessary. NOTE: If

you think the carburetor needs adjusting, contact your

nearest SEARS Service Center who has the proper

equipment and experience to make any necessary

adjustments.

UPPER WHEEL DRIVE

CONTROL R_

IMPELLER!AUGER CONTROL CABLE

ADJUSTMENT

If impeller/auger control should need adjustment because

impeller/auger wil! not engage or will not disengage, adjust

as follows:

1. Remove belt cover (figure 1 1).

POWER CLUTCH CABLE

IMPELLER/AUGER

CONTROL CABLE

SCREW

CLAMP

CABLE BRACKET

SELECTOR ARM

2. Move impeller/auger control lever from OFF to

ENGAGE and check action of selector arm (figure 16). When

impeller/auger control lever is in ENGAGE position, pin

through selector arm should fully engage wheel drive arm

and impeller/auger drive arm. When lever is in OFF position,

1/+ INCH CLEARANCE

CAUTION

Never tamper with engine governor which is factory

set for proper engine speed. Over+speeding engine

above factory high speed setting can be dangerous,

If you think the engine governed high speed needs

adjusting, contact your nearest SEARS Service

Center who has the proper equipment and

experience to make any necessary adjustments,

Changing of engine governed speed will void engine

warranty.

SPARK PLUG ADJUSTMENT

Check the spark plug periodically and reset spark plug gap to

0.030 inch using a wire feeler gauge.

The condition of the spark plug may be determined by color.

A carbonized plug is black and burnt plugs are greyish in

color, whereas a normal functioning spark plug is brown. If a

new spark plug is required, refer to the Engine Repair Parts

section for proper replacement spark plug.

Before installing spark plug, coat threads lightly with

graphite grease to insure easy removal.

DRIVE BELT REPLACEMENT

The drive belts on this unit are of special construction and

should be replaced with original equipment belts available

from your nearest SEARS Store or Service Center.

To Replace Unit Drive Belt (belt nearest engine):

I. Remove belt cover (figure 11).

2+ Loosen screw holding left belt guide (figure 12) and

swing guide away from pulley. Retighten screw.

3. Loosen screw holding right belt guide (figure 12) and

swing guide away from puIley. Retighten screw.

4. Roll belt off engine pulley. NOTE: It will be necessary to

roll impeller/auger drive belt off engine pulley to allow unit

drive belt to be removed from engine pulley.

5. Remove belt by threading up between large drive

pulleys.

6. Install new belt in reverse order.

--10--

Page 11

SNOW CHAIN

ROLLER CHAINS LOWER BELT GUIDES

IMPELLER/AUGER DRIVE PULLEY

UNIT DRIVE PULLEY

1. Remove the parts of the broken bolt.

2. Align the hole in the auger with the hole in the auger

shaft. Install new shear bolt.

ROLLER CHAIN REPLACEMENT

There are two roller chains on this unit as shown in figure

17. Bottom cover witI have to be removed to reach chains.

1. Stand unit up on auger end, remove screws from

bottom cover and remove cover.

2. Locate master link (figure 19) in chain to be replaced.

3. Check position of open end of keeper link (figure 19) so

that replacement Iink can be installed in the same manner.

Open end of keeper link must be in trailing position when

chain is operating in direction required for forward motion of

unit.

4. Remove master link and remove chain.

5. Install new chain in reverse order of removal.

To Replace Impeller/Auger Drive Belt {belt farthest from

engine):

!. Remove belt cover (figure 1 !).

2, Stand unit up on auger end, remove screws from

bottom cover and remove cover.

3. Loosen screws holding lower belt guides (figure t7)

and swing guides away from belt.

4. Roll belt off impeller/auger drive pulley and engine

pulley and remove between drive pulleys.

5. Install new belt in reverse order.

6. Move lower beJt guides back to within 1/16 inch of

Impeller/auger drive pulley and tighten screws.

7. Replace bottom cover and return unit to operating

position.

8. Adjust right and left belt guides (figure 12) as instructed

in Step 3 in paragraph Drive Belt Adjustment in

Adjustment section of this manual.

9. Replace belt cover.

SHEAR BOLT REPLACEMENT

The main auger assembty is made up of a right and Teft auger.

Each is secured with a special bolt (figure 18) that acts as a

shear bolt. These bolts are designed to break if an object

becomes lodged in the auger. Three spare shear bolts and

nuts have been furnished with your unit. If additional bolts

are required, order genuine replacement bolts. Use of a

harder bolt will destroy the protection provided by this

special bolt. To replace a broken shear bolt, proceed as

follows:

sHEAR BOLT

LEFT AUGER

AUGER GEAR CASE

RIGHT AUGER

SHEAR BOLT

KEEPER LINK

(Open end must trail)

DIRECTION OF TRAVEL MASTER LINK

TRANSMISSION REPLACEMENT

Tile replacement of the transmission on this unit is a major

service operation and should be done by a trained

technician. The Transmission Repair Parts section of this

manual contains a list of replacement parts and illustrations

to assist the trained technician in making repairs and

ordering proper replacement parts.

SNOW CHAIN REMOVAL

To remove the snow chains, release the chain hooks (figure

17). Flatten the chain out on the ground and push unit off the

chain. Illustration is the reverse of removal,

LUBRICATION

For lubrication points, frequency of lubrication and type of

lubricant, see Lubrication Chart.

1. Check crankcase oil level before starting engine and

after each 5 hours of continuous use. Add SEARS 5W-30

motor oif or equivalent as required. Change crankcase oil

after first 2 hours of operation and every 25 hours of

operation thereafter, or at beginning of each season. NOTE:

SEARS 5W-30 or 10W motor oil (or equivalent) are

acceptable substitutes.

To Drain Oil, Proceed as Follows:

A. Remove oil fill cap and dipstick (figure 20).

B° Remove oil drain cap (figure 20).

C. Tip unit toward oit drain cap and drain oil into a

suitable container. NOTE: OiI will drain more freely

when warm.

D. Replace oil drain cap securely and fill crankcase to

proper level shown on dipstick (approximately 11,/2

pints).

2. Check auger gear case oil level before each use by

removing oil level plug as shown in Lubrication Chart, Oil

should be visible in hole. If oil is required, remove oil fill plug

and add SEARS SAE 30 engine oil until oil begins to run out

oil level hole. Replace plug and tighten securely.

--11--

Page 12

OIL FILL CAP & DIPSTICK t. Prior to shut down for 30 days or more, and for seasonal

OIL DRAIN CAP

3. The transmission has been factory fubricated for life. If,

for some reason, lubricant should leak out, have

transmission checked by a competent repairman.

AUGER GEAR CASE

storage, drain gasoline from fuel tank.

DANGER

Drain fuel into approved container outdoors, away

from open flame.

2. Run engine until fuel tank is empty and engine stops

due to lack of fuel,

3, Remove spark plug and pour one (1) ounce of engine oil

through spark plug hole into cylinder. Crank engine several

times to distribute oil. Replace spark plug.

4. Store unit in wheel down, operating position. If unit is

stored in any other position, oil from crankcase could enter

cylinder head, causing a service problem.

5. When storing unit at the end of the snow blowing

season, service REWIND STARTER as follows:

A. Remove rewind starter from engine and brush away

accumulation of dirt and debris from starter pawl

and pawl post (figure 21).

B. Apply a few drops of engine oil to each pawl post and

rotate starter a few times.

C, Reinstall starter on engine. Be sure the four starter

retaining nuts are tightened securely.

ENGINE SERVICE

Unless the operator is fully qualified to make engine

adjustments and repairs, it is recommended that such work

be done by technicians trained to work on snow thrower type

gasoline engines.

The Engine Repair Parts section of this manual contains a

list of engine rep{acement parts and illustrations to assist the

trained technicians in making repairs and ordering proper

replacement parts.

The snow thrower should be immediately prepared for

storage at the end of the season or if the unit is to be un-used

for 30 days or more.

ENGINE STORAGE

DANGER

Never store engine with fuel in tank indoors or in

enclosed, poorly ventilated enclosures, where fuel

fumes may reach an open flame, spark or pilot light

as on a furnace, water heater, clothes dryer, etc.

Gasoline, if permitted to stand un-used for extended

periods (30 days or more), may develop gummy deposits

which can adversely affect the engine carburetor and

cause engine malfunction, To avoid this condition,

proceed as follows:

._r_//// /

UNIT STORAGE

1. Clean the unit thoroughly; remove all debris and wipe

the unit dry.

2. Inspect ti_e snow thrower for worn or damaged parts,

tighten all loose hardware.

3. Oil all points described in paragraph Lubrication.

4. Store the snow thrower in a protected area and cover

the unit for additional protection.

A yearly checkup or tuneup by the SEARS Service

Department is a good way of insuring that your snow

thrower will provide maximum performance for the next

season.

DANGER

Handle gasoline carefully, It is highly flammable and

careless use could result in serious fire damage to

your person and/or property.

--12--

Page 13

ALL FLANGE

BEARINGS

ENGtNE DISCHARGE CHUTE

O

O

ROLLER CHAIN

GAGE WHEEL AUGER GEAR CASE

Q Add Sears S.A.E. 10W oil (or equivalent) every 2 hours and after each use.

O Add Sears 5W-20 oil {or equivalent) as required. Check every 5 hours and before each use.

(_ Add Sears S.A.E. 30W oil {or equivafent) as required. Check before each use.

_) Remove chute and coat with clinging type grease such as lubriplate once each season.

For Service Helps Chart, see page 27.

--13--

Page 14

CRAFTSMAN 24" SNOW THROWER MODEL NUMBER 536,918300

14

211] 78

C

19

2

\

55

ALL UNNUMBERED

iTEMS ARE INTERCHANGEABLE

WITH OPPOSITE SIDE

42

52

53

11

11

51

49

\

\

\

5O

Ref. Item 4

2

_©

\

\

47

÷

_Q

I •

3O

Ref, Item 38

Page 16

Ref. Item 3

Page 16

Page 15

CRAFTSMAN 24" SNOW THROWER MODEL NUMBER 536.918300

Key

No. Pa_ No.

1 49551

2 122052

3 49106

4 49569

5 122033

6 996407

7 25644

8 49576

9 49557

I0 49558

11 9413447

12 50168

13 22822

14 443874

15 50607

16 997316

17 9417373

18 67194

19 68416

20 68413

*Standard Hardware Items - May Be Purchased Locally.

o1

Description

Cable, Impeller/Auger Control

*Screw, Hex Hd, 5/16-18 x 13,4 In.

Push Nut, 3/16 In.

Bracket, Chute Deflector Cable

*Screw, Hex Hd, 5/16-18 x 13/8 rn.

*Fiatwasher, 5/16 In. I.D.

Spring

Hand Grip

Lever Assembly, Chute Deflector

Bracket, Chute Deflector Lever

Locknut, 5/16-18 Thd

Panel, Control

Knob, Wheel Drive Control Lever

*Screw, Hex Hd, No. 10-24 xY_ In.

Knob, Control Lever

Locknut, No. 10-24 Thd

*FIatwasher, No. 10

Decal, Chute Control

Decal, Craftsman

Decal, Control PaneJ . ..I

I

Key

No. Pa_ No.

21 271166

22 50198

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

50197

25494

50393

50146

50152

9423771

122119

9413534

48395

455481

48400

120228

48399

23940

997319

23939

Description

Locknut, Keps, No. 10-24 Thd

Control Assembly, Impeller/

Auger

Control Assembly, Throttle

Shoulder Bolt

Lever Assembly, Wheel Drive

Rod, Wheel Drive, Upper

Retainer Bracket, Wheel Drive

Rod

*Screw, Hex Hd, No. 10-24 x 1/2 in.

*Screw, Hex Hd, 3/g-16 x 3,4 In.

Locknut, 3/8-16 Thd

Sprocket, 9 Tooth

*Roll Pin, 3/16 x 1 In.

Bracket, Lower Chute Control Rod

*Screw, Hex Hd, 5/16-18 x % in_

Rod, Chute Control, Lever

U-Bolt

Locknut, No. 10-32 Thd

Spring

Key

No. Part No,

39 48402

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

180022

47323

9424215

48405

120638

122017

22O25

40631

48403

48441

49545

47422

48641

49544

49564

49008

133058

61817

Description ..........

Bracket, Lower Chute Control

Rod, Rear

*Screw, Hex Hd, 1A-20 x 1 In.

Pivot Block

Locknut, _,4-20 Thd

Rod, Chute Control, Upper

*Lockwasher, Split, 5/16 Fn.

*Screw, Hex Hd, 5/16-18 x 1 in.

Washer, Formed

Nut, Retain

Bracket, Upper Chute Control Rod

Hand Grip

Handle, Left

Clamp, Cable

Hand Grip

Handle, Right

Cable, Power Clutch

Lever Assembly, Power Clutch

*Screw, Rd Hd, 1,4-20 x _,4 In.

Owner's. Manual (Not Illust.)

Page 16

CRAFTSMAN 24" SNOW THROWER MODEL NUMBER 536.918300

Ref. Item 23 8 9

Page 20 10

I

Ref. Item 3

Page 18

:'o _ 13

ALL UNNUMBERED

ITEMS ARE INTERCHANGEABLE

WITH OPPOSITE SIDE

6

21

4

I

22

24

62

Page 17

CRAFTSMAN 24" SNOW THROWER MODEL NUMBER 536.918300

Key

No.

!

_J

l

Pa_ No.

1 9413534

2 42619

3 49454

4 122119

5 68423

6 15316

7

48422

8

138538

9

10

1I

12

13

t4

15

16

17

18

19

20

2t

*Standard Hardware Items - May Be Purchased Locally.

35055

48424

41727

49577

49530

274517

40616

25177

48388

1O2883

27324

50158

50171

Description ,..

Locknut, _/_-16 Thd

Screw, Taptite, 3/B-16 x Vz In.

Plate, Engine Mount

*Screw, Hex Hd, 3/8-16 x 3,4 In.

Decal, Key, On/Off

Engine, Model No. 143.696102

(See Engine Repair Parts List)

Spring

*Lockwasher, Internal Tooth,

5/16 In. I.D.

Screw, Taptite, No. 10-24 x 1/2 In.

Bracket, Brake

Shoulder Bolt

Pad, Brake

Belt Guide, Lower

*Flatwasher, 3/_ In. I.D.

Bearing, ImpeIler

*Flatwasher, 3,4 In. I.D.

Pulley, Impeller/Auger

*Set Screw, 5/16-18 x 3¼ In.

Key, Hi-Pro, No. 606

Pulley, Transmission

Transmission, Model No. 143.735

(See Transmission Repair

Parts List)

Key

No. Part No.

22 50150

23 120380

24 181566

25 36625

26 50154

27 50170

28 50641

29 50640

30 20307

31 50542

32 50155

33 50149

34 996407

35 120638

36 180087

37 50153

38 50169

39 41891

40 138485

41

42

43

41890

25072

48666

Descrip,tion ..........

Gear, M;ter Drive

*Lockwasher, Split, % In. I.D.

*Screw, Hex Hd, 1A-28 x 3,4 In.

Ring, Retaining

Washer, Thrust

Side Frame Assembly, Right

Roller Chain Assembly

Roller Chain Assembly

Link, Connector

Sprocket & Bearing Assembly

Shaft, Intermediate

Spacer

*F}atwasher, 5/16 In. I.D.

*Lockwasher, Spilt, 5/16 In. I.D.

Screw, Hex Hd, 5/t6-18 x 2 In.

Washer, Thrust

Side Frame Assembly, Left

Washer, Bow

*Lockwasher, Externaf Tooth,

5/16 In. I.D.

Shoulder Bolt

Disc, Bearing Retainer

Bearing, Self-Aligning

Key

No.

44

45

46

47

48

49

50

51

52

53

54

55

59

61

56

57

58

60

62

Pa_ No.

9424215

48445

9413447

20712

180075

41709

36602

50624

35498

50163

50148

454512

50151

39024

50147

35144

50166

50164

Description ....

Locknut, V_-20 Thd

169

Wheel & Tire Assembly

*Screw, Hex Hd, 5/! 6-18 x 1% In.

Locknut, 5/16-18 Thd

Chains, Snow {Set of Two)

*Screw, Hex Hd, 5/16-18 x % In.

Spacer

*Bolt, Carriage, 1,4-20 x % In.

Axle & Sprocket Assembly

Screw, Hex Washer Hd Tap,

5/16-18 x 3/_ In.

Plate Assembly, Transmission

Mounting

Bearing, Flanged

Pin, Spring, 3/16 x 3,4 In.

Gear Miter Driver

Flat-washer, 1/2 In. I.D.

Rod, Wheel Drive, Lower

Screw, Hex Hd Slotted Taptite,

No. 10-24 x _/_ In.

Cover, Bottom

Cover, Rear

Page 18

CRAFTSMAN 24"" SNOW THROWER MODEL NUMBER 536.918300

Ref. Item 22

Page 114

3

2

Ref, Item 2

Page 16

I

L

ALL UNNUMBERED

ITEMS INTERCHANGEABLE

WITH OPPOSITE SIDE

55 _ 58

Ref, Item 3

Page 14

57

Ref. Item 19 50

51 \ 49

45

Ref. item 23

Page 20

Page 19

CRAFTSMAN 24- SNOW THROWER MODEL NUMBER 536.918300

Key

No. Part No. Description

t 159920 Screw, No. 10-24 × 1/2 In.

2 138479 Lockwasher, External Tooth

3 41652 Clip, Wire

4 49012 Bracket, Impel[er/Auger Cable

271166 Nut, Keps, No_ I0-24 Thd

120228 *Screw, Hex Hd, 5/16-18 x % In.

7 180016 Screw, Hex Hd, _,4-20 x 1/2 In.

8 120380 Lockwasher, Split

9 9424215 Locknut, 1,4-20 Thd

10 48994 Plate, Idler Mount

11 t 20394 Washer

12 40886 Screw, Taptite, Hex Washer Hd,

13 49018 Brace

14 49527 Spring, Idler

15 49010 Arm, Wheel Drive

16 49531 Spacer

17 456836 Pin, 1/_ x 21/_ In.

18 49014 Clevis Pin

19 48991 Bracket, Power Clutch Cable

L

*Standard Hardware Items - May Be Purchased Locally.

c.O

_A-20 x 3,/8 In.

F

Key

No. Part No.

2O 121223

21 49019

22 24347

23 49OO9

24 49016

25 49017

26 36285

27 48140

28 138557

29 46376

30 47410

31 45892

32 49504

33 50610

34 120382

35 124829

36 3140

37 46511

38 120918

39 49505

Description

Cotter Pin, 1/16 x 3/_ In.

Selector Assy

Spring

Arm, Impeller/Auger Drive

Bracket, Mounting

Plate

Key, Ignition

Locknut (Switch Part)

Lockwasher (Switch Part)

Switch (Incl. Items 26, 27 & 28)

Wire Assembfy, Ignition

Carriage Bolt, 3/8-16 x tl/2 In.

Idler Arm, Primary

Pulley, Idler

Lockwasher, Split 3/8 In,

Nut, Hex Jam, 3/8-16 Thd

Washer, Wave

Bolt, Shoulder

Screw, Hex Hd, %-16 x 11/2 In.

Idler Arm, Auger

Key

No.

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

Pa_ No.

50608

9413534

41727

138538

41728

49581

26794

44917

998503

120741

120638

49822

49570

48999

9413447

35144

46161

48534

68415

Description

Roller Arm Assembly

*Locknut, 3/8-16 Thd

Bolt Shoulder

Lockwasher, Internal Tooth

Spacer

V-Belt

Key, Square, _/_ x 1 I/2 in.

Pulley, Engine

*Set Screw, 5/16-18 x 1,4 In.

*Screw, Hex Hd, 5/16-24 x 3,/4 In.

*Lockwasher, Split, 5/16 f.D.

Belt Guide, LH.

V-Belt

Mounting Bracket Auxiliary

*Locknut, 5/16-18 Thd

Screw, Stotted Hex Hd, Taptite,

10-24 x 3/8 In.

Extension, Belt Cover

Cover, Belt

Decal

Page 20

CRAFTSMAN 24" SNOW THROWER MODEL NUMBER 536.918300

_ J --I

?

/ Ref. Item 1

<- 8 17

Page 14

9

24

3O

/

Page 21

CRAFTSMAN 24" SNOW THROWER MODEL NUMBER 536.918300

No, Pa_ No.

1 49573

2 67173

3 49560

4 120834

5 9413447

6 49550

180016

47240

9 9424215

10 49555

11 997316

12 49552

13 9413534

14 274517

15 27318

16 39119

17 271184

18 446363

19 25091

20 126358

21 6768O

*Standard Hardware Items - May Be Purchased Locally.

I

Description

Screw, Hex Hd, No' 10-24 x 5/8 In.

Decal, Caution

Chute Assembly, Top

*Screw, Hex Hd, 5/16-18 x ¾ In.

Locknut, 5/16-18 Thd, Type N

Chute Assembly, Bottom

*Screw, Hex Hd, _-20 x ½ In.

Chute Clip

Locknut, Hex, _-20 Thd, Type N

Chute Rod

Locknut, No. 10-24 Thd

Spring

Locknut, 3/8-16 Thd

*Flatwasher, 3/8 ID

Gage Wheel Assembly

Shoulder Bolt

*Nut, Keps, 5/16-18

*Flatwasher, 5/16 tD

Skid

Carriage Bolt, 5/16-18 x 1 In.

Decal, Caution

Key

No.

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

Part No.

68183

47238

67167

36602

180077

48209

48210

48216

48459

48217

48606

47256

454565

13322

48768

21970

48767

48264

48352

3021

24274

Description

Decal, Caution

Cover Assembly, Impeller

Decal, Name

Carriage Bolt, ¼-20 x 5/8 In.

*Screw, Hex Hd, 5/16-18 x ¾ In.

Bearing, Retainer

Bearing, Self-Aligning

Auger Housing End, R.H.

Auger Cover & Scraper Assembly

Auger Housing End, L.H.

Impeller Shaft, Assembly

Impeller Assembly

Roll Pin, _ x 1¼ In.

Shear Bolt

Auger Assembly, R.H.

*Washer, 1 tD x % OD x .125 Thk

Auger Assembly, L.H.

Gear Case Assembly

Shaft, Gear Box, Long

*Key, Woodruff, No. 9

Oil Seal

Key

No.

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

Pan No.

46274

48275

32397

47787

21682

21681

48273

23700

48265

21684

48271

47801

48279

48272

48266

35498

48269

21922

Description

Bearing

Washer, Thrust

Bearing, Needle

Worm Gear

Spring Washer

Ring, Retaining

Bearing, Input, Front

Pipe Plug

Gear Case Assy, L.H. (Incl. Items

59 & 60)

*Key, Hi-Pro

Washer, Thrust

Gear, Bronze

Gasket, Gear Case

Shaft, Gear Box, Short

Gear Case Assy, R.H. (Incl. Items

59 & 60)

Screw, Taptite, 5/16-18 x _ In.

Bearing

Oil Seal

Page 22

CRAFTSMAN 4-CYCLE ENGINE MODEl. NUMBER 143.696102

2

169

72

124

--22--

Page 23

CRAFTSMAN 4-CYCLE ENGINE

MODEL NUMBER 143.696102

Ref. Part

No. No.

1 32586B

2 27652

3 27642

4 32630

5 32783

5 32784

6

6

7 27882

8 27881

9 32581

11 32680A

12 29783

13 27884

t4 335928

14 33593B

14 33594B

14 34517

t4 34518

14 34519

15 32595

15 32596

15 32597

16 27888

17 3259IC

18 650662A

19 34242

2t 32115

22 34034

23 31303B

24

25

25A

25B

26

28

29

30

3t

32

33

34

35

36

37

37

38

39

40

41

43

44

45

46

48

49

50

52

27878A

27880A

28427

34011A

3359O

33893A

"30684

650488

650493

610118

650489

"32631

30938A

30939A

650697A

65069f

33636

34251

Canada

"27896

28423

28424

28425

650128

27627

*27915

30195A

30196

30969

32678

32326A

Ref.

Part Name No.

Cylinder Assy. (Incl. Nos. 2, 3 Et 4)

Pin, Dowel

Plug, Sq. hd. pipe (Oil drain)

Seat, Oil

Valve, Intake (Std.) (Incl. No. 9)

Valve, Intake {1/32" oversize) (Incl.

No. 9)

Valve, Exhaust IStd.) (Incl. No. 9)

Valve, Exhaust (1/32" oversize) (Incl.

No. 9)

Cap, Upper valve spring 66

Spring, Valve 67

Cap, Lower valve spring 69

Crankshaft Assy. (Incl. Nos. t2 8- t3) 70

Pin, Crankshaft gear 71

Gear, Crankshaft 72

Piston _t Pin Assy. (Incl. No. 16) (Std.) 75

Piston 8- Pin Assy. (Incl. No. 16) (.010 76

oversize) 77

Piston 8- Pin Assy. (incl. No. 16) (.020 78

oversize)

Piston, Pin 8 Ring Assy. (Inct. Nos. 15 80

8 16){Std.) 83

Piston, Pin 8 Ring Assy. (Incl. Nos. 15 84

8- t6) (.010 oversize) 85

Piston, Pin 8 Ring Assy. (Incl. Nos. 15 89

8- 16) (.020 oversize) 91

Ring Set, Piston (Std.) 93

Ring Set, Piston (.0t0 ov_ersize) 94

Ring Set, Piston (.020 oversize) 95

Ring, Piston pin retaining 96

Rod Assy., Connecting (Incl. Nos. t8 97

8 19) 98

Screw, Connecting rod

Dipper, Oil 99

Camshaft {Mect}. Compression 100

Release) 101

Lifter, Valve 102

Cover, Cytinder (Incl. Nos. 24, t06 _ 103

147) 104

Seat, Oil 105

Dipstick, Oil (Incl. No. 25A) 106

"O" Ring t07

Tube, Oil filler !08

Gasket, Cylinder cover 109

Screw, Hex hd. Seres, i/4-20 x 1-1/4 t10

Screw, Hex hd. Senqs, t/4 20 x 1 3/4 11I

Cover, Spark plug 112

Screw, Hex hd. Seres, 1/4-20 x 5/8 1t3

Gasket, Cylinder head

Head, Cylinder 114

Cover, Cylinder head 115

Screw, Hex flange hd., 5/16-18 x2 1/2 1t7

Washer, Flat 118

Plug, Spark (Champion J-8 or 119

equivalent) Exc_ for Canada

Resistor Spark Plug {Canadian Regula- 120

tions require RJ-17LM resistor spark 12I

plug) 124

Gasket, Valve spring cover 125

Body Assy., Breather I26

Element, Breather 127

Cover, Valve spring 129

Screw, Fil, hd. Seres, t0-24 x 1/2 130

Tube, Breather 131

Gasket, Intake

Flange, Carburetor (Incl. Nos. 77 E:t 80) 132

Screw, Fil. hd. Seres, 5/t6 18 x 3/4

Cap, Oil drain

Nippie, Pipe

Lever, Governor

61 650494

63 30699C

P_t !

No. P_tName

55 3O2O5

56 30826

57 30824

62 30700

64 29536

65 650561

34374

34170

29747A

32158B

650490

8116

231688

29752

27793

28942

650572

29642

29826

29216

31291

34585

650764

32398

28820

34581

650257

650765

650760

29538

26073

*2793O

32401

650694A

30196

31845

30591

29193

30588A

30590A

34159

34158

650561

34186

30998B

26460

30962

650665

650128

3O622

29716

34129

34133

34144

32589

31843A

28763

650548

Bracket, Governor adjusting

Spring, Extension

Link, Governor4o-throttle

Screw, Fil. hal. Seres, 6-40 x 5/16

Yoke, Governor

Rod Assy. Governor (Incl. Nos. 61 8

62)

Baffle, BIower housing

Screw, Hex washer hal. durlock,

1/4-20 x 5/8

Decal, Instruction

Decal, Instruction

Screw, Hex hd. Sems, 5/16-24 x 3/4

Housing, Blower (Ind. Nos. 135 8 136)

Washer, 8elleville

Nut, Crankshaft

Gasket, Carburetor

Nut 8r Lockwasher Assy., 1/4-28

Clip, Conduit

Screw, Hex washer hd. Seres, 10-32 x

3/8

Screw, Fiat hd. Seres, 1/4-28 x 1-1/8

Ring, Retaining

Screw, Hex washer hd., 10-32 x 3/4

Locknut, Hex, 10-32

Plug, Cover

Knob, Control

Nut, "U" Type

Bracket, Carburetor cover

Screw, Fil. hd. Seres, 10-32 x 1/2

Cover, Carburetor

Screw, Pan hd. Sems, 8-32 x 5/16

Screw, Hex washer hd. seff-drillin9,

10-32 x 1/2

Screw, Pan hd. taptite, 8-32 x 7/16

Base, Engine mounting

Washer, Flat

Gasket. Muffler

Muffler

Screw, Hex flange hd., 5/16-18 x 2

Screw, Fil. hd., 5/16-18 x 3/4

Shaft, Mechanical governor

Gear Assy., Governor (Incl. No. t10)

Ring, Retaining

Spool, Governor

Washer, Flat

Plate, Fuel tank mounting

Bracket, Fuel tank mounting

Screw, Hex washer hd. durlock,

t/4-20 x 5/8

Tank Assy., Fuel (Incl. No. 115)

Cap, Fuel

Clamp, Fuel line

Line, Fuel

Screw, Hex washer hd. Seres, self-

tap, 1/4-t4 x 7/8

Screw, Fii. hd. Seres, 10 24 x 1/2

Extension, Blower housing

Screw, Pan hd. Seres, 1/4-28 x 7/16

Decat, Warning

Decal, Choke

Decal, "Primer"

Key, Flywheel

Bracket, Governor gear

Screw, Hex washer hd., shakeproof,

10-32 x 19/32

Screw, Hex washer hd., 8-32 x 5/16

*Indicates Parts Included in

Gasket Set, Ref. No. t69.

--23--

Page 24

CRAFTSMAN 4-CYCLE ENGINE MODEL NUMBER 143.696102

Ref.

No.

134

134A

t35

t36

t37

138

139

140

141

144

145

146

147

148

!49

150

152

Part

No.

33io8A

6 ! 0973

650736

33013

32312

32180A

32182

32183

32184

650542

33876

34240

31546

34126

28545

650643

34127

Ref.

Part Name No.

Control Assy., Remote speed (incl. 154

Nos. 56 8- 134A) t62

Terminal Assy. 163

Screw, Pan hd., 10-t6 x 3/8 164

Cover, Starter bubble 166

Retainer, Primer bulb

Line, Primer

Primer Asy. (Incl. Nos. 137, 140 8-141)

Bulb, Primer

Body, Primer

Screw, Hex hd., 5/16-18 x 3/4 167

Gasket, Stator 168

Wire, Ground 169

Bushing, Crankshaft 170

Bracket, Grommet mounting

Grommet, Plastic

Screw, Pan hd. self-tap, 8-18 x 3/8

Guard, Starter

Part

i No,

32576

29918

32125

590417

610694A

631920

590473

33239

Part Name

seal, Snow guard

Lockwasher, No. 8 E.T.

Cup, Starter

Screen, Starter cup

Magneto (The complete magneto is

not available as an assembly. The

magneto number is shown for

reference purposes only. Order corn

ponent parts individually, as shown in

parts list.)

Carburetor (Incl. No, 75)

Starter Assy., Rewind

Gasket Set (Incl. items marked *)

Electric Starter Kit No. 143.88902

(Optional)

"Indicates Parts Included in

Gasket Set, Ref. No. 169.

MAGNETO NUMBER 610694A

available as an assembly. The

f_lA reference purposes only. O_der

_ 3__'" _J 13_

magneto number is shown for

The complete magneto is not l

1

Ref.

No.

1

1A

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

19

No.

610694A

30811A

610934

30551

610947

30992

30547A

610385

33356

61O408

29181

610593

30560A

30554

305488

30545

30561B

30549

31311

29629

610955

61O956

Parg Name

Magneto

Flywheel (Incl. No. IA}

Fan

Spring, Breaker box dust cover

Cover, Dust

Cam, Breaker

Contact Assembly, Breaker

Washer, Terminal

Tab, Ground terminal

Nut, Terminal

Screw & Washer, Breaker

Screw, Condenser

Coif Assy. (Incf. No. 12)

Wire, Lead

Condenser

Core & Plate

Stator Assy, (Incl. Nos. 2, 3, 5

thru 14 & 16thru 19)

Felt, Cam wiper

Clip, Coif locking

Spring, Coi{ wedge

Gasket, Dust cover

Gasket, Dust cover

8\

--24--

Page 25

CRAFTSMAN 4-CYCLE ENGINE MODEL NUMBER 143.696102

CARBURETOR NUMBER 631920

% 2%

I 5 / ,,

24 11 , I

@=

"'-. I3 1

" 14

, /

t

|

|

------ 16

I

8

23----_ ,_ --22

8_

30----_ i

32

Ref.

No.

15

10

11

12

13

14

t5

16

21

22

23

24

25

26

30

31

32

1

2

3

4

5

6

7

8

9

Part

No.

631920

31834

632016

631036

650506

630766

650417

631913

630739

631815

*630748

*631O27

*631021

631022

632019

*631024

631867

27110

*31839

*630740

*631078

*631028

6318O3

630738

630735

31840

Part Nmne

Carbu retor ......

Shaft & Lever Assy., Throttle

Spring, Throttle return

Shutter, Throttle

Screw, 4-40 x 3/t6

Spring, Idle regulating screw

Screw, Idle regulating

Shaft & Lever Assy., Choke

Washer, Flat

Shutter, Choke

Plug, Welch

Plug, Welch

Inter Needle, Seat & Clip Assy.

(Incl. No. 13)

Clip, Inlet needle

Float, Carburetor

Shaft, Float

Bowl, Float

Gasket, Bowl-to-body

Adjustment Screw Assy., Main

(Incl. Nos. 8, 21, 23 & 30)

"O" Ring, Adjustment screw

Screw, Idle adjustment

Gasket, Bowl-to-body

Fitting, Fuel inlet

Spring, Main Adjustment screw

Spring, Choke stop

Repair Kit (Incl. items marked *)

REWIND STARTER NUMBER 590473

//% ,.,_.

Q_12

3_D

iRef. Part

No. No.

i 590473

590409A

I

2

590474

3

590411

4

590148

5

59O475

6

590478

7

590414

8

590415

9

590451_

10

590387

11

590459

12

590476

13

590477

Part Name

Starter, Rewind

Screw, Retainer

Cam, Dog

Spring, Brake

Dog, Starter

Spring, Dog

Pulley

Spring & Keeper Assy.

Housing Assy., Starter (I ncl. No. 1 )

Rope, Starter

Handle Assy., Starter

Pin, Centering

Retainer, Dog

Screw, No. 6 x 5/16

--25--

Page 26

5 SPEED TRANSMISSION MODEL NUMBER 143.735

Ref.

No.

lO

11

12

13

t4

15

16

t7

18

Part

No.

1

2

3

4

5

6

7

8

9

794254

770061

772070

776161

77812lA

778122

778123

778124

778125

784266

786060

786061

776134

778109

778126

778127

778128

778129

776143

Complete Transmission

Case, Transmission

Cover, Transmission

Shaft, Output

Gear, Spur 120 teeth)

Gear, Spur {22 teeth)

Gear, Spur (25 teeth)

Gear, Spur (30 teeth)

Gear, Spur (35 teeth)

Collar, Shift

Sprocket (14 teeth)

Sprocket (!0 teeth)

Shaft, Counter

Gear, Bevel (42 teeth 8- 15 tooth spur

gear)

Gear, Spur (20 teeth)

Gear, Spur 125 teeth)

Gear, Spur (28 teeth)

Gear, Spur (30 teeth)

Shaft, Input

Part Name No. No.

Ref. Part

19 778113

20 786049

27 780105

28 786062

29 780072

30 780086

3I 792072

32 792035

33 780109

34 788040

35 784267

36 792073

37 792089A

40 792077

4t 792078

42 792079

43 780108

44 792074

45 792001

46 788054

Part Name

Bevel pinion, Input

Sprocket (8 teeth)

Bushing, Flanged

Chain, Roller (No. 41 chain, 22 links)

Race, Thrust

Bearing, Needle

Ring, Retaining

Ring, Retaining

Washer

Ring, Retaining

Rod 8 Fork Assy., Shift

Screw, Hex hal. tap-tire, 1/4-20 x !-!/4

Key

Ball, Steel, 5tt6

Screw, Set, 3/8-16 x 3/8

Spring

Washer, Thrust

Plug

Ring, Square cut

Gasket

--26 d

Page 27

TROUBLE

Difficult starting,

Engine runs erratic

"-Engine stalls;

Loss of power;

Engine runs erratic

Excessive vibration

Unit fails to propel

itself

Unit fails to

discharge snow

LOOK FOR

Defective spark plug

I_locked fue'i 'iine or

empty gas tank

Review paragraph

Unit running on CHOKE

Obstruction in

impeller housing

Water in fuel system

CAUTION:

Loose parts;

Damaged impeller

Drive belt loose or

defective

Broken shear bolt

Drive roller chain

defective

Unit drive b'e'li loose

or defective

Impeller drive belt loose

or defective

Impeller!Auger control

out of adjustment

Shear bolt broken

Discharge chute clogged

Foreign object lodged

in auger

Auger gear case trouble

Transmission trouble

REMEDY

Replace defective plug,

Clean fuel line; check fuel supply.

To Start Engine.

Set choke lever to RUN position.

Remove obstruction; clean impeller housing. Refer to Danger

after Step 6 of Snow Thrower Operation paragraph in

Operation section of this manual.

Remove carburetor bowl to drain fuel tank.

Refill with fresh fuel

Do

not remove carburetor bowl when the engine is hot.

Stop engine immediately; tighten all bolts and make all

necessary repairs. If vibration continues, have the unit serviced

by a competent repairman,

Replace drive belt. Refer to Drive Belt Replacement paragraph

in Maintenance section of this manual.

Replace shear bolt. Refer to Shear Bolt Replacement paragraph

in Maintenance section of this manual.

Replace roller chain. Refer to Roller Chain Replacement

paragraph in Maintenance section of this manual.

Adjust unit drive belt; replace if defective. Refer to Drive Belt

Adjustment paragraph in Adjustment section or Drive Belt

Replacement paragraph in Maintenance section of this manual.

Adjust impeller!auger drive belt; replace if defective. Refer to

Drive Belt Adjustment paragraph in Adjustment section or

Drive Belt Replacement paragraph in Maintenance section of

this manual,

Adjust impeller/auger control cable. Refer to Impeller/Auger