Page 1

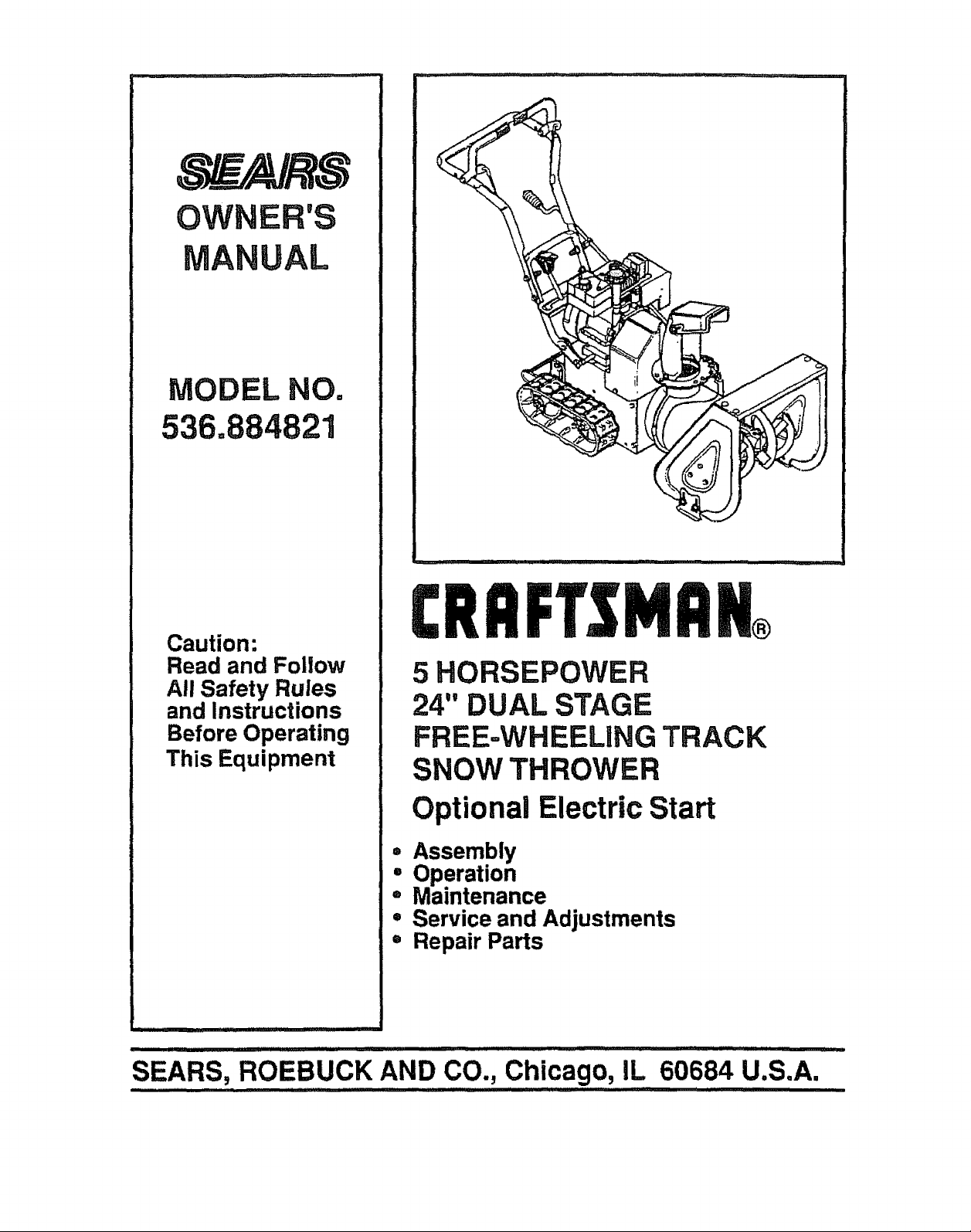

OWNER'S

MAHUAL

MODEL NO.

536.884821

Caution:

Read and Follow

All Safety Rules

and Instructions

Before Operating

This Equipment

CRRFr$IRN

5 HORSEPOWER

24" DUAL STAGE

FREE=WHEELIHG TRACK

SNOW THROWER

Optional Electric Start

• Assembly

=" Operation

Maintenance

• Service and Adjustments

= Repair Parts

-- [ ................................................. .._.... _ _ _ _ ql U q IIII1' ill

SEARS, ROEBUCK AND CO., Chicago, IL 60684 U.S.A.

..... , ................ i nl ii ii '11 IIII I _ ...... Z .......

Page 2

SAFETY RULES

CAUTION: ALWAYS DISCONNECT SPARK PLUG WIRE AND PLACE A

WIRE WHERE IT CANNOT CONTACT SPARK PLUG TO PREVENT

ACCIDENTAL STARTING WHEN SETTING-UP, TRANSPORTING, AD-

JUSTING OR MAKING REPAIRS.

IMPORTANT

SAFETY STANDARDS REQUIRE OPERATOR PRESENCE CONTROLS TO MINIMIZE THE

RISK OF INJURY. YOUR SNOW THROWER IS EQUIPPED WITH SUCH CONTROLS. DO NOT

ATTEMPT TO DEFEAT THE FUNCTION OF THE OPERATOR PRESENCE CONTROL UNDER

ANY CIRCUMSTANCES°

BEFORE USE

• Read the Owner's Manual carefully. Be thor-

oughly fan]iliar with the controls and the proper

use of the snow thrower. Know how to stop the

snow thrower and disengage the controls

quickly.

• Do not operate the snow thrower without wear-

ing adequate winter outer garments. Wear

footwear that will improve footing on slippery

surfaces. •

• Keep the area of operation clear of all persons,

particularly small chirdren, and pets.

• Thoroughly inspect the area where the snow

thrower is to be used and remove alldoormats,

sleds, boards, wires, and other foreign objects..

• Use extension cords and receptacles as

specified by the manufacturer for all snow

throwers with electric drive motors or with

factory-installed or optional starting motors

• Use only attachments and accessories ap-

provedby the manufacturer of the snow thrower

(such as eiectric starter kits, etc.)

o Never operate the snow lhrower without good

visibility or light. Always be sure of your foot}ng,

and keep a firm hold on the handles° Walk:

never run.

• This snow thrower is for use on sidewalks,

driveways, and other ground level surfaces.

CAUTION should be exercised whi(e using on

steep sloping surfaces. DO NOT USE SNOW

THROWER ON SURFACES ABOVE

GROUND LEVEL such as roofs of residences,

garages, porches or other such structures or

buildings,,

• Check shear bolts and other bolts at frequent

intervals for proper tightness to be sure the

snow thrower is in safe working condition.

• Disengage all clutches and shift into neutral

before starting the engine_

• ,Adjust the snow thrower height to clear gravel •

or crushed rock surface.

• Let engine and snow thrower adjust to outdoor

temperatures before starting to clear snow,

FUEL SAFETY

• Handle fuel with care; it is highly flammable.

• Use an approved fuel container,

• Check fuel supply before each use, aflowing

space for expansion as the heat of the engine

and/or sun can cause fuel to expand.

• Fill fuel tank outdoors with extreme care, Never

fill fuel tank indoors.

Replace fuel tank cap securely and wipe up

spilled fuel.

• Never remove fuel tank cap or add fuel to a

running engine or hot engine.

• Never store fuel or snow th rower wilh fuel in the

tank inside a building where fumes may reach

an open flame or spark.

OPERATING SAFETY

• Never atlow children or young teenagers to

operate the snow thrower and keep them away

while it is operating_ Never allow adults to

operate the snow thrower without proper in-

struction _ Do not carry passengers.

• Always wear safety glasses or eye shields

during operation or while performing .'n adjust-

ment or repair to protect eyes from foreign

objects that may be thrown from the snow

thrower.

• Exercise extreme caution when operating on or

crossing gravel drives, walks, or roads. Stay

alert for hidden hazards or traffic.

• Do not put hands or feet near or under rotating

parts. Keep clear of the discharge opening at

all times,,

• Exercise caution to avoid slipping or falling,

especially when operating in reverse or back-

ing up.

• Do not clear snow across the face of slopes.

Exercise caution when changing direction on

slopes_ Do not attempt to clear' steep slopes.

Neveroperate the snowthrowerwithoutproper

guards, plates or other safety protective de-

vices in place.

Page 3

SAFETY RULES

Never operate the snow thrower near glass

enclosures, automobiles, window wells, drop-

offs, and the like without proper adjustment of

the snow discharge angre. Keep children and

pets away_.

® Never operate the snow thrower at high trans-

port speeds on slippery surfaces_ Look behind

and use care when backing..

e Never direct discharge at bystanders or allow

anyone in front of the snow thrower.

® Do not run the engine indoors, except when

sta_ng the engine and for transporting the

snow thrower in or out of the building_ Open the

outside doors; exhaust fumes are dangerous

(containing CARBON MONOXIDE, an ODOR-

LESS and DEADLY GAS).

e Take all possible precautions when leaving the

snow thrower unattended_. Disengage the au-

gedimpeller, shift to neutral, stop engine, and

remove key,

e Do not overload the machine capacity by at-

tempting to clear snow at too fast a rate.

SAFE STORAGE

e Always refer to Owner's Manual instructions for

important details if the snow thrower is to be

stored for an extended period.

o Disengage power to the auger/impeller when

snow thrower is transported or not in use.

o Never store the snow thrower with fuel in the

fuel tank inside a building where ignition sources

are present such as hot water and space

heaters, clothes dryers, and the liken Allow the

engine to cool before storing in any enclosure_

REPAIR/ADJUSTMENTS SAFETY

o After striking a foreign object, stop the engine

remove the wire from the spark plug or dis-

connect the cord from the electric motor°

Thoroughly inspect the snow thrower for any

damage and repair the damage before restart-

ing and operating the snow thrower°

® If the snow thrower should start to vibrate

abnormally, stop the engine or electric motor

and check immediately for the cause. Vibration

is generally a warning of trouble.,

® Stop the engine or electric motor whenever

you leave the operating position before un-

clogging the auger/impeller housing or dis-

charge guide, and when making any repairs,

adjustments, or inspections. Removewire form

spark plug or disconnect cord from electric

motor.

• When cleaning, repairing, or inspecting, make

certain the auger/impeller and all moving parts

have stopped. Disconnect the spark plug wire

and keep the wire away from the plug to pre-

vent accidental staRting.

o Never attempt to make any adjustments while

the engine is running (exceptwhen specifically

recommended in this manual).

e Maintain or replace safety and instruction la-

bels, as necessary.

o Run the snow thrower a few minutes after

throwing snow to prevent freeze-up of the

auger/impeller.

LOOK FOR THIS SYMBOL TO POINT OUT

_ IMPOR'[ANT SAFETY PRECAUTIONS. IT

MEANS-ATTENTION!!! BECOME ALERT!I!

YOUR SAFETY IS INVOLVED.

3

Page 4

CONGRATULATIONS on your purchase of a Sears

Craftsman Snow _rower_ It has been designed, engi-

neered and manufactured to give you the best possible

dependability and performance.

Should you experience any problem you cannot easily

remedy, please contact your nearest Sears Service

Center/Department. We have competent, welt4rained

technicians and the proper tools to se_ce or repair this

uniL

Please read and retain this manual. 'The instructions will

enable you to assemble and maintain your snow thrower

_mpedy. Always observe the =SAFETY RULES."

MODEL

NUMBER 536_884821

SERIAL

NUMBER

DATE OF

PURCHASE

THE MODEL AND SERIAL NUMBERS WiLL BE

FOUND ON A DECAL ATTACHED TO THE REAR

OF THE SNOW THROWER HOUSING_

YOU SHOULD RECORD BOTH SERIALNUMBER

AND DATE OF PURCHASE AND KEEP IN A SAFE

PLACE FOR FUTURE REFERENCE°

MAINTENANCE AGREEMENT

A Sears Maintenance Agreement is available on this

product, Contact your nearest Sears Store for details_

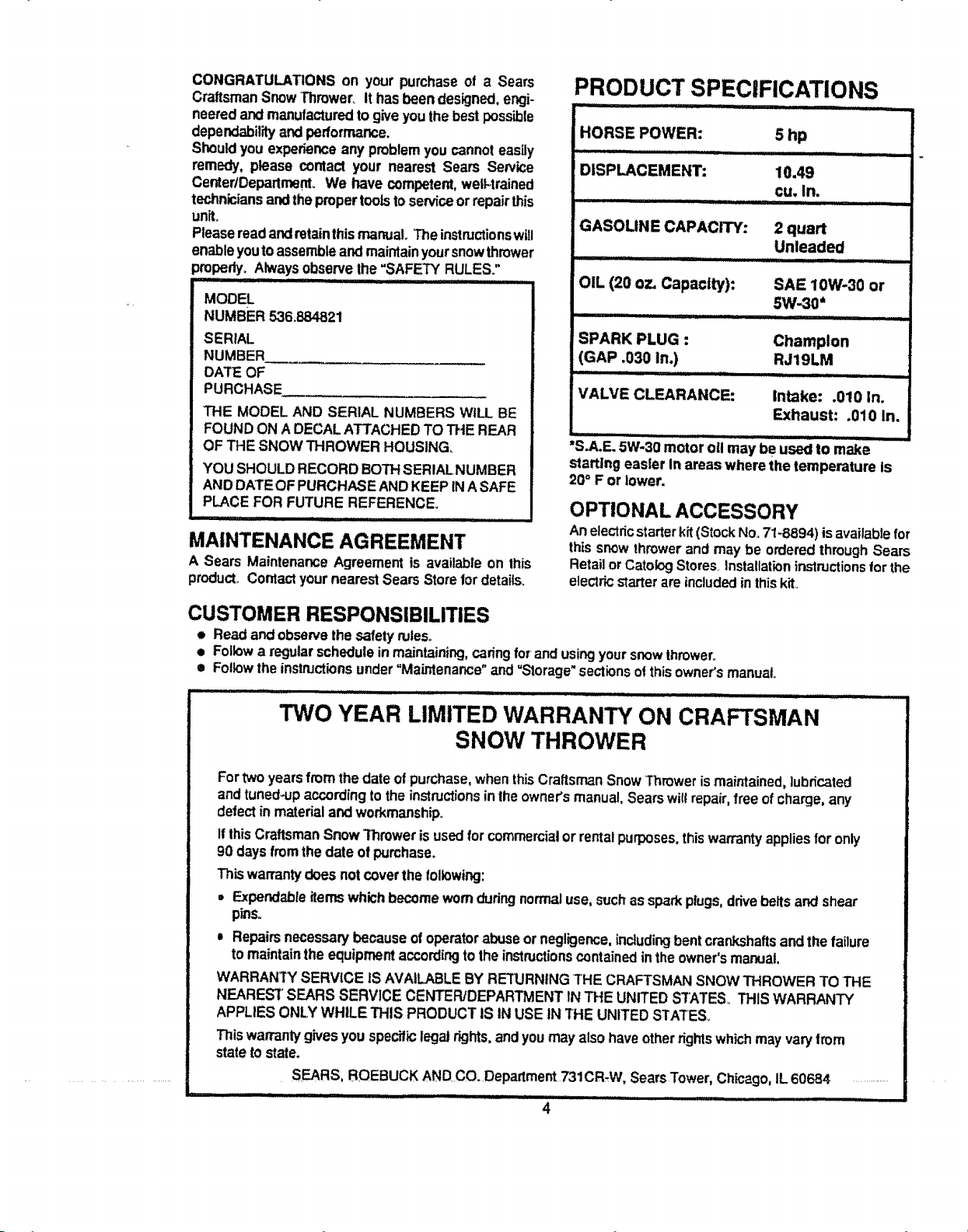

PRODUCT SPECIFICATIONS

_SE POWER: 5 hp

: : :- ,,,,,,,,,,,,,,

DISPLACEMENT: 10.49

cu. In.

GASOLINE CAPACITY: 2 quart

........... m ,,,,,,,,, ..... - ......... Hi

OIL (20 oz., Capacity): SAE 10W-30 or

SPARK PLUG :

(GAP .030 In.)

VALVE CLEARANCE:

"S.AIF... 5W-30 motor O" maybe used to make

starting easier In areas where the temperature Is

20 ° F or lower.

OPTIONAL ACCESSORY

An electric starter kit (Stock No., 71-8894) is available for

this snow thrower and may be ordered through Sears

Retail or Catolog Stores Installation instructions for the

electric starter are included in this kit.

Unleaded

5W-30"

Champion

RJ19LM

Intake: .010 In.

Exhaust: .010 in.

CUSTOMER RESPONSIBILITIES

• Read and observe the safety rules°

• Follow a regular schedule in maintaining, caring tot and using your snow thrower.,

• FolJow the instructions under "Maintenance" and =Storage" sections of this owner's manual

TWO YEAR LIMITED WARRANTY ON CRAFTSMAN

SNOW THROWER

For two years from the date of purchase, when this Craftsman Snow Thrower is maintained, lubricated

and tuned-up according to the instructions in the owner's manual, Sears witl repair, free of charge, any

detect in material and workmanship.

It this Craftsman Snow Thrower is used for commercial or rental purposes, this warranty applies for only

90 days from the date of purchase.

This warranty does not cover the following:

• Expendable items which become worn dudng normal use, such as spark plugs, ddve belts and shear

p_so

Repairs necessary because of operator abuse or negligence, including bent crankshafts and the failure

to maintain the equipment according to the instructions contained in the owner's manual.

WARRANTY' SERVICE IS AVAILABLE BY RETURNING THE CRAFTSMAN SNOW THROWER TO THE

NEAREST SEARS SERVICE CENTER/DEPARTMENT IN THE UNITED STATES. THIS WARRANTY

APPLIES ONLY WHILE THIS PRODUCT IS IN USE iN THE UNITED STATES,

This wan_anty gives you specitic legal rights, and you may also have other dghts which may vary from

state to state.

SEARS, ROEBUCK AND CO. Department 731CR_W, Sears Tower, Chicago, tL 60684 ...................

.......... : :: ............ ,,,J=, i ..... ,,, ,,,,,, i uH= ........

4

Page 5

TABLE OF

SAFETY RULES .................................................... 2,3

PRODUCT SPECIFICATIONS ........................... 4

CUSTOMER RESPONSIBILITIES ................. 4

WARRANTY ...................................................... 4

TABLE OF CONTENTS .................................. 5

INDEX ............................................................. 5

ASSEMBLY ........................................................ 6-9

OPERATION ............................................. 10-14

CONTENTS

MAINTENANCE .............................................. 15-! 6

SERVICE AND ADJUSTMENTS ........... 17-24

STORAGE ..................................................... 25

SERVICE RECOMMENDATIONS ................. 26

TROUBLE SHOOTING ................................. 27

REPAIR PARTS (SNOW THROWER),.. 2B-40

REPAIR PARTS (ENGINE) ...................... 41-44

PARTS ORDERING/SERVICE ........ Back Cover

iNDEX

A

Adjustmen!:

Auger .............................................................. 1B

Bm! .................................................................. 18

Bett Gui_e ............................................... 20

Cabie ............................................................ t 8

Carburelor ............................................. 24

Frick;on Wheei ........................................ 21

Span P!ug ............................................... 24

Track .................................................... 23

Traction and Auger ................................. 18

Assemoly

Cran_ Assembly ........................... 8

ShiI!er Lever ......................................... 9

Skio Hergnt Adjustment ............. 7, 17

Unpac_iog ........................................... 7

Belts:

Ad)ust Belts ........................................... 18

Belt Gu_oe Adjustment ........................ 20

Bett Maintenance ................................. 15

Replace Belts .................................. 19, 20

Cables..C:_ch ..................................... 7, 9_ t 8

Ca_ure_.or: ........................................... 24, 25

Chain ............................................................ 15

Choke ............................................. ;O. 11, i3

Clutch Levers ............................. 10, 11

Conlro_s:

Engine .................................... 10, 11, t3, 14

SnowThrower ....................................... t0

Crank:

Adjusting Rod ............................................ 8, 17

Assemoly ........................................................... 8

Operaticn ...................................................... 11

Customer Responsibilities ............................ 4

Drive, Auger .................................................. 1 t

Ddveo Traction ......................................... 11

De|lectoro Snow Chute ............................... 11

B

C

D

E

Engine:

Control ............................... 10, 11, 13, 14

Oil Cap ................................................. 12, 16

Oil Change .................................................. t6

Oil Level ..................................................... 12, 16

Oil Type .................................. 4. 12, 16

Speed Governor ................................................. 24

Starting ...................................................... t 3

Storage ............................................................. 25

F

Free-Wheel. Track ...................................... 12

Fuel. Type ............................................. 4. I3

Fuel, Storage .................................... 13, 25

Friction Wheel:

Adjustment ........................................... 21

Replacement ................................... 22

Gears:

Auger Gear Box ................................. 15

Hex Shaft ............................................ 15

Hanoi{e, Upper ano Lower ...................... B

Height Adjust Skids ......................... 7, 17

Hex Shaft ................................... 15.22

[gnilion. Key ............................ ";0.1 I, 13, 14

!ndex ................................................................ 5

Levers

AugerDrive Clutch .. 7.9, 10, 1 Io 18

Choke ......................................... I0, 1 I. 13, I4

Shffler ....................................................... 9, 10

Throttle Controt .......... I0, 11,13, 14

Traction Dr_e Clulcn ..7.. 9, 10, 11, 18

Lubrication:

Auger Gear Box .................................. 15

Auger Shatt .................................. 15, 26

Chart .................................................... 26

Engine ........................................................ 14, 16

Hex Shaft and Gears ........................... 15

Weight Trans|er System ............... 12, 15

Maintenance:

Agreement ............................................................ 4

Auger Gear Box ..................................... 15

Auger Shaft ................................................. 15

Engine ................................................................ 16

GeneraIRecommenoations ............. 15

Hex Shaft and Gears ......................... 15

Weight Transfer System ...................... 15

Oil:

Engine .......................................... 4, 12, 16

Extreme Cold Weather .................... 13,16

Storage .............................................................. 25

Type ...................................................... 4, 12, 16

Operation:

Engine Controls ............... 10,11, 13,14

Free-Whee!, Track ..................................... 12

Operating Snow Thrower.... 11, 12, t 4

G

H

l

L

M

O

Operating Tips .................................................. t4

Starting the Engine ...................................... I3

Snow Thrower Controls ................... 10-12

Weight Transfer System .......................... 12

P

Parts ................................................................. 28-39

PrimerButton ..................... ;0, _ !. _3. ;4

RepatrlReplacement Parts ............ 28-39

Replacemenls:

Auger Shear Bolt .......................................... 23

Belts .................................................... 19.20

Friction Wheel ................................. 22

Satety Rules ................................................. 2.3

Service and Adjustments:

Auger Housing Height ....................... 7.17

Auger Shear Bolt ........................................... 23

Betts ....................................................... 18-20

Belt Guide ............................................................ 20

Belt Replacements .............................. 19, 20

Cable ........................................................ 7, 9, 1

Carburetor .................................................... 24, 25

Friction Wheel .......................................... 22

Spark Rug .......................................................... 24

Track ....................................................................... 23,

Se rv k?.e Recommendations .................... 26

Spark Plug ............................................ 18, 24

Specifications .................................................. 4

Speed Governor ................................................. 24

Starting the Engine ......................................... t 3

Stopping the Engine ....................... 11, 13.14

Stopping the Snow Thrower .................... 11

Shipping Oarton ..................................... 6, 7

Skid Height ...................................................... 7, 17

ShitTer Lever ................................................. 9-I0

Shear Bofts ....................................................... 23

Storage ............................................................ 25

Table ol Contents .................................... 5

Trouble Shooting Chart .................... 26

Tools for Assembly ..................................... 6

Traction Drive Bert ................................... 18, 20

Track Adjustmanl .......................................... 23

Warranty ....................................................... 4

Weight Transter System ...................... 12, t5

R

S

T

W

5

Page 6

lllll ,,,, ................

ASSEMBLY

............................................. ii i!111 .................

THIS SNOW TI-IROWER HAS A TRACK DRIVE SYSTEM EQUIPPED TO GIVE

YOU FREE-WHEELING CAPABILITY

If your snow thrower must be moved without the aid of the engine, it will be easier to pull the snow thrower

backward by the handles, rather than pushing. For details on how to use the free-wheeling capability, see the

Track Drive/Free-Wheel Feature paragraph in the Operation section of this manual

On start up, the track drive system may be tight but will loosen up as the snow thrower is used After first use, check

the track for tension and adjust if necessary., See the "track Adjustment paragraph in the Service and

Adjustments section of this manual. Check track adjustment and fasteners reguladyo

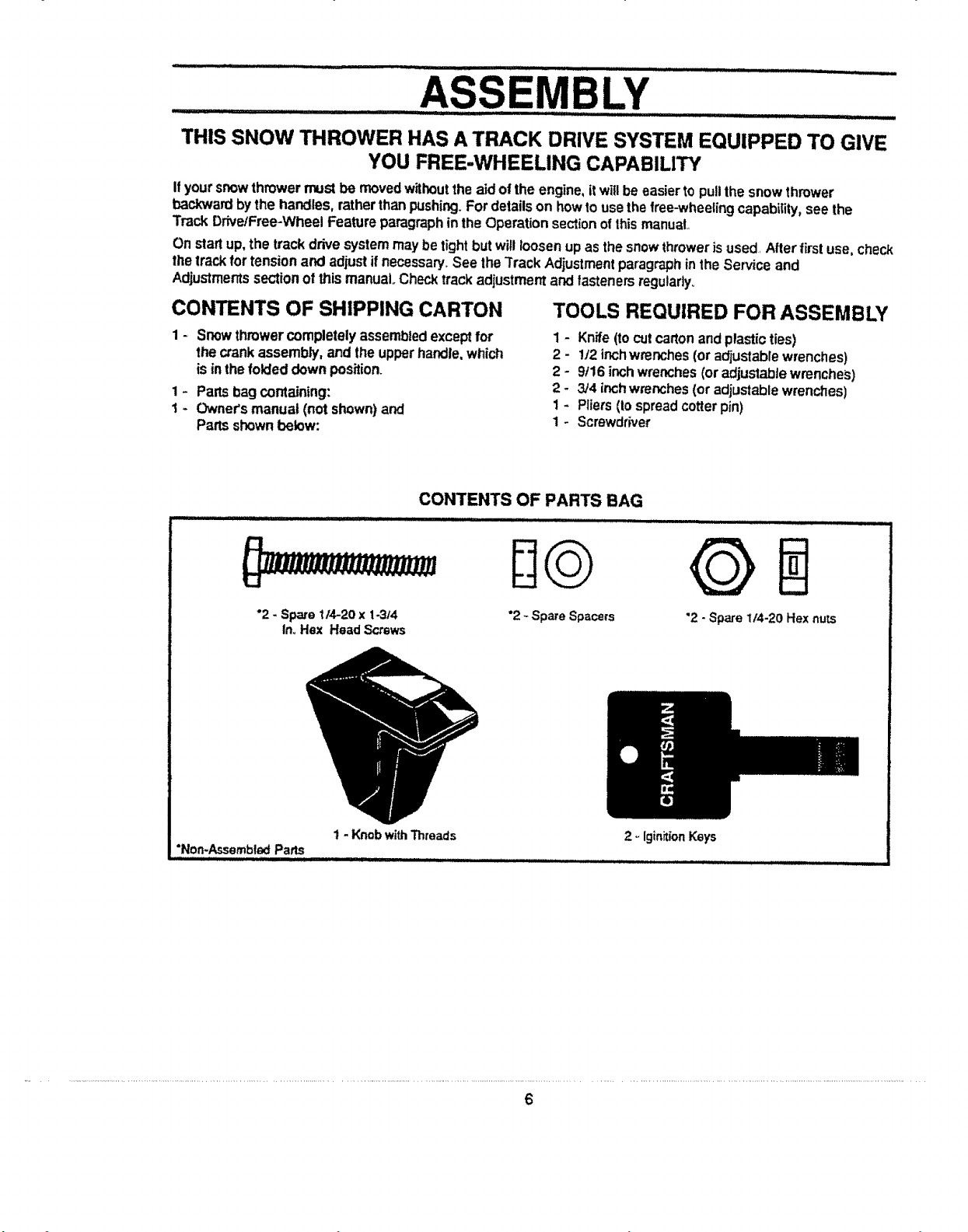

CONTENTS OF SHIPPING CARTON

1 - Snow thrower completely assembled except for

the crank assembly, and the upper handle, which

is in the folded down position.

1 - Parts bag containing:

1 - Owner's manual (not shown) and

Pans shown below:

CONTENTS OF PARTS BAG

............... i I IIIII I II I I IIIIIIII II1'11111[11 I i, iiiiiiiiiiiiii ii i III

TOOLS REQUIRED FOR ASSEMBLY

1 - Knife (to cut carton and plastic ties)

2 - 1/2 inch wrenches (or a_ustabre wrenches)

2 - 9f16 inch wrenches (or adjustable wrenches)

2 - 3/4 inch wrenches (or adjustable wrenches)

1 - Pliers (Io spread cotter pin)

1- Screwdriver

°2 - Spa_e 114-20 x 1-3/4

In. Hox Head Screws

"Non-Assembled Parts

ill IH,IL IJ ,,,I[HIIII _',11' III ............ , ,

1 - Knob with Threads

"2 - Spare Spacers

"2 - Spare 1/4-20 Hex nuts

2 _ iginition Keys

6

Page 7

...................... ASSE .......... L¥ .............. ' .............

Hi, _lll, lllll, .......... -.. ........................ ii ll.i ill _,_

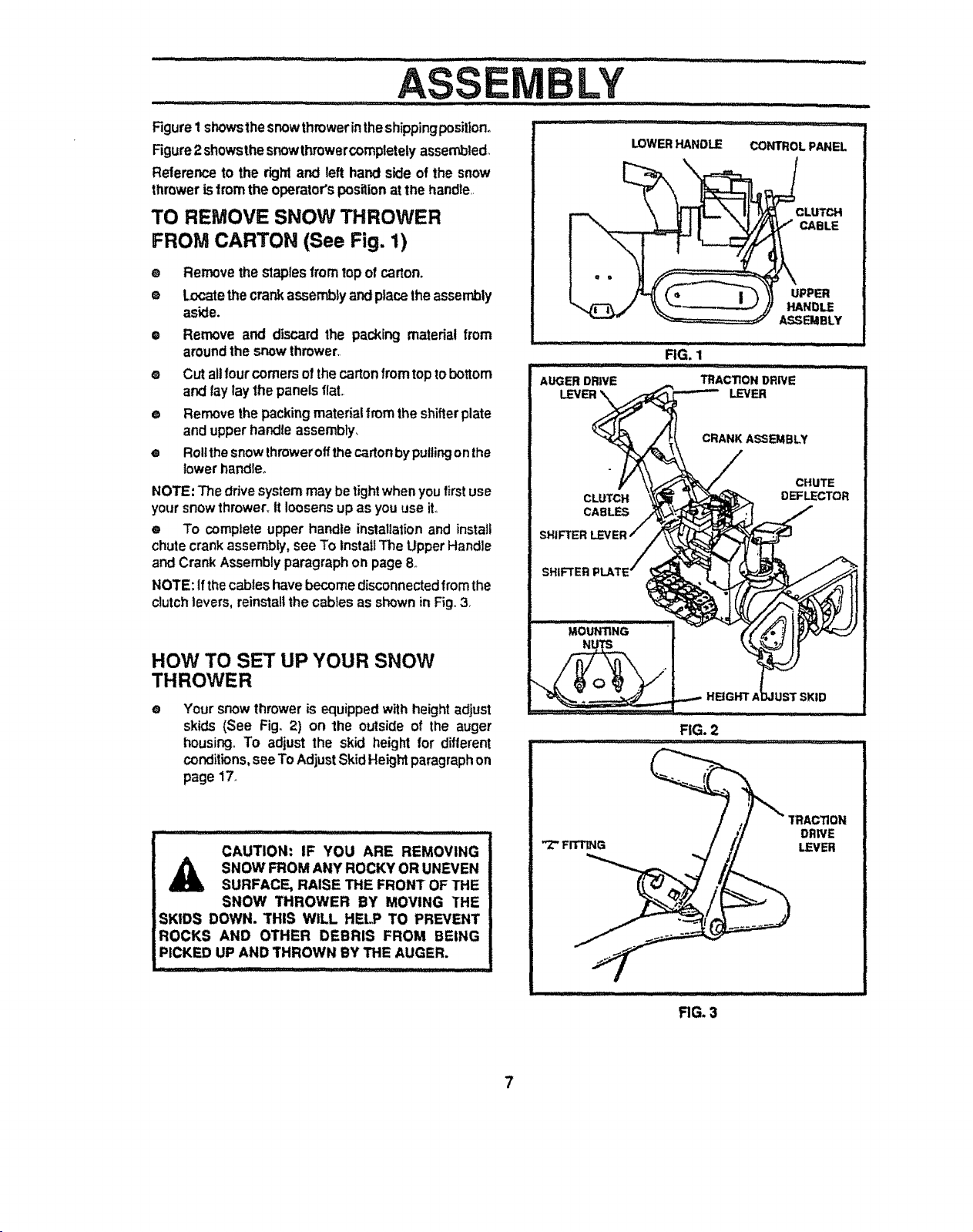

Figure 1 showsthe snowthmwer in the shipping position.

Figure 2 shows the snowthrowercomptetety assembled,

Reference to the righl and left hand side of the snow

thrower is from the operator's position at the handle,,

TO REMOVE SNOW THROWER

FROM CARTON (See Fig. 1)

e Remove the staples from top of carton.

o Locate the crank assembly and place the assembly

aside,

e Remove and discard the packing material from

around the snow thrower,.

® Cut all four comers of the carton from top to bottom

and lay lay the panels flat,.

e Remove the packing material from the shifter plate

and upper handle assembly.

e Rollthe snow lhmweroff the carton by pulling on the

lower handle,,

NOTE: The drive system may be tight when you first use

your snow thrower. It loosens up as you use ito

e To complete upper handle installation and install

chute crank assembly, see To Install The Upper Handle

and Crank Assembly paragraph on page 8.

NOTE: If the cables have become disconnected from the

clutch levers, reinstall the cables as shown in Fig. 3,

,,, .__..:. ...................... .......................................... .,_:..

LOWER HANDLE CONTROL PANEL

CLUTCH

CABLE

UPPER

HANDLE

ASSEMBLY

CRANK ASSEMBLY

CHUTE

CLUTCH

CABLES

SHIFTER

DEFLECTOR

HOW TO SET UP YOUR SNOW

THROWER

o

Your snow thrower is equipped with height adjust

skids (See Fig. 2) on the outside of the auger

housing,, To adjust the skid height for different

conditions, see To Adjust Skid Height paragraph on

page 17._

CAUTION: IF YOU ARE REMOVING

,_ SNOW FROM ANY ROCKY OR UNEVEN

SKIDS DOWN. THIS WILL HEt.P TO PREVENT

ROCKS AND OTHER DEBRIS FROM BEING

PICKED UP AND THROWN BY THE AUGER,

.............. _ ;; _ .......... ....... ±

SURFACE, RAISE THE FRONT OF THE

SNOW THROWER BY MOVING THE

7

"Z" FITTING

FIG. 2

TRACTION

DRt!/E

LEVER

FIG. 3

Page 8

i i illll, ii,i ii ,ll .... , ....................................

MBLY

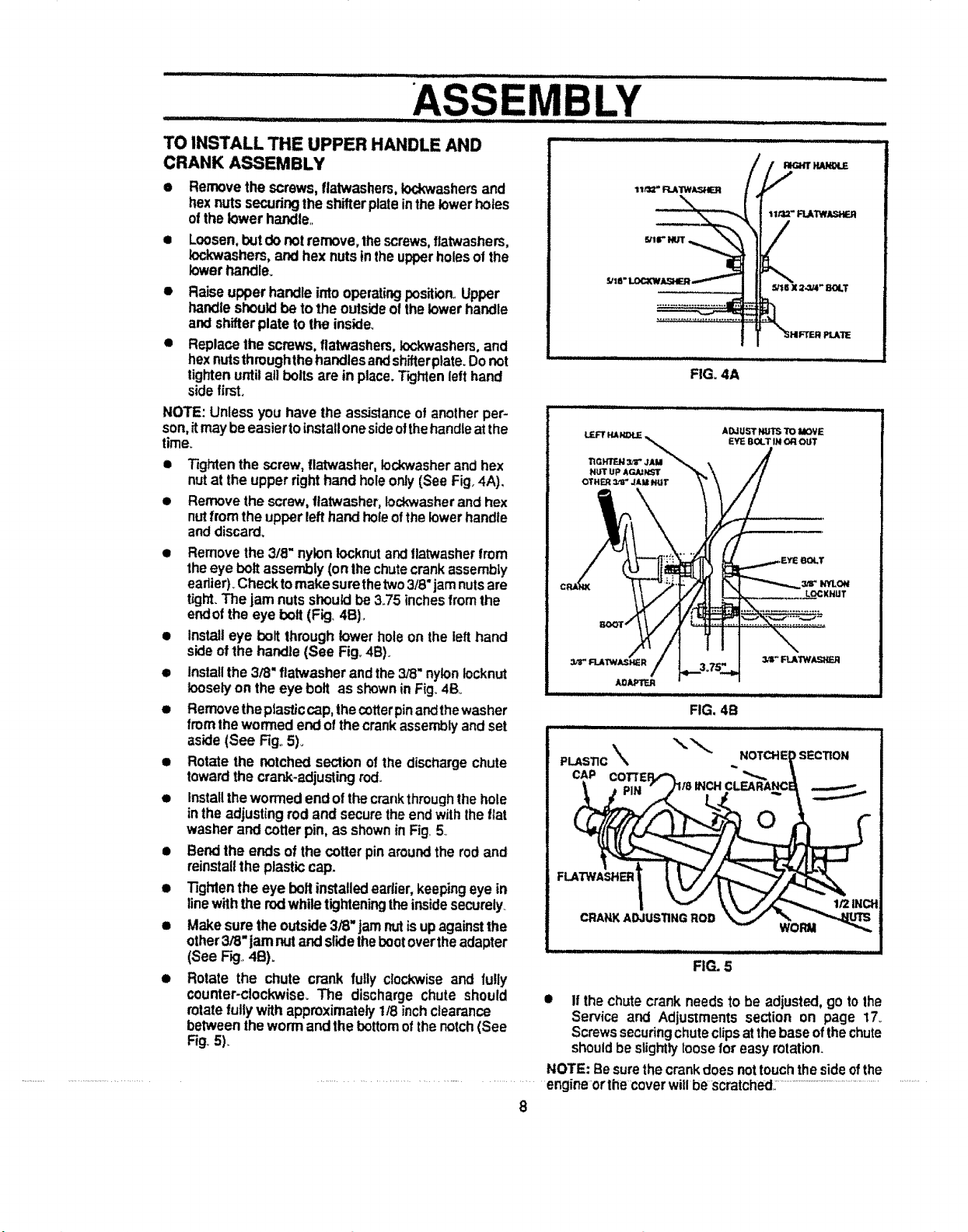

TO INSTALL THE UPPER HANDLE AND

CRANK ASSEMBLY

• Remove the screws, flatwashers, to.washers and

hex nuts secudng the shifter plate in the lower holes

of the lower handle..

• Loosen, t_Jt do not remove, the screws, flatwashers,

lockwashers, and hex nuts in the upper holes of the

lower handle_

• Raise upper handle into operating position., Upper

handle should be to the outside of the lower handle

and shifter plate to the inside.

• Replace the screws0 flatwashers, lockwashers, and

hex nutsthroughthe handles and shifter plate. Do not

lighten until all bolts are in ptace_ T'_jhten left hand

side first.

NOTE: Unless you have the assistance of another per-

son, it may be easier to install one side of the handle at the

time.

• Tighten the screw, flat'washer, Iockwasher and hex

nut at the upper dght hand hole only (See Fig, 4A),

• Remove the screw, flatwasher, Iockwasher and hex

nut from the upper left hand hole of the lower handle

and discard,

• Remove the 3/8" nylon iocknut and flatwasher from

the eye bolt assembly (on lhe chute crank assembly

eadier)_ Check to make sure the two 3/8" jam nuts are

tight. The jam nuts should be 3.75 inches from the

endof the eye bolt (Fig. 4B).

• Install eye bolt through lower hole on the left hand

side of the handle (See Fig., 4B)_

• Install the 3/8" ftatwasher and the 3/8" nylon locknut

loosely on the eye bolt as shown in Fig_ 4Bo

• Remove theptastic cap, the cotter pin andthewasher

from the wormed end of the crank assembly and set

aside (See Fig° 5)_

• Rotate the notched section of the discharge chute

toward the crank*adjusting rod..

• Install the wormed end of the crank through the hole

in the adjusting rod and secure the end with the flat

washer and cotter pin, as shown in Fig. 5

• Bend the ends of the cotter pin around the rod and

reinstall the plastic cap.

• Tighten the eye bolt installed earlier, keeping eye in

line with the rod while tightening the inside securely

• Make sure the outside 3/8" jam nut is up against the

other 3/8" jam nut and slide the boot over the adapter

(See F_,. 4B).

• Rotate the chute crank fully clockwise and fully

counter-clockwise, The discharge chute should

rotate fully with approximately 1/8 inch clearance

between the worm and the bottom of the notch (See

Fig. 5).

................................................. engine or the cover will be scratched,: ......................................................................

= _

• If the chute crank needs to be adjusted, go to the

NOTE: Be sure the crank does not touch the side of the

8

_'tB"

FIG. 4A

FIG. 5

Service and Adjustments section on page 17_

Screws securing chute clips at the base of the chute

should be slightly loose for easy rotation.

i/ J iui

Page 9

ASS LY

,llll

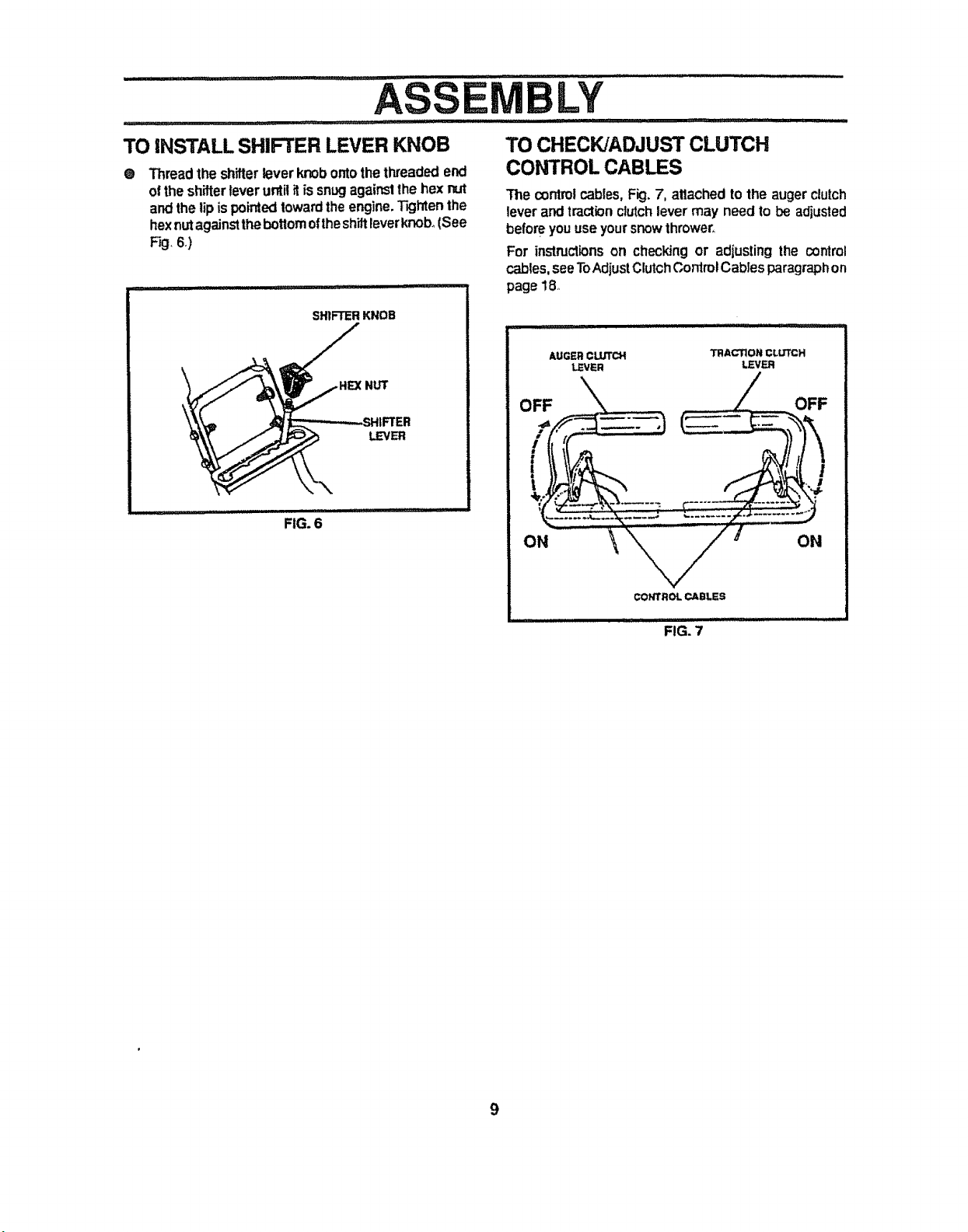

TO iNSTALL SHIFTER LEVER KNOB

0 Thread the shifter lever knob onto the threaded end

of the shifter lever until it is snug against the hex rut

and the lip is pointed toward the engine. T_jhten the

hex nut against the bottom of the shift leverknob_ (See

Fig, 6,)

..................... i ,,I,L

SNIFTER KNOB

NUT

LEVER

FIG. 6

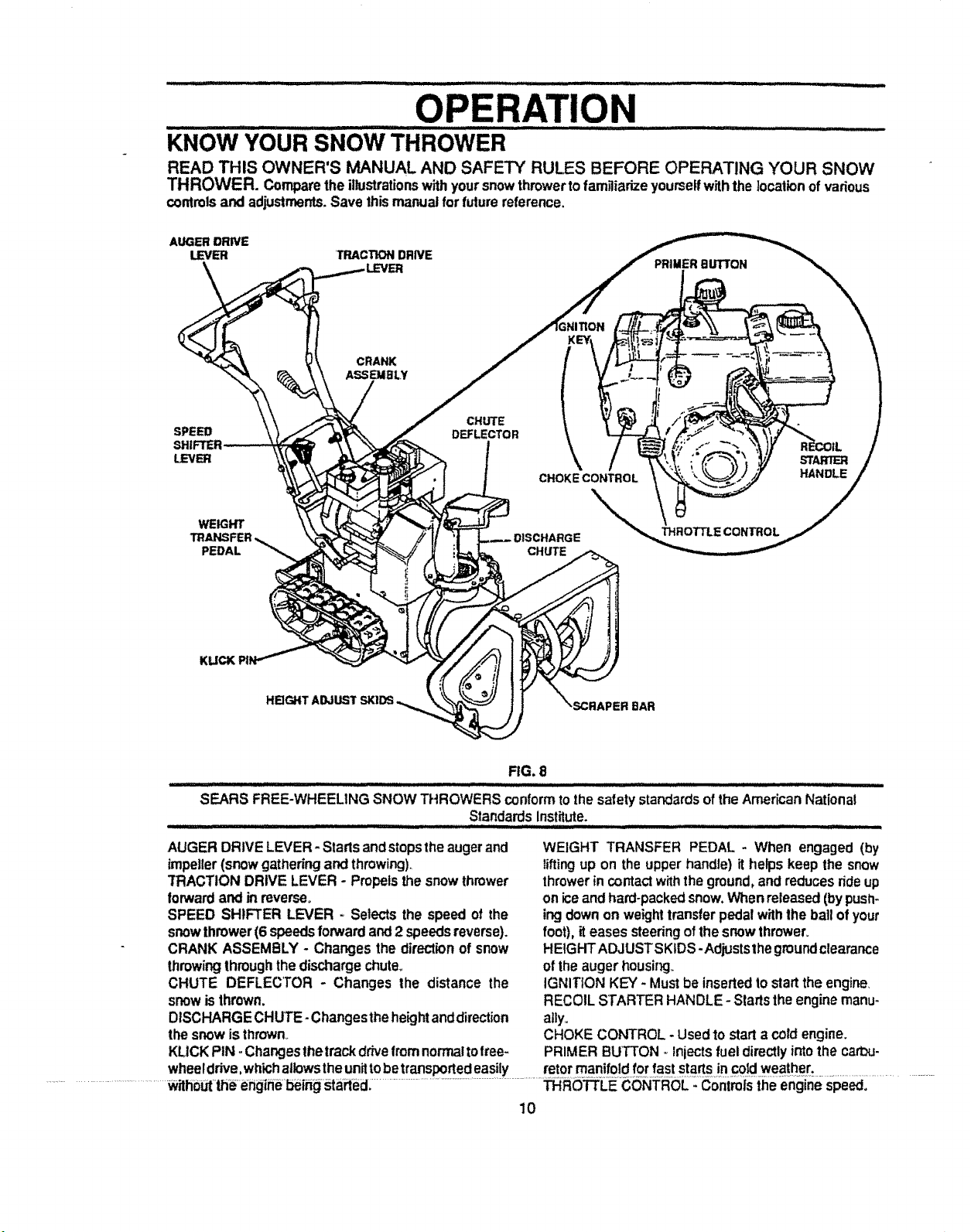

TO CHECKJADJUST CLUTCH

CONTROL CABLES

The control cables, Fig. 7, attached to the auger clutch

lever and traction clutch lever may need to be adjusted

before you use your snow thrower,,

For instructions on checking or adjusting the control

cables, see To Adjust Clutch Control Cables paragraph on

page 18,

i I I i,,11 iiiiiiiiiiii _T : :

AUGER CLUTCH TRACTION CLUTCH

LEVER LEVER

OFF OFF

ON ON

CONTROL CABLES

................ F,G. 7

Page 10

.......... IJWIILI IlU III IIII , , iiiiii IIIIIIIII I I II I IIIIII _ II I II i ..... III1'1111 i ii

OPERA: ION

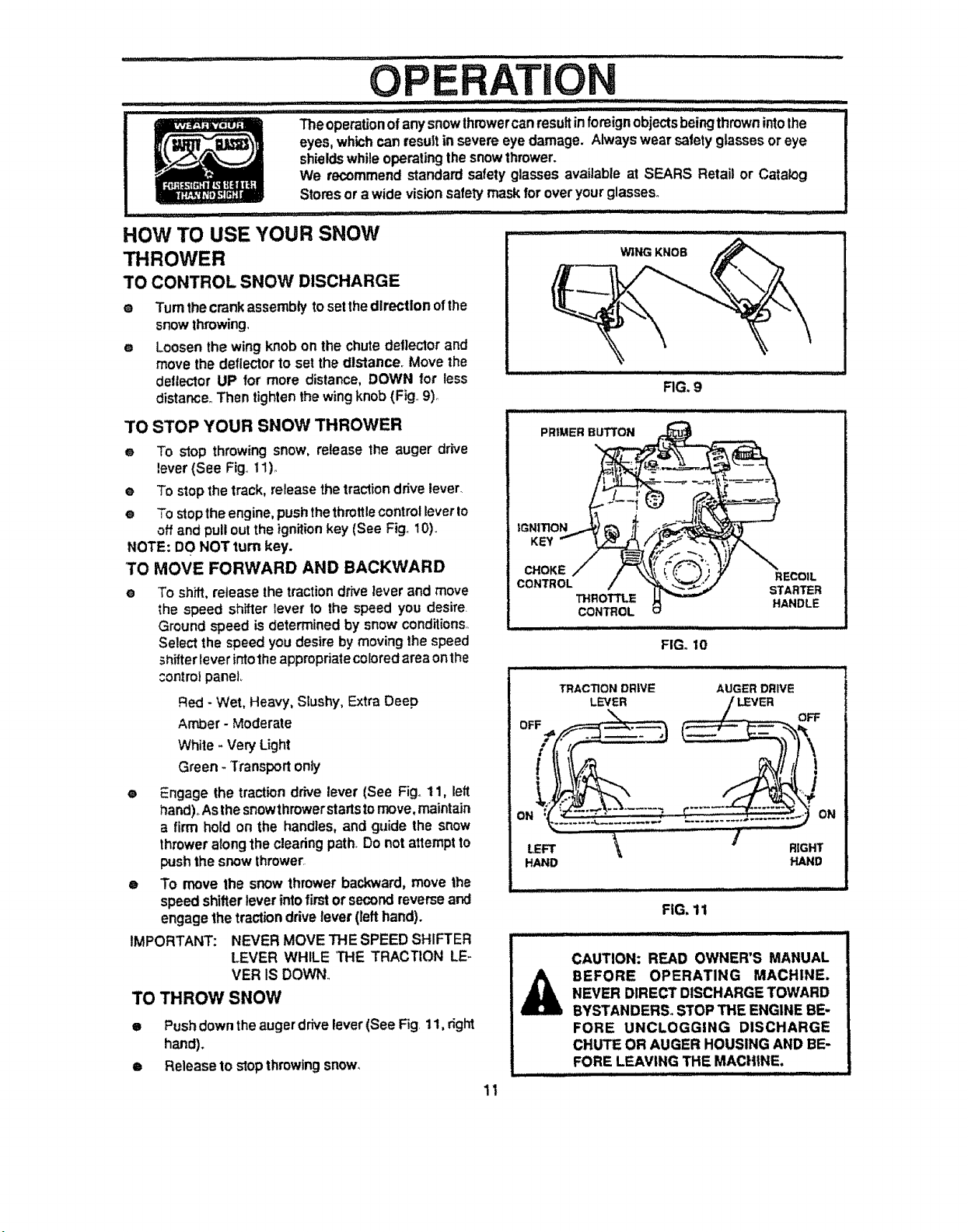

KNOwYOUR SNow THROWER .............................................................................

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR SNOW

THROWER. Compare the illustrations with your snow thrower to famgiarize yourseff with the location of vadous

commls and adjustments. Save this manual for future reference,

AUGER DRIVE

LEVER

SPEED

LEVER

WEmHr

PEDAL CHUTE

'TRACTION DRNE

CRANK

ASSEMBLY

CHUTE

DEFLECTOR

PRIMER B bq'TON

STARTER

CHOKE CONTROL HANDLE

THROTTLE CONTROL

HEIGHT ADJUST

FIG. 8

SEARS FREE-WHEELING SNOW THROWERS conform to the safety standards of the American National

Standards Institute.

AUGER DRIVE LEVER-Starts and stops the auger and

impeller (snow gatttering and throwing).

"rRACTION DRIVE LEVER - Propels the snow thrower

forward and in reverse,

SPEED SHIFTER LEVER _ Selects the speed of the

snow thrower (6 speeds forward and 2 speeds reverse).

CRANK ASSEMBLY - Changes the direction of snow

throwing through the discharge chute.

CHUTE DEFLECTOR - Changes the distance the

snow is thrown.

DISCHARGE CHUTE- Changes the height and direction

the snow is thrown

KLICK PIN - Changes the track drive from normal to free-

WEIGHT TRANSFER PEDAL * When engaged (by

lifting up on the upper handle) it helps keep the snow

thrower in contact with the ground, and reduces ride up

on ice and hard-packed snow. When released (by push-

ing down on weight transfer pedal with the ball of your

foot), it eases steedng of the snow thrower.

HEIGHTADJUSTSKIDS - Adjusts the ground clearance

of the auger housing_

IGNITION KEY. Must be inserted to start the engine.

RECOIL STARTER HANDLE- Starts the engine manu-

ally,,

CHOKE CONTROL - Used to start a cotd engine.

PRIMER BUTTON - Injects fuel directly into the cart_u-

wheeldrive,whk_haltowstheunittobettansportedeasily retor manifold for fast stars in cold weather.

................................... ........................................................................................................................ RO LE ihe engir e ............

10

Page 11

.............. i //_. ii, ii iii iiii ii i i i i iiiJllllllllllJll i 11111111 iii,

OPERATIO

I I II1,1 I11 iii1[11 i,iir

shields while operating the snow thrower.

I eyes, which can result in severe eye damage. Always wear safety glasses or eye

...... r=_l "lllqll_ll'lll" LI_

HOW TO USE YOUR SNOW

THROWER

TO CONTROL SNOW DISCHARGE

e Turn the crank assembly to setthe direction of the

snow throwing,

e Loosen the wing knob on the chute deflector and

move the deflector to set the distance Move the

deflector UP for more distance, DOWN for less

distance Then tighten the wing knob (Fig 9)_

We recommend standard safety glasses available at SEARS Retail or Catalog

Stores or a wide vision safety mask for over your glasses°

iiiiiii :

WING KNOB

RG. 9

TO STOP YOUR SNOW THROWER

e To stop throwing snow, release the auger drive

lever {See Fig 11)o

e To stop the track, release the traction drive lever.

e To stop the engine, push the throttle control lever to

off and pull out the ignition key (See Fig, 10)

NOTE: DO NOT turn key.

TO MOVE FORWARD AND BACKWARD

• To shift, release the traction drive lever and move

the speed shifter lever to the speed you desire

Ground speed is determined by snow conditions

Select the speed you desire by moving the speed

_hiffer lever into the appropriate colored area on the

control panel,

Red - Wet, Heavy, Slushy, Extra Deep

Amber - Moderate

White - Very Light

Green - Transport only

® Engage the traction drive lever (See Fig. 11, left

hand),, As the snowthrowerstarts to move, maintain

a firm hold on the handles, and guide the snow

thrower along the cleadng path Do not attempt to

push the snow thrower.

• To move the snow thrower backward, move the

speed shifter lever into first or second reverse and

engage the traction drive lever (left hand).

IMPORTANT: NEVER MOVE THE SPEED SHIFTER

LEVER WHILE THE TRACTION LE-

VER IS DOWN

TO THROW SNOW

e Pushdown the auger drive lever(See Fig, 11, dght

hand).

e Release to stop throwing snow.

PRIMER BUTTON

IGNITION

KEY

CHOKE RECOIL

CONTROL STARTER

LEFT RIGHT

HAND HAND

THROTTLE HANDLE

CONTROL

ill i ,,,H ii :

FIG. 10

TRACTION DRIVE AUGER DRIVE

LEVER

FIG. 11

_J LII III IIIIIIIII IIIIIIIIIIIIIII :: ....... _ ,,

CAUTION: READ OWNER'S MANUAL

BEFORE OPERATING MACHINE.

NEVER DIRECT DISCHARGE TOWARD

BYSTANDERS. STOP THE ENGINE BE,.

FORE UNCLOGGING DISCHARGE

CHUTE OR AUGER HOUSING AND BE-

FORE LEAVING THE MACHINE.

11

Page 12

...... 7IJIIIIMII IIIjIIIIIILI] ii L I'1 ill i Ill I iii iiil:llljii i ]_ l I illiilgilllJ J ........ II1'11 ill II II

OPERATION

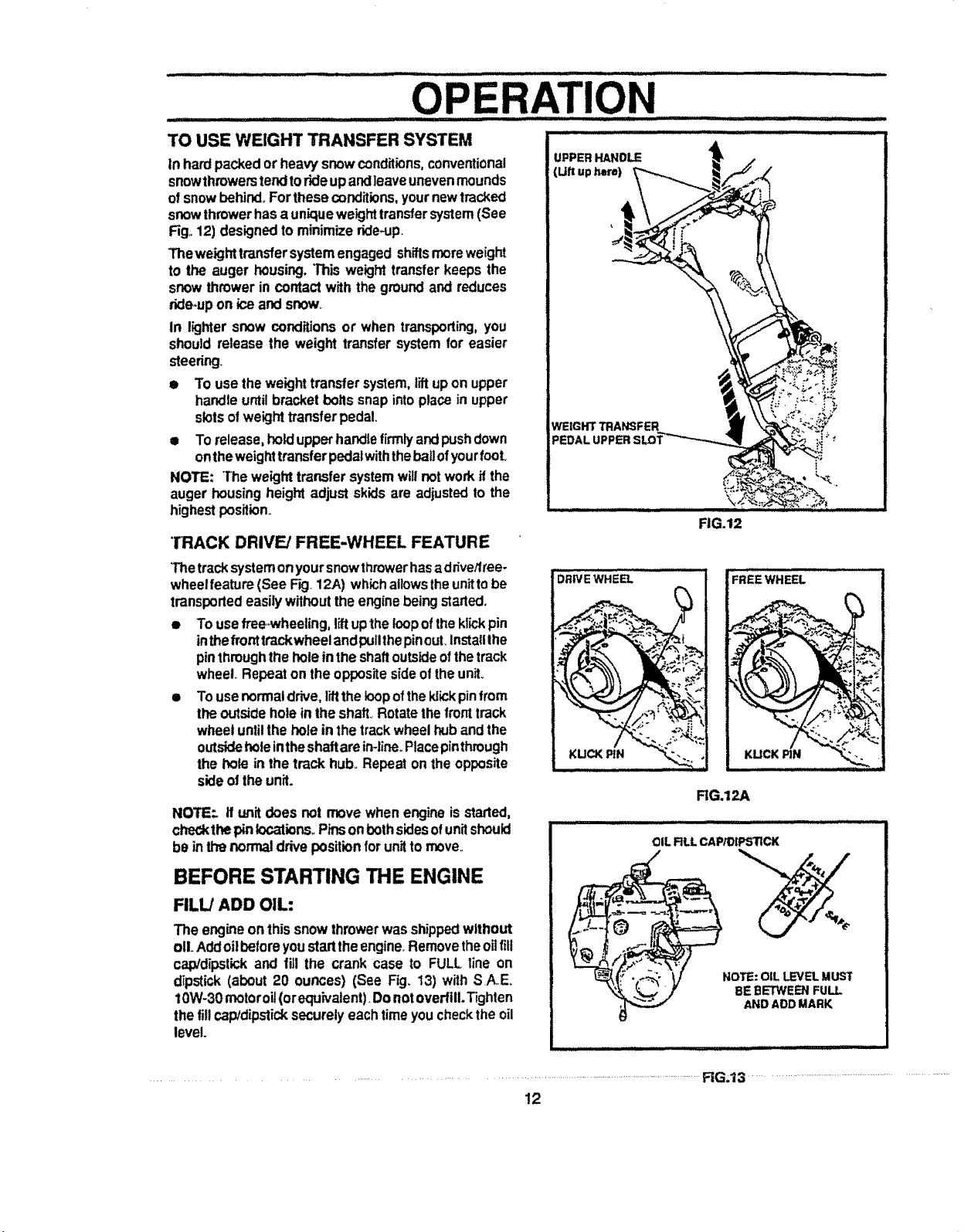

TO USE WEIGHT TRANSFER SYSTEM ....................................

tn hard packed or heavy snow conditions, conventional

snow throwers tend to ride up and leave uneven mounds

of snow behind. For these conditions, your new tracked

snow thrower has a unique weight transfer system (See

Fig,, 12) designed to minimize dde4Jp.

Theweight transfer system engaged shifts more weight

to the auger housing, This weight transfer keeps the

snow thrower in con*act with the ground and reduces

ride-up on ice and snow°

in lighter snow conditions or when transporting, you

should release the weight transfer system for easier

steedng.

• To use the weight transfer system, tilt up on upper

handle until bracket bolts snap into place in upper

slots of weight transfer pedal.

• To release, hold upper handle firmly and push down

on the weight transfer pedal with the bail of you r fool

NOTE: "[he weight transfer system will not work if the

auger housing height adjust skids are adjusted to the

highest position.

TRACK DRIVE/FREE-WHEEL FEATURE

(Uft up here)

WEIGHT TRANSFER

PEDAL UPPER SLOT'_

FIG.12

The track system on your snow thrower has a d dvetlree-

wheel feature (See Fig 12A) which allows the unit to be

transported easily without the engine being started.

• To use free_heeling, lift up the loop of the klick pin

in the front track wheel and pull the pin ouL Install Ihe

pin through the hole in the shaft outside of the track

wheel Repeat on the opposite side of the unit.

• To use normal drive, lift the loop of the Idick pin from

the outside hole in the shaft., Rotate the front track

wheel until the hole in the track wheel hub and the

outside hole inthe shaftare irHine_ Place pinthrough

the bole in the track hub_ Repeat on the opposite

side of the unit.

NOTE:. tf unit does not move when engine is started,

check the pin locations° Pins on both sides of unit should

be in the normal drive position for unit to move_

BEFORE STARTING THE ENGINE

FILL/ADD OIL:

The engine on this snow thrower was shipped without

oIL Add oil before you start the engine_ Remove the oil lilt

cap!dipstick and fill the crank case to FULL line on

d_pstick (about 20 ounces) (See Fig. 13) with SA, E.

10W-30 motoroil (orequivalent)_ Do not overfill. Tighten

the fill cap/dipstick securely each time you check the oil

level.

DRIVE WHEEL

RG.12A

i ......... ..........

.....

'_ _tk_,' ,/' BE1BETWEENFULL

AND ADD MARK

........................................................................................................... RGJ3 ...........................................................................................

!2

Page 13

' i ii , ,i ,r, , ii, L I1' I I I I,lll ,.I

OP TI

FILL GAS:

Fill the fuel tank with clean, fresh, unleaded grade

autornotive gasoline. Be sure that the container you pour

the gasoline from is clean and free from rust or other

foreign particles. Never use gasoline that may be stale

trom tong periods of storage in the container.,

NOTE: S,,A,,E_ 5W-30 motor oil may be used to make

starting easier in areas where the temperature is 20" F,

or lower,,

WARNING: Experience indicates that aP..ohol blended

fuels (called gasohot or those using ethanol or methanol)

can attract moisture which leads to separation and for-

mation of acids during storage. Acidic gas can damage

the fuel system of an engine while in storage

To avoid engine problems, the fuel system should be

emptied before storage for 30 days or linger Start the

engine and let it run until the fuel lines and carburetor are

empty. Use the carburetor bowl drain to empty residual

gasoline from the float chamber (Fig 42) Use fresh fuel

next season° (See Storage instructions on page 25 for

additional information°)

Never use engine or carburetor cleaner products in the

fuel tank or permanent damage may occur.

.... i,i ill,ill i, ii ill, i ii

CAuTIoN: GASOL,NE is FLA"ABLE

_L AND CAUTION MUST BE USED WHEN

DO NOT FILL FUEL TANK WHILE SNOW

THROWER RUNN,NG,WHEN rr IS HOT, OR

WHEN SNOW THROWER S IN AN ENCLOSED

AREA.

KEEP AWAY FROM OPEN FLAME OR AN ELEC-

TRICAL SPARK AND DO NOT SMOKE WHILE

FILLING THE FUEL TANK.

NEVER FILL THE TANK COMPLETELY. FILL

THETANKTO WITHIN 1/4"-1/2" FROMTHETOP

TO PROVIDE SPACE FOR EXPANSION OF FUEL

ALWAYS FILL FUEL TANK OUTDOORS AND

USE A FUNNEL OR SPOUT TO PREVENT SPILL-

ING.

MAKE SURE TO WIPE UP ANY SPILLED FUEL

BEFORE STARTING THE ENGINE.

STORE GASOUNE IN A CLEAN, APPROVED

CONTAINER AND KEEP THE CAP IN PLACE ON

THE CONTAINER.

i .............. ......

HANDUNG OR STORING ITo

.............. ii ,,

CAUTION: NEVER RUN ENGINE IN-

DOORS OR IN ENCLOSED, POORLY

VENTILATED AREAS. ENGINE EX-

HAUST CONTAINS CARBON MON-

OXIDE, AN ODORLESS AND DEADLY GAS.

KEEP HANDS, FEET, HAIR AND LOOSE

CLOTHING AWAY FROM ANY MOVING PARTS

ON ENGINE AND SNOW THROWER.

WARNING: TEMPERATURE OF MUFFLER AND

NEARBY AREAS MAY EXCEED 150 ° F. AVOID

THESE AREAS.

DO NOT ALLOW CHILDREN OR YOUNG TEEN-

AGERS TO OPERATE OR BE NEAR SNOW

THROWER WHILE IT IS OPERATING.

TO STOP ENGINE

e To stop engine, move the throttle control lever to

STOP position and remove key, Keep the key in a

safe place., The engine will not _lart without the key,_

TO START ENGINE

Be sure that the engine has sufficient oil Before starling

the engine, be certain that you have read the folliwing

information:

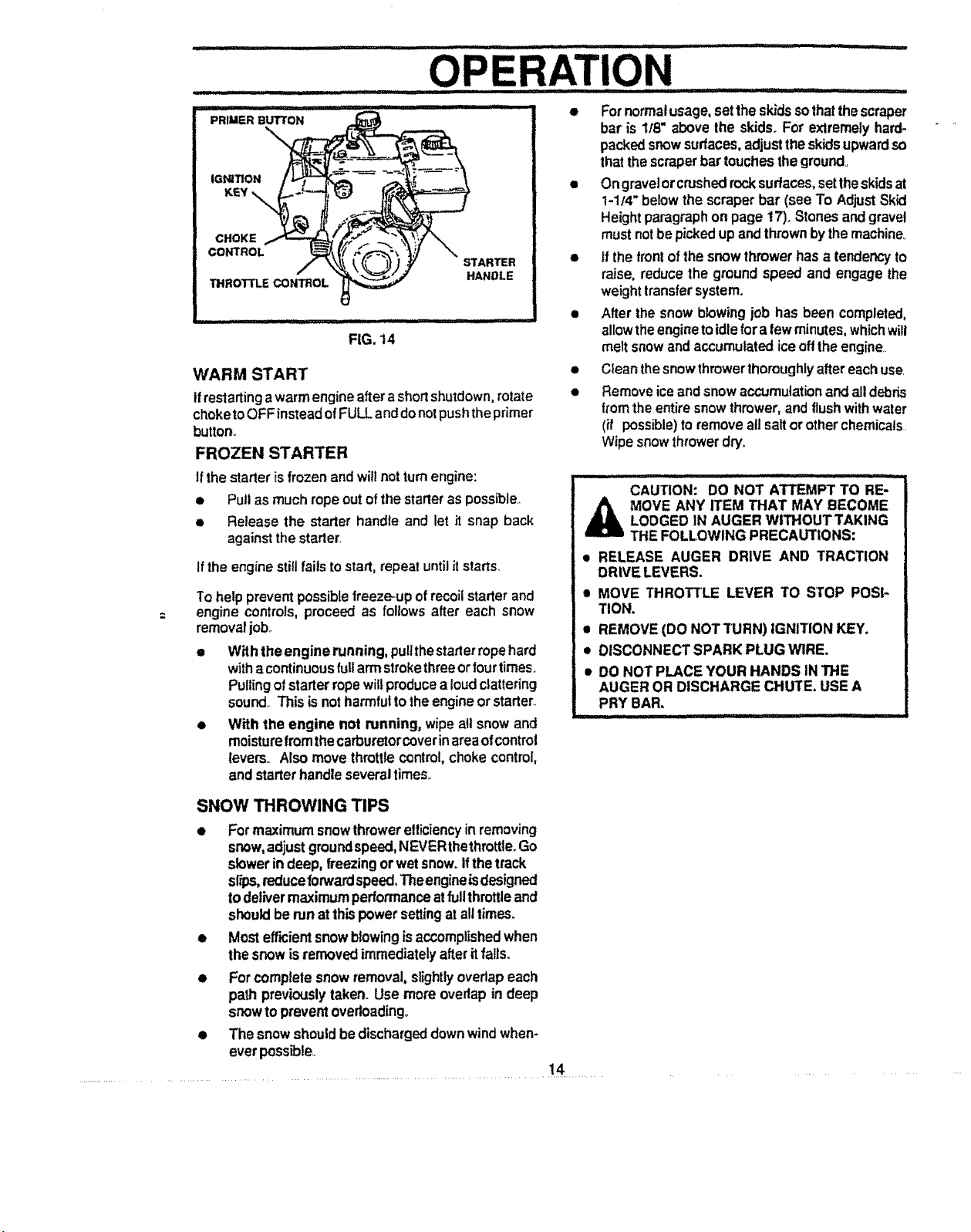

COLD START (See Fig. 14)

e Be sure the augerddve and the traction drive levers

are in the disengaged RELEASED position,

Move the throttle control up to RUN position. tp

O Push the key into the ignition slot found in parts

page, Be sure it snaps into place._ DO NOT TURN

KEY., Place extra key in a safe place.,

o Rotate choke contro! to FULL choke position,

o Press the primer I_Jtton in cold weather Press

two or three times, whife keeping your linger over

the vent hole on the pdmer button_ Additional

pdming may be necessary for the first start if the

temperature is below t5 ° F,, Do not prime it tem-

perature is above 50 ° F.

=, Pull the starter handle rapidly. Do not allow the

handle to snap back, but allow it to rewind slowly

while keeping a firm hold on the starter handle,,

® As the engine warms up and begins to operate

evenly, rotate the choke knob slowly to OFF

position° ff the engine falters, return to FULL choke,

then slowty move to OFF choke position_

NOTE: Before using the snow thrower, allow the engine

to warm up for a few minutes because the engine will not

developfult poweruntil it reaches operating temperature°

• Run the engine at or near the top speed when

throwing snow.,

13

Page 14

ii_pr_ iiiiii ........... it 7 ............... IIIIg JL iiiiiii lIIIILII I'IIIII lilt ._: _ . Ill'It' IJI

OPERATION

iiiiii, , i, iii i1,111 i ........................................

PRIMER BUTTON

IGNITION

KEY

CHOKE

CONTROL STARTER

THROTTLE CONTROL HANDLE

FIG, 14

WARM START

tf restarting a warm engine after a short shutdown, rotate

choketo OFF instead of FULL and do not push the primer

button..

FROZEN STARTER

If the starter is frozen and wilt not turn engine:

• Pull as much rope out of the starter as possible.,

• Release the starter handle and let it snap back

against the starter.

If the engine still fails to start, repeat until it starts_

To help prevent possible freeze-up of recoil starter and

engine controls, proceed as fol!ows after each snow

removal job..

o With the engine running, pull the starter rope hard

with a continuous full arm stroke three or four times.

Pulling of starter rope will produce a loud clattering

sound.. This is not harmful to the engine or starter..

• With the engine not running, wipe all snow and

moisture from the carburetor cover in area of control

levers., Also move throttle control, choke control,

and starter handle several times,

e

For normal usage, set the skids so thai the scraper

bar is 1/8" above the skids, Fo_" extremely hard-

packed snow surfaces, adjust the skids upward so

that the scraper bar touches the ground.,

• On gravel or crushed rock surfaces, set the skids at

t-1/4" below the scraper bar (see To Adjust Skid

Height paragraph on page t7). Stones and gravel

must not be picked up and thrown by the machine,.

• If the front of the snow thrower has a tendency to

raise, reduce the ground speed and engage the

weight transfer system.

• Alter the snow blowing job has been completed,

allow the engine to idle for a few minutes, which will

melt snow and accumulated ice oft the engine

• Clean the snow thrower thoroughly after each use.

• Remove ice and snow accumulation and all debris

from the entire snow thrower, and flush with water

(if possible) to remove all salt or other chemicals.

Wipe snow thrower dry,,

i=l ..... -- : .......... ::.:_ .... i

CAUTION: DO NOT ATTEMPT TO RE,,

LODGED IN AUGER WITHOUT TAKING

MOVE ANY ITEM THAT MAY BECOME

THE FOLLOWING PRECAUTIONS:

e RELEASE AUGER DRIVE AND TRACTION

DRIVE LEVERS.

• MOVE THROTTLE LEVER TO STOP POSI-

TION.

• REMOVE (DO NOTTURN) IGNITION KEY,

• DISCONNECT SPARK PLUG WIRE.

• DO NOT PLACE YOUR HANDS IN THE

AUGER OR DISCHARGE CHUTE. USE A

PRY BAR.

illl i ' ' ............

SNOW THROWING TIPS

• For maximum snow thrower efficiency in removing

snow, adjust ground speed, NEVERthethrottle. Go

slower in deep, freezing or wet snow. It the track

sr_s, reduce forward speed, Theengineis designed

to deliver maximum performance at fullthrottle and

should be run at this power setting at all times.

• Most efficient snow blowing is accomplished when

the snow is removed immediately after it falls.

• For complete snow removal, slightly overlap each

path previously taken. Use more overlap in deep

snow to prevent ovedoading_

• The snow should be discharged down wind when-

ever possible..

................................................................. !4 ...........

Page 15

MAINTENANCE

GENERAL RECOMMENDATIONS

The warranty on this snow thrower does not cover items

that have been subjected to operator abuse or negli-

gence,. To receive full value from the warranty, operator

must maintain snowthrower as instructed in this manual.

Some adjustments will need to be made periodically to

propedy mainlain your snow thrower,

All adjustments in the Service and Adjustments section of

this manual should be checked at feast once each

season,

AFTER FIRST USE

e Check thetracks for tension and adjust if necessary

(See To Adjust Track paragraph on page 23).

Checkthe track adjustment and fasteners reguladyr

e Be sure that all tasteners are tight..

AS REQUIRED

The following adjustments should be performed more

than once each season.

e Auger and Track Drive Belts shouid be adjusted

alter the first 2 hours of use and again after 25 hours

and at the beginning o! each season SeeTo Adjust

Belts paragraph on page 19

e All screws and nuts should be checked often to

make sure they are tight, pre{erabty alter each use.

SNOW THROWER

LUBRICATION - EVERY TEN HOURS

• Weight Transter System _ Coat weight transler side

plates with clinging type grease, such as Lubrip_ate,

every ten (10) hours and before storage,, See Lu-

brication Chart on page 26

e Auger Shaft- Using a hand greasegun,lubricatethe

auger shaft zerk fittings (See A, Fig 16) every ten

(10) operating hours, Each time a shear bolt is

replaced (see TO Replace Auger Shear Bolt para -

graph on page 23), the augershaft MUSTbe greased,

e For storage or when replacing shear boils, remove

shear boils and lubricate auger shaft zed_s,, Rotate

augers several times on the shaft and reinstal! the

shear bolts.

LUBRICATION - NOT REQUIRED

e Hex Shaft and Gears- Hex shaft and gears require

no lubrication, Altbearings and bushings are liletime

lubricated and require no maintenance (See Fig 17),,

NOTE: Any greasing or oiling of the above components

can cause contamination ol the friction wheel, If the disc

drive plate or friction wheel come in contact with grease

or oil, damage to the friction wheel will result,,

(PULL UP GENTLY AT CENTER)

FIG. 15

............ ,,r,;,,'r' ' "

FIG. 16

FRICTION

WHEEL

CHAINS

Should grease or oil come in contact with the disc drive

plate or friction wheel, be sure to clean the plate and

wheel thoroughly_

NOTE: For storage, the hex shaft and gears should be

wiped with 10W-30 motor oitto prevent resting (See Fig..

17)_

e Auger Gear Box - The auger gear box has been

factory lubricated for lite If for some reason lubri-

cant should leak out, have augergear case checked

by a competent repairrnan_

15

HEX

SHAFT

Page 16

1111 1111,11,1111111 , 1111111111111 I I' iii , i , i [ii I 111111 111111,,, 111 ::: IILI

TENANCE

ENGINE .... :

LUBRICATION

Check the crankcase oil level (See Fig. 18) before

starting the engine and after each five (5) hours of

continuous use° Add S.A.E_ 10W-30 motor oil or equ iva-

lenL Tighten fill capldipstick securely each time you

check the oil level SA,E_ 5W-30 motor oil may be used

to make starting easier in areas where the temperature

is 20 ° F or iower_

Changethe oil afterlirst two hours of operation and every

25 hours thereafter or at least once a year if the snow

thrower is not used for 25 hours (See Fig. 19).

• Position snow thrower so that the oil drain ptug is

lowest point on the engine. Remove oil drain plug

and oil fill captdipstick,. Drain oil into a suitable

container. Oil will drain more freely when warm,

• Replace oil drain plug and tighten securely,, Refill

crankcase with S_A E, i0W-30 motor oit (or equiva-

lent). S.A_E,. 5W-30 motor oil may be used to make

starting easier in areas where the temperature is

20 ° F or Iower_

: '11'1 '1 I t' i ........

i = u

FIG, 18

Hi ,ill ]lw

OIL FILL CAP/

DIPS'lICK

SPARK PLUG

• Make sure that the spark plug is tightened securely

into the engine and the spark pJug wire is attached

to the spark plug_

• If a torque wrench is available, torque plug to 18 to

23 foot pounds.

• Clean the area around the spark plug base before

removal to prevent dirt from entering the engine,

• Clean the spark plug and reset the gap periodically

ILl III I L I_I I'III I I I ..........

FIG. 19

16

Page 17

: ..... i,ii i,,ll_ i ,,11 ,i i, _, Ii

....... $ ..... CE AND ADJUST TS

: ............... : .......... ,,,, ,,,,,, i

::: _ ,ll,lll,lll,l,i ....... ii ,,

SPARK PLUG WIRE AND 'TIE BACK

AWAY FROM THE PLUG BEFORE MAK-

CAUTION: ALWAYS DISCONNECT THE I

ING ANY ADJUSTMENTS OR REPAIRS.

iii .

TO ADJUST SKID HEIGHT

This snow thrower is equipped with two height adjust-

merit skids, located on the outside of the auger housing

(See Fig. 20)° These skids elevate the front of the snow

thrower. For normal hard surfaces, adjust the skids as

follows:

e Make sure the weight transfer system is released

by holding upper handle firmly and pushing down

weight transfer pedal with the ball of your foot.

® Place extra shear bolts suppiied (found in parts

bag) under each end of the scraper bar near but not

under the skid..

e Loosen the skid mounling nuts (See Fig. 20) and

push the skid down until it touches the ground..

Retighten the mounting nuts.

® Set the skid on the other side at same heighL

For rocky or uneven surfaces, raise the front of the snow

thrower by moving the skids down furthers. This wifl help

prevent rocks and other debris from being picked up and

thrown by the auger

NOTE: if the skids are at the maximum height, the weight

transfer system will not work..

TO ADJUST SCRAPER BAR

After considerable use, the metal scraper bar will have

a detinite wear patternr The scraper bar may have to be

returned to its odginal lower setting to maintain the

original performance lever. To adjust:

o Position the snow thrower on a level surface

o Loosen the carriage bolts and nuts securing the

scraper bar _o the auger housing.

o Adjust the scraper bar to the proper position.

® Tighten the carriage bolls and nuts, making sure

:hat the scraper bar is parallel with the working

surface.

SKID MOUNTING NUTS

AUGER HOUSING

FIG. 20

0

Afler extended operation_ the scraper bar may be

HEIGH3 r ADJUST SKiD

i

i,l,,lll ,i ,,,

reversed if the scraperbar must be replaceddueto

wear, remove the carriage botts and nuts and install

a new scraper bar.

TO ADJUST CHUTE

CRANK ASSEMBLY

tf you cannot rotate the chute crank fully to the left and to

the right, you need to adjust the chute crank (See Fig. 21)

e Loosen both 1t2" nuts on the crank adjusting rod

(using 3/4" wrenches).

e Rotate the adjusting rod in or out to allow about

1/8" clearance between the notch in the flange and

the ouler diameter of the worm..

e Once this clearance is set, tighten the nuts

NOTE: Be sure the crank does not touch the side of the

engine or the cover will be scratched°

PLASTIC

CAP COTTER/-'_.

NOTCHED SECTION

CAUTION: BE CERTAIN TO MAINTAIN

PROPER GROUND CLEARANCE FOR

YOUR PARTICULAR AREA TO BE

CLEARED. OBJECTS SUCH AS

GRAVEL, ROCKS OR OTHER DEBRIS,

IF STRUCK BY THE IMPELLER, MAY BE

THROWN WITH SUFFICIENT FORCE TO

CAUSE PERSONALINJU RY, PROPERTY

DAMAGE OR DAMAGE TO THE SNOW

THROWER.

FIG. 21

17

Page 18

: IIIIIIII iiii iiiii ,111 I I iiii LL LI3UIL III1' ' iiiiiii ii IIIII I ,i

, S ...........

E AND ADJUSTMENTS

TO ADJUST THE CLUTCH CONTROL

CABLES

Pedodic adjustment of the cables may be required due to

non'natstretch andwearonthe belts Tocheck for correct

adjustment, the control lever must be in Ihe full forward

position, resting on theplasticbumper+Thecontrol cables

are correctly adjusted when the center of the"Z" Fitting is

in the center of the hole and there is no droop in the cable

(See Fig, 22),,

If adjustment is necessary:

• Remove gas from gas tank+ Stand blower on end

e Disconnect the "Z" Fitting from drive lever.

• Push the cable through the spring (See Fig+ 23) to

expose the threaded portion of the cable+

• Hold the square end of the threaded portion with

pliers and adjust the Iocknut in or out until the excess

slack is removed,,

e Pull the cable back through the spring and connect

the cable. Do the same for the other lever cabte+

NOTE: Whenever the traction drive or auger belts are

adjusted or replaced, the cables will need to be adjusted.

TO ADJUST BELTS

Belts stretch during normal use+ If you need to adjust

the belts due to wear or stretch, proceed as follows:

TRACTION DRIVE BELT (See Fig. 25)

The traction drive belt has constant spring pressure and

does not require adjustment,, Check the clutch control

cable adjustment before replacing the belt

Replace the traction drive belt if it +s still slipping (see To

Replace Belts paragraph on page 19).

AUGER DRIVE BELT (See Fig. 25)

If your snow thrower will not discharge snow, check the

control cable adjustment+ if it is correct, then check the

condition of the auger drive bell tt may be loose or

damaged+ If it is damaged, replace it. See To Replace

Belts paragraph on page 19+ If the auger drive belt is

loose, adjust as follows:

• Disconnect the spark plug wire.

Remove the belt cover_ e

o

Loosen the nut on the idler pulley (See Fig+ 25) and

move the pulley toward the belt about 1/8",,

• Tighten the nut.

• Press the auger drive tever_ Check the tension on

the belt (opposite idler pulley) The belt should

deflect about 1/2" with moderate pressure (See Fig+

24)+

NOTE: You may have to move the idler pulley more than

once to obtain the correct tension

e Replace the belt cover.

............. _ II IIIII iiii1,1,11111 ii '1 I

i ................. ,i II ..........................

TRACTION DRIVE _

LEVER _"_..,___?.

"Z" FITTING

CONTROL LEVER

MUST BE IN FULL

FORWARD POS_.

TION (Ju=t Contact.

lng Plastic Bumper)

WHEN CHECKING

_'_ PLASTIC BUMPER

FIG+ 22

TRACTION

DRIVE

FIG. 23

-- ........................... iiiiii i II

. DFIIVE PULLEY

ID_R PULLEY---_ } .__',_4.,_ DEFLEC33ON

_ I12 INCH

\ ' /---i.PeLLER

iiiij/ :,, _ _,,: _: .........

FIG. 24

............. i ...........

TRACTIO. Drove .ELT ......... ,dGE. R+VE B .T

TRACTION DRWE BELT GUIDE

PULLEY (Left Hand)

BELT GUIDE AUGER

(Right Hind) PULLEY

DRIVE AUGER IDLER

IDLER PULLEY PULLEY

FIG+ 25

• Check the clutch control cable adjustmenL

• Reconnect the spad_ plug wire.

PULLEY

Page 19

i1,,,, i ..... i i iiii,

,. SERVICE AND

TO REPLACE BELTS

The drive belts on this snow thrower are o! special

construction and should be replaced with original

equipment belts available from your nearest SEARS

Store or Service Center_

You will need the assistance of a second person while

replacing the belts°

Drain the gasoline from the fuel tank by removing the fuel

line., Drain the gas and reinstall fuel line,,

AUGER DRIVE BELT

If your snow thrower wilt not discharge snow, and the

auger drive belt is damaged, replace it as to!lows:

® Disconnect the spark plug wire.

o Remove the belt cover (See Fig,, 26).

® Loosen the belt guides (See Fig° 27) and pull away

from the drive pulley.

e Loosen the auger idler pulley (See Fig. 28) and slip

the belt out.,

e Remove top two bolls that secure auger housing

to motor mount frame. Loosen bottom two bolts.,

Auger housing and motor mount Irame will separate

hinged by bottom two bolts.

e Remove brake arm from housing, Do not remove

spdng,

e Remove the belt from the auger drive engine pulley

e Install the original equipment replacement bell in

reverse order of removal,

e Reinstall brake arm into housing,, Insure brake arm

is fully inserted into housing and brake pad is riding

in pulley groove°

0

Position drive belt onto the auger drive putley,

0

Adjust thedr_ve belt (seeTo Adjust Auger Drive Belt

paragraph on page 18),,

0

Adjust the belt guides (see To Adjust The Belt

Guides paragraph on page 20)+

0

Reinstall the belt cover.

O

Check clutch control cable adjustment (see page

18)+

• Reconnect the spark plug wire,,

(Right Hand)

TRACTION DRIVE

IDLER PULLEY

_32

{Righ! Hand)

AUGER

PULLEY ENGAGED

GUIDE

(Lalt Hand)

AUGER

DRIVE

BELT

:R DRIVE

PULLEY

PULLEY

FIG, 27

!11' ll_j II I

BELT GUIDE

Hand)

3/32 INCH

IMPELLER

PUL L_Y

,,i,, iii ,lira i,,,,11,

FIG. 28

19

Page 20

SERVICE AN ,.,DJUSTMENTS

ijj ii I1' ,111111 :: I'J ..... I

TRACTION DRIVE BELT TO ADJUST THE FRICTION WHEEL

If your snow thrower wilt not move forward, check the

traction drive belt for wear. tfthe traction drive belt needs

to be replaced, proceed as follows:

• Disconnect the spark plug wire.

e

Remove the belt cover (See Fig. 26).

o

Loosen belt guides (See Fig.. 27) and pull belt guides

away from the engine drive pulley..

e

Loosen nut on augeridler and pull auger idler pulley

away from bell

o

Remove auger drive belt from engine pulley.

e

Pull drive belt idler pulley away from drive belt

Remove drive belt..

i

e

Position new drive beft onto traction pulley.

e

Pull idler puUey away from belt, ailowing belt to be

positioned onto engine pulley

e

Release idler pulley Ensure idler pulley is properly

engaged with belt.

e

Adjust belt guides (see To Adjust The Belt Guides

paragraph below).

e

Reinstall the belt cover..

e

Reconnect the spark plug wire.

TO

ADJUST THE BELT GUIDES

After you replace a track or auger drive belt, you need to

adjust one or both of the belt guides. Proceed as follows:

e Disconnect the spark p_ug wirer

• Remove the belt cover (See Fig 26)

• Engage the auger drive clutch lever_

• Measure the distance between the belt guides and

the belt (See Fig. 28).. The distance should be 3/32"

for each guide_

• If adjustment is necessary, loosen the belt guide

mounting bolts. Move the belt guides to the correct

position. Tighten the mounting bolts

e Reinstall the belt cover..

• Reconnect the spark plug wire.

If the snow thrower will not move forward, you need to

check the track drive belt, the traction drive cable or the

friction wheel, If the friction wheel is damaged; it will need

to be replaced. See the To Replace Friction Wheel

paragraph on page 21 .. If the friction wheel is not worn.

check the adjustment, as follows:

e Disconnect the spark plug wire,

• Drain the gasoline from the gas tank.

• Stand snow thrower on the auger housing end.

• Remove the bottom panel (See Fig. 29)

• Position the shifter lever in first (1) gear.

• Note the position of the friction wheel on the disc

drive plate. The right outer side of the disc drive plate

should be 3" from the center of the friction wheel

(See Fig,. 30).

if adjustment is necessary:

• Loosen nut "A" on the speed select rod.. Remove

the ball joint by removing nut "B" from the shift yoke

assembly_ Lengthen or shorten the rod by turning

the adaptor to obtain the correct friction wheel po.

sition (See Fig, 31),

• Reinstall the ball joint and nut "Bo" Tighten nut "A."

• Reinstall the bottom panel

WHEEL

/

/

- ............... /, .......

LOOSEN BOLT:_ :

i

....................... FIG, 29 ...................................................................................................................................... FlG.31 .................................................................................

REMOVE BOLT

OTTOM PANEL

li I BOTTOM PANEL

,,-.-- LOOSEN BOLT

2O

SPEED SELECT

ROD

ADAPTOI

8ALL JOINT _ NUT "B"

YOKE

ASSEMBLY

Page 21

SERVICE ................................................................ ADJUSTME TS

TO REPLACE FRICTION WHEEL

t!the snow thrower will not move forward, and the friction

wheel is worn or damaged, you need to replace it, as

follows: (First allow the engine to cool).

ti, tt ,i, ii, t, ttttti, t t ,t _tt it ,t,t,,ttt,_

I ,_ CAUTION: DRAIN GASOMNE OUTDOORS I

AWAY FROM FIRE OR FLAME. i

e Drain the gasoline from the fuel tank,.

e Disconnect the spark plug wire

e Stand the snow thrower up on the auger housing

end (See Fig. 34),,

o Remove the bottom panel (See F3g., 32)

e Remove ball joint from shift yoke assembly.,

o ._emove the three (3) fasteners securing the friction

:Jneel to the hub (See Fig 34), and set fasteners

_side,_

® _emove the four bolts securing bearing plates (both

_ides],

I t ' "_"L

,lira L

FRICTION WHEEL,,

_H LOCKWASHER

BOLT

T

FIG. 33

i,,i ....

FRICTION WHEEL

HEX SHAFT

I

EMOVE BOLT

,_ REMOVE BOLT

lit

LOOSEN BOLT -,,_

• _emot, e fhe right side bearing plate.. Leave hex

shaft in original position.

e Remove friction wheel from hub., Slip friction wheel

off hex shaft towards right sfde_

® Position new friction wheel onto hub._ See Fig. 34.

• Install bearing plates to original position., Ensure

hex shaft is engaged with both bearing plates.

e Secure bearing plates, using boils removed earlier

• Secure friction wheel to hub, using fasteners re

moved earlier, Ensure hex shaft turns freely.

• Reinstall ball joint to shift yoke assembly,,

• Should friction wheel require adjustment, see To

Adjust The Friction Wheel on page 20

....... ........... _ LOOSEN BOLT

e'_

TRACK CONNECTING ROD

FIG, 32

BEARING

PLATE

BOLTS

FASTENERS

(Screws_, '"" '

Iockwashers,

and nuls)

(UNIT STANDING ON

AUGER HOUSING END)

BEARING

PLATE

BOLTS

\;, AUGER

tJSING

FIG. 34

NOTE: Ensure friction wheel and friction disc are free

from grease or oil

• Replace bottom panel,

2!

Page 22

......... SERVICE AND ADJUSTMENTS ......

.............. i ii ......... .............. iii/1_1'1'_ _,

TO REPLACE AUGER SHEAR BOLT " '":'

The augers are secured to the auger shaft with special

bolts (See Fig. 35) that are designed to break (to protect

the machine) if an obiect becomes lodged in the auger

housing. Use of a harder bolt wiU destroy the protection

provided by the shear bolt.

IMPORTANT: TO iNSURE SAFETY AND

PERFORMANCE LEVELS, ONLY

ORIGINAL EQUIPMENT SHEAR

BOLTS SHOULD BE USED.

To replace a broken shear bolt, proceed as follows:

• Move the throttle to STOP and turn off all controls,.

• Disconnect the spark plug wire.. Be sure all moving

parts have stopped,

• Lubricate the auger shaft zerk fitting (see the Main

tenance section, pages 15-16).

• Align the hole in the auger with the hole in the auger

shaft. Install the new shear boll and shear boll

spacer provided.

• Reconnect the spark plug wire.

TO ADJUST TRACK

If the snow thrower does not move forwar d evenly and the

trackslips slightly, you needto check thetrack as follows:

• Pull up gently on the center of the track near the

center.

Measure the distance betweenthetrack and the top

of the track support frame (See Fig.. 36).

The distance should not be more than one and

one-quarter (1-1t4) inches..

if the distance is greater, you need to adjust the track as

follows:

• Loosen or tighlentheadjusting bolt atthe rear of the

track support frame (See Fig 36) to obtain the

proper distance between the track and the track

support frame,.

• Adjust the track on the opposite side in the same

manner.

SHEAR BOLT

AUGER SHAFT

FIG. 35

'TRACK (property adjusted)

SUPPORT FRAME

1-1/4"

TRACK (out of adjustmant)

FIG,. 36

22

Page 23

SE CE A ADJUST TS

TO ADJUST CARBURETOR

The carburetor (See Fig. 37 and Rg, 39) has been pre-set

at the factory and readjustment should not be necessary.

However, if the carburetor does need to be adjusted,

proceed as follows:

e Close the high speed adjusting screw by hand.,

® Do nol overtighten.

e Then open it t-1/4 to 1-1t2 turns,,

® Close the idle adjusting screw by hand,, Do not

overtighten,

e Then open it 1-1/4to tdt2tums,,

® Start the engine and le! it warm upo

e Set the throttle control to RUN,, Adjust the high

speed adjusting screw in until the engine speed or

sound aiters_ Adjust the screw out until the engine

speed sound alters. Note the difference between

the two limits and set the screw in the middle ol the

range,,

e Set the throttle control to SLOW,, Adjust the idle

adjusting screw in until the engine speed drops,

then adjust the screw out until the engine speed

drops. Note the difference between the two limits

and set the screw in the middle of the range.

e if the engine tends to stall under load or not accel-

erate from low speed to high speed properly, adjust

the high speed screw out in 1/8 turn increments until

the problem is resolved

e Let the engine run undisturbed for 30 seconds

between each setting to allow the engine to react to

the previous adjustments,

IDLE ADJUSTING SCREW"

(Close finger tight o_tly)

HIGH SPEED ADJUSTING

SCREW

BOWL DRAIN (Close finger light only)

FIG. 37

TO ADJUST:

o

Clean the spark plug by carefully scraping elec-

trodes (do not sand blast or use a wire brush).

@

Be sure the spark plug is clean and free of foreign

material Check electrodes gap (See Fig. 41) with a

wire feeler gauge and reset the gap to .030 inch if

necessary°

IMPORTANT:

NEVER TAMPER WITH THE ENGINE

GOVERNOR. WHICH IS FACTORY

SET FOR PROPER ENGINE SPEED.,

OVERSPEEDING THE ENGINE

ABOVE THE FACTORY HIGH SPEED

SETTING CAN BE DANGEROUS.

IF YOU THINK THE ENGINE -

GOVERNED HIGH SPEED NEEDS

ADJUSTING, CONTACT YOUR

NEARESTSEARS SERVICECENTER,

WHICH HAS THE PROPER

EQUIPMENT AND EXPERIENCE TO

MAKE ANY NECESSARY

ADJUSTMENT&

TO ADJUST OR REPLACE

THE SPARK PLUG

If you have difficulty startingyoursnowthrower, you may

need to adjust or replace the spark plug. Follow the

i_structions below,,

Replace the spark plug if electrodes are pitted or burned

or it the porcelain is cracked.

. : ,,,i ,11,,, I i i

FIG. 38

TO REPLACE:

If you need a new spark plug, use only the proper

replacement spark plug (See page 38),,

• Set the gap to .030,

® Before installing the spark plug, coat its threads

lightly with graphite grease to insure easy removal

e Tighten the plug firmly into the engine.

e tf a torque wrench is available, torque the plug to t 8

to 23 ft - lbs.

23

Page 24

......................... STORAG: 111111'11111 111111111 111 ' ........................ IIIII IIIIIIII!L

I'111"! IXILII I II II I'111111 .............. : ....... lj I'[11111 II ..... iii, I

"_HROWER INDOORS OR IN AN EN-

CAUTION: NEVER STOREYOUR SNOW

CLOSED, POORLY VENTILATED AREA

............ i, ,i,i ii ......... IU U

IF GASOLINE REMAINS IN THE TANK. FUMES

MAY REACH AN OPEN FLAME, SPARK OR PI-

LOT LIGHT FROM A FURNACE, WATER HEATER,

CLOTHES DRYER, CIGARETTE, ETC.

,11111 ............. :: ::: iiii Ill I' II ll'l' J" I II"

DRAIN

CARBURETOR

BOWL

To prevent engine damage (if snow thrower is not used

for more than 30 days) follow the steps below.

FIG. 42

ENGINE STORAGE

Gasoline must be removed or treated to prevent gum

deposits from forming in the tank, filter, hose, and

carburetor during storage. Also during storage, al-

cohol blended gasoline that uses ethanol or metha-

nol (sometimes called gasohol) attracts water° It acts

on the gasoline to form acids which damage the

engine.

@

To remove gasoline, run the engine until the tank is

empty and the engine stops.. Then drain remaining

gasoline from carburetor by pressing upward on

bowl drain !ocated on the bottom of carburetor (See

Fig 42).

I

if you do not want to remove gasoline, a fuel

stabilizer (such as Craftsman Fuel Stabilizer No..

33500) maybeaddedto anygasolineleft in thetank

to minimize gum deposits and acids_ If the tank is

almost empty, mix stablilizer with fresh gasoline in

a separate container and add some to the tank..

ALWAYS FOLLOW INSTRUCTIONS ON STABI-

LIZER CONTAINER. THEN RUN ENGINE AT

LEAST 10 MINUTES AFTER STABILIZER IS

ADDED TO ALLOW MIXTURE TO REACH CAR-

BURETOR. STORE SNOWTHROWER IN A SAFE

PLACE= SEE WARNING ABOVE.

You can keep your engine in good operating condi-

tion during storage by:

• Changing oilo

• Lubricating the piston/cylinder area. This can be

done by first removing the spark plug and squirting

clean engineoilintothe spark plug hole. Then cover

SNOW THROWER STORAGE

• Thoroughly clean the snow thrower.

• Lubricate aB lubrication points (see the Mainte-

nance section on pages 15-16).

• Be sure that ai[ nuts, bolts and screws are securely

fastened.. Inspect all visible moving parts for dam-

age, breakage and wear. Replace if necessary..

= Touch up all rusted or chipped paint surfaces; sane

_ightly before painting.

• Cover the bare metal parts of the blower' housing

auger and [he impeller with rust prevenlative, such

as sprayable lubricant.

NOTE: A yearly checkup or tuneup by a SEARS Service

Center is a good way to insure that you r snow t hrower will

provide maximum performance for the next season.

LUBRICATION

OTHER

• If possible, store your snow thrower indoors and

cover ff to give protection from dust and dirt.

• tfthe machinemust bestoredoutdoors,b!ock up the

snow throwerto be sure the entire machine is off the

ground.

• Cover Ihe snow thrower with a suitable protective

cover that does not retain moislure Do not use

plastk:.

IMPORTANT: NEVER COVER SNOW THROWER

WHILE ENGINE AND EXHAUST

AREAS ARE STILL WARM..

the spark plug hole with a rag to absorb oil spray..

Next, rotate the engine by pulling the starter rope

fulPf out two or three times. Finally, reinstall spark

plug and attach spark plug wire.

24

Page 25

SERVICE

i i , ,,ll,U i,,

i SERVICE RECORDS

Fill In dates as you co_

plete regular _l_

Check F__j_ Oa Lave

Change _gme Oil 1_

I I u / i i, ,,_, JJ ...........

T_jh_n All Screws _ Nuts

Check Aug_ Clu'c.h CabLe

Adj_nt (See Cable Adius_l )

SCHEDULE

i=,l,i .......

Aftor Belomi Often Every Evew

Rrst 2 Each 10 25 _ch Before

hours Usa Hours Houm Season Storage

SERVICE

DATES

ill

LUBRICATION CHART

.............................. ,...r...,,.;;;, .....

_bfi_te auger shaft.

Coat with a clinging type

grease such as _briplate.

,,,lUll,, l ll'l mill' l l mill ll' lllll'l'll l UI'I'U'IIIIII ::CCC:C::_

Page 26

........ TROUBLE SHOOTING POINTS ..............

, ,,,,,,,,,,,,,,,,,,,, I/l/Ull/lUI/ll/l/l/I ' I,I, Illl 'l II' l llll

TROUBLE

Otlflcult =tBllng

Engine r_n_ =talk=

En=tne =IaUi

Engln= PJr.a err=llc_mlly;

L=_ of power

Excessive vtbr=tlon

Untt fall= to propel

ite, e4r

Unit tfatia to

dlzcl_rge =now

CAUSE

Defective spark #ug

Water or d'_ in fuel sys_m

Blo_d _e! line or low on fuel

Unit running on CHOKE

Water or dirt in fuel system

Carburetor out o! adjustment

Loose pa_.,s; damaged impairer

KlP..,k pins improperly instaJk_d

Dnva bett loose at damaged

incorrect adjustment of traction

drive cable

Worn or damaged tric_n whee!

Auger drive belt loose or damaged

CORRECTION

Replace da fe==tive plug.

Use ca_oumtor bowl drain to flush and refitl with fresh

fuel.

Jiu,ii i _ • ,,lllll,i ,lli H,i i .................

fuel (gasoline/oil mixture if 2 cycle engine).

Move chek_ lever to OFF pos_don..

,,,,,,,,,,,,,, ,,, ,,,,,,,,, , ,,, ,,,,, ,,,,,,,,,,,, ,, ,, ,,, ,,,, ,,

J J llJIIIIII

use c=_u,e=_ bowl dr_ _ _ush an_ radii _th fresh

fuel

Adjust ca_'buretor

IIIII IIIIIIIILIL IlL i I Ilmlll

Stop engine immediately and disconnect spark plug wire

Tighten atl bo!_ and make all necessary repairs if vibration

continues, have the unit serviced by a competent ml_irman,

Replace d,6ve belL

Adiust t_ction drive c_le,

Rel_a,ce f'dct_on wheel

iillllllllllllllllll i i i i iiiiiiiiiii i i i i ill Jli J I I I _iillilliill II I I I i i lililllllllll III L J

Adjust auger drive belt; repla_ if damaged=

!,baWighl doel nol work

Unit ride= up

Auger control cable not adtusted

con'ec_y

Shear bolt broken

Discharge chute dogged

Foreign object lodged in auger

Loosewimconnection

Butb I_.tmed out

: : IIIIIIIIIIIIIIIII I ii ii1_ ii i i ii iiiiii ii ii ii iiii L L I

Weight t_ansfer disengaged

26

Adjust auger control cable,,

Replace shear boll

Stop engine imme_ately and cfsc_nnect spark plug wire

Ck_an disct_rge chute and i_side of auger housing

Stop engine immoo_tely and disconnect spask plug wire,,

Remove object Earn auger.

Tighten connec_ort,,.

Replace headlight bulb.

ii Illlllll Illllll IIII li

Engage weight _ansfer system by lifting up on upper hand)e

un_i bracket belts snap into p_ce in upper slots of weight

transfer pedaJ

Page 27

i

NOTES

i i i,iii, iii, i, _11 i i .... ii I'H'I _ _ :

27

Page 28

CRAFTSMAN 24" SNOW THROWER 536.884821

HANDLE ASSEMBLY REPAIR PARTS

?

9

\

12

1!

\

I

5

21

REF.

NO.

PART NOD

1 318457

2 4049

3 307978

4 307976

5 3535

6 302578

7 1579

8 11234

9 71071

10 71060

11 71037

PART NAME

Handte, Upper

Bumper

Auger Drive Lever, RH

Traction Drive Lever, LH

Nut, Push On Cap, 5/16 In.

Pin, Clutch ftandle, Pivot

Cable, Clutch

Screw, Hex. 5/16-18 x 2-3/4 In.

* Ratwasher. 11/32 in..

Lockwasher` Split 5/16 In..

" Nut, Hex. 5/16-18 TI_.

PARTNAME

Slop, Red Plastic, 5t16 In.

Screw. HHC, 5/16-18 x 2 In

Spring, Drive C_utch LH

Boot, Clutch Spdng

Nut, Hex Nyt, 11420 in

Screw, HHC, 5116-18 x 3/4 In.

Spdng, Auger Clutch RH

Hand{e. Lower

Bra_et, Shift

O',vnet's Manua}

Page 29

CRAFTSMAN 24" SNOW THROWER 536.884821

CHUTE CONTROL ROD REPAIR PARTS

Ret. Ilem . \ ,, . | ,

RE_. ¸ I

PART NO. PART NAME

NO. !

t

10