Sears 507.459820,507.459830,SPYDER,SCREAMER,SPYDER 500,CONVERTA-BIKE Owner's Manual

Sears

owners manual

..

--"

MODEl NO.

507.459820

507.459830

CAUTION:

Read Rules for

Safe Operation

and Instructions

Carefully

/

SPYDER

.Assembly

. Operating

. Maintenance

. Repair Parts

-t

o

-t

m

I

n

-<

n

r-

m

SCREAMER

SPYDER

500

---~~ ~~

.

-

l[

f\

-

-S5~~~

~@~~~~ ~~; (£0)0--

. .

I'

II @}{]O:[;&@@, mlJl.

@

0;0

."

11 ~. :1

Printed in U.S.A.

J

TOTE-CYCLE ASSEMBLY

1. HANDL EBAR AND STEM (FIGURE 1)

A. Loosen stem bolt.

B.

Turn

stem to point forward and lower it into locknut at least 3"

or more. The stem must be lowered this far to hold securely.

Tighten stem bolt securely.

C. Insert handlebar in stem and adjust handlebar to suitable posi-

tion, tighten clamp screw and put grips on handlebar ends.

2. SADDLE AND SADDLE POST

A. Place saddle on post, adjust to level position and tighten clamp

securely.

-

B. Loosen saddle post quick-release lever in bike frame and adjust

height of saddle to comfortable position, then tighten lever.

NOTE: Seat post must be lowered at least

2W'

into frame.

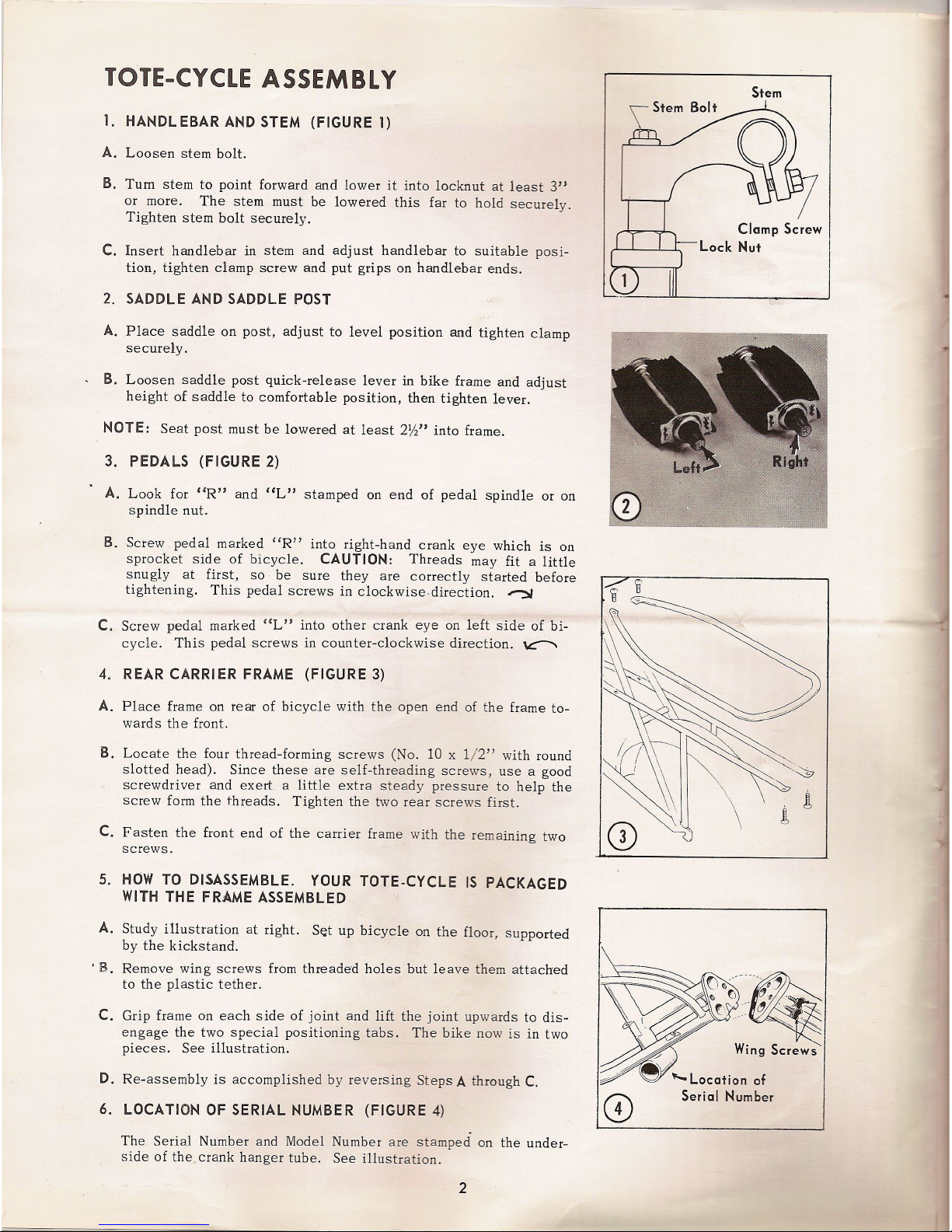

3. PEDALS (FIGURE 2)

.

A. Look for «R" and "L" stamped on end of pedal spindle or on

spindle nut.

B. Screw pedal marked

"R" into right-hand crank eye which is on

sprocket side of bicycle. CAUTION: Threads may fit a little

snugly at first, so be sure they are correctly started before

tightening. This pedal screws in clockwise. direction.

"':S

C. Screw pedal

marked

C(L"

into other crank eye on left side of bi-

cycle. This pedal screws in counter-clockwise direction.

~

4.

REAR CARRI ER FRAME (FIGURE 3)

A. Place frame on rear of bicycle with the open end of the frame to-

wards the front.

B.

Locate the four thread-forming screws (No. 10 x 1/2" with round

slotted head). Since these are self-threading screws, use a good

screwdriver and exert. a

little extra steady pressure to help the

screw form the threads. Tighten the two rear screws first.

C. Fasten the front end of the carrier frame with the remaining two

screws.

5. HOW TO DISASSEMBLE.

YOUR

TOTE.CYCLE IS PACKAGED

WITH THE FRAME ASSEMBLED

A.

Study illustration

at right. S~t up bicycle on the floor, supported

by the kickstand.

.

B.Remove

wing

screws from threaded holes but leave them attached

to the plastic tether.

C. Grip frame on each side of joint and lift the joint upwards to dis-

engage the two special positioning tabs. The bike now is in two

pieces.

See

illustration.

D. Re-assembly is accomplished by reversing Steps A throughC.

6. LOCATION OF SERIAL NUMBER (FIGURE 4)

The Serial Number and Model Number are stamped on the under-

side of the,

crank

hanger tube. See illustration.

2

Stem

Clamp Screw

I

Lock Nut

I

CD

7. TIRES

Never ride on under-inflated tires. Tires should be

kept inflated to the pressure marked on the tire.

CALI

PER BRAKE ADJUSTMENT

Make

sure the brake releases evenly on each side. If not, tap the

return spring on the side which releases too far.

8.

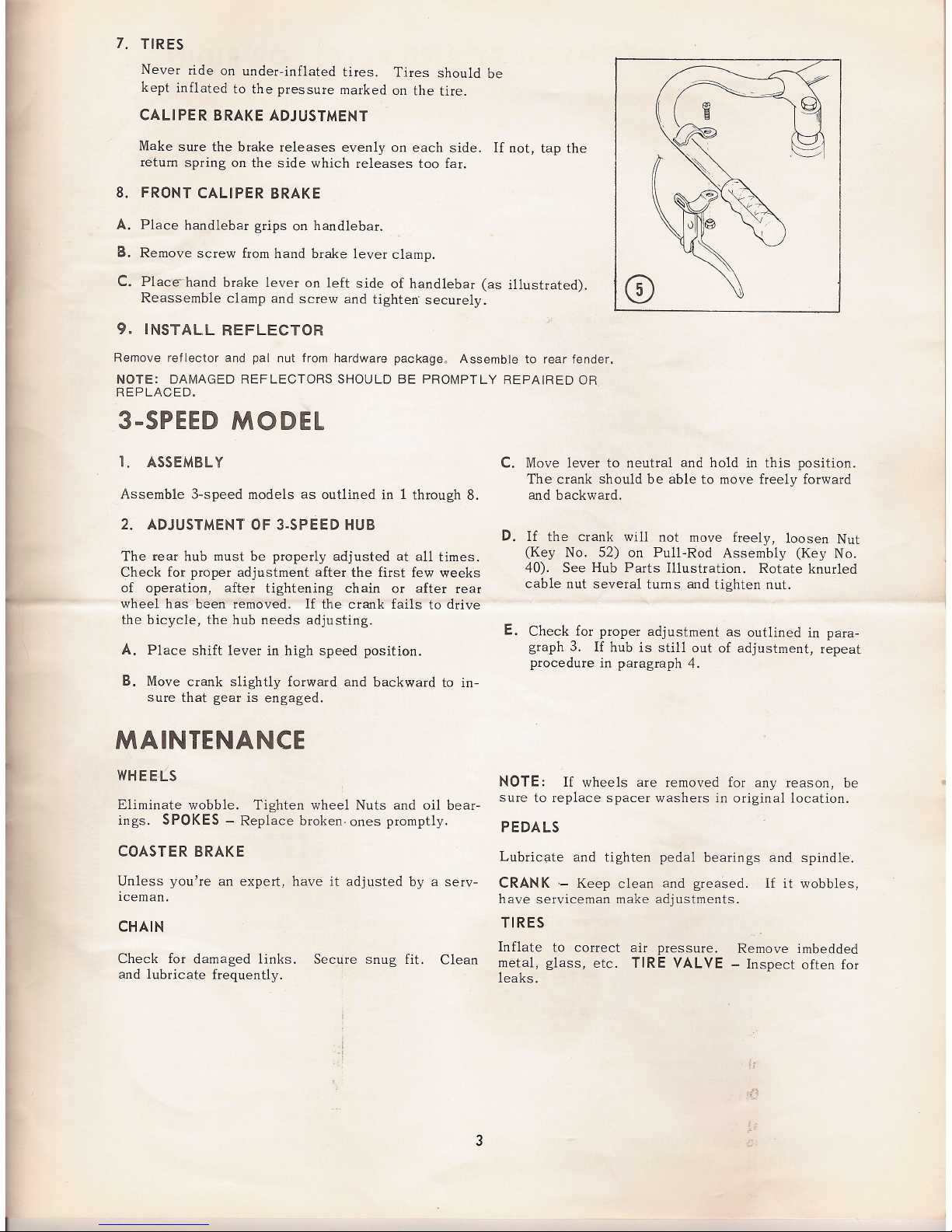

FRONT CALIPER BRAKE

A. Place handlebar grips on handlebar.

S. Remove screw from hand brake lever clamp.

C. Place" hand brake lever on left side of handlebar (as illustrated).

Reassemble clamp and screw and tighten: securely.

9. INSTALL REFLECTOR

Remove reflector and pal nut from hardware packageo Assemble to rear fender.

NOTE: DAMAGED REFLECTORS SHOULD BE PROMPTLY REPAIRED OR

REPLACED.

3-SPEED MODEL

1.

ASSEMBL

Y

Assemble 3-speed models as outlined in 1 through

8.

2. ADJUSTMENT OF 3.SPEED

HUB

The rear hub must be properly adjusted at all times.

Check for proper adjustment after the first few weeks

of operation, after tightening chain or after rear

wheel has been removed. If the crank fails to drive

the bicycle, the hub needs adjusting.

A. Place shift lever in high speed position.

B. Move crank slightly forward and backward to in-

sure that gear is engaged.

MAINTENANCE

WHEELS

Eliminate wobble. Tighten wheel Nuts and oil bear-

ings.

SPOKES

- Replace broken. ones promptly.

COASTER

BRAKE

Unless you're an expert, have it adjusted by a serv-

Iceman.

CHAIN

Check for damaged links.

and lubricate frequently.

Secure snug fit.

Clean

,

i

.,

C. Move lever to neutral and hold in this position.

The crank should be able to move freely forward

and backward.

D. If the crank will not move freely, loosen Nut

(Key No. 52) on Pull-Rod Assembly (Key No.

40). See Hub Parts Illustration. Rotate knurled

cable nut several turns and tighten nut.

E. Check for proper adjustment as outlined in para-

graph 3. If hub is still out of adjustment, repeat

procedure in paragraph 4.

NOTE:

If wheels are removed for any reason, be

sure to replace spacer washers in original location.

PEDALS

Lubricate and tighten pedal bearings and spindle.

CRAN K

'-

Keep clean and greased.

have serviceman make adjustments.

If it wobbles,

TIRES

Inflate to correct air pressure. Remove imbedded

metal, glass, etc. TIRE

VALVE -

Inspect often for

leaks.

I.

3

-

Loading...

Loading...