Page 1

OWNERS

™

the fastest way to purchase parts

www.speedepart.com

MANUAL

Model No.

45-0424

25 GALLON ATV

TOW SPRAYER

CAUTION:

Read Rules for

Safe Operation

and Instructions

PRINTED IN USA

Carefully

Assembly

Operation

Maintenance

Repair Parts

FORM NO. 40165 (REV. 2/07)

Page 2

RULES FOR SAFE OPERATION

1

3

6

10

9

4

7

5

2

8

Any power equipment can cause injury if operated improperly or if the user does not understand how to operate

the equipment. Exercise caution at all times when operating equipment.

1. Read this owners manual carefully before attempting to assemble or operate this sprayer.

2. Read your vehicle owners manual for operating and safety rules before using this equipment.

3. Never allow children to operate this sprayer, and do not allow adults to operate without proper instructions.

4. Do not allow anyone to ride on or sit on this sprayer. Do not allow passengers on the towing vehicle.

5. Keep the area of operation clear of all persons, particularly small children. Also keep area clear of pets.

6. Read the chemical label carefully for instructions and caution notes on handling and mixing of chemicals.

7. Wear eye and hand protection and wear protective clothing when handling and applying lawn chemicals.

8. Do not spray on windy days.

9. Attachment of this sprayer may affect your tractor's braking and stability. Be aware of your tractor's capabilities. Refer to

the safety rules in the vehicle owner's manual concerning safe operation on slopes. Be aware of changing conditions on

slopes. STAY OFF OF STEEP SLOPES.

10. Operate at reduced speed on rough terrain, along ditches and on hillsides to prevent loss of control.

11. Follow maintenance and lubrication instructions as outlined in this manual.

LOOK FOR THIS SYMBOL TO POINT OUT IMPORTANT

SAFETY PRECAUTIONS. IT MEANS — ATTENTION!

BECOME ALERT! YOUR SAFETY IS INVOLVED.

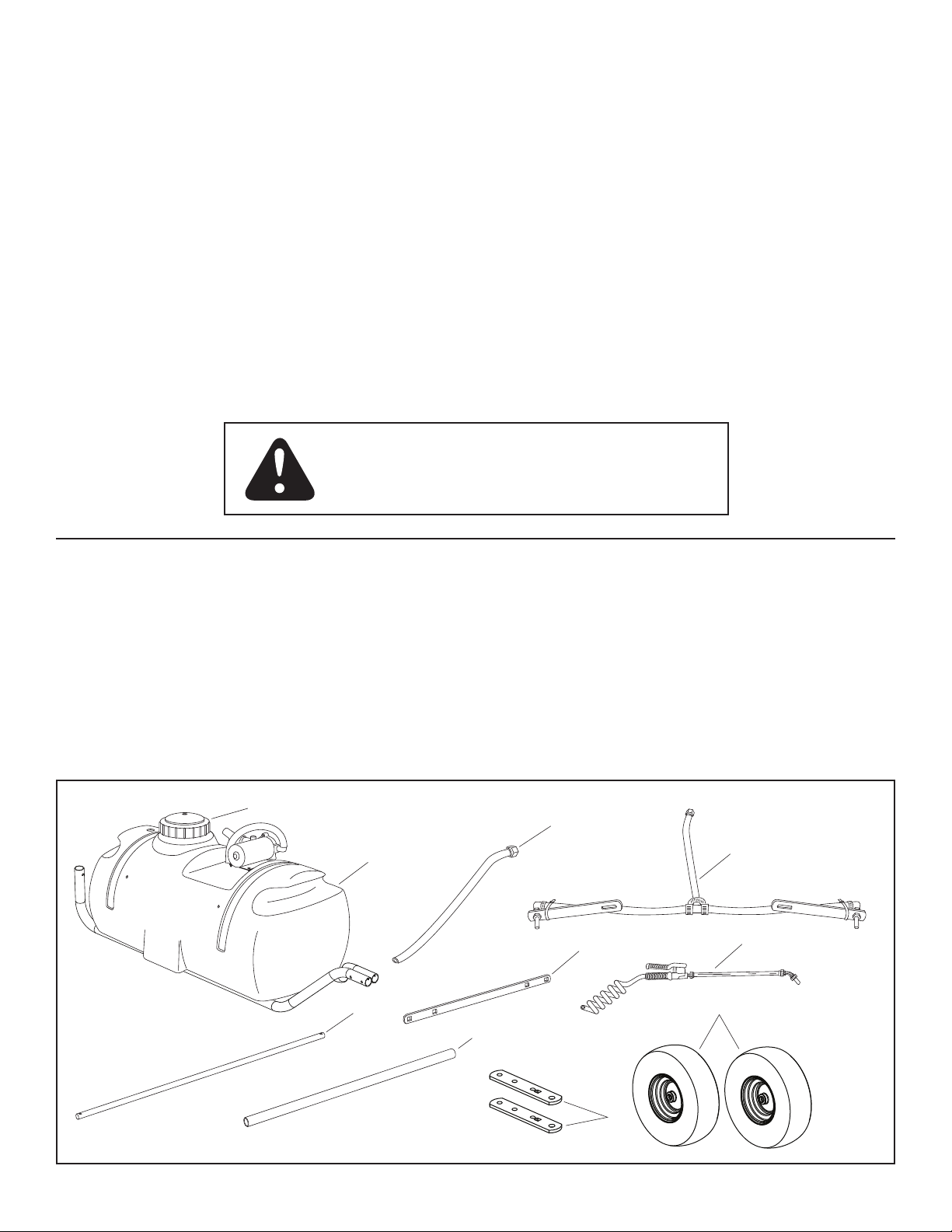

Your sprayer carton contains parts as shown below. The hardware package contains parts as shown on page 3.

Identify all parts before beginning assembly.

CARTON CONTENTS

LOOSE PARTS IN CARTON

1. Lid

2. Tank

3. Return/Bypass Hose (may be assembled to tank)

4. Boom Assembly

5. Boom Mount Bracket

6. Spray Gun Assembly

7. Axle

8. Axle Support Tube

9. Hitch Brackets (2)

10. Wheels (2)

2

Page 3

SHOWN FULL SIZE

BA

G

I

J

K

M

N

F

E

D

C

H

L

NOT SHOWN FULL SIZE

O

P

20

40 60

80

100

0

Q

S

T

R

U

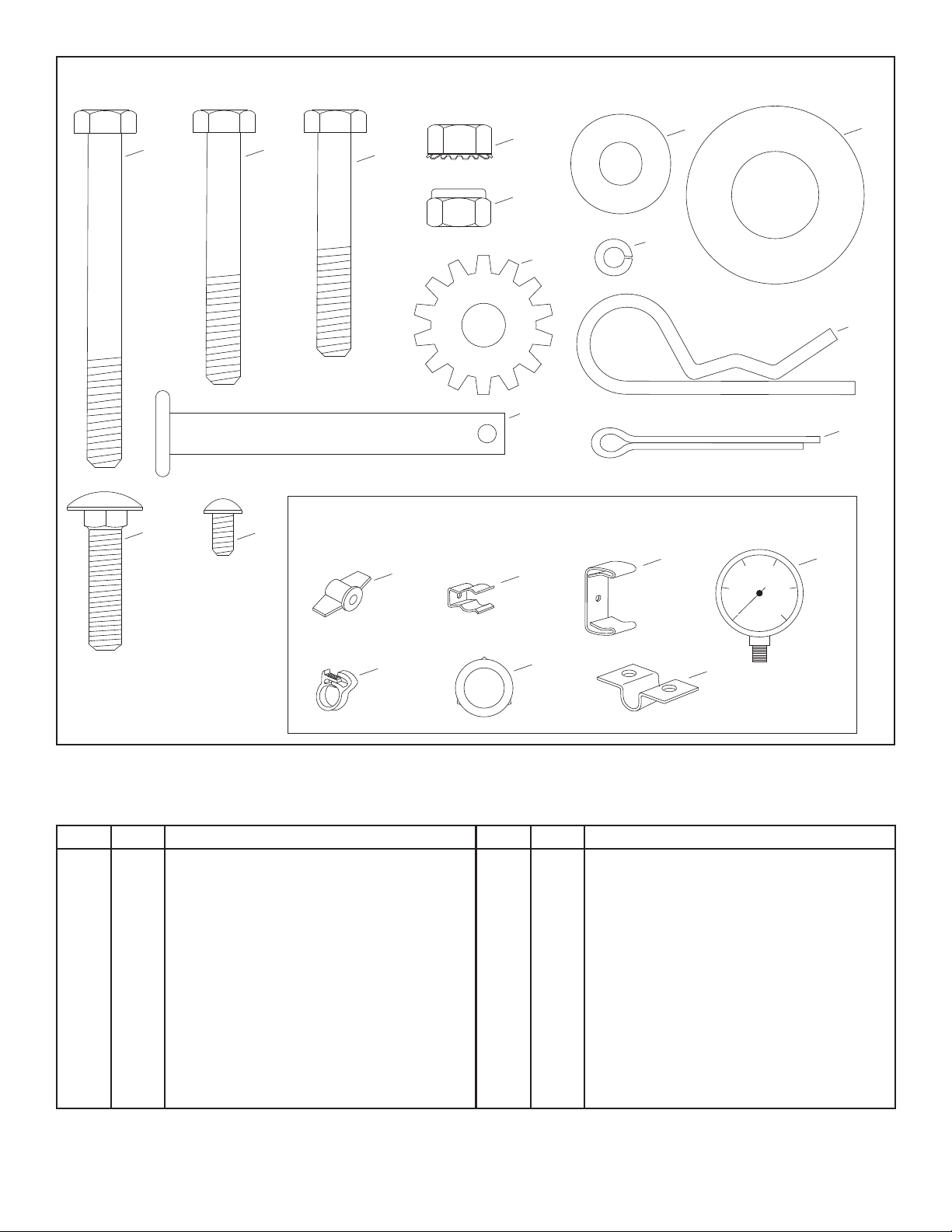

HARDWARE PACKAGE - FULL SIZE

KEY QTY. DESCRIPTION

A 2 Hex Bolt, 5/16" x 3"

B 2 Hex Bolt, 5/16" x 2-1/4"

C 2 Hex Bolt, 5/16" x 2"

D 4 SEMS Nut, 5/16"

E 6 Nylock Nut, 5/16"

F 6 Flat Washer, 5/16"

G 4 Flat Washer, 3/4"

H 2 Lock Washer, #10

I 2 Washer, 5/16" Tooth Lock

J 1 Hitch Pin

K 1 Hair Cotter Pin

KEY QTY. DESCRIPTION

L 2 Cotter Pin

M 2 Carriage Bolt, 5/16" x 1-1/4"

N 2 Screw, #10 x 3/8"

O 2 Knob

P 1 Spray Gun Clip, Small

Q 1 Spray Gun Clip, Large

R 1 Pressure Gauge

S 1 Coiled Hose Clamp

T 2 Gasket, 3/4" Garden Hose

U 2 Axle Clamp

3

Page 4

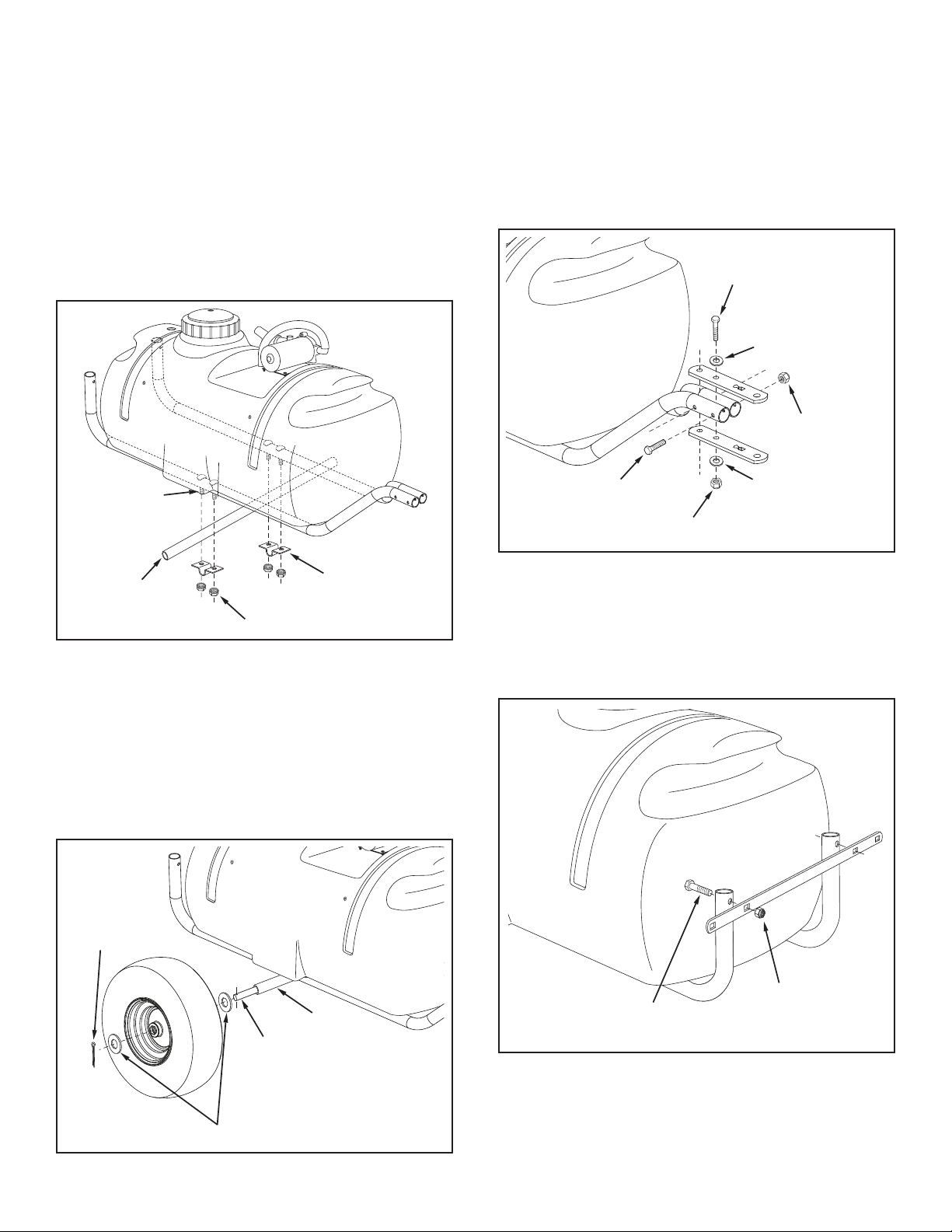

ASSEMBLY INSTRUCTIONS

FACTORY

INSTALLED

BOLT

AXLE

CLAMP

AXLE

SUPPORT

TUBE

5/16" SEMS NUT

3/4" WASHER

AXLE

AXLE

SUPPORT

TUBE

1/8" x 1-1/2"

COTTER PIN

5/16" x 2-1/4"

HEX BOLT

5/16" NYLOCK NUT

5/16" x 3"

HEX BOLT

5/16" WASHER

5/16" WASHER

5/16" NYLOCK NUT

5/16" NYLOCK NUT

5/16" x 2"

HEX BOLT

TOOLS REQUIRED FOR ASSEMBLY

(2) 1/2" Wrenches

(1) Screwdriver

(1) Pliers

1. Remove all items from carton and lay out as shown on

pages 2 and 3.

2. Assemble the axle clamps, axle support tube and four

5/16" SEMS nuts to the factory installed bolts in the

frame tubes. See gure 1.

5. Fasten the front ends of the frame tubes together using

two 5/16" x 3" hex bolts and 5/16" nylock nuts. Do not

tighten yet. See gure 3.

6. Assemble hitch brackets to frame tubes using two 5/16"

x 2-1/4" hex bolts, four washers (one on each side) and

5/16" nylock nuts. Position each bolt behind a cross bolt

in the hitch arms. Do not tighten yet. See gure 3.

7. Tighten bolts assembled in step 7 then tighten bolts

assembled in step 8. See gure 3.

FIGURE 1

3. Slide the axle through the axle support tube. See

4. Assemble a 3/4" washer, a wheel (valve stem facing

FIGURE 3

8. Assemble the boom mount bracket to the rear of the

frame tubes using two 5/16" x 2" hex bolts and 5/16"

nylock nuts. See gure 4.

gure 2.

out) and another 3/4" washer onto the axle. Assemble

a cotter pin through the end of the axle. Repeat on other

end. See gure 2.

FIGURE 2

FIGURE 4 REAR VIEW

4

Page 5

9. Assemble the boom bars to the boom mount bracket

CARRIAGE BOLT

5/16" x 1-1/4"

KNOB

5/16" FLAT

WASHER

WASHER

(TOOTH LOCK)

BOOM BAR

BOOM CONNECTING HOSE

SPRAY GUN

CLIP (LARGE)

SPRAY GUN

CLIP (SMALL)

#10 x 3/8"

SCREW

#10 LOCK

WASHER

BOOM CONNECTING HOSE

SPRAY

GUN

HOSE

PRESSURE

GAUGE

BYPASS/RETURN HOSE

GARDEN

HOSE

GASKET

COILED

HOSE

CLAMP

PLUG

NEGATIVE PIN

12 VOLT TRACTOR BATTERY

POSITIVE

"HOT"

POST

+

NEGATIVE

POST

BROWN

RED

QUICK COUPLER

BATTERY

+

RED

BROWN

IN LINE SWITCH

using two 5/16" x 1-1/4" carriage bolts, tooth lock washers

(between the bar and bracket), 5/16" at washers and

knobs. The boom connecting hose should extend upward.

See gure 5.

NOTE: Make sure the nozzles are adjusted so that the

openings face straight down when the boom bar is in the

horizontal operating position.

13. Slide coiled hose clamp onto spray gun hose. Push

hose onto hose adapter on the side of the "T" tting

as shown in gure 7. Tighten clamp around hose and

adapter. Snap spray gun into clips on side of tank.

14. Carefully screw the pressure gauge into the top of the

"T" tting. See gure 7.

FIGURE 7

FIGURE 5

10. Assemble the large and small spray gun clips to the

side of the tank using two #10 x 3/8" screws and #10

lock washers. See gure 6.

FIGURE 6

11. Insert a garden hose gasket into the swivel nut on the

bypass/return hose. Screw nut onto upper outlet of the

"Y" valve tting. Place the other end of the hose down

through the hole at the rear of the tank. See gure 7.

12. Insert a garden hose gasket into the swivel nut on the

boom connecting hose. Screw the nut onto the lower

outlet of the "Y" valve tting. See gure 7.

15. Attach sprayer to tractor hitch and connect the wiring to

tractor battery. Red wire must be connected to positive

post on battery or to "HOT" connection on a tractor switch

or ammeter. Brown wire may be grounded or connected

to negative battery post. See gures 8 and 9.

IMPORTANT: This sprayer should be connected to 12

volt batteries only!

FIGURE 8

NEVER ALLOW NEGATIVE PIN ON PLUG

TO COME IN CONTACT WITH POSITIVE

"HOT" POST ON BATTERY. FIRE OR

EXPLOSION MAY RESULT!

FIGURE 9

5

Page 6

OPERATION

80"

40"

14"

BEFORE STARTING

It is important to test the boom and spray gun with plain

water before using chemicals. This will enable you to check

the sprayer for leaks and to set the spray pattern and nozzle

pressure. If a leak should occur, thread tape may be used

to better seal the tting.

ON-OFF SWITCH

This switch is connected in line to the wiring assembly and

is used by the operator to turn the pump motor on or off.

PUMP PRESSURE SWITCH

The pump is equipped with a pressure switch. The pressure

switch senses outlet pressure of the pump and will turn off

the electrical power to the pump at a predetermined high

pressure point (60 PSI). If the ow demand is very low, the

pump may reach this high pressure point and the switch will

cause "cycling" (the pump cycles on and off rapidly). This is

not a problem unless the pump is subject to continuous cycling

within one second intervals for long periods of time.

ADJUSTING OPERATING PRESSURE

The sprayer is equipped with a "Y" tting containing a bypass

valve and a boom valve. The bypass valve controls the ow

to the return (bypass) hose. The amount of ow through the

return hose determines the operating pressure when the

boom or the spray gun is in use. Adjust the bypass valve

while either the boom or the spray gun is in use to obtain

the desired pressure, indicated by the pressure gauge. The

tip chart on page 9 shows how different pressure settings

affect boom application rates.

ON-OFF ADJUSTMENT OF BOOM NOZZLES

The boom valve on the "Y" tting controls ow to the boom

nozzles. It should be either completely open or completely

closed. The boom operating pressure can be controlled

using the bypass valve on the "Y" tting.

ADJUSTING SPRAY GUN NOZZLE

Turn the nozzle on the spray gun to adjust the spray from

a cone shaped ne mist to a straight stream. Control the

spray gun operating pressure with the bypass valve on the

"Y" tting. Maximum spray gun pressure can be attained

when the boom is shut off.

USING THE SPRAYER

1. Determine the application rate (gallons per 1,000

sq. feet or gallons per acre) based on the chemical

manufacturers recommendations. Use this rate to help

select the pressure setting and tractor speed in the

following instructions.

2. Determine the approximate square footage of the area to

be sprayed and estimate the number of gallons required.

This can help avoid unneeded solution left in the tank.

3. Determine the appropriate speed at which to travel, based

on the chosen pressure setting and the recommended

application rate. Use the tip chart on page 9.

4. To determine the throttle setting for attaining the

appropriate speed, mark off 100, 200 and 300 feet

intervals. The speed chart at the bottom of page 9

indicates the number of seconds it takes to travel these

distances. Set the throttle and, with a running start, travel

the distances in the number of seconds indicated by

the speed chart. Once you have determined the throttle

and gear settings needed, mark the throttle location

so that you can easily resume the same speed after

stopping.

5. Set the operating pressure. Spray with plain water to

help determine the best setting. For best results stay

in the 20 to 30 PSI range. (At 10 PSI the spray pattern

begins to break up, at 40 PSI some drift develops.) Refer

to the tip chart on page 9.

6. Add the chemical solution to the tank, following the

product instructions.

7. Drive to the starting place for spraying. Set the boom

in position for spraying. Set the throttle at the position

determined in step 4. Flip the sprayer's in-line switch to

the "ON" position to start spraying.

8. Stay clear of owers, shrubs and evergreen trees when

spraying weed control solutions to prevent contact of

the solution with these sensitive plants.

CAUTION: WEAR EYE PROTECTION,

GLOVES AND PROTECTIVE CLOTHING

WHEN HANDLING AND WORKING WITH

LAWN CHEMICALS.

SETTING THE BOOM FOR SPRAYING

The correct positioning of the boom places the nozzles

approximately 40" apart and 14" above the ground. This

gives a spray width of approximately 80" with a slight center

overlap. See gure 10.

a. Slide the boom bars out to the ends of the

slots.

b. Swivel the boom bars until the nozzles are

approximately 14" above the ground.

c. Make sure the nozzles are adjusted so that the

openings point straight down.

FIGURE 10

6

Page 7

MAINTENANCE

1. Do not store sprayer with any solution left in tank.

2. Periodically clean the strainer in the end of the intake

hose at the bottom of the tank. Remove the nylon swivel

nut from the hose, pull out the screen and ush it with

clear water.

3. Periodically clean the strainers in the boom nozzles.

Remove the nozzle, pull out the screen and ush it with

clear water.

ATTENTION!

Do not allow chemicals to sit in pump for extended times

of idleness. Some chemicals will damage the pump

valve if allowed to soak untreated for a length of time.

Always ush the pump with water after each use. Follow

the procedures in the AFTER EACH USE instructions

for ushing and disposal.

WINTER STORAGE

AFTER EACH USE

4. After use, ll the sprayer part way with water, start the

sprayer and allow clear water to be pumped through the

plumbing system and out through the boom assembly

and the handgun. Use the handgun to thoroughly wash

all internal parts of the tank, the outside of the tank and

the boom.

5. Rell the tank about half full with plain water and a

chemical neutralizer and repeat the cleaning instructions

above. Flush the entire sprayer with the neutralizing

agent. Follow the chemical manufacturers instructions

for disposal of all wash or rinsing water.

6. Drain all water out of the sprayer, paying special

attention to the pump and handgun. These items are

especially prone to damage from chemicals and freezing

weather.

7. The sprayer should be winterized before storage by

pumping a 50-50 solution of water and R. V. antifreeze

through the entire plumbing. Proper care and

maintenance will prolong the life of the sprayer.

7

Page 8

U.S. GALLON TIP CHART

Tip Spray Pressure Tip Capacity GALLONS PER ACRE (BASED ON WATER)

No. Height PSI US Gallons

Inches Per Minute 1 MPH 2 MPH 3 MPH 4 MPH 5 MPH 7.5 MPH 10 MPH

10 .30 44.2 22.1 14.8 11.1 8.9 5.9 4.4

#3 13" 20 .42 63 31.5 20.9 15.7 12.6 8.4 6.3

30 .52 76.8 38.4 25.8 19.3 15.4 10.3 7.7

Tip Spray Pressure Tip Capacity GALLONS PER 1000 SQ. FT. (BASED ON WATER)

No. Height PSI US Gallons

Inches Per Minute 1 MPH 2 MPH 3 MPH 4 MPH 5 MPH 7.5 MPH 10 MPH

10 .30 1.0 0.50 0.34 0.26 0.20 0.14 0.10

#3 13" 20 .42 1.4 0.72 0.48 0.35 0.29 0.19 0.14

30 .52 1.8 0.88 0.59 0.44 0.35 0.24 0.18

IMPERIAL GALLON (LITER) TIP CHART

Tip Spray Pressure Tip Capacity

No. Height PSI Imperial Gallons

Inches (Bar) per minute 1 MPH 2 MPH 3 MPH 4 MPH 5 MPH 7.5 MPH 10 MPH

(mm) (liters per minute) 1.6 K/H 3.2 K/H 4.8 K/H 6.4 K/H 8 K/H 12 K/H 16 K/H

10 .25 36.8 18.4 12.3 9.2 7.4 4.9 3.7

(0.7) (1.135) (167.3) (83.6) (56.0) (42.0) (33.7) (22.3) (16.7)

#3 13" 20 .35 52.5 26.2 17.4 13.1 10.5 7.0 5.2

(330 mm) (1.4) (1.59) (238.5) (119.2) (79.1) (59.4) (47.7) (31.8) (23.8)

30 .433 64.0 32.0 21.5 16.1 12.8 8.6 6.4

(2.1) (1.97) (290.7) (145.3) (97.7) (73.1) (58.3) (39.0) (29.1)

Tip Spray Pressure Tip Capacity

No. Height PSI Imperial Gallons

Inches (Bar) per minute 1 MPH 2 MPH 3 MPH 4 MPH 5 MPH 7.5 MPH 10 MPH

(mm) (liters per minute) 1.6 K/H 3.2 K/H 4.8 K/H 6.4 K/H 8 K/H 12 K/H 16 K/H

10 .25 0.85 0.42 0.28 0.21 0.17 0.11 0.08

(0.7) (1.135) (3.85) (1.92) (1.29) (0.97) (0.77) (0.51) (0.38)

#3 13" 20 .35 1.21 0.60 0.40 0.30 0.24 0.16 0.12

(330 mm) (1.4) (1.59) (5.48) (2.74) (1.82) (1.37) (1.10) (0.73) (0.55)

30 .433 1.47 0.74 0.49 0.37 0.29 0.20 0.15

(2.1) (1.97) (6.68) (3.34) (2.24) (1.68) (1.34) (0.90) (0.67)

IMPERIAL GALLONS (Liters) PER ACRE (BASED ON WATER)

IMPERIAL GALLONS (Liters) PER 1000 SQ. FT. (BASED ON WATER)

GROUND SPEED CHART

M.P.H. (K/H) Time Required in Seconds to

Travel a Distance of:

1.0 (1.6) 68 136 205

2.0 (3.2) 34 68 102

3.0 (4.8) 23 45 68

4.0 (6.4) 17 34 51

5.0 (8.0) 14 27 41

6.0 (9.7) 11 23 34

7.0 (11.3) 9.7 19 29

8.0 (12.9) 8.5 17 26

9.0 (14.5) 7.6 15 23

10.0 (16.1) 6.8 14 20

100 ft (30.5 M) 200 ft (61 M) 300 ft (91.5 M)

8

Page 9

NOTES

9

Page 10

REPAIR PARTS FOR 25 GALLON SPRAYER MODEL 45-0424

28

25

65

40

43

46

51

27

23

42

49

56

C

40

24

51

28

45

44

44

52

39

19

20

31

21

37

30

36

33

35

34

51

63

21

21

32

21

30

37

36

21

33

35

34

63

21

57

58

59

B

C

38

40

29

1

A

7

53

6

55

54

18

17

2

14

3

8

15

4

9

10

55

B

16

61

5

13

7

50

48

47

60

50

48

15

22

55

7

21

B

63

26

11

26

41

A

64

62

62

10

Page 11

REPAIR PARTS LIST FOR 25 GALLON SPRAYER MODEL 45-0424

the fastest way to purchase parts

www.speedepart.com

REF

NO.

10 43910 4 Flat Washer, #10 SAE

11 46980 4 Nut, Hex 5/16-18 (SEMS)

12 45085 2 Terminal, .25 Male Tab (not shown)

13 46276 1 Adapter, 3/4" GH x 1/2" Barb

14 46277 1 Elbow, 3/8 NPT x 1/2" Barb

15 45025 2 Clamp, 1/2" Hose (For Black Hose)

16 49754 1 Switch and Wire Assembly

17 45049 1 Nipple, (Nylon) 1/2" x 3/8" Red.

18 45050 1 Tee, 1/2" x 1/2" x 1/2" (1/4" Port)

19 47406 1 Spray Gun

20 49761 1 Hose, 1/4" ID (15' Lg)

21 45026 6 Clamp, 3/8" Hose (For Black Hose)

22 45034 1 Hose Barb, 3/8"

23 40166 1 Frame Tube (RH)

24 40167 1 Frame Tube (LH)

25 24192 2 Hitch Bracket

26 25896 2 Axle Clamp

27 25898 1 Axle

28 48511 2 Wheel

29 46700 1 Lid

30 24122 2 Boom Bar

31 24585 1 Bracket, Boom Mount

32 47394 1 Tee, Plastic 3/8" Hose

PART

NO.

1 46283 1 Tank (25 Gal.)

2 45015 1 Pump and Motor

3 46278 1 Hose, 1/2" ID (24" Lg.)

4 45021 1 Hose, 1/2" ID (20" Lg.)

5 45024 1 Strainer, Cap Type 1"

6 45031 1 Adapter, 1/2" NPT x Hose

7 45032 3 Nut, Swivel 3/4" Garden Hose

8 45033 1 Hose Barb, 1/2"

9 45069 4 Screw, Ph. Pan Hd. 10-24 x 1"

45026 2 Clamp, 3/8" Hose (For Clear Hose)

47405 6 Clamp, 1/4" Hose (For Clear Hose)

QTY. DESCRIPTION

REF

NO.

33 45028 2 Nozzle, SS Floodjet

34 45029 2 Strainer, Screen Type

35 45037 2 Nut, Screen Body

36 47396 2 Elbow, Plastic 11/16" Thd.

37 726-0178 2 Nylon Tie

38 44180 2 Bolt, Hex 5/16-18 x 2"

39 46782 2 Bolt, Hex 5/16-18 x 3"

40 47810 6 Nut, Nylock 5/16-18

41 44947 4 Bolt, Curved Head 5/16-18 x 1-5/8"

42 43086 4 Lock Washer, 5/16"

43 43343 1 Pin, Hair Cotter #4 (1/8")

44 43009 4 Washer, 3/4"

45 43093 2 Cotter Pin, 1/8" x 1-1/2"

46 47623 1 Hitch Pin

47 45180 1 Hose Clip, Small

48 736-0722 2 Lock Washer, #10

49 44695 4 Washer, Bowed

50 46677 2 Screw, Phillips Hd. #10-24 x 3/8"

51 43081 6 Washer, 5/16" Std. Wrt.

52 25897 1 Axle Support Tube

53 45017 1 Hose "Y" W / Valves 3/4"

54 45071 1 Gauge, Pressure 2" 100 PSI

55 45072 3 Gasket, 3/4" Garden Hose

56 43085 4 Bolt, Hex 5/16-18 x 1-1/2"

57 712-0421 2 Knob

58 43682 2 Bolt, Carriage 5/16-18 x 1-1/4"

59 44732 2 Washer, Tooth Lock 5/16"

60 47397 1 Hose Clip (Large)

61 47390 1 Adapter, 1/2" NPT x 1/4" Barb

62 49779 2 Clamp, Coiled Hose

63 47392 3 Hose, 3/8" ID (20" Lg.)

64 48719 1 Drain Cap

65 43224 2 Bolt, Hex 5/16-18 x 2-1/4"

PART

NO.

40165 1 Owners Manual

QTY. DESCRIPTION

11

11

Page 12

the fastest way to purchase parts

www.speedepart.com

© 2006 Agri-Fab, Inc.

REPAIR PARTS

Agri-Fab, Inc.

809 South Hamilton

Sullivan, IL. 61951

217-728-8388

www.agri-fab.com

Loading...

Loading...