Sears 397.19591 Owner's Manual

Sears

owners

manual

MODEL NO.

397.19591

1/2

H.P.

•

Assembly

•

Installation

•

Operation

•

Repair Parts

CAUTION:

Read Rules for

~,

Safe Operation

and Instructions

Carefully

COPYRIGHT, 1969, BY POWER TOOL INSTITUTE, INC. ALL RIGHTS RESERVED

CRAFTSMAN GRINDER

THIS SAFETY SEAL OF THE POWER TOOL INSTITUTE ASSURES YOU:

1. That the manufacturer's power tools, including the particular tool associated with the Seal, are

produced in accordance with applicable Standards for Safety of Underwriters' laboratories.

2. That compliance with appl icable safety standards is assured by independent inspection and

, testing conducted by Underwriters' laboratories (UU.

3. That every motorized tool is inspected under power.

4. That every tool has with it adequate instructions and a list of safety rules for the protection of

the user.

5. That the tool manufacturer is a member of the Power Tool Institute and is a sponsor of the

Institute's Consumer Safety Education Program.

Sears, Roebuck and Co.,Chicago,

Ill.

60607 U.S.A.

and Simpsons Sears Limited, Toronto

I

RULES FOR SAFE OPERATION.

Read instructions carefully before using.

1. KEEP GUARDS IN PLACE and in working order.

2. REMOVE ADJUSTING KEYS AND WRENCHES.

Form habit of checking to see that keys and adjusting

wrenches are removed from tool before turning it on.

3. KEEP WORK AREA CLEAN. Cluttered areas and

benches invite accidents.

4. AVOID DANGEROUS ENVIRONMENT. Don't use

power tools in damp or wet locations. Keep work area

well lit.

5. KEEP CHILDREN AWAY. All visitors should be kept

safe distance from work area.

6. MAKE WORKSHOP KID PROOF - with padlocks,

master switches, or by removing starter keys.

7. DON'T FORCE TOOL. It will do the job better and

safer at the rate for which it was designed.

8. USE RIGHT TOOL. Don't force tool or attachment to

do a job it was not designed for.

9. WEAR PROPER APPAREL. No loose clothing or

jewelry to get caught in moving parts. Rubber-soled

footwear is recommended for best footing.

10. USE SAFETY GLASSES. Also use face or dust mask if

cutting operation is dusty.

11. SECURE WORK. Use clamps or a vise to hold work

when practical. It's safer than using your hand and it

frees both hands to operate tool.

12. DON'T OVERREACH. Keep proper footing and

balance at all times.

13. MAINTAIN TOOLS WITH CARE. Keep tools sharp

and clean for best and safest performance. Follow

instructions for lubricating and changing accessories.

14. DISCONNECT TOOLS before servicing; when

changing accessories such as blades, bits, cutters, etc.

15. AVOID ACCIDENTAL STARTING. Make sure switch

is in "Off" position before plugging in.

16. USE RECOMMENDED ACCESSORIES. Consult the

owner's manual for recommended accessories. The use

of improper accessories may cause hazards.

17. GROUND THE OUTLET BOX to prevent possible

fatal shocks. SEE "OPERATION" PAGE 5.

18. BE SURE YOUR VOLTAGE SUPPLY AGREES with

r

the voltage specified on the nameplate. Use the proper

fuse and extension cord to prevent fires and wiring

damage.

19. EXAMINE GRINDING WHEELS FOR CRACKS or

other damage before operating. Replace cracked wheel

immediately. When wheels are replaced, do not

overtighten retaining nut.

20. ALL GUARDS MUST BE IN PLACE and all

adjustments securely tightened before starting grinder.

Protect your eyes and body by wearing shatterproof

glasses and attaching the eyeshields and spark arresters

to the grinder. Do not stand in front of grinder during

first minute of operation.

21. USE ONLy WHEEL FLANGES FURNISHED WITH

GRINDER.

22. MOUNT THE GRINDER SECURELY to prevent

damage. SEE "INSTALLATION" PAGE 3. Do not

force work against the wheels, since thrown wheel

chips may injure the operator or bystander.

23. DO NOT FORCE WORK against the grinding wheel!

Excessive pressure may cause injury to the operator

and damage or breakage to the grinding wheel.

24. BE SURE YOU READ ALL INSTRUCTIONS

pertaining to 115 volt and 230 volt operation before

attempting to change connections.

ASSEMBLY

The key numbers in the instructions refer to the adjacent

assembly instructions.

INSPECT GRINDING WHEELS FOR DAMAGE BEFORE

USING.

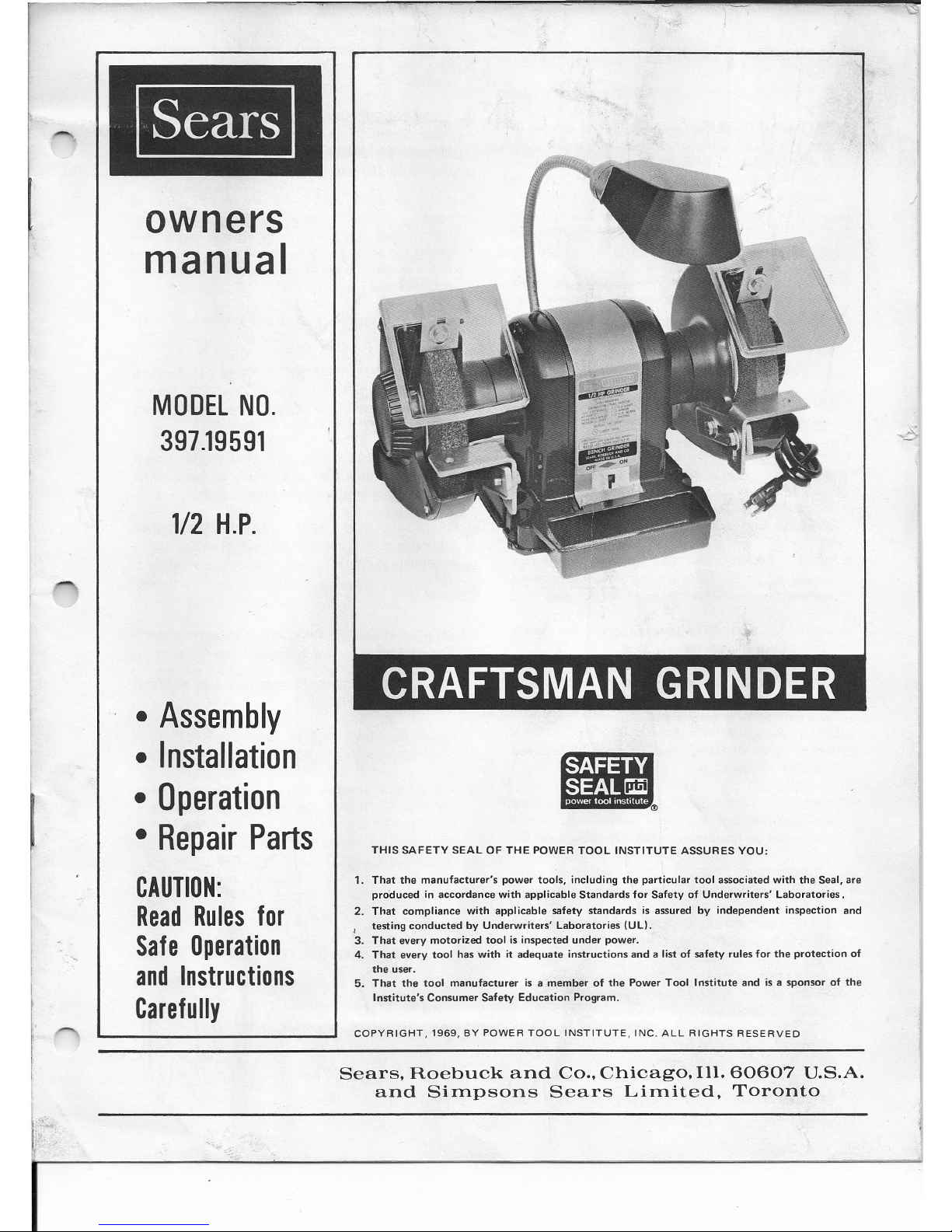

1.

Attach wheel covers (4&24) to wheel guards (9&21)

using eight screws (3) furnished. See figure 1.

2.

Attach spark arresters (53) to top front of wheel

guards (9&21) using flat washers (38) and bolts -

5/16-18 x 3/8 (54). Adjust spark arresters to 1/16 inch

from wheel and tighten bolts. See figure 1.

~

;f

9 and21 51 49

50

m

t ~~

3~ , ~

4-L.~:i .

I

24-R.H.1'

FI6URE~

2

3. Fasten eyeshield (49) to top of wheel guards (9&21)

using bolts - %-20 x 2% (50) and wing nuts (51). See

figure 1.

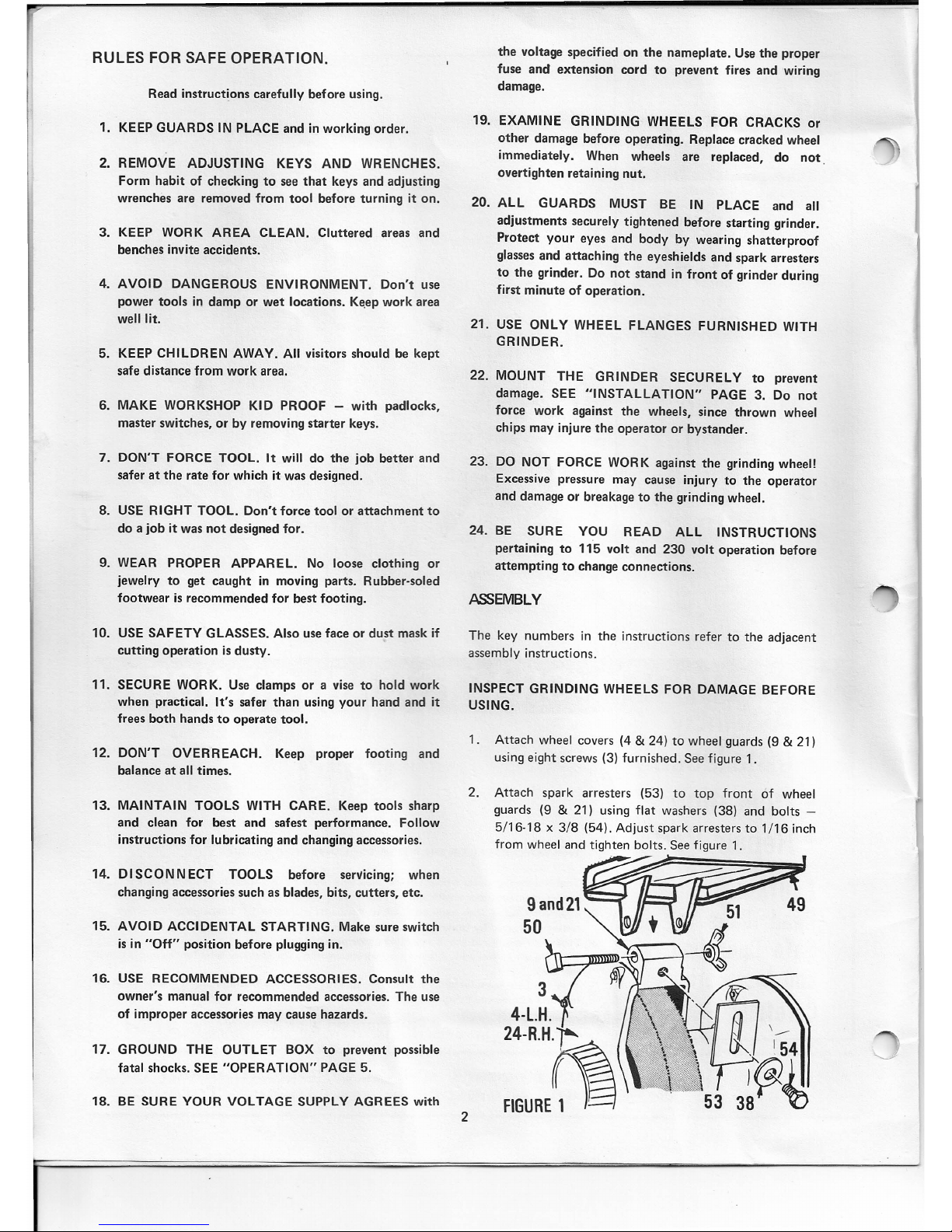

4.

Attach tool rest arms (37) to inner side of wheel guards

(9&21) using flat washers (38) and bolts - 5/16-18

x

3/4 (39) as shown. Attach tool rests (35&36) to tool

rest arms using bolts (39) and washers (38). Adjust as

desired and tighten. See figure 2.

5. Insert 4 base bushings (33) in slots provided at each

corner of base as shown in illustration. Thick section of

bushing extends below grinder base. See figure 2.

6. Assemble lamp shade cover (18) to metal lamp shade

(17) with screw (19). Clamp this assembly to lamp

holder. For 115 volt operation we recommend either

40 watt "regular" or 50 watt "rough service" bulb in

your grinder lamp. For 230 volt operation use a 230

volt 50 watt "rough service" bulb. (G.E. 50A/RS or

equivalent.) See figure 3.

7. Attach quench tray (40) to front of cover band (15) in

knockout slot provided. Lip at side of tray hooks into

slot. Seefigure 3.

l~

,

15 40

FIGURE 3

8.

The. illustration shows how the washer spacer (56) is

assembled to your grinder when accessories are used.

Seefigure 4.

Accessory

Wheel

6

FIGURE4

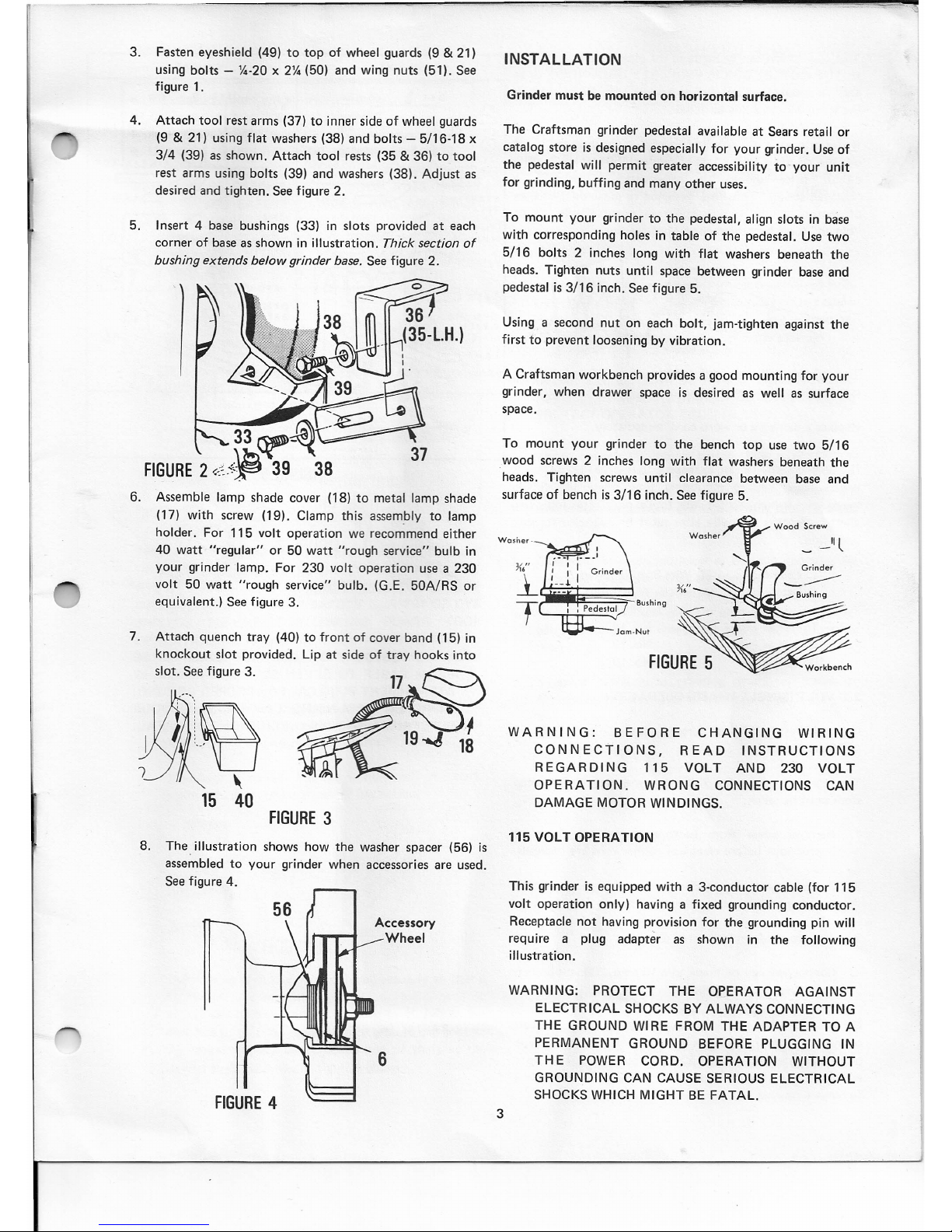

INSTALLATION

Grinder must be mounted on horizontal surface.

The Craftsman grinder pedestal available at Sears retail or

catalog store is designed especially for your grinder. Use of

the pedestal will permit greater accessibility

to

your unit

for grinding, buffing and many other uses.

To mount your grinder to the pedestal, align slots in base

with corresponding holes in table of the pedestal. Use two

5/16 bolts 2 inches long with flat washers beneath the

heads. Tighten nuts until space between grinder base and

pedestal is 3/16 inch. Seefigure 5.

Using a second nut on each bolt; jam-tighten against the

first to prevent loosening by vibration.

A Craftsman workbench provides a good mounting for your

grinder, when drawer space is desired as well as surface

space.

To mount your grinder to the bench top use two 5/16

wood screws 2 inches long with flat washers beneath the

heads. Tighten screws until clearance between base and

surface of bench is 3/16 inch. See figure 5.

Wc sher .

_ -Ill

Grinder

~.~~~~BUShing

WARNING: BEFORE CHANGING WIRING

CONNECTIONS, READ INSTRUCTIONS

REGARDING 115 VOLT AND 230 VOLT

OPERATION. WRONG CONNECTIONS CAN

DAMAGE MOTOR WINDINGS.

115

VOLT OPERATION

This grinder is equipped with a 3-conductor cable (for 115

volt operation only) having a fixed grounding conductor.

Receptacle not having provision for the grounding pin will

require a plug adapter as shown in the following

illustration.

WARNING: PROTECT THE OPERATOR AGAINST

ELECTRICAL SHOCKS BY ALWAYS CONNECTING

THE GROUND WIRE FROM THE ADAPTER TO A

PERMANENT GROUND BEFORE PLUGGING IN

TH E POWER CORD. OPERATION WITHOUT

GROUNDING CAN CAUSE SERIOUS ELECTRICAL

SHOCKS WHICH MIGHT BE FATAL.

3

Loading...

Loading...