Page 1

___A_/h_

Save This Manual

Future Referencel

PRINTED IN U S A

"HYDRO-GLASS"®

SELF-PRIMING

CENTRIFUGAL PUMP

* Installation

o Operation

® Repair Parts

Sears, Roebuck and Co., Chicago, III. 60684 U.S.A.

F642-7985

Page 2

Carefully r_r_._._., safety instructions in this

manual _ _'_"

_,._ This ig tl-" _ .... ,=bol. When you see this

symbol,my-\ -_---- .;,=smanual, look for one of

the follf_w H'..,"_z_ ..... _dbe alert to the potential

for permm,'_ :_'-:-

_ =",-_K.._-...... _sabout hazards that will

cause s_ t,_,_-_=--_........ y, death or major property

damag_ If ,_'\'_=-_

[jI,WARNIN_, t_:_r_=_r.,_rns about hazards that

can calms' ._>°-_-;..... ._I injury, death or major

properly ,t_'_- - _ ....

III, CAU1 I*'_N _.._.L---_,_.,_,.ns about hazards that will

or can cnl _' '_--- :--_-_. ,njury or property damage

if ignore, I

The word NOTL_ ;_'_>._ _pecial instructions which

are imp(_ I_u_,-_-;=c _ to hazards.

CONTENTS

Safety/Introduction ............................ 2

Warranty ..................................... 3

Installation .................................. 4-6

Operation ..................................... 7

Maintenance ................................. 10

Troubleshooting/Pump Performance ........... 11

Repair Parts .............................. 12-13

INTRODUCTION

Please take a few minutes to read our instructions

before you install and use your pump. This will help

you obtain the full benefits from this pump. It will also

help you avoid any needless service costs that result

from causes we cannot control and cannot cover in

our warranty.

_._., Safety

, kwAHNINC-

.... Wire motor for correct

,I_ voltage. See "Electrical"

and motornameplate.

Groundmotorbefore

,_-_connectingto power

sectionofthis manual

supply.

Meet National Electrical

d_

Hazardou_ wfll_O e-

Can shock, lit.n, or

cause dealh

Ground puml _I_h_e . ,_ in this manual when

_:onnectinc! h_ p,_\_er i

_upply. _j power lines.

Make worksh_q _ _'hildprc'4 _,_# padlocks and master

r_witches; rel_t_ _\'_ _hlrter t_%,£

_lk Code and local codes for

all wiring.

Follow wiring instructions

I connecting motor to

General Safety

WARNING

Hazardouspressure!

Donot runpump

against closeddischarge,

Releaseall pressureon

systembeforeworking on

anycomponent.

Pump is designed as a lawn sprinkler only. To avoid

heat build-up, over pressure hazard and possible

injury, do not use in a pressure tank (domestic

water) system. Do not use as a booster pump;

pressurized suction may cause pump body to

explode.

Do not allow pump or piping system to freeze.

Freezing can damage pump and pipe, may lead to

injury from equipment failure, and will void warranty.

Pump water only with this pump.

Periodically inspect pump and system components.

Wear safety glasses when working on pumps.

Keep work area clean, uncluttered and well lighted;

store properly all unused tools and equipment.

Keep visitors at a safe distance from the work areas.

Page 3

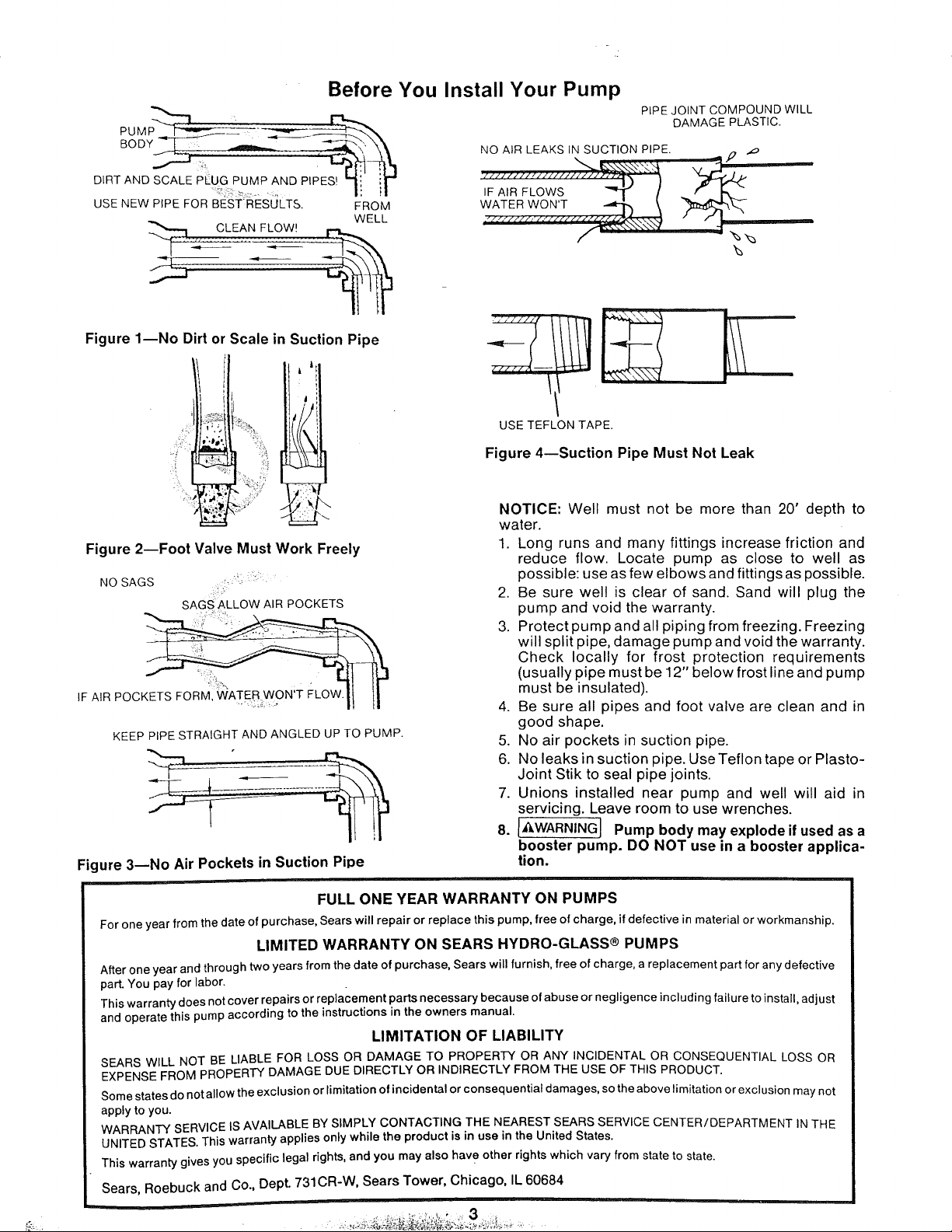

Before You

USE NEW PIPE FOR BEST:RESULTS, FROM

CLEAN FLOW!

Figure 1--No Dirt or Scale in Suction Pipe

WELL

I"-'11,,,__

Install Your Pump

PIPE JOINT COMPOUND WILL

DAMAGE PLASTIC.

NO AIR LEAKS IN SUCTION PIPE. #

/ / / / i ///////////////zz_lZl_''""_'__f,,_. .,

IF AIR FLOWS _ / _ f K -

WATER WON'T -._ \ "_._

USE TEFLON TAPE.

Figure 4--Suction Pipe Must Not Leak

,_,

NOTICE: Well must not be more than 20' depth to

water.

Figure 2--Foot Valve Must Work Freely

NO SAGS :-:!i "::

SAGSALLOW AIR POCKETS

1. Long runs and many fittings increase friction and

reduce flow. Locate pump as close to well as

possible: use as few elbows and fittings as possible.

2. Be sure well is clear of sand. Sand will plug the

pump and void the warranty.

3. Protect pump and all piping from freezing. Freezing

will split pipe, damage pump and void the warranty.

Check locally for frost protection requirements

IF AIR POC_

(usually pipe must be 12" below frost line and pump

must be insulated).

4. Be sure all pipes and foot valve are clean and in

good shape.

KEEP PIPE STRAIGHT AND ANGLED UP TO PUMP.

5. No air pockets in suction pipe.

6. No leaks in suction pipe. Use Teflon tape or Plasto-

Joint Stik to seal pipe joints.

7. Unions installed near pump and well will aid in

servicing. Leave room to use wrenches.

8. I_kWARNINGI Pump body may explode if used asa

booster pump. DO NOT use in a booster applica-

Figure 3--No Air Pockets in Suction Pipe

tion.

FULL ONE YEAR WARRANTY ON PUMPS

For one year from the date of purchase, Sears will repair or replace this pump, free of charge, if defective in material or workmanship.

LIMITED WARRANTY ON SEARS HYDRO-GLASS® PUMPS

After one year and through two years from the date of purchase, Sears will furnish, free of charge, a replacement part for any defective

part. You pay for labor.

This warranty does not cover repairs or replacement parts necessary because of abuse or negligence including failure to install, adjust

and operate this pump according to the instructions in the owners manual.

LIMITATION OF LIABILITY

SEARS WILL NOT BE LIABLE FOR LOSS OR DAMAGE TO PROPERTY OR ANY INCIDENTAL OR CONSEQUENTIAL LOSS OR

EXPENSE FROM PROPERTY DAMAGE DUE DIRECTLY OR INDIRECTLY FROM THE USE OF THIS PRODUCT.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not

apply to you.

WARRANTY SERVICE IS AVAILABLE BY SIMPLY CONTACTING THE NEAREST SEARS SERVICE CENTER/DEPARTMENT IN THE

UNITED STATES. This warranty applies only while the product is in use in the United States.

This warranty gives you specific legal rights, and you may also hav e other rights which vary from state to state.

Sears, Roebuck and Co., DepL 731CR-W, Sears Tower, Chicago, IL 60684

Page 4

Well Pipe Installation

PRIMING PLUG _ CHECK

PRIMING TEE _VALVE

SURFACE WATER SOURCE

Pump suction size: 11/2"NPT

Pump discharge size: 11/2"NP

SUCTIONJ

PIPE

DING WATER I I

fl STEEL

-P4HI -- LEVEL I I

I ] (PUMPOFF) [ I

I I II DRAWDOWNWATER I I

(PUMP ON) coD#/VlEN G

I III f EI -WEL,

_1 @ST 5 FEET _ POINT

II DRIVEN POINT

Figure 6--Cased/Dug Well

Installation

NOTICE: Use the installation method below which

matches your well type.

CASED WELL INSTALLATION

1.

Inspect foot valve to be sure it works freely. Inspect

strainer to be sure it is clean.

2

Connect foot valve and strainer to the first length of

suction pipe and lower pipe into well. Add sections

of pipe as needed, using Teflon tape on male

threads. Be sure that all suction pipe is leakproof or

pump will lose prime and fail to pump. Install foot

valve 10 to 20 feet below the lowest level to which

water will drop while pump is operating (pumping

water level). Your well driller can furnish this

information.

.

To prevent sand and sediment from entering the

pumping system, the foot valve/strainer should be

at least 5 feet above the bottom of the well.

4. When the proper depth is reached, install a sanitary

well seal over the pipe and in the well casing.

Tighten the bolts to seal the casing.

5. When using a foot valve, a priming tee and plug as

shown in Figure 6 are recommended.

DUG WELL INSTALLATION

Same as cased well installation.

DRIVEN POINT INSTALLATION

1. Connect the suction pipe to the drive point as

illustrated in Figure 7. Keep horizontal pipe run as

short as possible. Use Teflon tape on male pipe

threads. Multple well points may be necessary to

provide sufficient water to pump.

Figure 7--Driven Point

Installation

VALVE "- . ""

!ALVE __"

Figure 5--Match Pump to Water Source

--- PRIME HERE

TO

SERVICE

SERVICE

Figure 8--Multiple Discharge

2. Install a check valve in horizontal pipe. Flow arrow

on check valve must point toward pump.

HORIZONTAL PIPING FROM WELL TO PUMP

1. Never install asuction pipe that is smaller than the

suction port of the pump.

2. To aid priming on well point installations, install a

line check valve as shown in Figure 7. Be sure

check valve flow arrow points toward pump.

DISCHARGE PIPE SIZES

1.

If increasing discharge pipe size, install reducer in

pump discharge port. Do not increase pipe size by

stages.

.

When the pump is set away from the points of water

use, the discharge pipe size should be increased to

reduce pressure losses caused by friction•

e Up to 100' run: Same size as pump discharge

port•

• 100' to 300' run: Increase one pipe size.

• 300' to 600' run: Increase two pipe sizes.

LAWN SPRINKLING APPLICATION

This pump is designed for lawn sprinkling. It is

designed to deliver plenty of water at full sprinkler

pressure. It can pump from a pond, cistern or well

points.

Pump discharge can be divided to supply two (2) or

more sprinkler systems. A suggested multiple dis-

charge to service is shown in Figure 8.

Do not use in a pressure tank or booster pump

application.

TO

Page 5

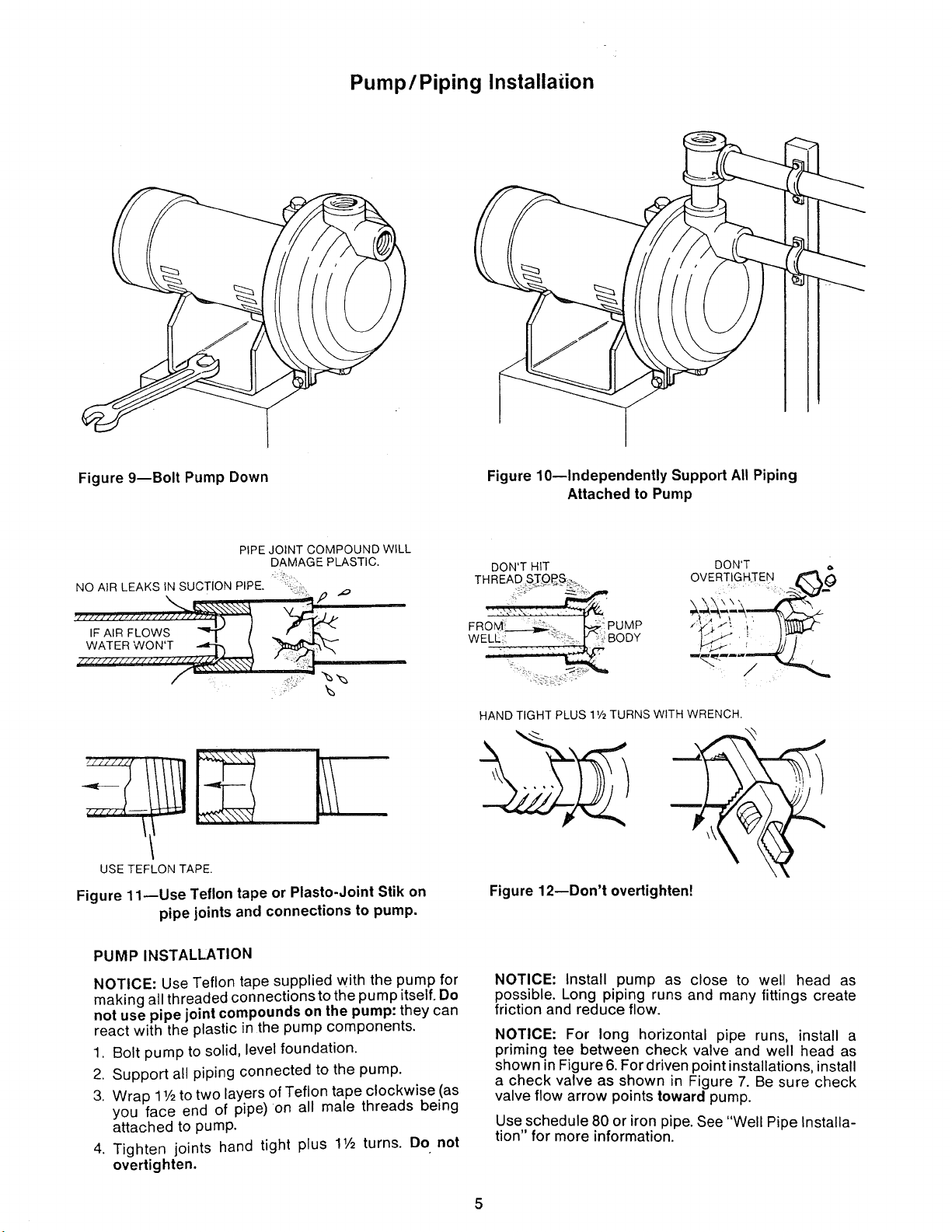

Pump/Piping Installation

Figure 9--Bolt Pump Down

PIPE JOINT COMPOUND WILL

DAMAGE PLASTIC.

NO AIR LEAKS IN SUCTION PIPE. "_.'(: ,

'W--)

WATER WON'T _ \ _ _"

/l!ll!//l///(l!!!//!/I/P / * -,'{[

USE TEFLON TAPE.

Figure 11--Use Teflon tape or Plasto-Joint Stik on

pipe joints and connections to pump.

Figure 10--Independently Support All Piping

Attached to Pump

DON'T HIT

THREAD STO_S _

W BODY

HAND TIGHT PLUS 11/2TURNS WITH WRENCH.

Figure 12--Don't overtighten!

DON'T

OVERT!GHZEN _,_

PUMP INSTALLATION

NOTICE: Use Teflon tape supplied with the pump for

making all threaded connections to the pump itself. Do

not use pipe joint compounds on the pump: they can

react with the plastic in the pump components,

1. Bolt pump to solid, level foundation.

2. Support all piping connected to the pump.

3. Wrap 11/2to two layers of Teflon tape clockwise (as

you face end of pipe)on all male threads being

attached to pump.

4. Tighten joints hand tight plus 1Vz turns. Do not

overtighten.

NOTICE: Install pump as close to well head as

possible. Long piping runs and many fittings create

friction and reduce flow.

NOTICE: For long horizontal pipe runs, install a

priming tee between check valve and well head as

shown in Figure 6. For driven point installations, install

a check valve as shown in Figure 7. Be sure check

valve flow arrow points toward pump.

Use schedule 80 or iron pipe. See "Well Pipe Installa-

tion" for more information.

Page 6

MOTOR

10-32 GROU

(BINDING HEAD)

UNDER MOTOR

CANOPY

WHITE W/BLACK TRACER[ Io7, i X

115

VOLT

LINES

Electrical

Motor Terminal Block Wiring

10-32 GROU

(BINDING HEAD)

UNDER MOTOR

CANOPY

WHITE _ L_,

W/BLACK TRACER i s _

MOTOR

I

230

VOLT

\ LINES

BLACK _

Figure 13 -- 115V Wiring diagram

Figure 14 -- 230V Wiring diagram

BLACK !IQ_ _

WIRING CHART

Recommended Wire and Fuse Sizes

DISTANCE IN FEET FROM MOTOR TO METER

0' 51' 101' 201' 301' 401'

Pump

Model HP

390.262401 1

390.262501 1½

390.262601 2

Volt

115

230

115

230

230

Max.

Load

Amps

15.4

7.7

18.2

9.1

12.0

Branch

Fuse*

Rating*

Amps

20

15

30

15

15

Min. TO TO TO TO TO TO

Wire 50' 100' 200' 300' 400' 500'

Size WIRE SIZE

12 12 12 8 6 6 - 4

14 14 14 14 12 12 10

10 10 10 8 6 4 2

14 14 14 14 12 10 10

14 14 14 12 12 10 8

(*) Dual element or Fusetron time delay fuses recommended for all motor circuits.

WIRING

kWARNING

,_ Ground motor before

connecting to electrical

power supply.

1. Install, ground, wire and maintain this pump in

accordance with your local electrical code and all

other codes and ordinances that apply. Consult

your local building inspector for local code in-

formation.

,_ Failure to ground motor

can cause severe or fatal

electrical shock hazard.

2. Ground the pump permanently using a wire of size

and type specified by local or National Electrical

Code.

_h, Do not ground to a gas supply line.

A_IL Do not ground to a gas

supply line.

3. Connect ground _vire first. Connect to ground first,

then to green grounding terminal provided under

motor canopy (see Figures 13 and 14)identified as

Hazardous voltage.

Can shock, burn, or ,_b,

cause death.

Ground pump before

connecting to power

To avoid dangerous or

fatal electrical shock, turn

OFF power to motor

before working on

electrical connections.

supply,

,_ Supply voltage must be

within +10% of nameplate

voltage. Incorrect voltage can cause fire or

seriously damage motor and voids warranty. If in

GRD. Make ground connection to this terminal. Do

not connect motor to electrical power supply until

unit is permanently grounded; otherwise serious or

fatal electrical shock hazard may be caused.

4. For best ground connection,connecttoagrounded

lead in the service panel or to a metal underground

water pipe or well casing at least 10 feet long. If

plastic pipe or insulated fittings are used, run

ground wire directly to the metal well casing or use

ground electrode furnished by the power company.

doubt consult a licensed electrician.

,_Use wire size specified in Wiring Chart (above.) it

possible, connect pump to a separate branch circuit

with no othe_ appliances on it.

Page 7

G

Operation

i

Figure 15--Remove Priming Plug

Figure 16--Fill Pump Before Starting

PRIMING THE PUMP

NOTICE: 'Priming' refers to the pump expelling all air

in the system and beginning to move water from its

source out into the system. It does not refer only to

pouring water into the pump (although pouring water

in is usually the first step).

NOTICE: NEVER runpump dry. Running pump without

water in it willdamage seals and can melt impeller and

diffuser. To prevent damage, fill pump with water

before starting.

1. Remove priming plug (Figure 15).

2. Make sure suction and discharge valves and any

hoses on discharge side of pump are open.

3. Fill pump and suction pipe with water.

4. Replace priming plug, using Teflon tape on thread;

tighten plug.

NOTICE: If a priming tee and plug have been

provided for a long horizontal run, be sure to fill

suction pipe through this tee and replace PlUg.

(Dont' forget to Teflon tape the plug.)

5. Start pump: water should be produced in 10minutes

or less, the time depending on depth to water (not

more than 20') and length of horizontal run (10' of

Figure 17--Run Ten Minutes or Less

i" ,!

/ i '

i ,i

f _'" it

x.j\ _,

\ :

\

Figure 18--Do Not Run Pump with

Discharge Shut-off.

horizontal suction pipe -- 1' of vertical lift due to

friction losses in the pipe).

If no water is produced within 10 minutes, stop

pump, release all pressure, remove priming plug,

refill and try again.

[_kWARNING] Hazardous pressure and risk of ex-

plosion and scalding. If pump is run continuously at

no flow (that is, with discharge shut off or without

priming), water may boil in pump and piping system.

Under steam pressure, pipes may rupture, blow offof

fittings or blow out of pump ports and scald anyone

near.

To prevent explosion, do the following:

A. Be sure discharge (valve, pistol grip hose nozzle,

etc.) is open whenever pump is running.

B. If pump fails to produce water when attempting to

prime, release all pressure, drain pump and refill

with cold water after every two attempts.

C. When priming, monitor pump and piping tempera-

ture. If pump or piping begin to feel warm to the

touch, shut off pump and allow system to cool off.

Release all pressure in system and refill pump and

piping with cold water.

Page 8

I

ol

Maintenance

O

O

Figure 19--Disconnect Power

(

Figure 21--Remove Diffuser

MAINTENANCE

Pump and piping need not be disconnected to repair

or replace motor or seal (see Figure 20). If motor is

replaced, replace the shaft seal (Key No. 7, Page 12).

Keep one on hand for future use.

Be sure to prime pump before starting.

NOTICE: Check motor label for lubrication instruc-

tions. The mechanical shaft seal in the pump is water

lubricated and self-adjusting.

NOTICE: Drain pump when disconnecting from ser-

vice or when it might freeze.

PUMP DISASSEMBLY

1. Disconnect power to motor.

NOTICE: Mark wires for correct assembly.

2. Remove clamp (see Figure 20).

3. Remove pump base mounting bolts. Motor

assembly and back half of pump can now be pulled

away from pump front half (Figure 20). CAREFULLY

remove O-ring.

Figure 20--Slide Motor Back

_kWARNING

To avoid electrical

shock hazard, use

insulated-handle

screwdriver to short

capacitor terminals

as shown.

Figure 22--Hold Shaft

CLEANING/REPLACING IMPELLER

NOTICE: First, follow instructions under "Pump

Disassembly".

1. Remove four screws fastening diffuser to seal plate;

remove diffuser (see Figure 21). Exposed impeller

can now be cleaned.

2. If impeller must be replaced, loosen two machine

screws and remove motor canopy (see Figure 22).

3. I_kWARNINGI Capacitor voltage may be hazardous.

To discharge capacitor, hold insulated handle

screwdriver BY THE HANDLE and short capacitor

terminals together (see Figure 22). Do not touch

metal screwdriver blade or capacitor terminals. If in

doubt, consult a qualified electrician.

4. Unscrew capacitor clamp and remove capacitor.

Do not disconnect capacitor wires to motor.

5. Slide 7/16" open end wrench in behind spring

loaded switch on motor end of shaft; hold motor

shaft with wrench on shaft flats and unscrew

impeller by turning counterclockwise when

looking into eye of impeller.

6. To reinstall, reverse steps 1 through 5.

7. See directions under "Pump Reassembly," Page

10.

Page 9

Figure 23mRemove Seal Plate

Maintenance (Continued)

Figure 24--Tap Out Seal

Figure 25--Press In New Seal

REMOVING OLD SEAL

1. Follow instructions under "Pump Disassembly".

2. Follow steps 2 through 5 under "Cleaning/

Replacing Impeller".

3. Unscrew four nuts holding pump back half to motor.

Remove rotating half of seal by placing two screw-

drivers under back half of pump body and carefully

prying up (Figure 23). Back half of pump body will

slide off shaft, bringing seal with it.

NOTICE: Be sure you do not scratch or mar shaft; if

shaft is marred, it must be dressed smooth with fine

emery or crocus cloth before installing new seal. DO

NOT reduce shaft diameter!

4. Place pump body half facedown on flat surface and

tap out stationary half of seal (see Figure 24).

NOTICE: Be sure you tap on ceramic seat, not on

copper heat sink. Do not disturb heat sink (Key No. 6,

Page 12).

INSTALLING NEW SEAL

1. Clean sea! cavity in copper heat sink. Do not disturb

heat sink. (If heat sink is moved or dislodged, see

instructions for "Installing Copper Heat Sink", Page

10).

2. Wet outer edge of Rubber Cup on ceramic seat with

liquid soap. Be sparing!

BE CAREFUL THAT

SHAFT SHOULDER

CERAMIC

FACE

DOES NOT DAMAGE

SEAL FACE

CARBON

FACE

Figure 26--Protect Seal Faces

3. Put clean cardboard washer on seal face. With

thumb pressure, press ceramic sea! half firmly and

squarely into seal cavity in copper heat sink (See

Figure 25). Polished face of ceramic seat is up. If

seal will not seat correctly, remove, placing seal

face up on bench. Reclean cavity, seal should now

seat correctly.

4. If seal does not seat correctly after recleaning

cavity, place a cardboard washer over polished

seal face and carefully press into place using a

piece of standard 3/4" pipe as a press.

NOTICE: Be sure you do not scratch seal face.

5. Dispose of cardboard washer and recheck seal

face to be sure it is free of dirt, foreign particles,

scratches and grease.

6. Inspect shaft to be sure it is free of nicks and

scratches.

7. Reassemble pump body half to motor flange. BE

SURE it is right side up.

8. Apply liquid soap sparingly (one drop is sufficient)

to inside diameter of rotating seal member.

9. Slide rotating seal member (carbon face first) onto

shaft until rubber drive ring hits shaft shoulder.

NOTICE: Be sure not to nick or scratch carbon face of

seal when passing it over threaded shaft end or shaft

shoulder. The carbon surface must remain clean or

short seal life will result.

Page 10

Figure 27--Hold Shaft

_kWARNING

To avoid electrical

shock hazard, use

insulated-handle

screwdriver to short

capacitor terminals

as shown.

WIPE ON SMALL AMOUNT OF

Figure 27A

r_l___/_ '' SOCKET

i BOLT

Figure 27B P_OPERLY_

Figure 27C _

Figure 28--Assemble Pump

10. Hold motor shaft with 7/16" open end wrench on

shaft flats and screw impeller onto shaft. Be sure

you do nottouch capacitor terminals with body or

any metal object. Tightening impeller will auto-

matically locate seal in correct position.

11. Remount diffuser on pump body half with five

screws.

12. Follow instructions under "Pump Reassembly".

NOTICE: If the copper heat sink moves or shifts during

seal removal, it should be removed and reinstalled.

PUMP REASSEMBLY

1. Clean O-ring and O-ring groove.

2. Put O-ring in groove on face of flange; put pump

halves together (see Figure 28).

3. BE SURE inside of clamp is clean. Place clamp on

pump halves; snug up. Alternately tighten screw

and tap clamp with mallet to seat O-ring (see Figure

29),

4. Replace base mounting bolts.

5. Replace pressure switch tubing andmotor wiring;

close draincock.

Figure 29--Tap Clamp While Tightening

6. Prime pump according to instructions. See "Opera-

tion."

7. Check for leaks.

COPPER HEAT SINK REMOVAL

Remove Ceramic portion of sink (see "Removing Old

Seal"). Grasp with fingers at the large end andmove

back and forth. Be careful not to deform it.

COPPER HEAT SINK INSTALLATION

1. Clean off all sealant and foreign material.

2. Clean out heat sink cavity in seal plate.

3: Apply thin layer of non-hardening Permatex on

outer surface of heat sink (part that fits into cavity,

Figures 27A and 27C).

4. Using standard 7/8" socket, bolt, and 13/8'' washer

pull heat sink into cavity as shown in Figure 27B.

5. Clean out any surplus Permatex from insert cavity

where new seal will be located (Figure 27C).

6. Follow steps 2 through 11 under "Installing New

Seal".

!

10

Page 11

Troubleshooting Chart

SYMPTOM

Motor wile not

run

Motor runs hot

and overload

kicks off

Motor runs but

no water is

is delivered

*(Note: Check

prime before

looking for

other causes.

Unscrew prim-

ing plug and see

if there is water

in priming hole.)

Pump does not

deliver water

to full capacity

(Also check

point 3 imme-

diately above)

POSSIBLE CAUSE(S)

1. Disconnect switch is off

2. Fuse isblown

3. Starting switch is defective

4. Wires at motor are loose, dis-

connected, or wired incorrectly

1. Motor is wired incorrectly

2. Voltage is too low

"1. Pump in a new installation did

not pick up prime through:

a. Improper priming

b. Air leaks

c. Leaking foot valve

*2. Pump has lost its prime

through:

a. Air leaks

b. Water level below suction

of pump

3. Impeller is plugged

4. Check valve or foot valve is

stuck in closed position

5. Pipes are frozen

6. Foot valve and/or strainer are

buried in sand or mud

1. Water level in well is lower than

estimated

2. Steel piping (if used) is

corroded or limed, causing

excess friction

3. Offset piping is too small in size

CORRECTIVE ACTION

1. Be sure switch ison

2. Replace fuse

3. Replace starting switch

4. Refer to instructions on wiring. Check and tighten

all wiring.

1. Refer to instructions on wiring

2. Check with power company. Install heavier

wiring if wire size is too small. See Electrical, P. 7.

1. In new installation:

a. Re-prime according to instructions

b. Check all connections on suction line.

c. Replace foot valve

2.

In installation already in Use:

a. Check all connections on suction line and

shaft seal

b. Lower suction line into water and re-prime. If

receding water level in well exceeds suction

lift, a deep well pump is needed.

3.

Clean impeller; see Maintenance

4.

Replace check valve or foot valve

5.

Thaw pipes. Bury pipes below frost line. Heat pit

or pump house.

6.

Raise foot valve and/or strainer above well

bottom

1. A deep well jet pump may be needed (over 20 ft. to

water)

2. Replace with plastic pipe where possible, other-

wise with new steel pipe

3. Use larger offset piping

DISCHARGE

PRESSURE

P.S.I.

10

15

20

25

30

35

DISCHARGE

PIPE

TAPPING

SUCTION

PIPE

TAPPING

PERFORMANCE CHART (IN GALLONS PER MINUTE)

390.262401 390.262501 390.262601

1 H.P. 11/zH.P. 2 H.P.

5' 10' 15' 20'

65 59 56 48

58 55 50 45

51 47 44 39

42 37 34 29

31 26 22 --

18 4 -- --

11/2'' NPT

11/2"NPT

TABLE II

DISTANCE ABOVE WATER

5' 10' 15' 20'

80 71 68 56

77 68 66 55

69 63 60 54

59 55 50 46

49 44 36 33

36 27 12 --

1!/2"NPT

11/2"NPT

11

5' 10' 15' 20'

83 78 68 57

81 77 67 56

78 76 66 55

72 69 62 54

61 56 50 45

46 41 22 7

11/2"NPT

11/2'' NPT

Page 12

SEARS "HYDRO-GLASS ''®CENTRIFUGAL PUMPS

MODELS 390.262401, 390.262501, AND 390.262601

9 11

10

14

2

13

12

Page 13

SEARS "HYDRO-GLASS"® CENTRIFUGAL PUMPS

MODELS 390.262401, 390.262501, AND 390.262601

Key

No.

10

®

11

12

13

14

15

16

17

18

O

1

1A

2

3

4

5

6

7

8

9

Part

Description

Motor

Motor Canopy

Slinger

Priming Plug 1/2"NPT

Tank Body Back Half Complete (Includes No. 3)

"O" Ring

Seal Plate Insert

Shaft Seal for %" Shaft

impeller

Diffuser

Screw #8-32 RH (4 Required)

Lockwasher #8

"V" Clamp

Tank Body Front Half (Includes No. 13)

Drain Plug 1,4NPT

"O" Ring

Base

Washer 5/16 (4 Required)

Nut 5/16-18 (4 Required)

Rubber Pad

Owner's Manual

390.262401

115/230V

60Cy/1Ph

1HP

J218-596AC

U18-1235

C69-2

L276-35P1

U9-389

J3-2

2784

C105-138PBB

C1-258PA

U30-542SS

C19-54SS

C176-53P

U9-226

J104-9C

U43-11ZP

• U36-37ZP

C35-5

F642-7985

390,262501

115/230V

60Cy/1Ph

1½ HP

J218-601AC

U18-1235

C69-2

L276-35P1

U9-389

J3-2

2784

C105-137PH

C1-258PB

U30-869SS

C19-54SS

C176-53P

YrW

U9-226

J104-9C

U43-11ZP

U36-37ZP

C35-5

F642-7985

390.262601

230V

60Cy/1Ph

2 HP

J218-880AC

U18-1235

C69-2

L276-35P1

U9-389

J3-2

2784

C105-137PJ

C1-258P

U30-869SS

C19-54SS

C176-53P

U9-226

J104-9C

U43-11ZP

U36-37ZP

C35-5

F642-7985

• Not illustrated,

• * Purchase Locally

13

Page 14

"HYDRO-GLASS"®

SELF-PRIMING

CENTRIFUGAL PUMP

Now that you have purchased your Centrifugal

Pump, should a need ever exist for repair parts or

service, simply contact any Sears Service Center. Be

sure to provide all pertinent facts when you call or

visit.

The Model Number of your Centrifugal Pump will

be found attached to the side of the pump body.

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE

THE FOLLOWING INFORMATION:

• PART NUMBER

• MODEL NUMBER • NAME OF ITEM

All parts listed may be ordered from any Sears

Service Center.

If the parts you need are not stocked locally, your

order will be electronically transmitted to a Sears

Repair Parts Distribution Center for handling.

When Sears arranges the installation, you can be

sure the job is done right. We will arrange for

professional workmanship . . . and we'll take care

of the entire project. What's more, during installa-

tion you get insured protection . . . against property

damage and also against accidents to workmen. All

you have to do is talk to your Sears salesperson or

call your nearest Sears store today for detailed

information.

• PART DESCRIPTION

Form No. F642-7985 (Rev. 9/90)

Sears, Roebuck and Co., Chicago, i11.60684 U.S.A.

Loading...

Loading...