Sears 385.188418 Owner's Manual

OWNER'S MANUAL

S _A/RS

SEWING MACHINE

MODEL 385. 1884180

SEARS CANADA |NC,

Dear Customer:

You have just invested m a very fine zigzag sewing machme. Before using your new Kenmore machine,

please pause for a moment and carefully read this booklet which contains instructtons on how to operate

and care for your machine.

Specific instructions are given on threading, tension adjustments, cleamng, oiling, etc_ Th_s wilt help you

obtain the best sewing results and avoid unnecessary service expense for conditions beyond our control.

Advice on the operation and care of your machine is always available at your nearest Sears Retail Store,

Please remember, if you have questions about your machine or need parts and service, always mentton

the model number and seria_ number when you inquire.

Kenmore Sewing Machine

Record _n space provided betow the mode_ number and serial

number of this appliance. The model number and serial number

are located on the nomenclature plate, as identified on Page 3 of

th_s booklet,

Model No..385. Serial No,

Retain these numbers for future reference,

THIS MODEL IS A CENTER NEEDLE, LOW BAR SEWING MACHINE.

SECTION1.

SECTION 2.

SECTION 3.

TABLE

KNOW YOUR MACHINE

A Portable Caseor Cabinet _sAvailable ............. 2

Locate and Identify the Parts ................. 2_3

Identify the Accessories ....................... 4

PREPARE YOUR MACHINE FOR SEWING

Set Up the Machine ....................... 5_9

o Plug in the Machine and Switch on the Power ....... 5

u Foot Control Use ..................... 5

• Set the Speed Range Switch ................... 6

• Set the Pressure Dial ....................... 6

• Setting Spool Pins .......................... 7

o Adjust the Presser Foot Lever .................. 7

• Thread Cutter ............................ 7

• Accessory Storage Box ....................... 8

o Free-Arm Sewing: the Removable Extension Table. o 8_9

Know What the Presser Feet Will Do ............ t0_14

e Check Your Presser Foot .................... t0

e Change the Presser Foot .................. t0

o Presser FootTypes ...................... t!_14

Choose Your Needle and Thread ............... 14"15

• Check Your Needle ........................ t4

o Fabric, Needle, Thread and Stitch Length Chart ..... 15

a To Change Your Needle ..................... 15

Prepare the Bobbin ...................... 16_t7

e To Remove the Bobbin from the Machine ......... t6

o Wind the Bobbin ........................ 16

• Insert the Bobbin into the Bobbm Holder ......... 17

Prepare Your Top Thread ................... 18_21

o Thread Your Needle .................. 18

o Pick Up Your Bobbin Thread ................. 19

e Adjust the Top Thread Tension .............. 20_2t

Stitch Selector ............................ 21

Stitch Length ControI ..................... 22

Adjusting Stretch Stitch Balance ................ 22

Stitch Width Contro_ ...................... 23_24

• Three Needle Position .................. 23_24

Reverse Stitch Control ........................ 25

Starting To Sew ............................ 25

LEARN THE STITCHES

Practical Stitch Chart ...................... 26_30

Straight Stitches ........................ 31_33

• Straight Stitch ......................... 31

• Use the Seam Guides ..................... 31

• Turn a Square Corner ..................... 3t

Use the Daring Plate .................... 32

• Topstitching ........................... 32

OF CONTENTS

• Quilting ............................ 33

Darning .............................. 34

Stralght Stretch ........................ 34

Zigzag Stitches ........................... 35_42

o Basic Zigzag ............................. 35

• Satin Stitch ............................ 36

- Applique ............................... 37

• Bar Tacking ........................... 37

• Monogramming ........................ 38

o Embrmdery ............................. 38

• Sew a Button ............................ 39

• Overcasting Stitch ........................ 40

o Rick-Rack Stretch ...... _ ............. 40

• Three-Step Zigzag ........................ 41

• Overcast Stretch Stitching .................. 42

® Serging or Pine Leaf Stretch Stitching ............ 42

Blind Hemming ........................ 43

Lace Work ................................ 44

Buttonhole Making ...................... 45_5t

• Learning to Sew Buttonholes ................. 45

• Built-in System .................... 46_47

o Using Buttonhole Attachment ............... 48_51

Sew in a Zipper ........................... 52_53

Shell Stitching ............................ 54

Two-Point Shell Stitching ...................... 54

Smocking ............................. 55

Stretch Patching ............................ 55

Fagoting Stitch ............................. 56

Herring Bone Stretch ........................ 56

Elastic Stretch Stitch ......................... 57

Box Stitching .............................. 57

Two-point Box Stitch ........................ 58

Overedg_ng Stitch .......................... 58

Decorative Stretch Patterns .................... 59

Decorate w_th Geometric Patterns ................ 60

SECTION 4. PERFORMANCE PROBLEMS CHART

What to Do When ......................... 61_62

SECTION 5.

CAREFORYOUR MACHINE

Replace the Light Bulb ...................... 63

C_ean the Bobbin Holder .................... 63

Clean the Hook Race and Feed Dogs ............. 64

Oiling the Machine ........................ 64

PARTS LIST ................................... 65_66

INDEX ........................................ 67_68

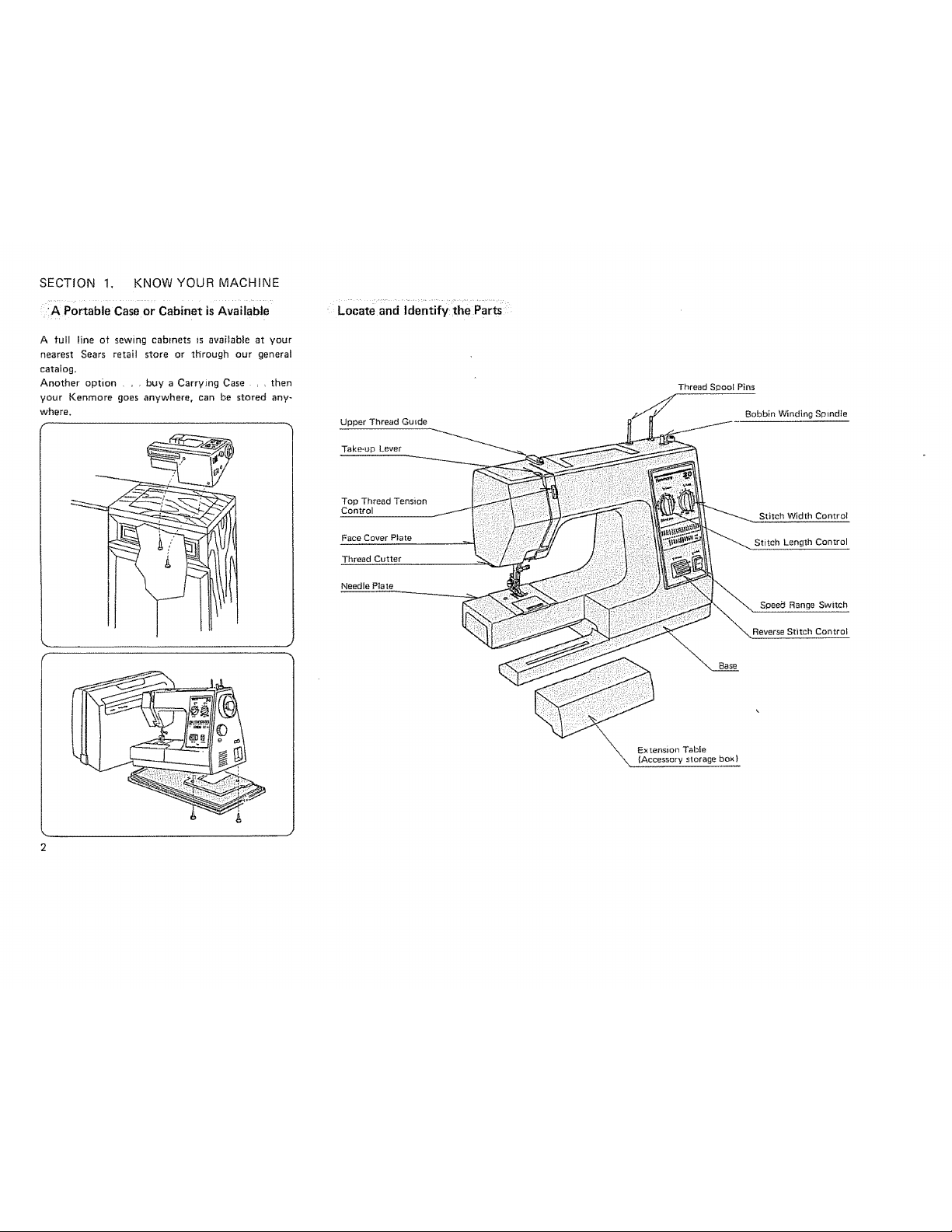

SECTION 1. KNOW YOUR MACHINE

A Portable Case or Cabinet is Available

A full line of sewing cabinets is available at your

nearest Sears retail store or through our general

catalog.

Another option , , buy a Carrying Case : =then

your Kenmore goes anywhere, can be stored any-

where.

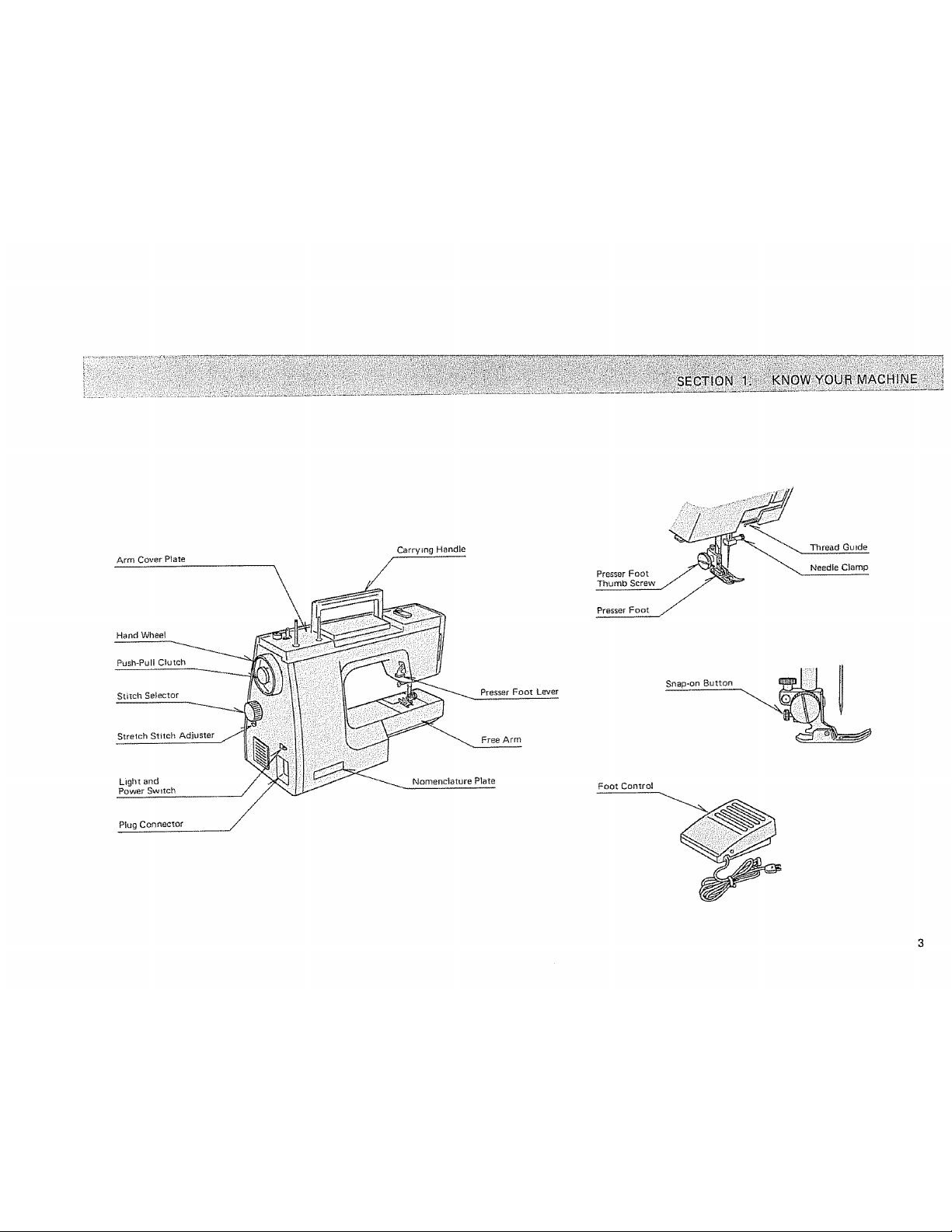

Locate and Identify the Parts

Upper Thread Guide

Take-up Lever

Thread Spool Pins

Bobbin Winding Spindle

Top Thread Tension

Control

Face Cover Plate

Thread Cutter

Needle Plate

Stitch Width Control

Spee_ Range Switch

Reverse Stitch Control

Extension Table

{Accessory storage box}

Arm Cover Plate

Carrying Handle

Presser Foot

Thumb Screw

Thread Guide

Needle Clamp

Presser Foot

Hand Wheel

Push-Pull Clutch

Stitch SeSector

Strelch Stitch Adjuster

Presser Foot Lever

Free Arm

Snap-on Button

Light and

Power Swttch

Nomenclature Plate

Foot Control

P_ug Connector

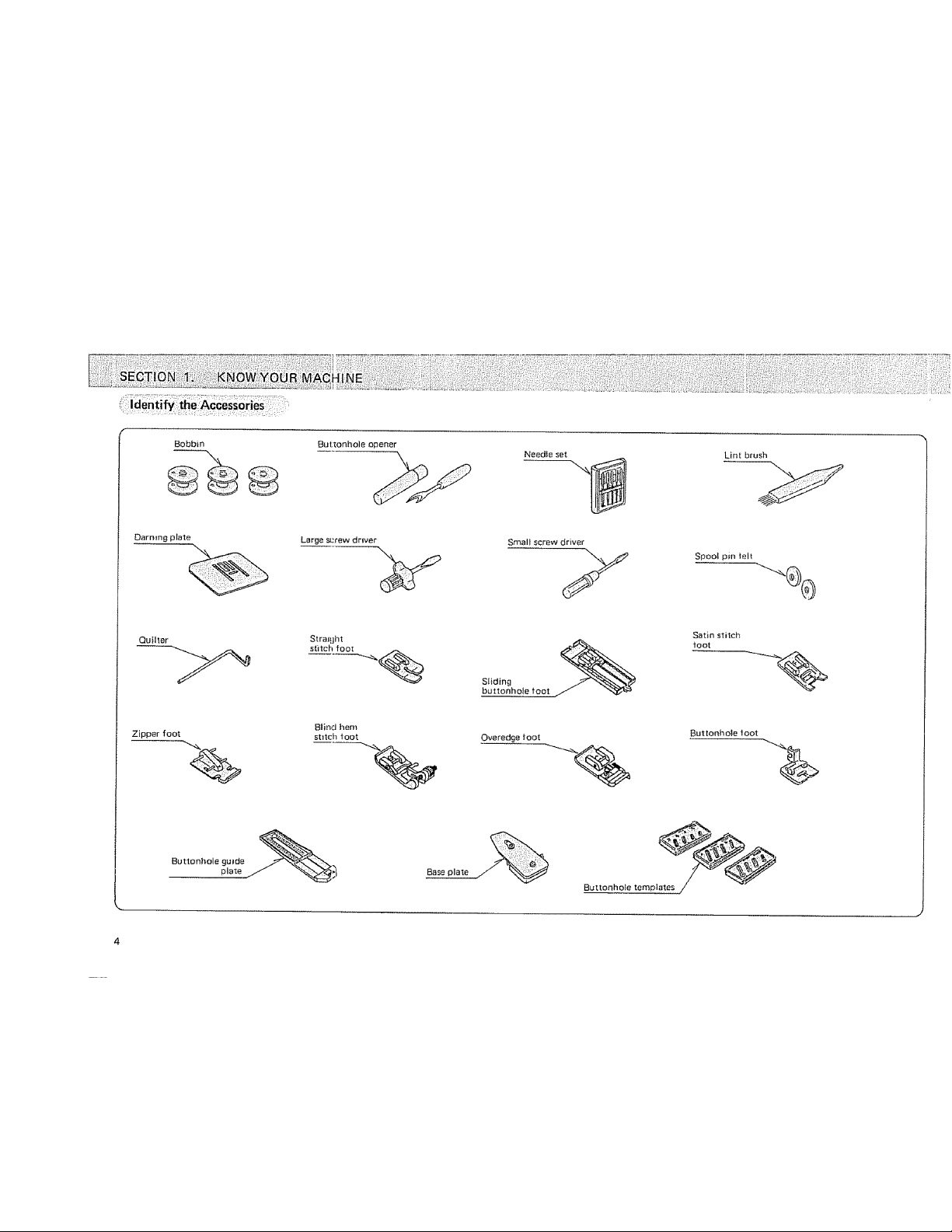

Bobbin

Buttonholeopener

\

Needle set

Lint brush

Darmng plate

Large st:rew dr_ver

Smell screw driver

/

Spool pin telt

Quilter Straight

stitch foot

Sliding %

buttonhoSe foot

Satin stitch

foot

Zipper foot

Blind hem

stitch foot

-%,

Overedge foot

Buttonhole loot

Buttonhole gutde

p,a,o/ _'_. _

Base plat

Buttonh o_e templates

........... J

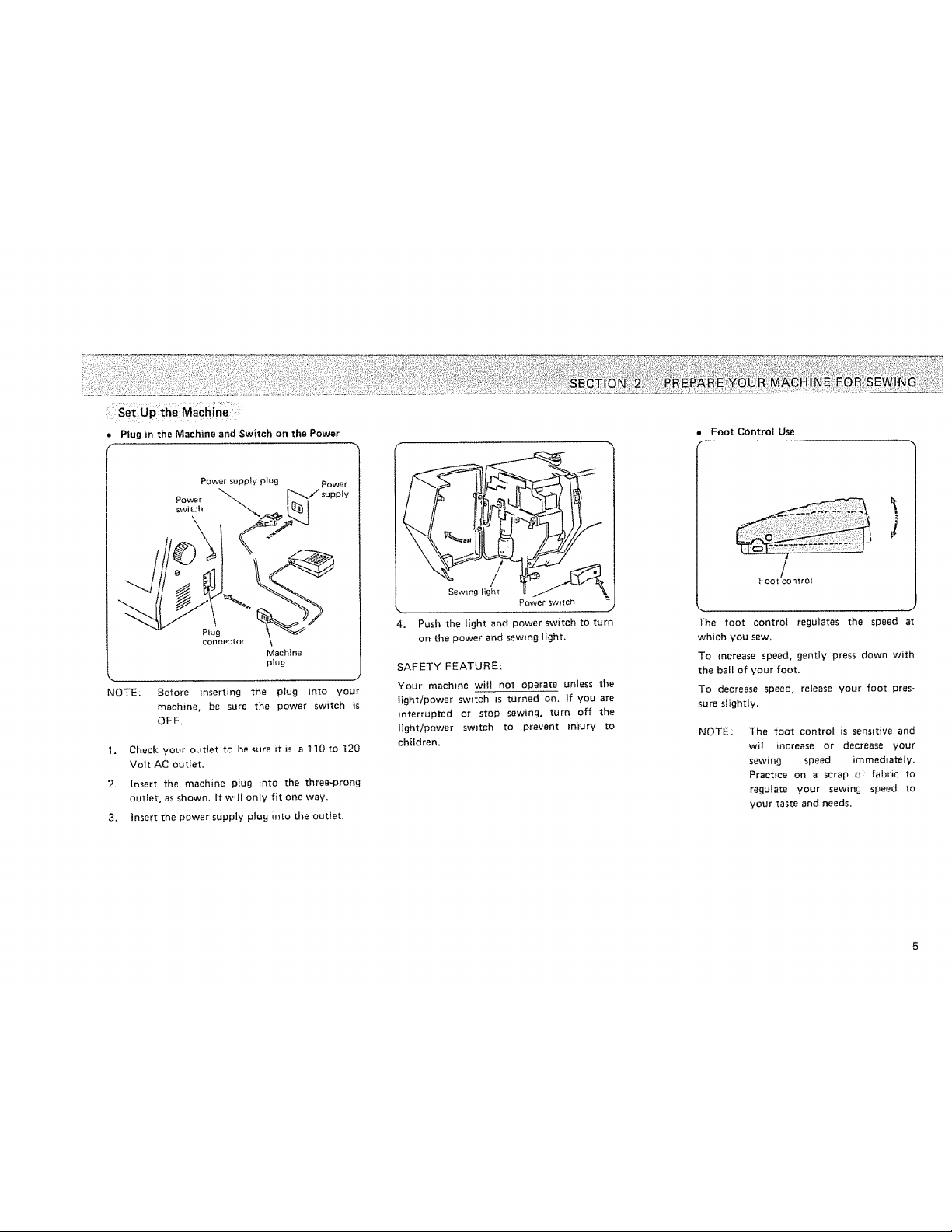

Plug in the Machine and Switch on the Power

Power supply plug

Power

/ supply

NOTE:

Plug

connector

Machine

plug

Before inserting the plug into your

machine, be sure the power switch is

OFF

t. Check your outlet to be sure it is a 110to 120

Volt AC outlet,

2. Insert the machine plug into the three-prong

outlet, as shown, tt will only fit one way.

3. Insert the power supply plug into the outlet.

4.

Sewing ligh_ _

Power sw_Ich

.J

Push the light and power switch to turn

on the power and sewing light,

SAFETY FEATURE:

Your machine witl not operate unless the

llght/power switch _s turned on, If you are

interrupted or stop sewing, turn off the

light/power switch to prevent mllury to

children.

Foot Control Use

J

The toot control regulates the speed at

which you sew.

To increase speed, gently press down with

the ball of your foot.

To decrease speed, release your foot pres-

sure slightly.

NOTE:

The foot control is sensitive and

will increase or decrease your

sewing speed immediately.

Practice on a scrap of fabric to

regulate your sewing speed to

your taste and needs.

j

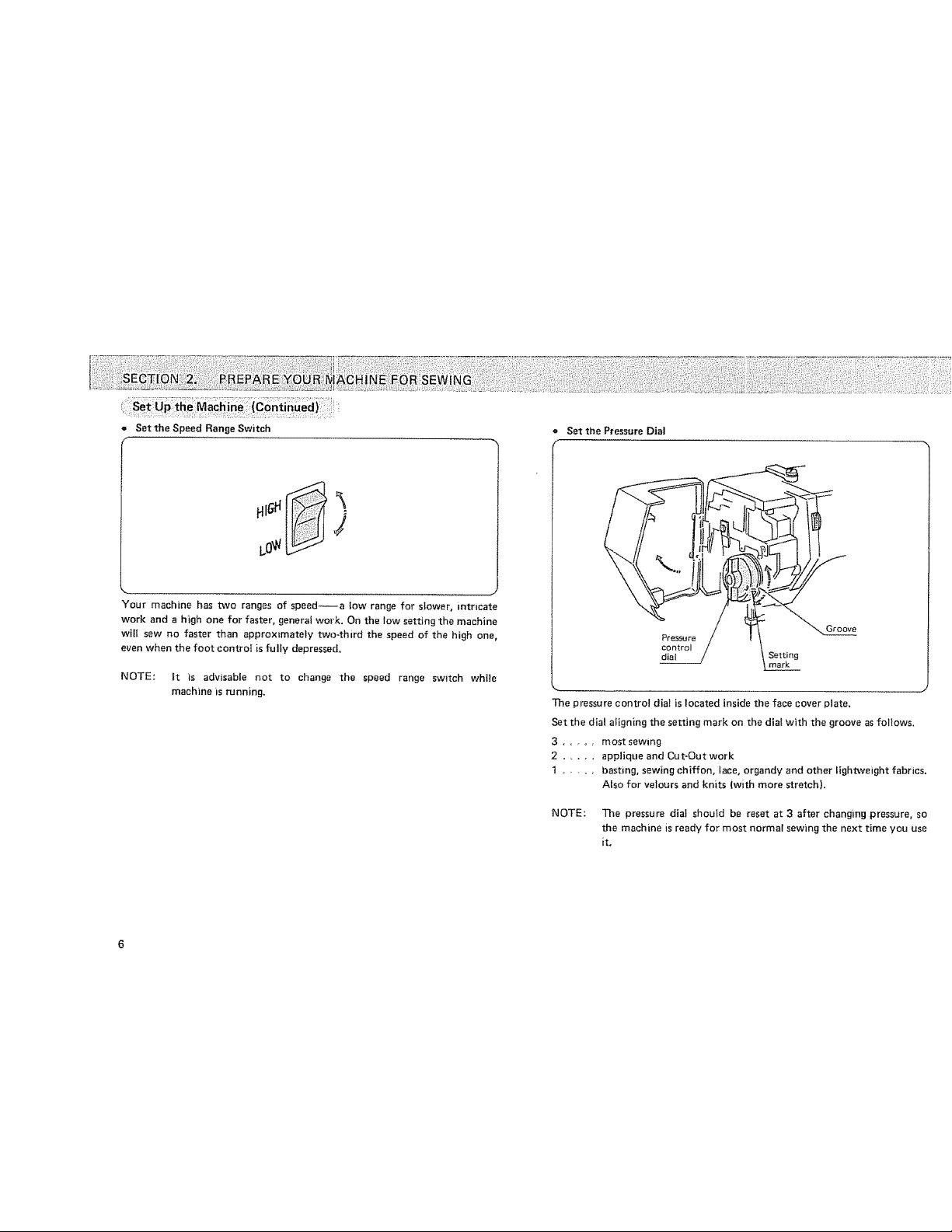

Your machine has two ranges of speed--a low range for slower, intricate

work and a high one for faster, general work. On the low setting the machine

will sew no faster than approximately two4hird the speed of the high one,

even when the foot control is fully depressed.

NOTE: It is advisable not to change the speed range switch while

machine isrunning.

Set the Pressure Dial

Setting

mark

The pressure control dial islocated inside the face cover plate,

Set the dial aligning the setting mark on the dial with the groove as follows.

3 ..... most sewing

2 ..... applique and Cut-Out work

1 ..... basting, sewing chiffon, lace, organdy and other lightweight fabrics.

Also for vetours and knits (with more stretch),

NOTE: The pressure dial should be reset at 3 after changing pressure, so

the machine isready for most normal sewing the next time you use

it.

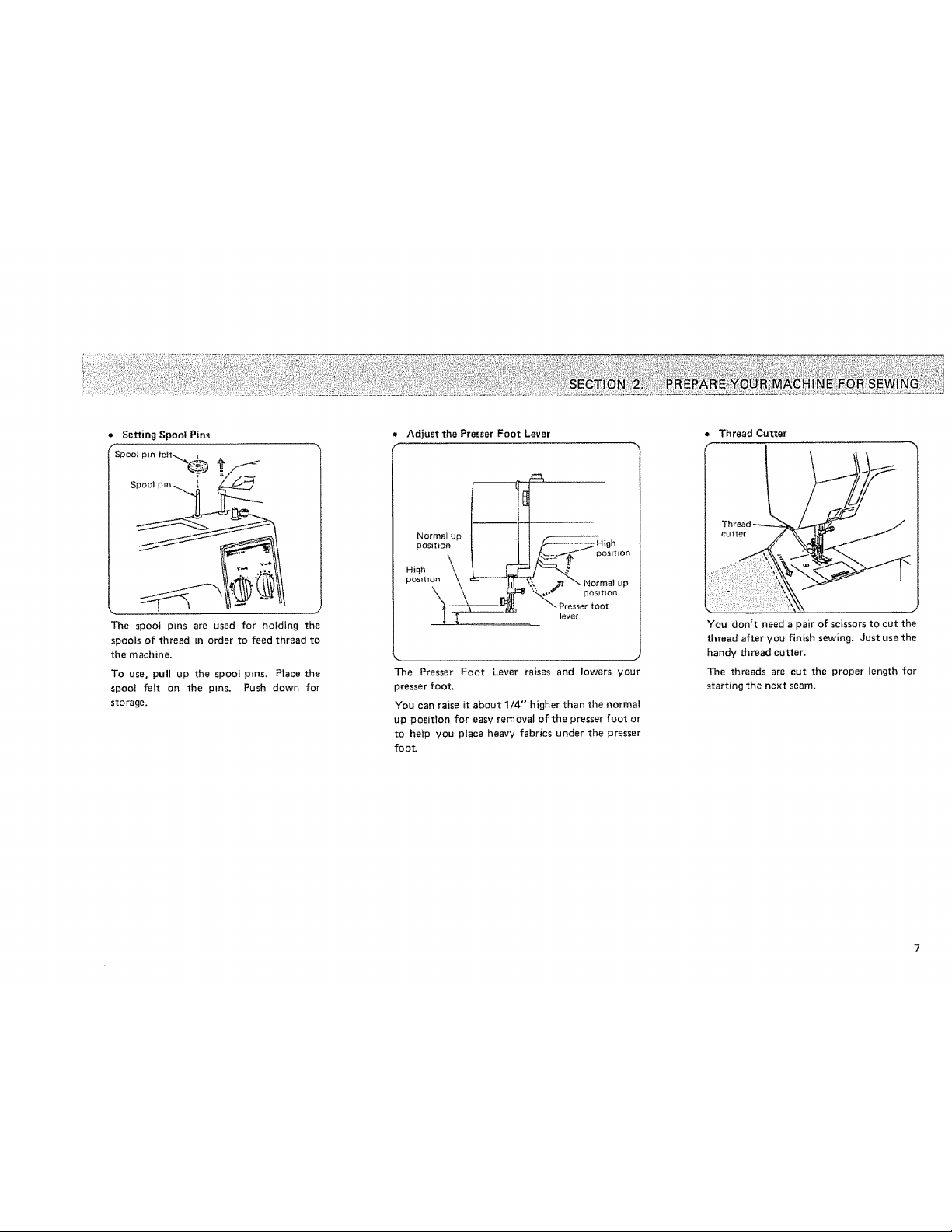

= Setting Spool Pins

r

_poo_ p,N fe,t_

The spool pros are used for holding the

spools of thread in order to feed thread to

the machine.

To use, pult up the spool pins, Place _he

spool felt on the pros. Push down for

storage,

= Adjust the Presser Foot Lever

The Presser Foot Lever raises and lowers your

presser foot.

You can raise it about 1/4" higher than the normal

up position for easy removal of the presser foot or

to help you place heavy fabrics under the presser

foot_

= Thread Cutter

You don't need a pair of scissors to cut the

thread after you finish sewing. Just use the

handy thread cutter,

The threads are cut the proper length for

starting the next seam,

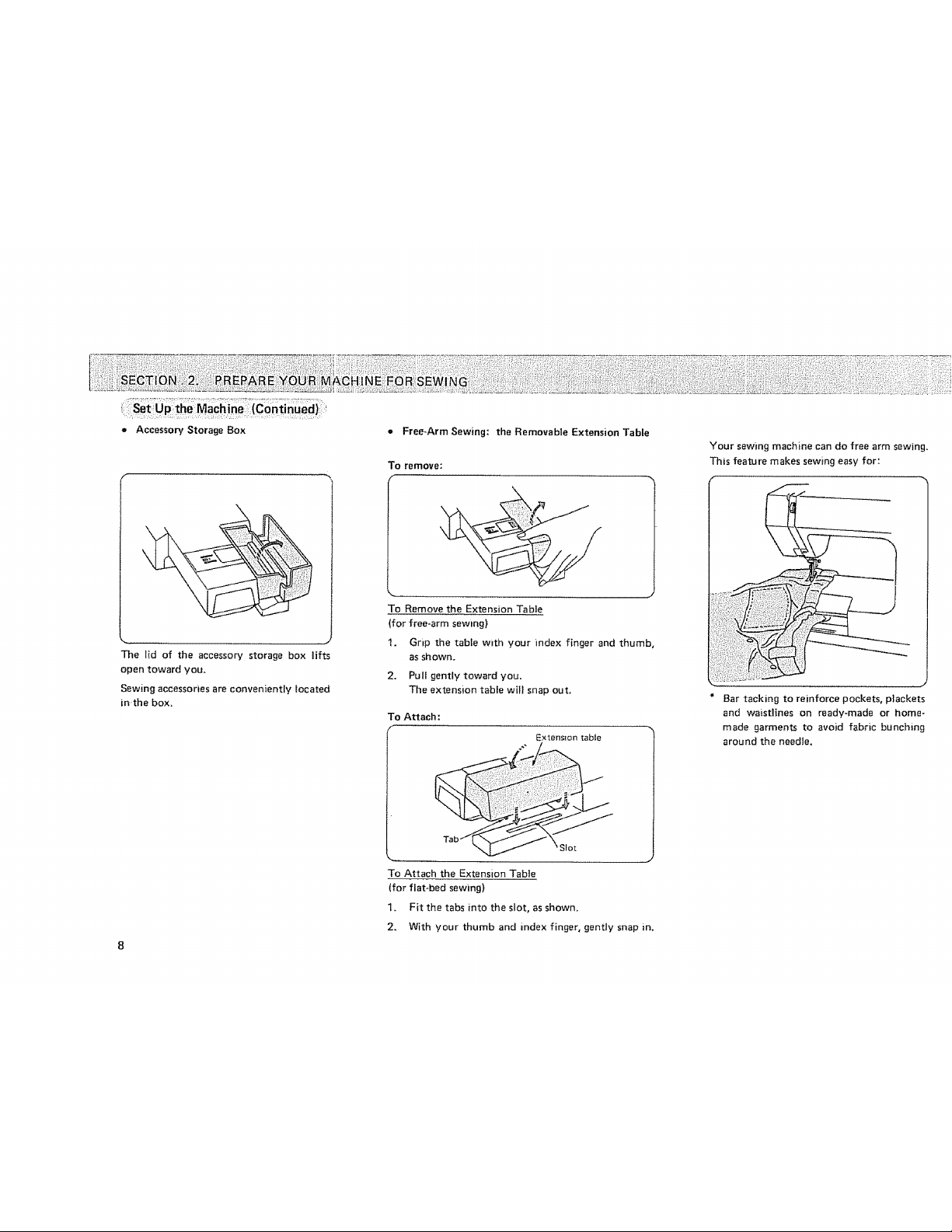

o AccessoryStorage Box

J

The lid of the accessory storage box lifts

open toward you.

Sewing accessories are conveniently located

inthe box.

= Free-Arm Sewing: the Removable Extension Table

To remove:

To Remove the Extension Table

(for free-arm sewing)

1. Grip the table with your index finger and thumb,

as shown.

2. Pull gently toward you.

The ex_nsion table will snap out,

To Attach:

Extension table

• :_,_;_,i!:i_ii_:,_,_i_:_ii_!ii_ii_;i!_i:i_=_ii!_:';_

To Attach the Extension Table

(for flat-bed sewing)

1. Fit the tabs into the slot, as shown.

2. With your thumb and index finger, gently snap in.

Your sewing machine can do free arm sewing.

This feature makes sewing easy for:

Bar tacking to reinforce pockets, plackets

and waistlines on ready-made or home-

made garments to avoid fabric bunching

around the needle.

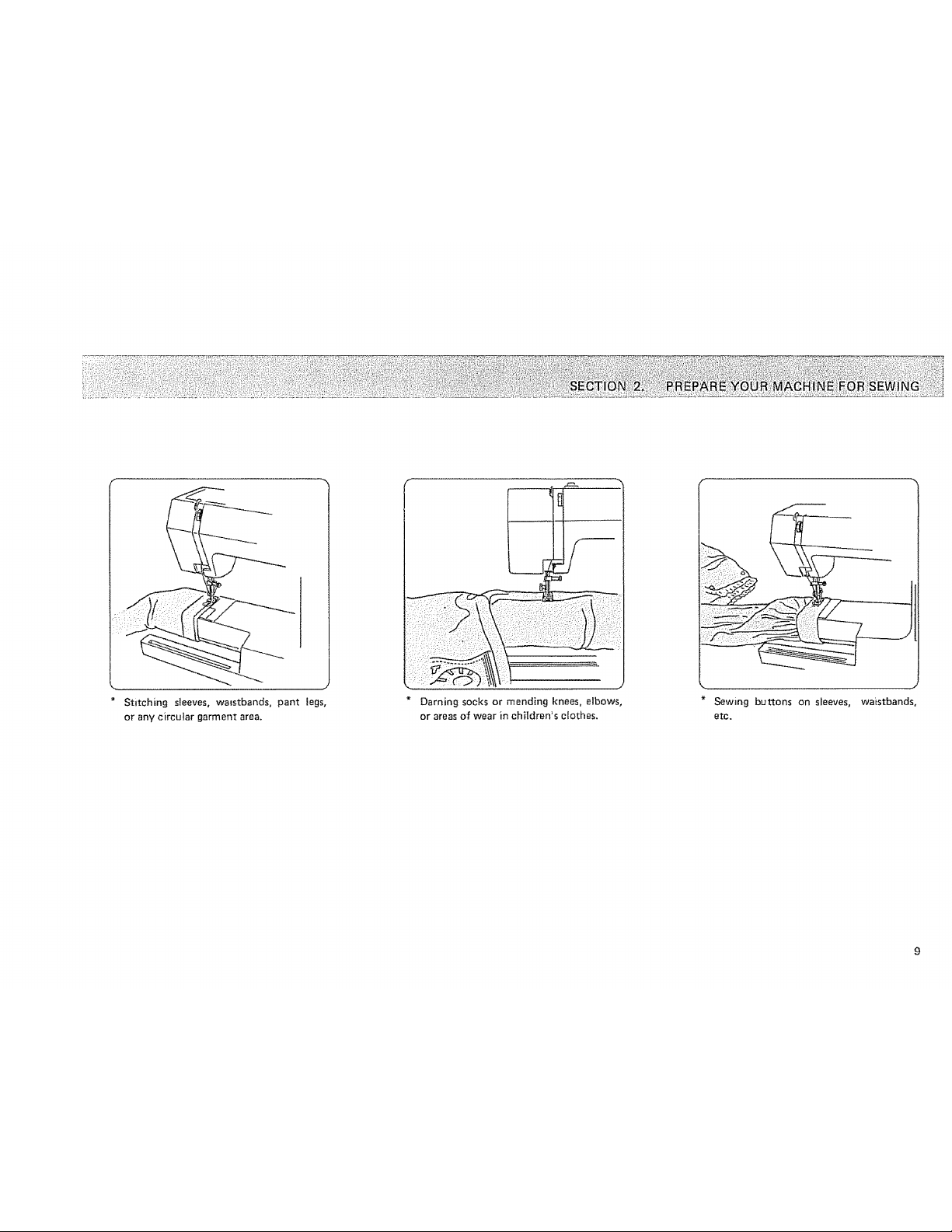

* Stitchingsleeves,waistbands,pantlegs,

oranycirculargarmentarea.

* Darningsocksormendingknees,elbows,

orareasofwearinchildren'sclothes.

* Sewingbuttonsonsleeves,waistbands,

etc.

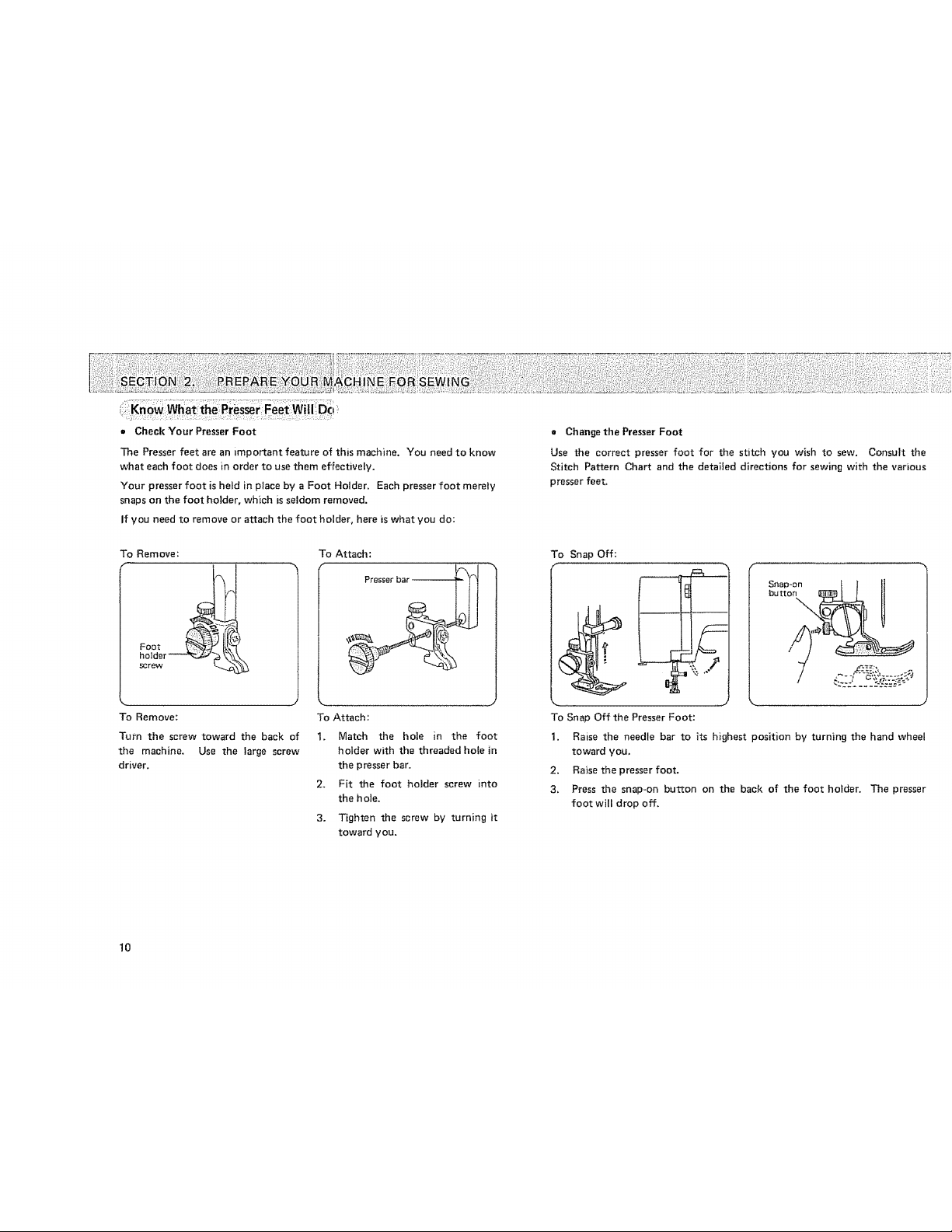

The Presser feet are an important feature of this machine. You need to know

what each foot does in order to use them effectively.

Your presser foot is held in place by a Foot Holder. Each presser foot merely

snaps on the foot holder, which isseldom removed.

If you need to remove or attach the foot holder, here is what you do:

To Remove:

Foot _ !

holder

SCrew

To Remove:

Turn the screw toward the back of

the machine. Use the large screw

driver,

To Attach:

To Attach:

1. Match

2.

3.

the hole in the foot

holder with the threaded hole in

the presser bar.

Fit the foot holder screw into

the hole.

Tighten the screw by turning it

toward you.

o Changethe Presser Foot

Use the correct presser foot for the stitch you wish to sew. Consult the

Stitch Pattern Chart and the detailed directions for sewing with the various

presser feet,

To Snap Off:

To Snap Off the Presser Foot:

1.

2.

3.

Raise the needle bar to _ts hlghest position by turning the hand wheel

toward you.

Raise the presser foot.

Press the snap-on button on the back of the foot holder. The presser

foot will drop off.

10

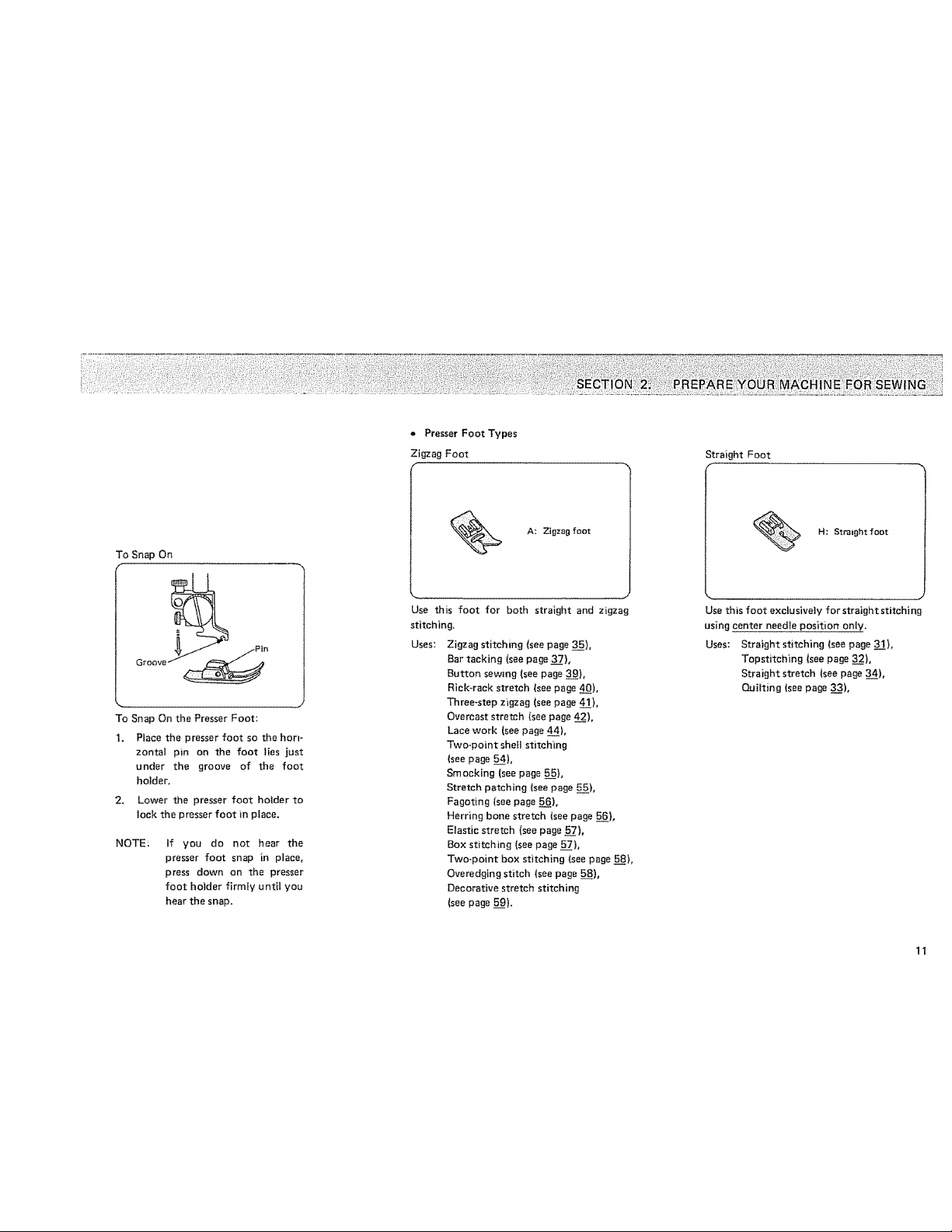

To Snap On

G

To Snap On the Presser Foot;

1. Place the presser foot so the hori-

zontal pin on the foot lies just

under the groove of the foot

holder.

2. Lower the presser foot holder to

lock the presser foot in place.

NOTE:

If you do not hear the

presser foot snap in place,

press down on the presser

foot holder firmly until you

hear the snap.

• PresserFoot Types

Zigzag Foot

f

%

A: Zigzag foot

Use this foot for both straight and zigzag

stitching_

Uses: Zigzag stitching {see page 35),

Bar tackir_g (see page 37),

Button sewing (see page 39),

Rick-rack stretch (see page 40_1,

Three-step zigzag (see page 41},

Overcast stretch (see page 42),

Lace work (see page 44),

Two-point shell stitching

(see page 54),

Smocking (see page 55),

Stretch patching {see page 555),

Fagoting (see page 56),

Herring bone stretch tsee page 56),

Elastic stretch (see page 5_7),

Box stitching (see page 57),

Two-point box stitching (see page 58),

Overedging stitch (see page 58),

Decorative stretch stitching

(see page 59).

Straight Feot

H: Straight foot

Use this foot exclusively for straight stitching

using center needle position only,

Uses: Straight stitching lsee page 31),

Topstitching {see page 32),

Straight stretch (see page 34),

Quilting (see page 33),

1t

o PresserFoot Types (Continued)

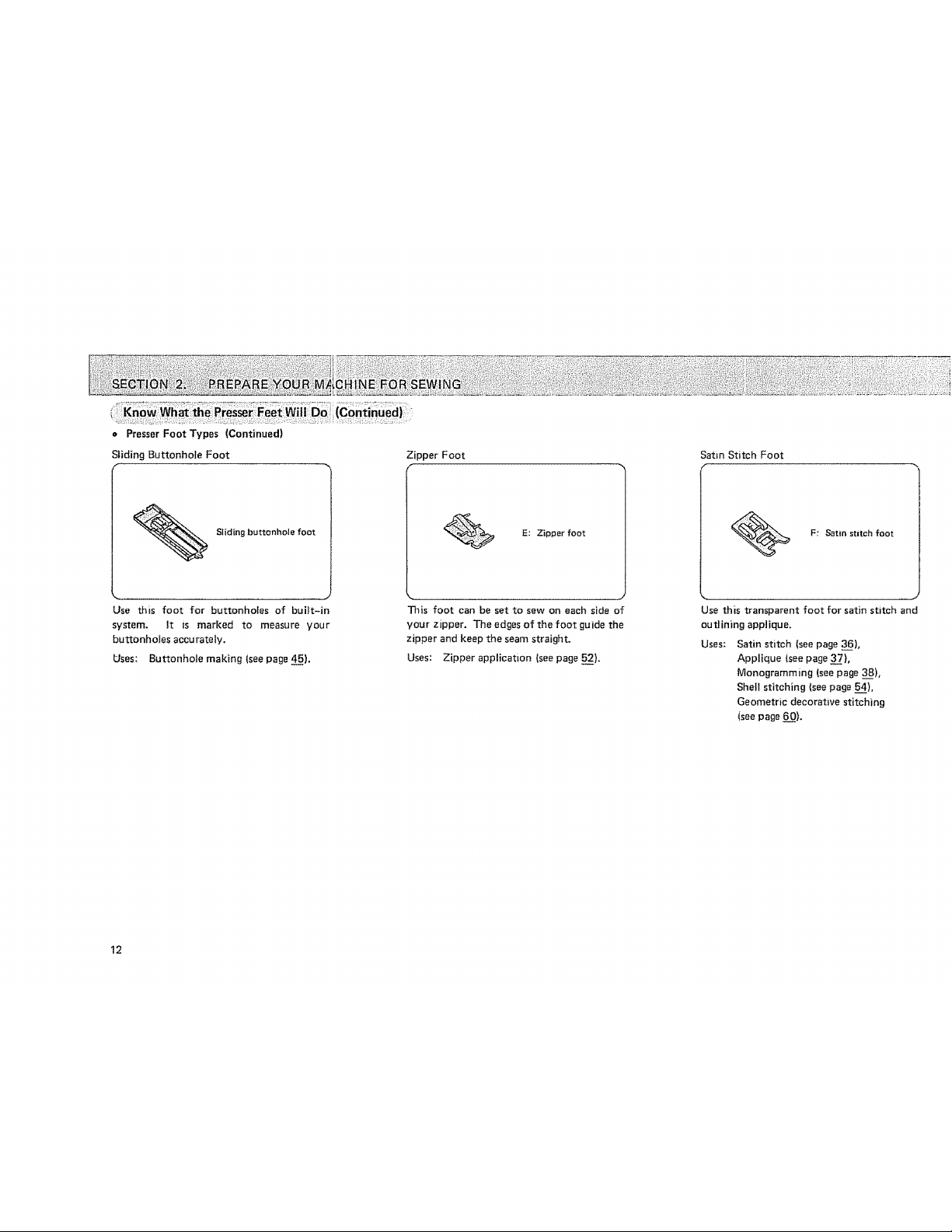

Sliding Buttonhole Foot

%

Sliding buttonhole foot

J

Use this foot for buttonholes of buift-ln

system. It is marked to measure your

buttonhofes accurately.

Uses: Buttonhole making {see page 45).

Zipper Foot

E: Zipper foot

This foot can be set to sew on each side of

your zipper. The edges of the foot guide the

zipper and keep the seam straight.

Uses: Zipper application (see page 52).

Satin Stitch Foot

F: Satin stitch foot

Use this transparent foot for satin stitch and

outJining applique.

Uses: Satin stitch {see page 36),

Applique {see page 37),

Monogramming (see page 3_88),

Shell stitching (see page 5__44),

Geometric decorative stitching

(see page 60).

12

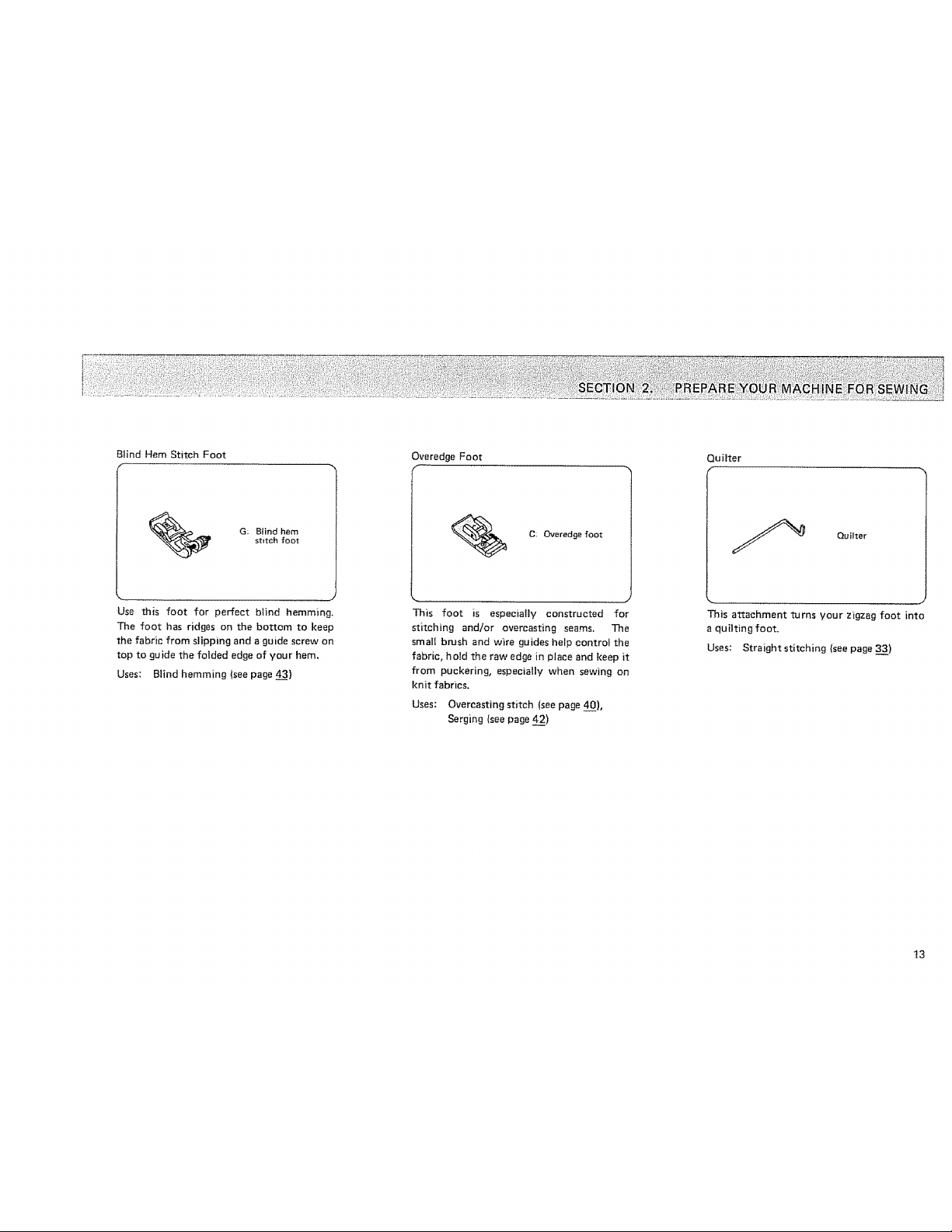

Blind Hem Stitch Foot

G; Blind hem

stitch foot

Use this foot for perfect blind hemming.

The foot has ridges on the bottom to keep

the fabric from slipping and a guide screw on

top to guide the folded edge of your hem.

Uses: Blind hemming (see page 43}

Overedge Foot

C: Overedge foot

This foot is especially constructed for

stitching and/or overcasting seams. The

small brush and Wire guides help control the

fabric, ho_d the raw edge in place and keep it

from puckering, especially when sewing on

knit fabrics.

Uses: Overcasting stitch (see page 40),

Serging tsee page 42)

Qu liter

Quilter

J

This attachment turns your zigzag foot into

a quilting foot.

Uses; Straight stitching {see page 33)

13

= Presser Foot Types (Continued)

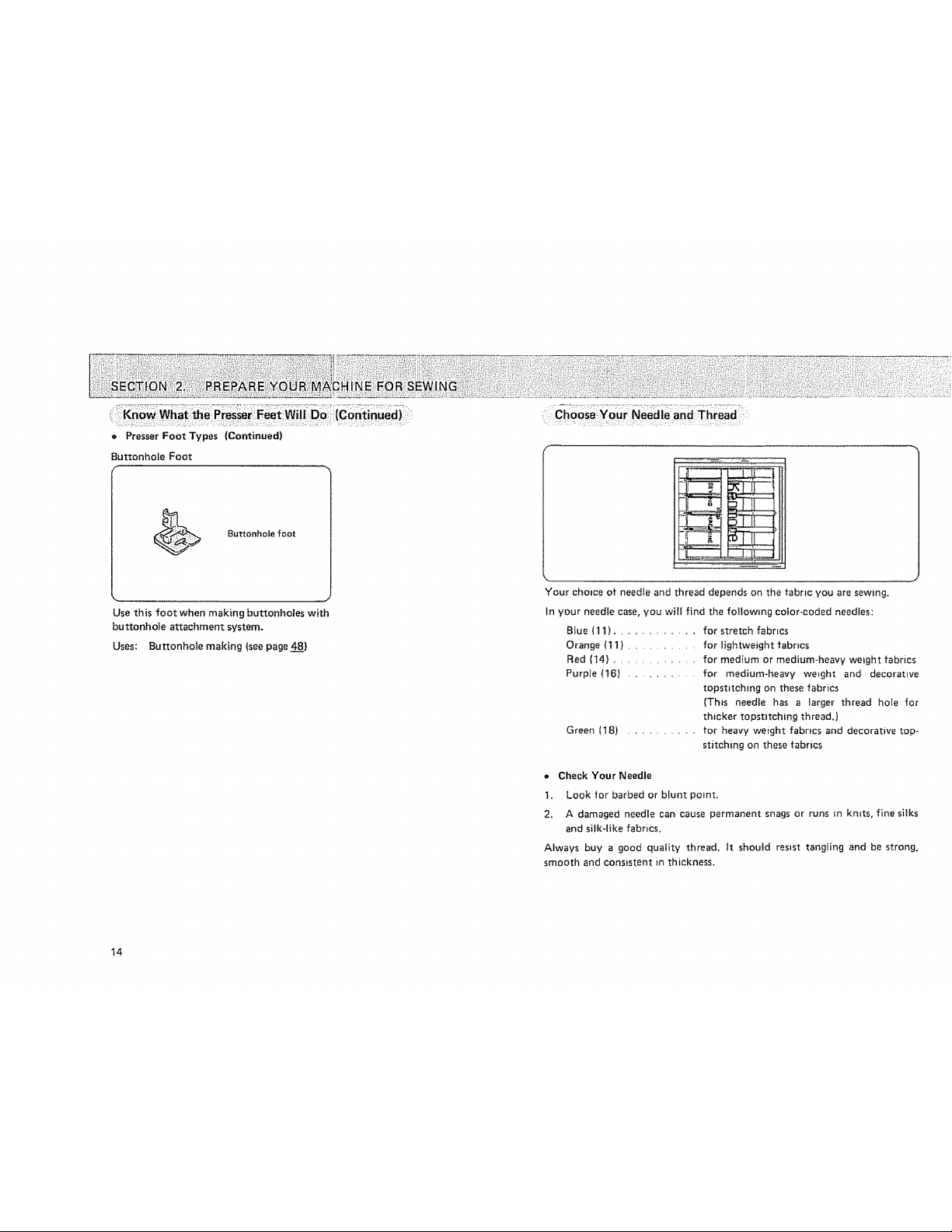

Buttonhole Foot

Buttonhole foot

Use this foot when making buttonholes with

buttonhole attachment system.

Uses: Buttonhole making tsee page 48)

14

Your choice of needle and thread depends on the fabric you are sewing.

tn your needle case, you will find the following color-coded needles:

Btue (t 1 ) .......... for stretch fabrics

Orange (11 ) ........ for _ightweight fabrics

Red (14) ........... for medium or medium-heavy wetght fabrics

Purple (16) ........ for medium-heavy weight and decorative

topstitching on these fabrics

(This needle has a larger thread hole for

thicker topstitching thread.)

Green (18) ........ for heavy weight fabrics and decorative top-

stitching on these fabNcs

• Check Your Needle

1. Look for barbed or blunt point.

2. A damaged needle can cause permanent snags or runs _n knits, fine silks

and silk-like fabrics.

Always buy a good quality thread. It should resist tangling and be strong.

smooth and consistent in thickness.

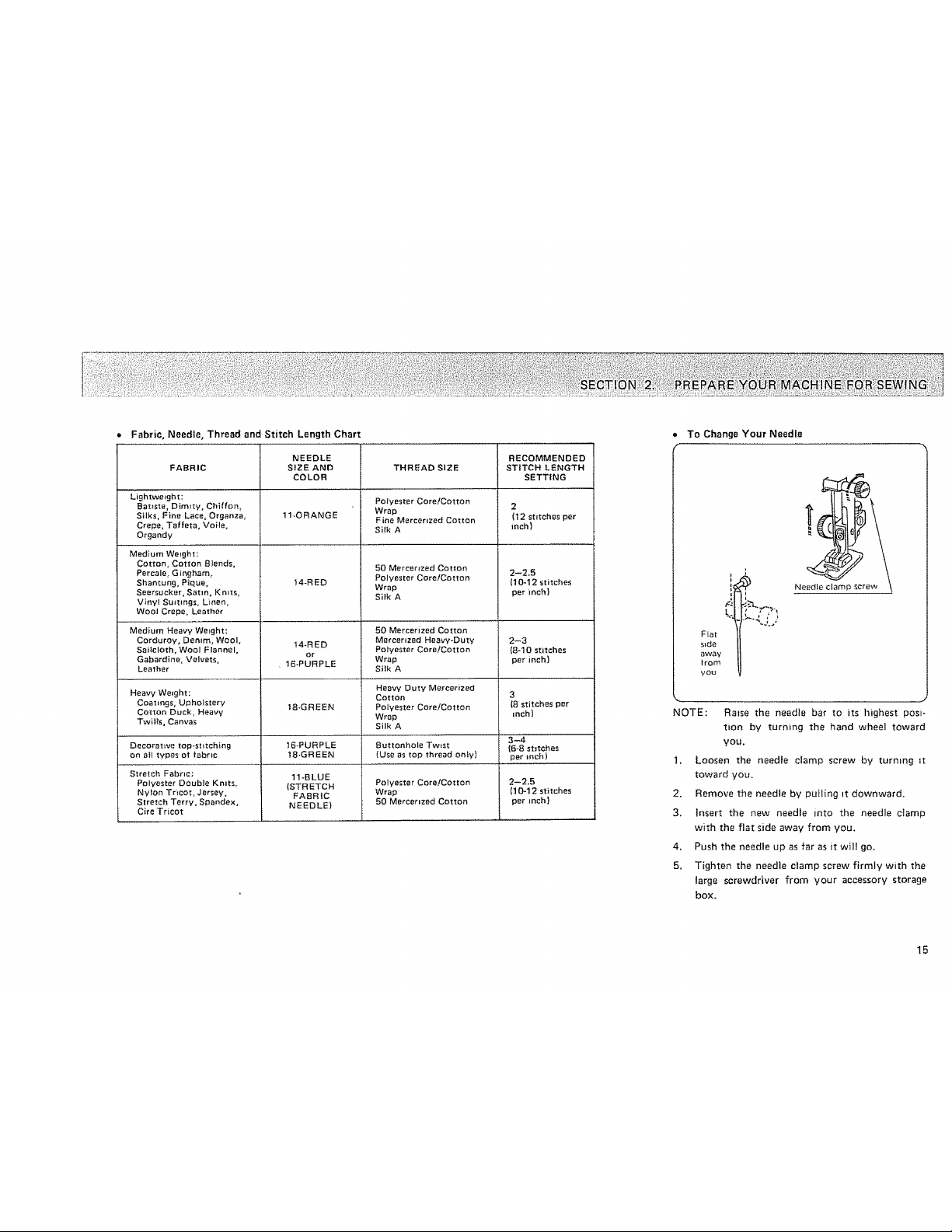

Fabric, Needte, Thread and :

FABRIC

Lightweight:

Batiste, Dimtty, Chiffon,

Silks, Fine Lace° Organza,

Crepe, Tar{eta, Voile,

Organdy

Medium Wetght:

Cotton, Cotton Blends,

Percale_ G ingham_

Shantung, Pique,

Seersucker, Satin. Kmts,

Vinyl Su_tings_ Linen,

Wool Crepe, Leather

Medium Heavy Wmght: l

Corduroy, Detain, Wool,

1

Sailcloth, Wool Flannel,

Gabardine, Velvets,

Leather

;titch Length Chart

NEEDLE

SIZE AND

COLOR

11.ORANGE

THREAD SIZE

Polyester CorelCotton

Wrap

Fine Mercerized Cotton

Silk A

14-RED

14-RED

or

• 16-PURPLE

50 Mercerized Cotton

Polyester CorelCotton

Wrap

Silk A

50 Mercerized Cotton

Mercerized Heavy-Duty

Polyester Core/Cotton

Wrap

SHk A

Heavy Duty Mercerized

Cotton

Polyester Core/Cotton

Wrap

Silk A

RECOMMENDED

STITCH LENGTH

SETTtNG

2

(t2 stitches per

inch]

2--2.5

(1 0.12 stitches

per inch)

2--3

(8-10 stitches

per inch)

Heavy Weight: 3

Coat rags, Upholstery 18-G R E EN (8 stitches per

Cotton Duck Heavy tnch)

Twitls, Canvas

3-4

Decorative top-stitching 16-PURPLE Buttonhole Twist {6-8 stitches

on aH types of fabric 18-GREEN (Use as top thread onSy) per inch)

Stretch Fabrtc: 11 -BLUE

Polyester Double Kmts_ (STRETCH Polyester CoretOotten 2--2.5

Nylon Tricot, Jersey, FABRtC Wrap (1O-12 stitches

Stretch Terry, Spandex, NEEDLE) 50 Mercerized Cotton per inch}

Cire Tricot

To Change Your Needle

Flat

s_de

away

lrom

you

C,

"" "--4 ,/'

NOTE:

Raise the needle bar to its highest post-

tion by turning the hand wheel toward

you,

1. Loosen the needle clamp screw by turning it

toward you.

2. Remove the needle by pulling it downward.

3. insert the new needle into the needle ciamp

with the fiat side away from you.

4. Push the needle up as far as it will go,

5. Tighten the needle clamp screw firmly with the

large screwdriver from your accessory storage

box.

15

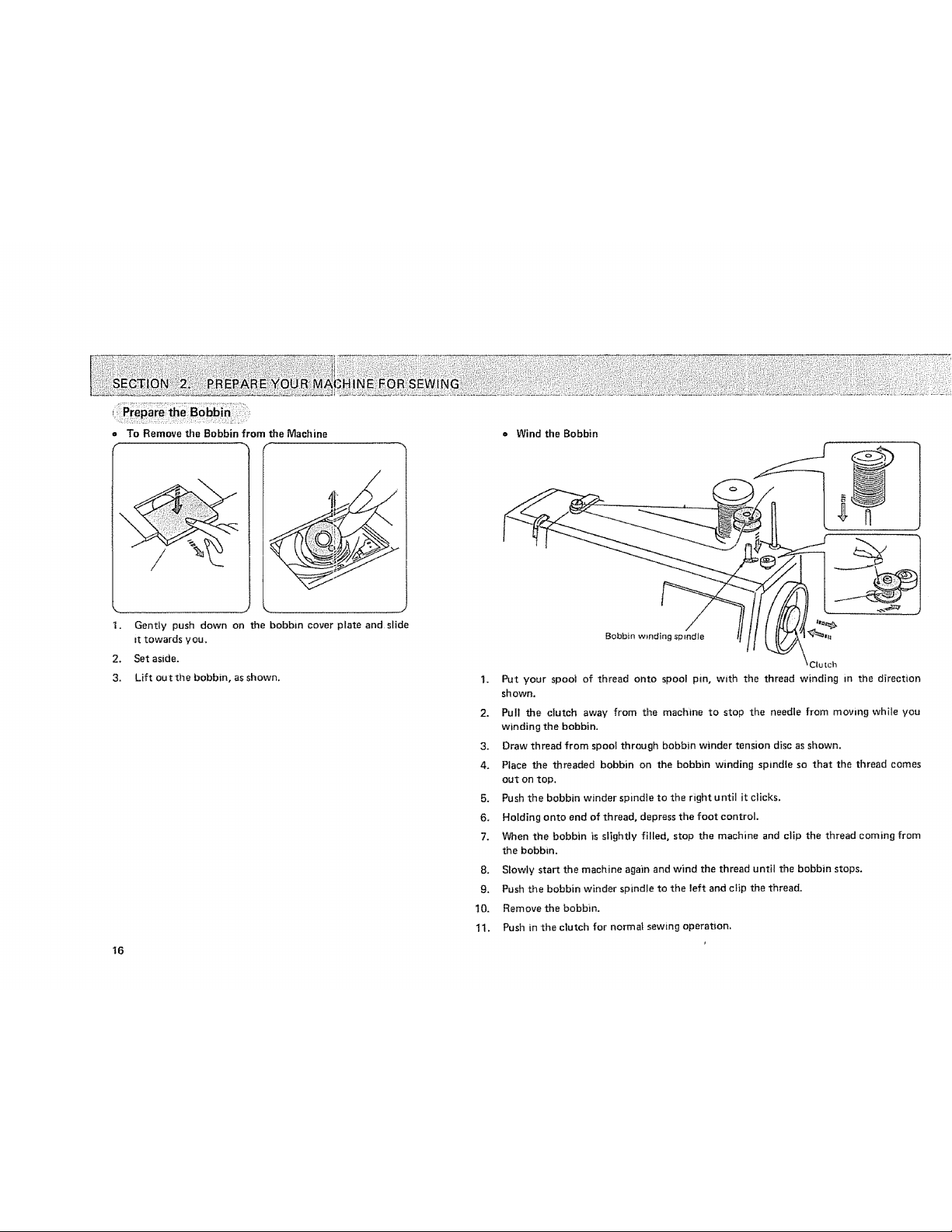

= To Remove the Bobbin from the Machine

1. Gently push down on the bobbin cover plate and slide

=ttowards you.

2. Set aside.

3. Lift out the bobbin, as shown.

16

= Wind the Bobbin

3lurch

I. Put your spool of thread onto spool pin, with the thread winding in the direction

shown.

2. Pull the clutch away from the machine to stop the needle from moving while you

winding the bobbin,

3. Draw thread from spool through bobbin winder tension disc as shown,

4. Place the threaded bobbin on the bobbin winding spindle so that the thread comes

out on top.

5, Push the bobbin winder spindle to the right until it clicks,

6, Holding onto end of thread, depress the foot control.

7, When the bobbin is slightly filled, stop the machine and cilp the thread coming from

the bobbin.

8. Slowly start the machine again and wind the thread until the bobbin stops.

9. Push the bobbin winder spindle to the left and clip the thread.

10. Remove the bobbin.

11. Push in the clutch for normal sewtng operation.

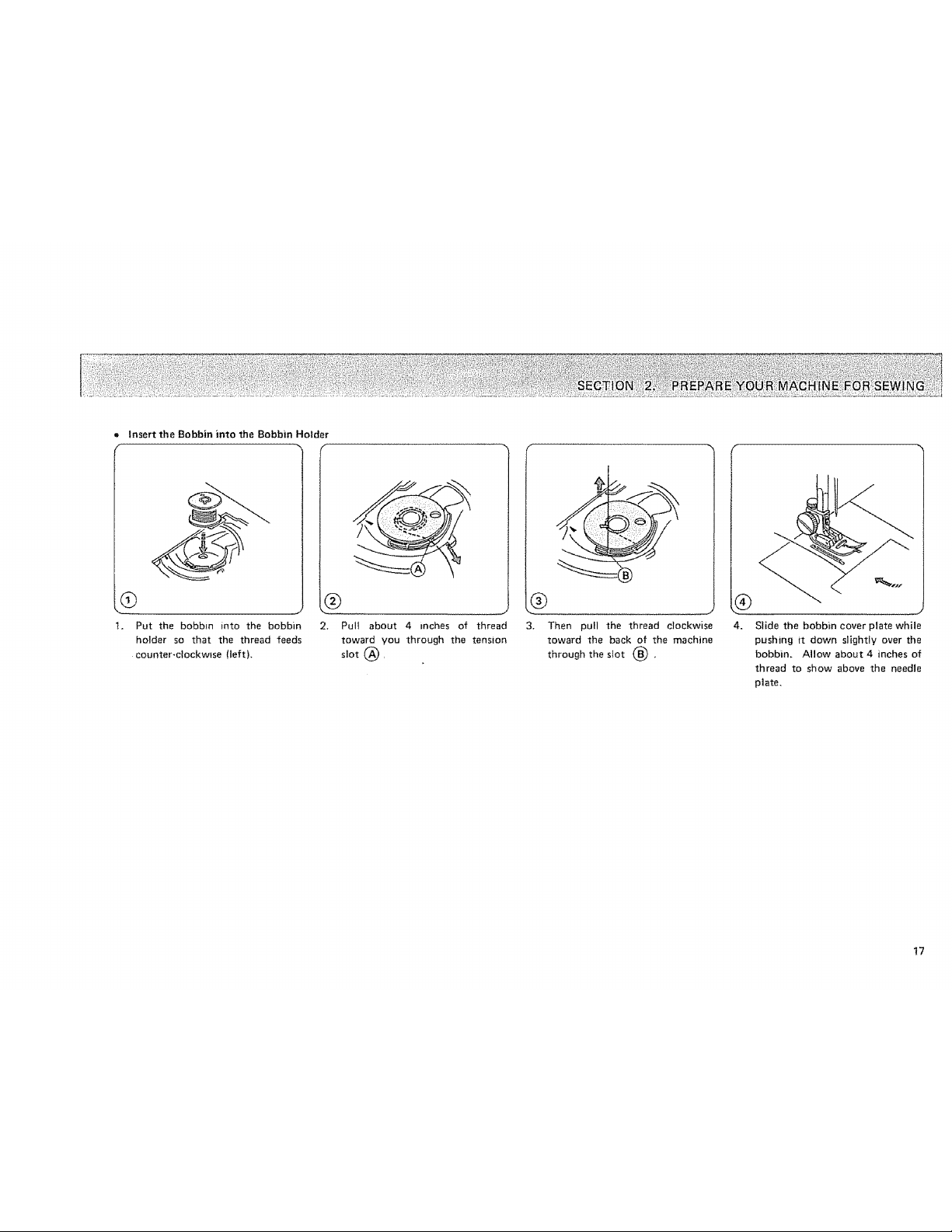

Insertthe Bobbin into the Bobbin Hotder

1.JPut the bobbin into the bobbin

holder so that the thread feeds

counter-clockwise (left)_

2_

7

Pull about 4 inches of thread 3.

toward you through the tension

slot @.

Then pull the thread clockwise

toward the back of the machine

through the slot @ .

®

4. Slide the bobbin cover plate while

pushing it down slightly over the

bobbin, Allow about 4 inches of

thread to show above the needle

plate.

t7

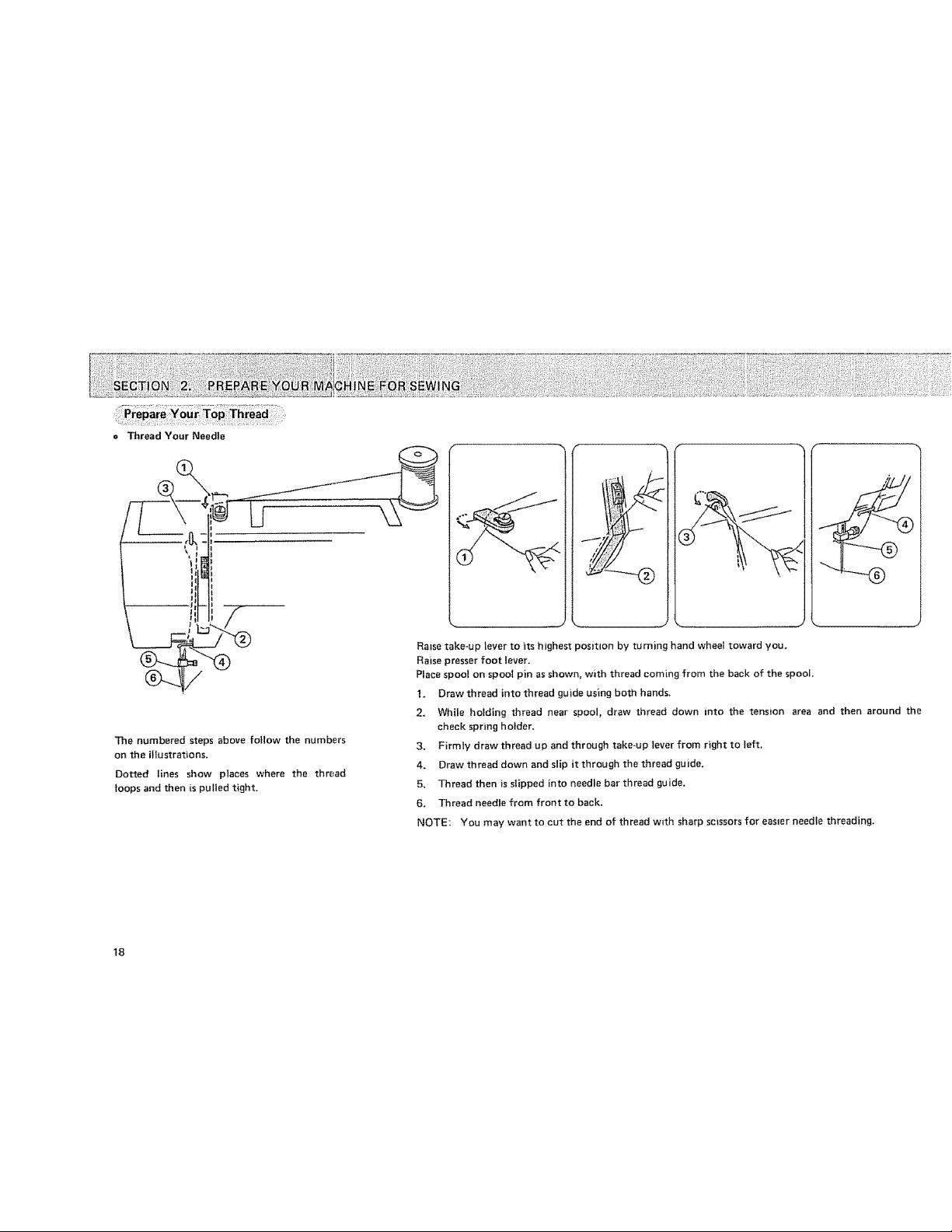

o Thread Your Needle

II I

II l

--I l I

,,PI,7

I I I

The numbered steps above follow the numbers

on the illustrations.

Dotted lines show places where the thread

loops and then is pulled tight.

]

Raise take-up lever to its highest position by turning hand wheel toward you.

Raise presser foot lever.

Place spool on spoot pin as shown, with thread coming from the back of the spool.

1. Draw thread into thread guide using both hands.

2. While holding thread near spool, draw thread down into the tension area and then around the

check spring holder.

3. Firmly draw thread up and through take*up lever from right to left.

4. Draw thread down and slip it through the thread guide,

5. Thread then is slipped into needle bar thread guide.

6, Thread needle from front to back.

NOTE: You may want to cut the end of thread with sharp scissors for easier needle threading.

18

Pick Up Your Bobbin Thread

Raise presser foot lever. Hold

needle thread loosely in left hand

and rotate handwheet toward

you one complete turn,

2. Bring bobbin thread up by pulling

top thread,

3. Pull both threads under and to the

back of the presser foot, leaving 4

to 6 inches of thread clear.

19

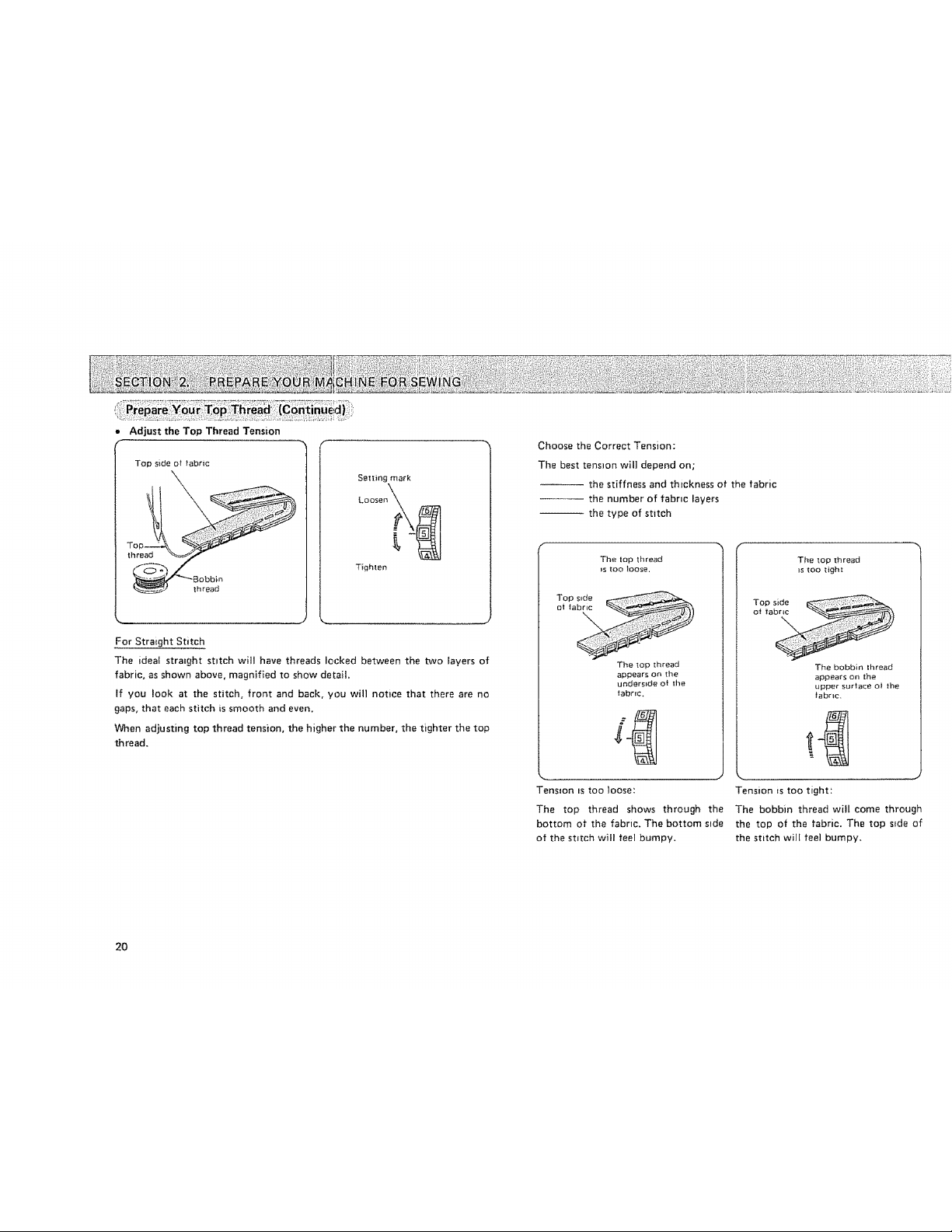

m Adjust the Top Thread Tension

Top side of fabric

Top ___

thread

SelUng mark

Tighlen

For Straight Stitch

The ideal straght stttch witl have threads locked between the two layers of

fabric, as shown above, magnified to show detail.

If you look at the stitch, front and backt you will notice that there are no

gaps, that each stitch is smooth and even.

When adjusting top thread tension, the higher the number, the tighter the top

thread,

Choose the Correct Tension:

The best tension will depend on;

the stiffness and thickness of the fabric

the number of fabric layers

--- the type of stitch

The top thread

_s too loose.

The top thread

appears on the

undemde of the

fabric.

Tension _s too loose:

The top thread shows through the

bottom of the fabric. The bottom s_de

of the stitch will feel bumpy.

The top thread

_s1oo tigh_

Top side

o_ Ta

The bobbin lhread

appears on the

upper sudace o_ the

_abrlc.

Tension ts too tight:

"The bobbin thread will come through

the top of the fabric. The top side of

the stitch wi]l fee] bumpy.

20

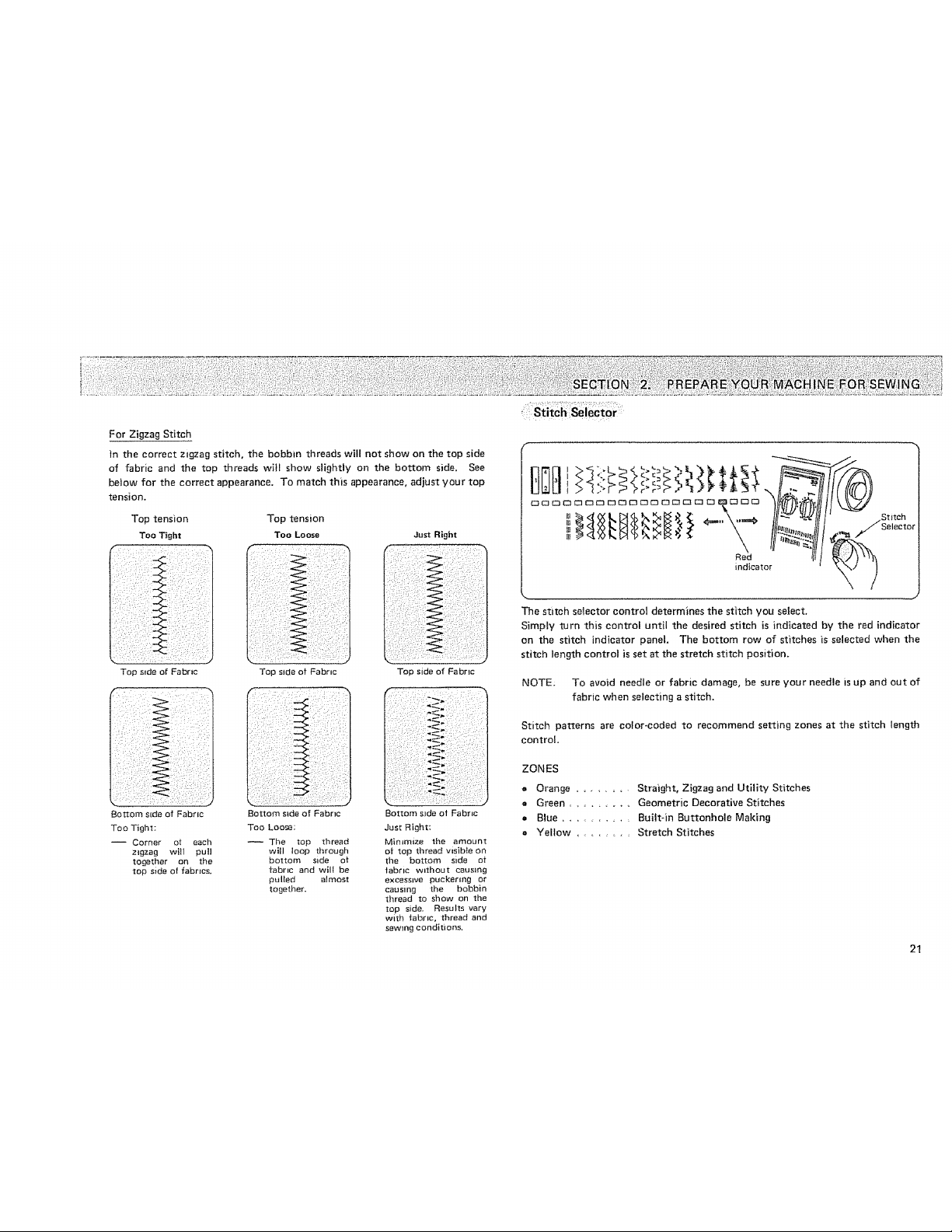

For Zigzag Stitch

in the correct zigzag stitch, the bobbin threads will not show on the top side

of fabric and the top threads will show slightly on the bottom side. See

below for the correct appearance. To match this appearance, adjust your top

tension.

Top tension Top tension

Too Tight Too Loose

Top s_de of Fabric Top side of Fabric

Just Right

Top side of Fabric

Bottom sCde of Fabric Bottom side of Fabric Bottom side of Fabric

Too Tight: Too Loop; Just Right:

--Corner ot each --The top thread Minimize the amount

zigzag will pull will loop through of top thread visible on

together on the bottom side ot the bottom side of

top side of fabrics, fabric and will be fabric w_thout causing

pulled almost excessive puckering or

together, eausmg the bobbin

thread to show on the

top side. Results vary

with fabric, thread and

sewing conditions,

The stktch selector control determines the stitch you select.

Simply turn this control until the desired stitch is indicated by the red indicator

on the stitch indicator panel. The bottom row of stitches is selected when the

stitch length control is set at the stretch stitch posit'=on.

NOTE: To avoid needle or fabric damage, be sure your needle is up and out of

fabric when selecting a stitch.

Stitch patterns are color-coded to recommend setting zones at the stitch length

control

ZONES

= Orange ........ Straight, Zigzag and Utility Stitches

o Green ......... Geometric Decorative Stitches

= Blue ......... Built-in Buttonhole Making

= Yellow ...... Stretch Stitches

21

Loading...

Loading...