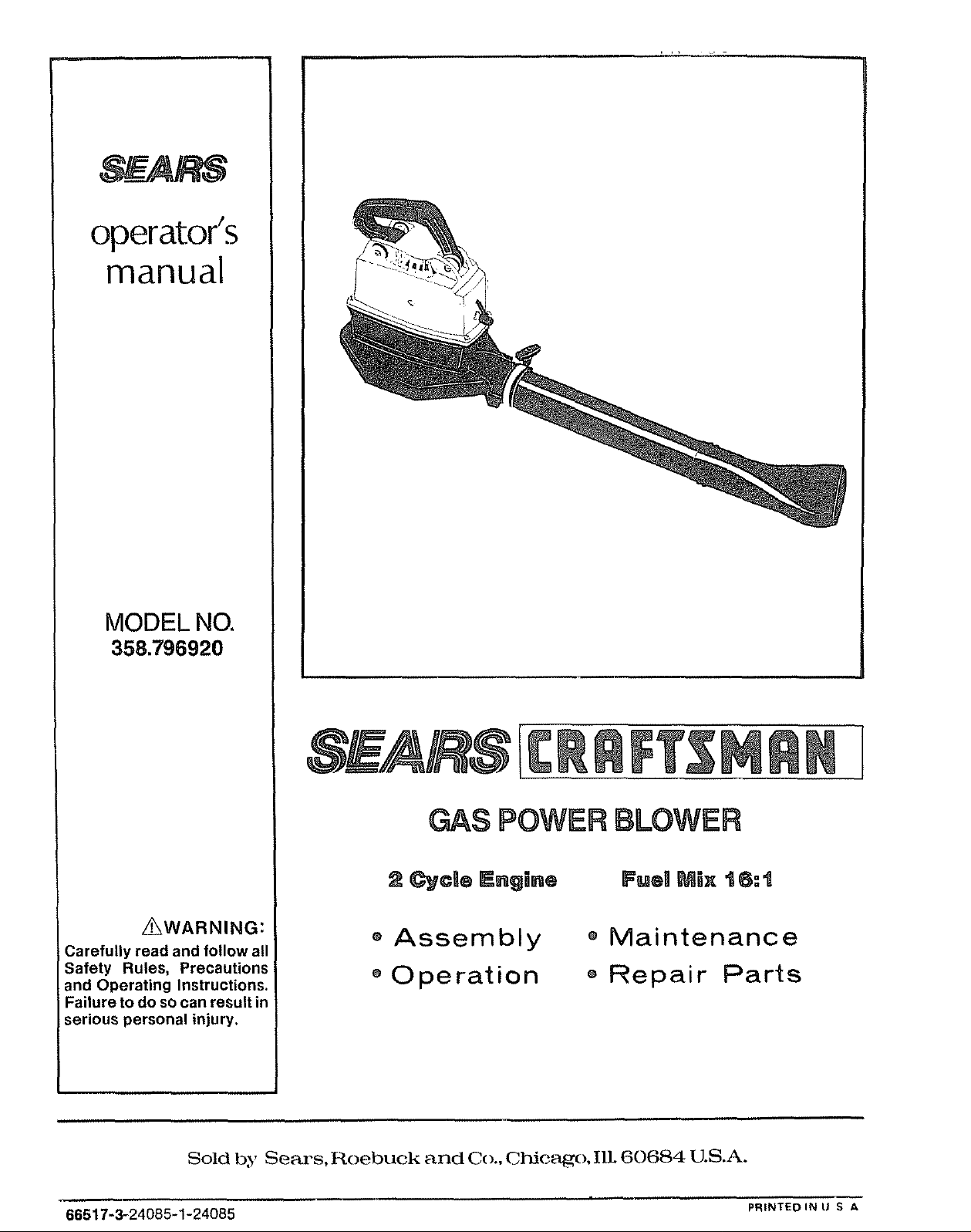

Page 1

,,,,,

operator's

manual

MODEL NO.

358.796920

Z_WARNING:

Carefully read and follow all

Safety Rules, Precautions

and Operating Instructions.

Failure to do so can result in

serious personal injury,

2 _©6® Eng_n®

o Assembly

o Operation

I

Fu®nU_x t 6:1

e Maintenance

Repair Parts

Sold by Sears, Roebuck and C()., Cllicago, IlL 60684 U.S.A.

, ,, ,,,

66517-3-24085-1-24085 PRINTEO IN U S A

Page 2

TABLE OF

C@NTEN3=$

SAFETY RULES AND PRECAUTIONS .............. 3

KNOW YOUR UNIT ................................... 4

ASSEMBLY ........................................ 5

ENGINE INFORMATION ............................. 7

A, Fueling Your Unit............................ 7

B, Pre-Operation Checks ........................... 7

C Starting Instructions............................ 8

D. Engine Adjustments.......................... 9

USING YOUR UNIT AS A BLOWER ............... 10

A, Operating Instructions............................. 10

B_Operating Tips ........................... 10

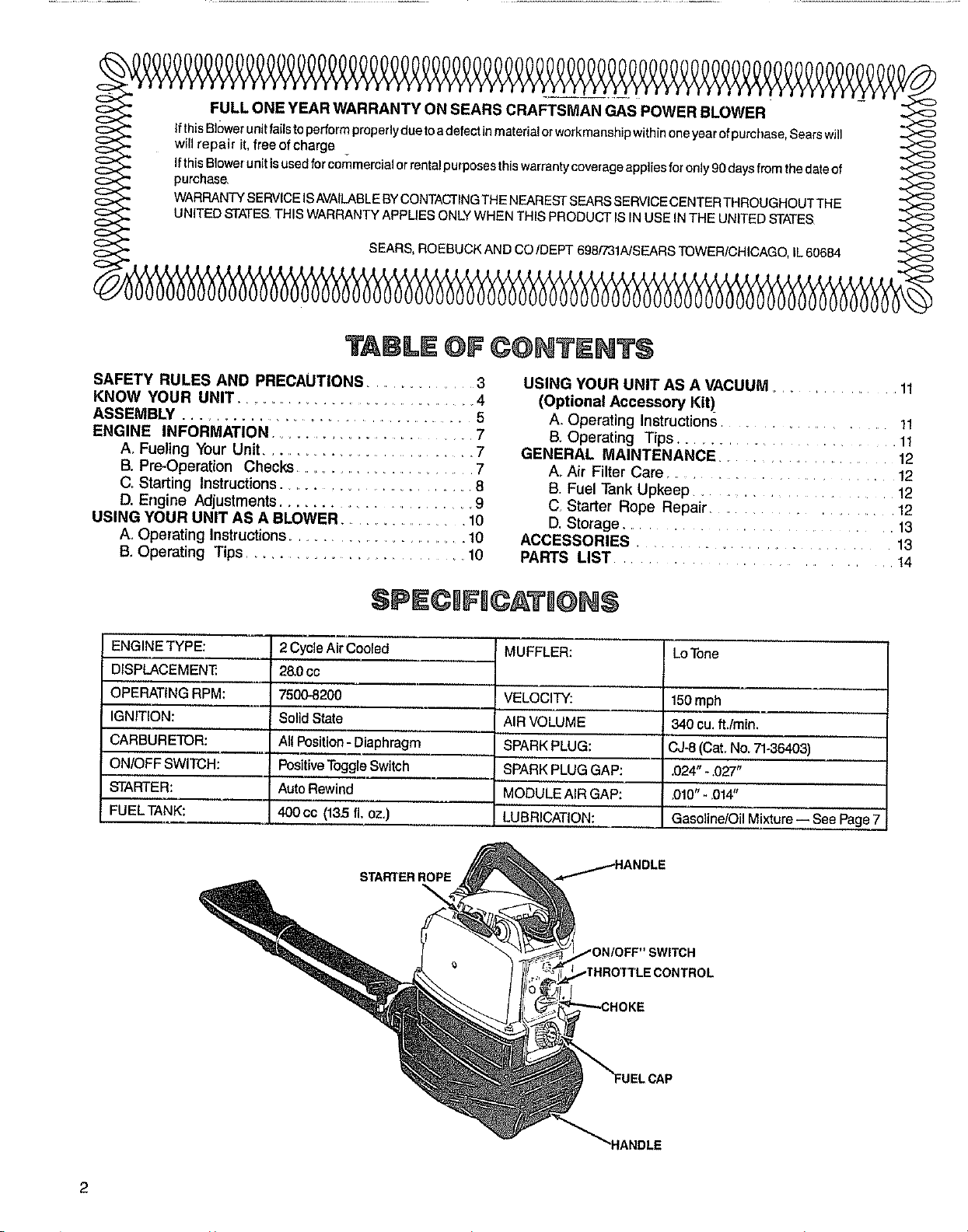

SPECJFI©ATJ@N$

ENGINE TYPE:

DISPLACEMEN31

OPERATING RPM:

IGNITION:

CARBURETOR:

ON/OFF SWITCH:

STARTER:

FUELTANK:

2 Cycle Air Cooled

28.0cc

75008200

Solid State

All Position - Diaphragm

Positive Toggle Switch

Auto Rewind

400cc (13.5 fl, oz.)

USING YOUR UNIT AS A VACUUM

(Optional Accessory Kit)

A Operating Instructions

B. Operating Tips. . .

GENERAL MAINTENANCE

A, Air Filter Care

B Fuel Tank Upkeep

C, Starter Rope Repair

D. Storage.

ACCESSORIES

PARTS LIST

MUFFLER:

VELOCITY:

AIR VOLUME

SPARKPLUG:

SPARKPLUGGAP:

MODULE AIR GAP:

LUBRICATION:

LoTone

150mph

340 cu.ft./min.

CJ-8(Cat,No, 71-36403)

.024"- .027"

.010"- .014"

Gasoline/oil Mixtu're_ see Page7

11

11

12

12

12

12

13

13

14

STARTER ROPE

/HANDLE

;WITCH

2

Page 3

Failure to follow all Safety Rules and Precautions could result in serious personal injury.

A. KNOW YOUR

1 Read your Operator's Manual carefully until you

completely understand and can follow all safety

rules, precautions, and operating instructions

before operating the unit.

2, Restrict your unit to users who understand and

follow all safety rules, precautions, and operating

instructions found in this manual,

PLAN AHEAD

1 Always wear eye protection to prevent recks or

debris from being blown or ricocheting into eyes

and face which can result in loss of vision or

serious personal injury.

2, Always wear a respirator or facemask when

working with the blower in dusty environments.

3, Dress safely in long pants. Do not wear loose

clothing, jewelry, short pants or sandals; or go barefoot

4 Do not operate the unit when you are tired, ill, or

upset; or if you are underthe influence of alcohol,

drugs, or medication.

5 Keepchlldren, bystandersandanimalsawayfrem

the work area, a minimum of 3Ofeet (lO meters),

when starting or operating the unit.

6 Inspectthearaabeforestartingtheunit. Removeall

debris and hard or sharp objects such as rocks, glass,

wire, etc that can be blown or cause damage during

operation. Asa vacuum, the unit is designed topick up

dry material such as leaves, grass, small twigs and bits

of paper. Do notvacuum stones, gravel, metal, broken

giass etc. to avoid severe damage to the impelle_ Do

not attempt to vacuum water or other liquids to

avoid damage to the engine.

C, NANDILI IFU ' = WSTH CAUTaON

1 Eliminate all sources of sparks or flame (including

smoking, open flames, orworkthat can causesparks)

in the areas where fuel ismixed, poured, or stored

2, Mix and pour fuel in an outdoor area; store fuel in

a cool, dry, wen,ventilatedplace; and use an

approved, marked container for all fuel purposes.

3. Do not smoke while handling fuel or while

operating the unit.

4 Do not fill the fuel tank while the engine isrunning

or strapped to the operator.

5 Wipe up all spills before starting the engine.

6_ Move at least 10 feet (3 meters) away from fuel and

fueling site before starting the engine_

D, OPERATE _'OUR UNgT SAFI_LY

1 Stoptheenginebeforeopeningthevacuuminlet

door or attempting to insert or remove the suction

tube. The engine must be stopped and the impeller

blades no longer turning to avoid contact with the

rotating blades

2_ Inspect the entire unit before each use for worn,

loose, or damaged parts. Do not use until the unit is

in proper working order.

3 Keep the outside surfaces free of oil and fuel.

4 Never start or run the engine inside aclosed room

or building. Exhaust fumes contain dangerous carbon

monoxide

5 Do not wear rubber or any other insulated gloves

when using the unit as a vacuum to avoid static

electricity shock.

6 Donotsettheunitonthegreundtostarttheengine

orwhile the engine isrunning. Debris such asgravel,

sand, dust, grass, etc could be picked up by the air

intake and thrown out through the discharge opening,

damaging the unit, property or causing serious

personal injury to bystanders or the operator

7 Avoid dangerous environments. Do not use in

unventilated areas or where explosive vapors or carbon

monoxide build up could be present

8 Do not overreach or use from unstable surfaces such

as ladders, trees, steep slopes, rooftops, etc Keep firm

footing and balance at all times

9 Never place objects inside t he blower tubes; always

direct the blowing debris away from people,

animals, glass, and solid objects such as trees,

automobiles, walls,etc The force ofair cancause rocks,

dirt, or sticks.to bethrown or to ricochet which can hurt

people or animals, break glass or cause other damage

10 Neverplaceanyobjectintheairlntakeopeningas

this could restrict proper air flow and cause damage to

the unit

11 Never run the unit without the proper equipment

attached. When used as a blower, always install a

blowertube When used asa vacuum, alwaysinstallthe

suction tube and collection bag Make sure the

collection bag assembly iscompletely zipped when the

unit isrunning to avoid flying debris

12 Always use the shoulder strap attached to the

collection bag when vacuuming to avoid loss of

controJ

13 Never use for spreading or misting chemicals, fer-

tilizera or toxic substances.

14 Avoid situations that could catch the collection

bag on fire. Do not operate near an open flame Do

not vacuum warm ash from fireplaces, barbecue pits,

brush piles, etc_Do not vacuum discarded cigars or

cigarettes unless cinders are completely cool

15,

Use only for jobs explained in this manual.

E. MA"NTADN YOUR UNliT PROPERLY

1oMaintain the unit according to recommended

procedures.

2, Disconnect spark plug before performing

maintenance except for carburetor adjustmenL

3 Use only genuine replacement parts as recom-

mended by Sears to avoid creating a hazard and/or

voiding your warranty.

4 Check air intake openings and blower tubes fre-

quently, always with the engine stopped. Keep

vents and tubes free of debris which can accumulate

and restrict proper air flow

5 Never make engine adjustments with the unit

strapped to the operator.

6. Drain fuel frem the fuel tank before storing for 30 or

more days.

7 Do not use any accessory or attachment other

than those supplied by Sears for use with this par-

ticular uniL

8 Do not store the unit or fuel in a closed area where

fuel vapors can reach sparks or an open flame from

hot water heaters, furnaces, etc.

9 Store in a dry area out of the reach of children.

3

Page 4

NOW YOUR UNIT

A, _NTRODUCT_ON B. UNPACKONG mNSTRUCTqONS

Your unit is a high performance product designed for

tough jobs.

Special Features Include:

= One-handed Operation

o Direct Drive

o Vibration Dampened Handle

° Weight- 1151bs.

= Convenient Upright Storage

Easy Conversion to Vacuum Capability with the

Optional Accessory Kit #71-79991.

CARTON CONTENTS:

KEY NO. QTY.

1 Engine Assembly 1

2 Blower Tube 1 4

3 Nozzle 1 f_l

4 8 oz.,2-cycle Engine Oil 1

-- Operator's Manual - 1

(Not Shown)

Your unit has been carefully packed at the factory to

preventdamage during shipping and storage, Carefully

unpack the carton as follows:

1 Remove corrtents from the carton_

2. Check parts against the list below

3. Examine parts for damage

4 Notify your Sears Store immediate/y if a part is

missing or damaged,

1

3

/

SPECIAL NOTICE

For users onU.S. Forest Land and in thestates of California, Maine, Oregon and Washington. All US ForestLand and

the statesofCaUfornia(PublicResourcesCodes 4442 and4443), Oregon and Washington require,by law,thatcertaininter-

nalcornbustion enginesoperated onforest, brushand/or grass-coveredareas beequipped withasparkarrestor, maintained

ineffectiveworkingorder,orthe enginebe constructed,equipped andmaintained forthe preventionoffire. Check withyour

state orlocal authoritiesfor regulationspertainingtothese requirements.Failuretofollow these requirementscouldsubject

youtoliability ortoa fine. This unit is not factory-equipped with aspark arrestor. Ifthese items are required inyourarea,

ask yourdealer toinstallPart# 69207.

Page 5

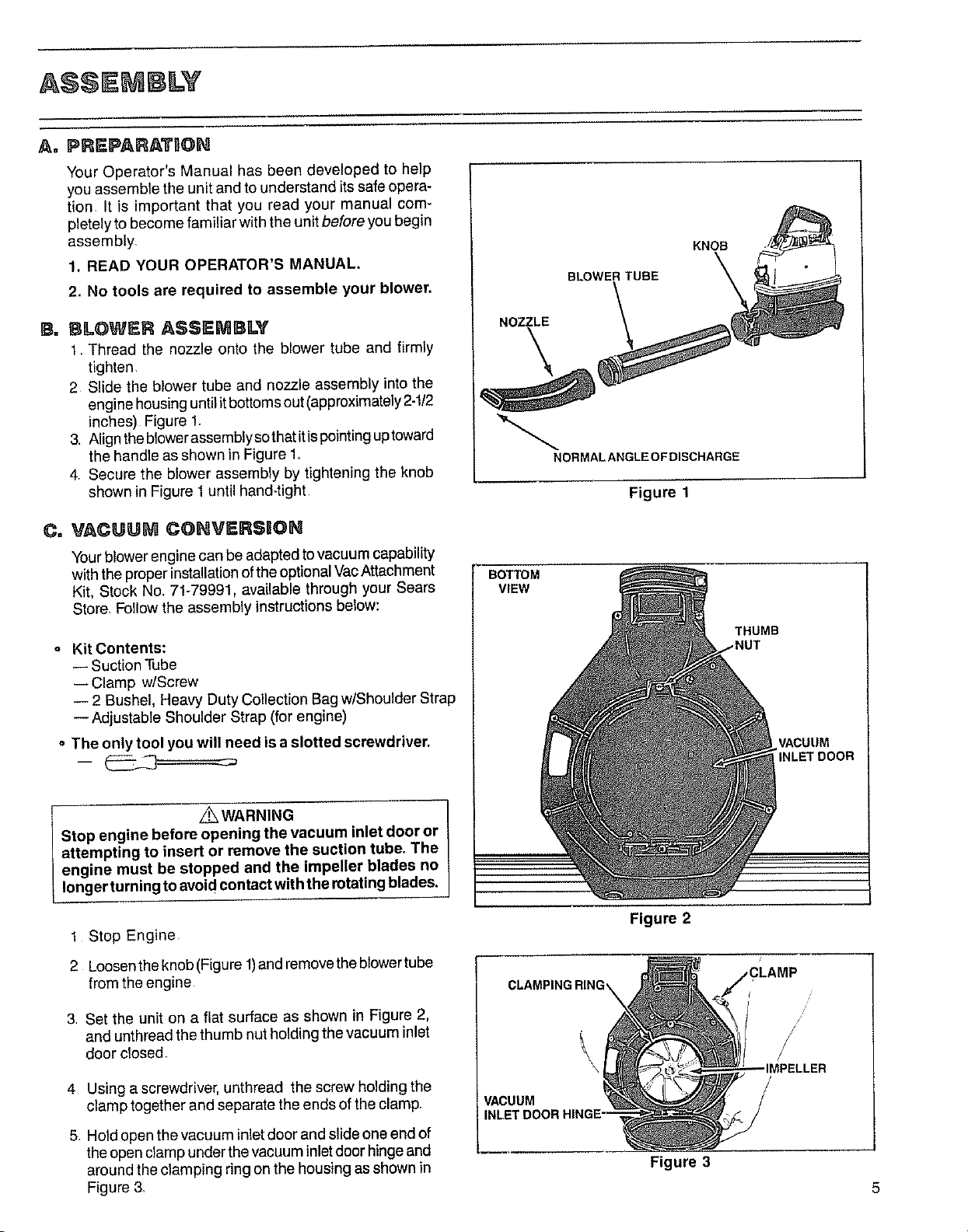

Your Operator's Manual has been developed to help

you assemble the unit and to understand its safe opera-

tion It is important that you read your manual com-

pletely to become familiar with the unit before you begin

assembly,

1. READ YOUR OPERATOR'S MANUAL,

2_ No tools are required to assemble your blower,

KNOB

BLOWER TUBE

B. BLOWER ASSEMBLY

1 Thread the nozzle onto the blower tube and firmly

tighten,

2 Slide the blower tube and nozzle assembly into the

engine housing until it bottoms out (approximately 2-t/2

inches) Figure 1_

3, Align theblower assembly sothat itispointing uptoward

the handle as shown in Figure 1.

4, Secure the blower assembly by tightening the knob

shown in Figure 1 until hand-tight

Co VACUU_ COHVERSION

Your blower enginecan be adapted to vacuum capability

with the properinstallation of the optional Vac Attachment

Kit, Stock No_71-79991. available through your Sears

Store, Follow the assembly instructions below:

o Kit Contents:

-- Suction Tube

-- Clamp w/Screw

-- 2 Bushel. Heavy Duty Collection Bag w/Shoulder Strap

--Adjustable Shoulder Strap (for engine)

o The only tool you will need is aslotted screwdriver.

NOZZLE

\

NORMALANGLEOFDISCHARGE

Figure 1

BOTTOM

VIEW

THUMB

_NUT

VACUUM

INLET DOOR

_WARNING

Stop engine before opening the vacuum inlet door or

attempting to insert or remove the suction tube. The

engine must be stopped and the impeller blades no

longer turning to avoidcontact with the rotating blades.

1 Stop Engine

2 Loosen the knob (Figure 1)and remove the blowertube

from the engine

3 Set the unit on a flat surface as shown in Figure 2,

and unthread the thumb nut holding the vacuum inlet

door closed

4 Using a screwdriver, unthread the screw holding the

clamp together and separate the ends of the clamp,

5 Hold open the vacuum inlet door and slide one end of

the open clamp under the vacuum inlet door hingeand

around the clamping ring on the housing as shown in

Figure 3.

Figure 2

CLAMPING RING_

//

IMPELLER

VACUUM

Figure 3

Page 6

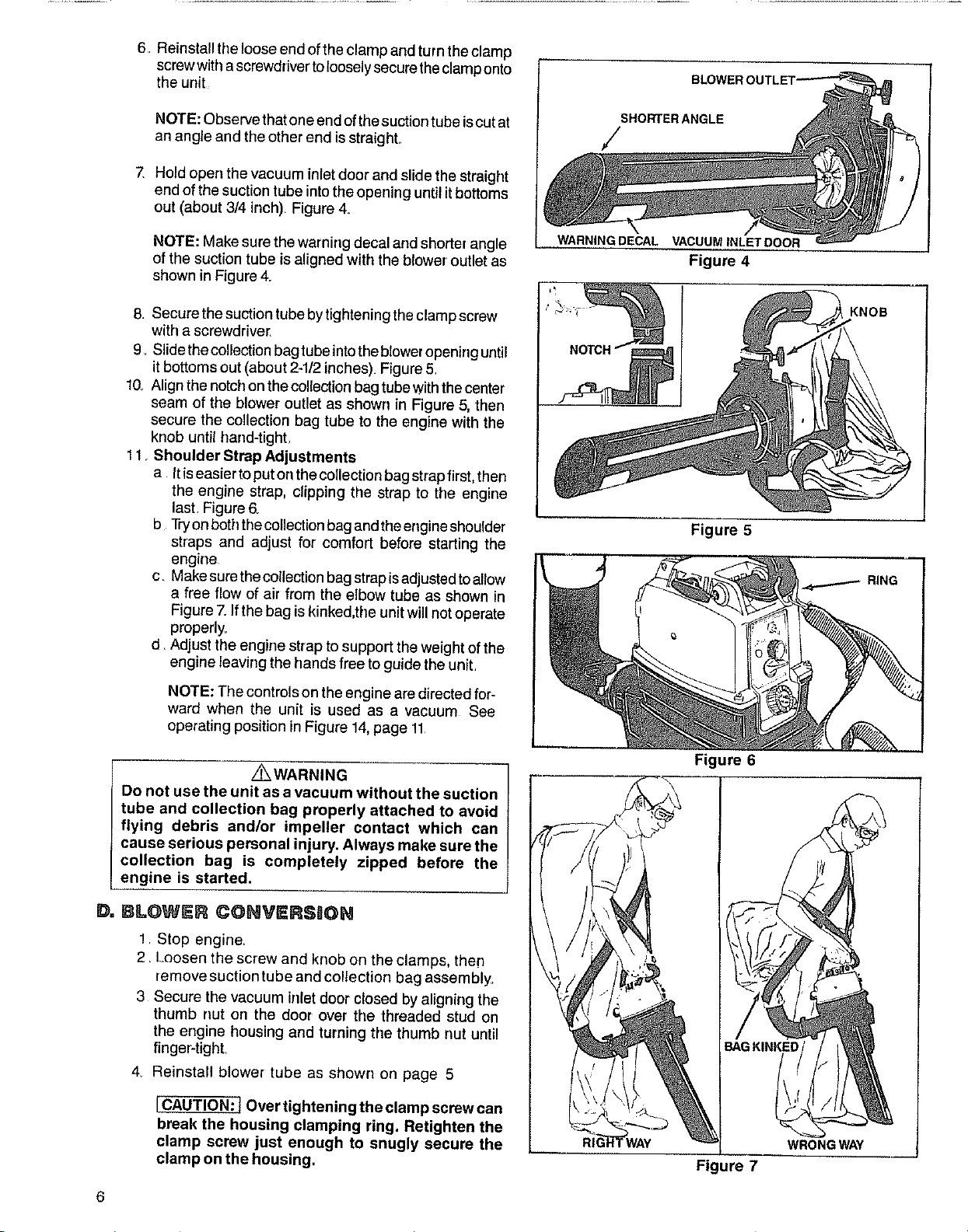

6, Reinstall the loose end of the clamp and turn the clamp

screwwith ascrewdriver to loosely secure the clamp onto

the unit

NOTE: Observe that one end of the suction tube is cut at

an angle and the other end is straight,

7, Hold open the vacuum inlet door and slide the straight

end of the suction tube into the opening until itbottoms

out (about 3/4 inch). Figure 4,

/

NOTE: Make sure the warning decal and shorter angle

of the suction tube is aligned with the blower' outlet as

shown in Figure 4.

8. Secure the suction tube bytightening the clamp screw

with a screwdriver,

9. Slide the collection bagtube into theblower opening until

it bottoms out (about 2-1/2inches). Figure 5,

10, Align the notch on the collection bag tube with the center

seam of the blower outlet as shown in Figure 5, then

secure the collection bag tube to the engine with the

knob until tland-tighL

11 Shoulder Strap Adjustments

a Itiseasiertoput on thecollectionbag strap first, then

the engine strap, clipping the strap to the engine

last Figure 6_

b Tryon boththe collection bagand the engine shoulder

straps and adjust for comfort before starting the

engine

c. Make sure the collection bag strapis adjusted toallow

a free flow of air from the elbow tube as shown in

Figure 7.Ifthe bag is kinked,the unit will not operate

properly.

d Adjust the engine strap to support the weight of the

engine leaving the hands free to guide the unit,

WARNING DECAL VACUUM INLET DOOR

Figure 4

KNOB

Figure 5

RING

NOTE: The controls on the engineare directed for-

ward when the unit is used as a vacuum See

operating position in Figure 14,page 11

Z_WARNING

Do not use the unit as a vacuum without the suction

tube and collection bag properly attached to avoid

flying debris and/or impeller contact which can

cause serious personal injury. Always make sure the

collection bag is completely zipped before the

engine is started.

DoB -OWER CONVERSaON

! Stop engine,

2 loosen the screw and knob on the clamps, ther]

remove suctiontube and collection bag assembly.

3 Secure the vacuum inletdoor closed by aligning the

thumb nut on the door over the threaded stud on

the engine housing and turning tile thumb nut until

fingePtighL

4 Reinstall blower tube as shown on page 5

[CAUTION: ! Over tightening the clamp screw can

break the housing clamping ring. Retighten the

clamp screw just enough to snugly secure the

clamp on the housing.

Figure 6

BAG KINKED

WAY WRONGWA'_/

Figure 7

Page 7

EN@ NE INF@RMATMON

A= FU_L,gNG YOUR UNI;T (See "Specifications, page 2, for location of Fuel Cap.)

1. FUEL MIXTURE

o Your unit is powered by a 2-cycle engine which

requires a fuel mixture of regular, unleaded

gasoline and a high quality engine oil specially

made for 2-cycle, air-cooled engines, The inter-

nal design ofthe 2-cycle enginerequireslubrication

ofmoving parts Lubricationisprovidedwhen you

use the recommended mixtureof gasolineand oil.

• Gasoline must be clean and not over two

months old. After a short period oftime, gasoline

begins tochemicallybreak down and willform com-

pounds that can cause hard starting and damage in

2-cycle engines

o The correct measure of gasolinetoeilisveryim-

portant. Too much oil will foul the spark plug. Toolit-

tle oilwill cause the engine tooverheat and freeze up

• Always mix the fuel thoroughly in a container

since gasoline and oildo not readily combine. Donot

try to mix fuel directly in the fuel tank

USE THE FOLLOWING:

2_

1 GALLON

REGULAR

UNLF_DED _-

-- OR-- _

4. DO NOT USE:

° BIA OIL (Boating Institute of America) --

-- Does not have proper additives for air-cooled,

2_cycle engines and could cause damage

o AUTOMOTIVE OIL --

--Does not have proper additives for 2-cycle

engines and could cause damage

• GASOLINE CONTAINING ALCOHOL

(High Test, Premium or Gasohol) --

--Stiffens critical carburetor fuel metering

eler_ents and causes engine damage from

overheating

--Increases vapor lock (causes hard starting)

-- Attracts water causing corrosion damage

5. IMPORTANT POINTS TO REMEMBER

a, Use only recommended fuel mixtures.

b Eliminate all sources of sparks or flame in the

areas where fuel is mixed, poured, or stored.

There should be no smoking, open flames or

work that can cause sparks.

3. HOW TO MIX FUEL

a Pour one-half of the gasoline into an approved

marked container. Do not try to mix fuel directly

in the h_el tank.

b Add entire measure of 2-cycle Engine OiL

c. Mix.

d. Add remainder of gasoline.

e Mix thoroughly for one mim,te.

B, PRE-OPERATBON CHECKS

Before operating your unit, always:

t. _- CHECK OVER SAFETY RULES AND PRECAU-

TIONS in this Operator's Manual Make certain you

completely understand and follow each one

2. ,-- CHECK THE AIR FILTER.

Clean thefilter before operating the unit, See Figure 15.

c Use an approved, marked container for all fuel

purposes.

d Mix and pour fuel in an outdoor area. Store fuel

in a cool, dry, well-ventilated place. Gasoline

vaporsare harmful to your health and can cause

serious hazards,such as explosionand fire Use a

funnel or spout when pouring fuel

e. Wipe up all fuel spills before starting the

engine.

f. Move at least 10 feet (3 meters) away from fuel

and fueling site before starting the engine.

3. v" CHECK THE UNIT FOR lOOSE BOLTS, NUTS,

OR FITTINGS.

Tighten, repair or replace parts as necessary. Use

only genuine replacement parts;

4. v" CHECK THE FUEL TANK.

Fill with a clean, fresh fuel mixture according to

instructions in fuel mixture section

Page 8

,,,,,, i,

A=STARTING mN$3"RUCI"I]ON$ (Refer to "Specifications," page 2, for location of controls.)

z_WARNING

Hold the unit for starting as shown in Figure 8.Do notset

the unit on the ground to start the engine or while the

engine is running. Debris such as gravel, sand, dust,

grass, etc. could be picked up by the air intake and

thrown out through the discharge opening, damaging

the unit or property or causing serious personal injury

to bystanders or the operator.

1 STARTING PROCEDURE

Hold the unit in the starting position as shown

inFigure 8 Make sure theend of the unit isdirect-

ed away from people, animals, glass and solid

objects

b Move the ignition switch to the "On" position.

Figure9

c Turn the throttle control knob clockwise to

the "Fast" position. Figure 10_

d

Turn choke knob to "On" position. Figure 11

e_

Hold handle with your right hand and pull

starter handle with your left hand until the

engine fires (attempts torun)

BLOWER

STARTING

VACUUM

STARTING

NOTE: Do not let the starter rope snap back

between pulls_Hold the handle and let the rope

rewind slowly

f Turn choke knob to "Half" position and pull

starter handle until engine runs. Figure11.

Allow engine to warm-up as indicated below,

then turn choke knob to the "Off" position.

Figure 11

-- Above40°1:,warm-up 10o20seconds

-- Below40°F, warm-up45.60 seconds

h.

Stop engine by moving ignition switch to the

"Off" position. Figure 9

2. IMPORTANT POINTS

a

When starting the engine, always pull the

starter rope sharply and quickly, but not

more than 10 times to avoid flooding the

engine. If flooding occurs, turn choke to the

"Off" position (Figure 11)and pull starter rope

untilengine starts

b_

Start a cold engine with the choke atthe "On"

position Figure 11

C

Start awarm engine with the choke at the"Off"

position If unit fails to start witilin 2 pulls, move

choke tothe "Half" positiorLFigure 11

Figure 8

IGNITION SWITCH

THROTTLE CONTROL

ON

/

OFF ,

Figure 9 Figure 10

CHOKE KNOB

Figure 11

OFF

8

Page 9

D= ENGBN ADJUSTMSNTS

1. CARBURETOR ADJUSTMENTS

The carburetor has been carefully adjusted at the

factory. Due to changes in altitude and operating

conditions, your carburetor may require adjusting.

Tomake the adjustment follow the procedure below

very carefully:

a PREPARATION

1) Use fresh fuel mix See Fuel Mixture page 7

2) Remove air filter

3) Turn mixture screw clockwise _ until

fully closed, but do not overtighteno Figure

12 Unscrew mixture screw one full turn

counterclockwise

4) Turn Idle Speed Screw clockwise

==,=-_ until it stops Do not overtighten.

Open screw three full turns counterclockwise

/

b IDLE SPEED ADJUSTMENT

1) Start the engine and turn throttle control to

halfway between "Fast" and "Slow"

2 ) Operate the unit for 3 minutes to warm up

engine

3) Turn throttle control counterclockwise

to slow setting

4) Adjust Idle Speed Screw:

Clockwise _ if the engine stalls:

Counterclockwise _ to slow engine

down

5 ) Adjust the Idle Speed Screw until the engine

idles as slow as possible without the engine

stalling

tCAUTION:] The mixture setting is a highly

critical adjustment. If set incorrectly,

permanent damage will occur to the

engine. Do not operate engine at fast

throttle fdr prolonged periods while making

the mixture adjustment.

c MIXTURE ADJUSTMENT:

1) Adjust throttle knob to "Fast" position

2 ) Turn the Mixture Screw slowly clockwise

until the engine speed is reduced

Note position

3) Turn the screw slowly counterclockwise

_===_ Stop when the engine just begins

to run rough

4) Turn the screw slowly the minimum amount

clockwise ==="_ until the engine runs

smoothly

-i

Figure 12

IDLE SPEED

ADJUSTMEN1

NOTE 1: The mixture screw should be in the

range of 3/4 to 1-1/4turns open

NOTE 2: For the best engine performance, it

is better to run a slightly rich mixture setting

(counterclockwise _ )than too lean a

setting

d REPLACE AIR FILTER

2. SPARK PLUG (Cat. No. 71-36403)

Check spark plug periodically and clean or replace

as necessary. After cleaning, reset the electrode gap

to "025,

N ES

9

Page 10

USING YOUR @N T AS L@WER

A. OFE T NG HSTRUCTaON$

1 Read your Operator's Manual, Make certain you

completely understand and can follow all safety rules,

precautions, and operating instructions, before

operating the uniL

2 Always wear eye protection to prevent rocks or

debris from being blown or ricocheting into eyes

and face which can result in loss of vision or

serious personal injury.

3 Always wear a respirator or facemask when work-

mg in dusty environments.

4 Dress safely in long pants. Do not wear loose

clothing, jewelry, short pants or sandals; or go barefoot

5 Check the unit before operation. Look for worn,

loose, or damaged parts Do not use until the unit is in

proper working order

6 Inspect the area before starting unit. Remove all

debris and hard objects such as rocks, glass, wire, etc

that can be blown or cause damage during operation

7 Keepobservers, children, bystanders, andanimals

safely away. Before starting the engine and during

_Pseration, make certain children, animals and

tanders are away from the work area -aminimum of

30 feet (10meters).

8 Check air intake opening and blower tubes fre-

quently, always with the engine stopped. Keep

vents and discharge tubes free of debris which can

accumulate and restrict proper air flow

9 Use the correct operating position. (Figure 13.)Do

not overreach or use from unstable surfaces such as

ladders, trees, steep slopes, roof tops, etc_Keep firm

footing and balance at all times

1Q

Never place objects inside the blower tubes; always

direct the blowing debris away from people,

animals, glass, and solid objects such as trees.

automobiles, walls,etc Theforce ofaircancauserocks.

dirt,orsticks tobethrownorto ricochetwhichmay hurt

people or anirnals, break glass, orcause other damage

ALWAYS USE

"_EYE PROTECTION

USE RESPIRATOR

OR FACEMASK

FOR DUSTY

ENVIRONMENTS

OPERATION

WITHBOTH

HANDLE

CONTROL

PANEL

TO THE _`_

REAR

HANDLE

HANDLES

Figure 13

z_WARNING

Hold the unit for starting as shown in Figure 8. Do not

set the unitontheground tostart theengineorwhilethe

engine is running. Debris such as gravel, sand, dust,

grass, etc. could be picked up by the air intake and

thrown out through the discharge opening, damaging

the unit or property or causing serious personal injury

to bystanders or the operator.

B. OPI RATBNG TIPS

Always work going away from solid objects such as

walls, large stones, automobiles and fences,

2

Clean spaces with corners by starting in corners

and moving outward tostraight areas toprevent an

accumulation ofdebris whichcould fly into face

,

Becareful when working near valuable plants. The

force ofthe air could damage tender plants

4

Direct air flow byadjusting the nozzle.

5,

Run the engine at full throttle for full air power=

6

Vary or reduce the air flow by setting the throttle

knob at any position from "Fast" to "Siowo"

7

Use the handle located on the bottom of the unit

below the control panel when working above the

waistorwhenatwo-handedgripisdesired. Refer

tothe unitdrawing, page 2, and Figure 13,this page

10

z_WARNING

Always wear eye protection to prevent rocks or debris

frern being blown or ricocheting into the eyes and face

which can result in loss of vision or serious personal

injury.

8 -Uses For Your Blower:

a Sweeping debris or grassclippings from driveways,

sidewalks, patios, park, parking lots, barns,

stadiums, etc

b Gathering grass clippings, straw or leaves intopiles

c Fastdrying wet, outdoor areas such as a patio

d Removing debris from corners, around joints and

between bricks

e Blowing light snow from driveways, sidewalks or

patios

Page 11

As a vacuum, the unit is designed topick up dry material

such as leaves,grass, small twigsand bits ofpaper. Donot

attempt tovacuum stones, gravel, metal, broken glass, etc.

to avoid severe damage tothe impeller.

1 Read your Operator's Manual, Make certain you

completely understand and can follow all safety

rules, precautions, and operating instructions,

before operating the unit

2 Always wear eye protection to prevent rocks or

debris from being blown or ricochet;_g into eyes

and face which can result inloss of visionorserious

personal injury.

3 Dress safely in long pants. Do not wear loose

clothing, jewelry, short pants or sandals; or go

barefoot

4 Check the unit before operation, Look for worn,

loose, or damaged parts Do not use until the unit

is in proper working order

5 Inspect the area before starting the unit. Remove

all debris and objectssuch asrocks,glass,wire,large

sticks, etc thatcancause damage during operation

6 Keepobservers, children, bystanders, andanimals

safely away. Before starting the engine and during

operation make certain people and animals are away

from the work area -a minimum of 30 feet (10meters).

7 Check air intake opening and collection bag tube

frequently, always with the engine stopped. Engine

RPM will increase significantly when the suction or

collection bag tube isclogged. Keep vents and tubes

free ofdebris which can accumulate and restrict proper

air flow.

8 Use the correct operating position. (Figure 14)

Do not overreach or use from unstable surfaces

such as ladders, trees, steep slopes, roof tops, etc

Keep firm footing and balance at all times

9 Do not wear rubber or any other insulated gloves

to avoid static electricity shock.

10 Never run the unit without the proper equipment

attached. Always install the suction tube and col-

lectionbag. Make surethe collection bag assembly

iscompletelyzipped when the unit is in use to avoid

flying debris

11 Always use the collection bag and engine shoulder

straps to avoid loss ofcontrol.

Z_WARNING

Do not insert orremove suction tube with engine run-

ning toavoid serious personal injury. Always stop the

engine before unclogging the unit or performing any

maintenance on the collection bag.

COLLECTION

BAG

STRAP

ENGINE

STRAP

CONTROL

"/PANEL

B. OP_RATnNG T_PS

1, Move the unit slowly back and forth over debris

to be vacuumed, Avoid forcing the suction tube into

a pile of debris as this can clog the unit.

2 If the unit becomes clogged:

a. Stoptheengineanddisconnectthesparkplug.Do

not attempt to remove obstructions with engine

running.

b Wait until the impetler has completely stopped turn-

ing, then remove the suction tube

c Carefully reach into the vacuum opening and clear

out debris

Figure 14

3 The collection bag must be properly emptied

,and maintained to avoid deterioration and ob-

structing air flow which will reduce the

performance of the vacuum.

a. Empty the bag after each use. Do not store bag

containing wet grass, leaves, etc

b. Clean the bag after every three uses by turn-

ingthe bag inside out after initial emptying and

vigorously shaking out dust and excess debris

c. Wash the bag once a year

1) Turn bag inside out

2). Hang up

3). Hose down thoroughly

4). Hang to dry 11

Page 12

MA NTENAN©E

Ao AIR FILTER CARE

A dirty air filter decreases engine performance and

increases fuel consumption_

Clean the Air Filter:

• Frequently,

o Always clean after 5 tanks of fuel or 5 hours of

operation, whichever is less.

Follow these steps:

1 Remove the air filter (located above the control

panel; see Figure 15)

2 Wash in soap and water

ICAUTION:I Do not clean filter in gasoline or

other flammable solvent to avoid creating a fire

hazard.

& Squeeze filter dry

4 Add a small amount of oil to coat the filter,

NOTE: Avoid soaking the filter with oil

5 Squeeze out excess oil

6 Replace the air filter.

NOTE: Make sure the filter is properly fitted into the

housing, paying particular attention to the corners.

Bo FUEL TANK UPKEEP

Never use gasoline that is more than 2 months old

in a fuel mixture. Gasoline begins to break down after

a short period of time and will form compounds that

cause hard starting and damage in 2-cycle engines

1 Inspect the unit for fuel leaks each time it is

used. Repair or replace parts as necessary

2 Always begin operation with a clean, fresh

mixture of fuel.

3 Drain all fuel from the unit or allow unit to run

out of fuel before storing for 30 or more days.

C. STARTER ROPE REPAIIR

• Repair the starter rope if the rope breaks next to

the pulley.

o Replace the starter rope if the rope breaks more

than 2-3 inches away from the pulley as the rope

will be too short to repair properly.

Z_WARNING

Always wear eye protection when servicing the starter

rope. The recoil spring, located beneath the pulley, is

under tension. Ifthe spring pops out, serious personal

injury can result.

Figure 15

FAN HOUSING --_.

REMOVE

SCREWS

F

SPARK PLUG WIRE

12

° To repair or replace:

1 Disconnect the spark plug wire and remove the 6

screws from the fan housing.Figure 16,

2 Separate the far] housing completely from the

shroud

Figure 16

Page 13

3

Ifthe starter rope is notbroken, release the spring's

tension by pulling about 10inches of rope from the

pulley and catching the rope inthe notch as shown

Figure 17 If the rope is broken, remove the broken

piece.

NOTE: The tension on the starter spring will be

released ifthe rope is broken

4_ Remove screw and pulley very carefully, Figure 17

The recoil spring which lies beneath the pulley

must stay in the housing, flat against the bot-

tom. If the spring is disturbed, it will require con-

siderable time and effort to reinstall. Twist the

pulleygentlycounterclockwise _ asyoupull

up to release the spring

5 Move away from the fueltank and melttheend ofthe

rope to go into the pulley`

6 Allow the melted end to drip once; then while the

rope is still hot, pull the melted end through a ragto

obtain a smooth, pointed end

7 Insert rope through the rope exit hole in the fan

housing

8 Snake rope inside the pulley, then through topside

pulley hole by pushing the rope from the underside

holewith a small round object such as a Phillips

screwdriver. See Insert, Figure 18

9 Wrap rope counterclockwise _ around

pulley ratchet and tuck loose end back under rope

leaving a 3/8 to 1/4inch tail Figure 18 Pull tightly

l& Wind all but about 10 inches of the rope counter

clockwise _ around pulley

11_ Replace pulley inthe housing Be sure the pulley is

all the way down and the spring is secured

12. Replace and tighten pulley screw Figure 17.

13 Hold the 10 inch slack in the rope and catch rope

in pulley notch. Figure 19

14 Hold the rope taut and make 2 complete turns

of the pulley counterclockwise _ to place

tension on the pulley Hold the pulley to retain

tension

I5. Align pulley notch with rope exit hole, pull starter

handle to the full extent of the rope and allow the

rope to slowly wind around the pulley

16 Reinstall the fan housing tothe shroud.

;HET

Figure 17

SCREWDRIVER ._" / /

/

__ Figure 18

\

NOTCH

Figure 19

D, STORAGE

1 Clean the unit before storing. Pay particular atten-

tion to the air intake area,keeping itfreeof debris Use

a mild detergent and sponge to clean the plastic

surfaces

A©©A$$@RBA$

VACUUM ATTACHMENT K_T ..................

2-CYCLE ENG_IRE OHL .......................

SPARK PLUG ...........................

SHOULDER STRAP I_BT (for Engine) ............

2 Do not store the unit or fuel in aclosed area where

fuel vapors can reach sparksor an open flame from

hot water heaters, furnaces, etc.

3. Store in a dry area out of reach of childrenr

mmwwmwmlmmwm=_lm

====B=l=mm.mm#_

............ 71-79991

....... 7%36555

illll.......

mmmm_m=#==m=_#=

............ 7t-85783

13

Page 14

SEARS BLOWER PARTS UST _ MODEL 358.796920

Figure 1

10

11

2

.j 15 16

/

101

14

13

31

32

102

19

25

2O

33

34

35

33

o

38

43 41 40

42

38

14

Page 15

SEARS BLOWI=R PARTS LOST -- MODEL 358.796920

Figure 1

KEY PART CITY, DESCRIPTION QTY, DESCRIPTION

NOo NO. NO. NO,

1 10828 1 Ass'y - Handle(Incl #2) 31 26776 1 Deflector- Heat

2 15635 2 Screw - 10- 14 x 11116Bind, Hd- 32 10824" 1 Shroud - (Incl #12 &45)

Handle 33 10835 1 Ass'y- Blower Hsg (IncL 9of#38)

5 24256 3 Isolator - Handle 34 94215 1 Impeller

6 15343 1 Spacer - Isolator (Front) 35 15661 1 Screw - 10- 14 x 88 -

7 26163 6 Cup - Isolator Blower Hsg/Inlet Door

8 15629 2 Washer #8 - Front 37 15064 1 Nut - 10- 24

g 15628 2 Screw -8 - 32 x 7/16Rind Hd - 38 15367 10 Screw - 10- !4 x 3/4

Fan Hsg/Crankcase Pivot Pin/Blower Hsg

10 15561 2 Screw- 12- 11x2 39 15644 1 Nut - Impeller

11 15342 2 Spacer - Isolator (Rear) 40 15441 ! Washer +Conical - Impeller

12 32091 * 1 Bearing-Ball (Shroud) 42 15632 4 Screw - 1/4- 20 x 7/8 +

13 15678 2 Screw - 10+24 x 5/8 Bind Hd + Blower Hsg/Shroud

14 24371 1 Air Filter

15 15676 4 Screw- 10 - 24x 7/8 -Fan Housing 44 15168 4 Screw- 10+24 x5/8-

16 15677 4 Washer - Fan Hsg Shroud/Crankcase

17 10821 1 Fan Housing 45 1516 1 Retainer-Bearing-Shroud

18 42023 1 Spring - Starter Pulley 46 15667 1 Spring - Tension (Right)

19 26780 1 Baffle - Air 47 15647 ! Pin - Pivot

20 28626 1 Pulley Starter 48 15672 1 Spring - Tension (Left)

21 15479 1 Screw +10 - 3/4 Hex Hd +Pulley 49 94241 1 Ass'y - Inlet Door

22 15123 1 Washer - Starter Pulley 50 15638 1 Screw - 1/4x20 1/2- Retainer

23 15544 4 Screw - 10 x3/8 Pan Hd - 51 !5637 1 Retainer +Fuel Tank

24 22289 1 Rope (3 ft ) 53 91678 1 Ass'y - Fuel Pick-up

25 26735 1 Handle - Starter Rope 54 21058 1 Line - Fuel - Tank

27 15664 1 Bolt - 1/4- 20 x 1-1/2-Clamp 56 10729 1 Ass'y - Fuel Cap w/Retainer

28 94222 1 Clamp - Blower Tube 57 10615 1 Ass'y -Fuel Tank

29 94242 ! Knob - Clamp (Incl #53, 54 & 56)

30 15636 3 Screw -10 - Heat Deflector DECALS

Fan Hsg/Crankcase 43 15682 4 Washer - Blower Hsg/Shroud

Air Baffle 52 26781 1 Cushion - Fuel Tank

KEY PART

41 15626 1 Washer- Flat- Impeller

101 26778 1 Decat- Instruction

102 26777 2 Decal - (Left & Right) Fan

Housing

103 26925 1 Deca_- Warning-Blower Hsg

Key Nos+Excluded: #3, 4, 26, 36 & 55

*When removing or installingthe bearing (#32091), the area of the shroud (#10824) receiving the bearing must be heated to

approximately 3000E to avoid damaging the shroud

15

Page 16

SEARS BLOWER PA_$ L_S_=-- MODEL 358.796920

14

o/

29

15

28

22

21

18

Figure 2

19

21

/

5

7

8

22

13

12

11

16

56

26

12

72

52

53

SPARK

ARRESTOR

KIT

3

/

55

Page 17

SITARS BLOWER PARTS LIST -- MODEL 358.796920

Figure 2

KEY PART

NO. NO.

1 12112

2 19111

3 26681

4 15162

5 15239

6 26949

7 10809

8 24361

9 24903

10 69203

11 94219

12 94218

13 94243

14 626605

15 23817

18 26765

19 32057

20 15351

21 32058

22 1O819

23 19059

26 15377

27 15126

28 15168

29 39111

30 15127

31 24438

32 19108

33 191O5

34 15241

35 23367

36 26818

37 19115

38 25472

39 21056

40 26797

41 26772

QTY, DESCRIPTION KEY PART

1 Cylinder 42 15676 1 Screw* 10-24x7/8-

1 Gasket- Cylinder Carburetor

2 Ring - Piston 28cc 43 35196 1 Carburetor

2 Retainer - Wrist Pin 44 15254 1 Washer - Wave -Carburetor

2 Screw - 1/4- 20 x 3/4- 45 15673 1 Spacer - Carburetor

Hex Soc Hd.* Cylinder 46 15630 1 Screw- 10- 24 x 2 3/8- Carb.

1 Diffuser - Muffler Shoulder

1 Ass'y - Body-Muffler 47 15654 1 Ring - External Retaining

1 Cover - Muffler Throttle

2 Spring - Muffler Attachment 48 15147 1 Washer-Wave-Throttle

1 Piston Kit (IncL#3, 4 & Pin) 49 15407 1 Screw - 8 -32 x 5/16Pan Hd. -

1 Shaft - Arbor Choke Knob

2 Coupling - Shaft 50 26773 1 Actuator - Choke

1 Coupling - Plastic 51 15147 1 Washer - Wave -Choke

1 Nut - Flywheel - 5/16 x 24 52 26764 1 Cover - Carb_Case

2 Spring - Starter Dog 53 23807 1 Knob -Choke

1 Ass'y-Crankshaft&Rod 54 15675 4 Screw- 8- 18x 5/8 Phil.

1 Bearing - Wrist Pin 55 15660 1 Screw 10- 14x 3/8 -Throttle

2 Washer-Thrust-Crankcase 56 15658 1 Washer- Flat Throttle

2 Bearing - Crankshaft 57 15614 1 Knob -Throttle

1 Crankcase Ass'y. 58 23575 1 Nut -Grounding Switch

(Incl. #21& 23) 59 24569 1 Washer - Ground

2 Seal - Crankcase 60 26766 1 Switch Toggle

1 Washer - Coupling (IncL #58,59, 62, 63)

1 Key- Flywheel 61 26771 1 Ass'y -Throttle Wire

4 Screw - 10- 24 x 5/8 Fil. Hd. 62 26950 1 Wire - Ignition

1 Flywheel Assembly (Incl. #15) 64 24435 1 Grommet - Plug Wire

1 Washer* Flywheel 65 15128 2 Screw_ 8-32 x 3/4 FiL Hd -

1 Seal - Carburetor Case 68 3933 1 Connector - Spark Plug Lead

1 Screw- 6 - 19x 5/16- Pan Hd. - 69 3934 1 Boot - Spark Plug

1 Washer- Reed Valve Screw 71 39103 1 High Tension - Lead Assembly -

1 Case - Carburetor (IncL #68,69, &70)

1 Gasket -Carburetor 72 30054 1 Sealant - Crankcase -

1 Fitting - Fuel Line (Not Supplied With Unit)

1 Line - Fuel -Carburetor 73 69207 1 Spark Arrestor-Kit

1 Guide Plate - Choke (Not Supplied With Unit)

Crankcase 63 26829 1 Wire - Ground

1 Reed Valve Ignition Module

1 Gasket -Carburetor Case to 66 39124 1 Ignition Module

Crankcase 67 STD360946 1 Spark Plug (CJ-8) -(CaL No. 71-36403)

Reed Valve 70 39082 1 High Tension Lead Wire

1 Shutter- Choke

NO. NO. QTY. DESCRIPTION

Key Nos. Excluded: #16, 17, 24, & 25

17

Page 18

S_=AR$ BLOWER PA_S LaST -- MODEL 358.796920

CARBURETOR ASSEMBLY -- #35196

Figure 3

18

KEY PART

NO. NO_ DESCRIPTION

1

35197

2

35015

3

35132

4

35156

5

35138

7

35200

8

35198

9

35162

11

35017

12

35191

13

35164

14

35166

15

35178

18

35007

19

35008

20

35139

21

35031

22

35028

23

35016

24

35151

25

35014

26

35003

27

35021

35199

35186

Valve Throttle

Screw-Throttle Valve

Shaft Assembly-Throttle

Idle Speed Screw

Spring-Throttle Return

Spring-High Speed Mixture Needle

Needle-High Speed Mixture

*Plug-5/16 Dia Welch

Screw-Pump Cover

Cover-Fuel Pump

+" Gasket-Fuel Pump

+* Diaphragm-Fuel Pump

Screen-Fuel inlet

Ring-Throttle Retainer

"Valve-inlet Needle

*Spring-Metering Lever

•Lever-Metering

"Pin*Metering Lever

•Screw-Metering Lever Pin

+" Gasket-Metering Diaphragm

+" Diaphragm*Metering

Cover-Metering Diaphragm

Screw,_ssembly-Metering Cover

Kit-Repair (includes parts marked*)

Kit-Gasket/Diaphragm (includes parts marked +)

Page 19

SEARS BLOWER PARTS LaST -- MODEL 358.796920

Figure 4

1

/

VACUUM KIT #71-79991 (Optional Accessory Kit)

KEY NO.

1

2

3

PART

QTY. NO. DESCRIPTION

1 94225 Nozzle - Blower

1 94224 Tube- Blower (Upper)

1 66517 Operator's Manual

3

Ol

KEY NO.

1

2

3

4

5

6

101

PART

QTY. NO.

1 94394

1 94231

1 94227

1 15671

1 94230

1 94232

Decal

1 26937

\

4

DESCRIPTION

Strap-Shoulder-Engine

Tube-Collection Bag

Bag-Collectionw/Strap

Strap-Tie

Clamp-Suction Tube

Tube-Suction

Decal - SuctionTube

19

Page 20

operator's

manual

The Model Number wilt be found under the handle with the Serial

Number Always mention the Model Number when requesting service

or repair phrts for your' unit,

All parts listed herein may be ordered from any Sears Service Center

and most Sears Stores

WHEN ORDERING REPAIR PARTS ALWAYS GIVE THE FOLLOWING

INFORMATION AS SHOWN IN THIS LIST

1 The PART NUMBER

3 The PART DESCRIPTION

MODEL NO

358.796920

How to Order

Repair Parts

2 The MODEL NUMBER

358.796920

If the parts you need are not stocked locally, your order will be elec-

tronically transmitted to a Sears Repair Parts Distribution Center for

expedited handling

4 The NAME OF ITEM --

GAS POWER BLOWER

When you buy merchandise from

Sears you get an extra something

that nobody else can 0ffe! Sears

Service

Across town or across the country,

Sears Service follows you, pro-

viding trustworthy, competent ser-

vice technicians using only Sears

specified factory parts

SEARS SERVICE

IS AT YOUR SERVICE

66517-3-24085-1-24085

Your Sears Merchandise takes on added value when you discover

that Sears has Service Units throughout the country. Each is staffed

by Sears-Trained, professional technicians using Sears approved

methods.

Sear bu -k an . _ 4 .S.A.

s, Roe c d Co, C licago, Ill. 6068 U

Loading...

Loading...