Sears 149.23632,Craftsman 149.236320 Owner's Manual

owners

manual

MODELNO.

149.236320

SERIAL

OR CODE

NUMBER:

Model and code number may be

found on the back of the base.

You should record both model and

code number and retain in a safe

place for future use.

CALIFORNIA OWNERS: a unique

serial code number is stamped on

the underside of the machine.

SWAIRS / r.RRFTSMRN®

CAUTION:

Read All Instructions

Carefully Before Start-

ing Assembly and Use.

Save This Manual For

FutureReference.

SEARS, ROEBUCK AN D CO., Dept. 698/731A, Sears Tower, Ch icago, IL 60684

51_.INCH

JOINTER-- PLANER

• assembly

• operating

• repair parts

d_o-15A- oo

FULL ONE-YEAR WARRANTY ON £RRFTSMRN, JOINTER -- PLANER

If within one year from the date of purchase, this Craftsman Jointer -- Planer fails due to a defect

in material or workmanship, Sears will repair it, free of charge.

WARRANTY SERVICE IS AVAILABLE BY CONTACTING THE NEAREST SEARS STORE OR SERVICE

CENTER IN THE UNITED STATES.

This warranty gives you specific legal rights and you may also have other rights which vary from

state to state.

Sears, Roebuck and Co. Dept. 698/731A, Sears Tower, Chicago, IL 60684.

GENERAL SAFETY RULES FOR POWER TOOLS

1. KNOW YOUR POWER TOOL

For your own safety, read the owner's manual carefully.

Learn its application and limitations as well as the specific

hazards peculiar to this tool.

2. GROUNDING INSTRUCTIONS

A. All grounded, cord-connected tools:

In the event of a malfunction or breakdown, grounding pro-

vides a path of least resistance for electric current to reduce

the risk of electric shock. This tool is equipped with an

electric cord having an equipment-grounding conductor and

a grounding plug. The plug must be plugged into a matching

outlet that is properly installed and grounded in accordance

with all local codes and ordinances.

Do not modify the plug provided - if it will not fit the outlet,

have the proper outlet installed by a qualified electrician.

Improper connection of the equipment-grounding conductor

can result in a risk of electric shock. The conductor with

insulation having an outer surface that is green with or with-

out yellow stripes is the equipment-grounding conductor. If

repair or replacement of the electric cord or plug is necessary,

do not connect the equipment-grounding conductor to a live

terminal.

Check with a qualified electrician or serviceman if the

grounding instructions are not completely understood, or if

in doubt as to whether the tool is properly grounded.

The use of any Extension Cord will cause some loss of power.

To keep this to a minimum and to prevent overheating and

motor burn-out, use the table below to determine the MINI-

MUM wire size (A.W.G.) Extension Cord.

Use only 3-wire extension cords that have 3-prong grounding

plugs, and 3-pole receptacles that accept the tool's plug.

Extension Cord Length Wire Size, A.W.G.

25 Feet 16

50 Feet 16

100 Feet 14

Extension Cords suitable for use with your Jointer-Planer are

available at your nearest Sears Catalog Order or Retail Store.

Repair or replace damaged or worn cord immediately.

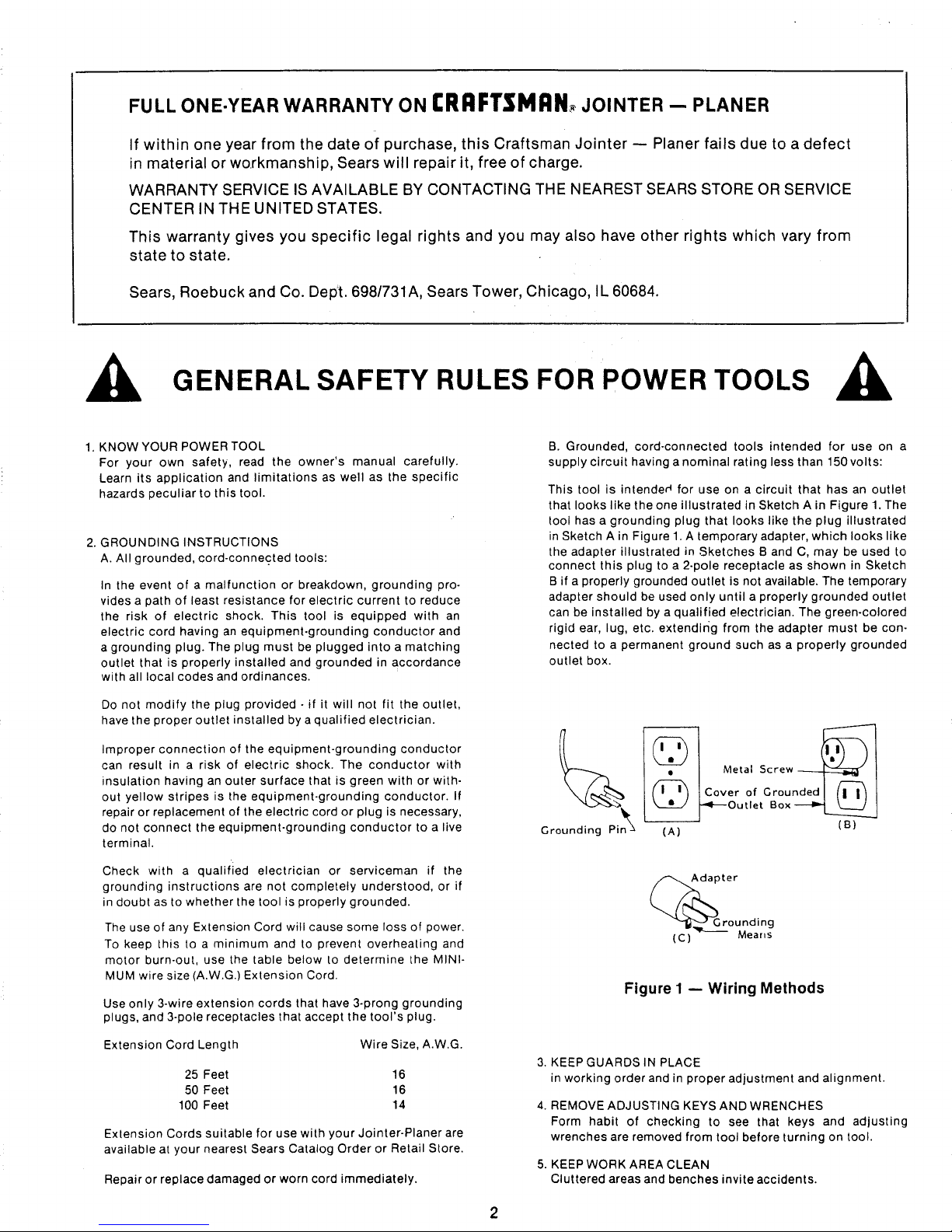

B. Grounded, cord-connected tools intended for use on a

supply circuit having a nominal rating less than 150 volts:

This tool is intended for use on a circuit that has an outlet

that looks like the one illustrated in Sketch A in Figure 1. The

tool has a grounding plug that looks like the plug illustrated

in Sketch A in Figure 1. A temporary adapter, which looks like

the adapter illustrated in Sketches B and C, may be used to

connect this plug to a 2-pole receptacle as shown in Sketch

B if a properly grounded outlet is not available. The temporary

adapter should be used only until a properly grounded outlet

can be installed by a qualified electrician. The green-colored

rigid ear, lug, etc. extendirig from the adapter must be con-

nected to a permanent ground such as a properly grounded

outlet box.

_ _ Meta=Screw

I ( I , ) t Cover of Grounded I (I I / I

____Out,et Box---_

Grounding Pin (A) (B)

Adapter

(G) Means

g

Figure I m Wiring Methods

3. KEEP GUARDS IN PLACE

in working order and in proper adjustment and alignment.

4. REMOVE ADJUSTING KEYS AND WRENCHES

Form habit of checking to see that keys and adjusting

wrenches are removed from tool before turning on tool.

5. KEEP WORK AREA CLEAN

Cluttered areas and benches invite accidents.

6.DON'TUSEINDANGEROUSENVIRONMENT

Don'tusepowertoolsindamporwetlocations,orexpose

themtorain.Keepworkareawellillumina'ced.

7.KEEPCHILDRENAWAY

Allvisitorsshouldbekeptasafedistancefromworkarea.

8.MAKEWORKSHOPKIDPROOF

withpadlocks,masterswitches,orbyremovingstarterkeys.

9.DON'TFORCETOOL

Itwilldothejobbetterandbesaferattherateforwhichit

wasdesigned.

10.USERIGHTTOOL

Don'tforcetoolor'attachmenttodoajobforwhichitwasnot

designed.

11.WEARPROPERAPPAREL

Nolooseclothing,gloves,neckties,rings,bracelets,or

jewelrytogetcaughtinmovingparts.Nonslipfootwearis

recommended.Wearprotectivehaircoveringtocontainlong

hair.

12.ALWAYSUSESAFETYGLASSES

Alsousefaceordustmaskif cuttingoperationisdusty.

Everydayeyeglassesonlyhaveimpactresistantlenses.They

areNOTsafetyglasses.

13.SECUREWORK

Useclampsoravisetoholdworkwhenpractical.It'ssafer

thanusingyourhandandfreesbothhandstooperatetool.

14.DON'TOVERREACH

Keepyourproperfootingandbalanceatalltimes.

15.MAINTAINTOOLSINTOPCONDITION

Keeptoolssharpandcleanforbestandsafestperformance.

Followinstructionsforlubricatingandchangingaccessories.

16.DISCONNECTTOOLSFROMPOWERSOURCE

beforeservicingandwhenchangingaccessoriessuchas

blades,bits.cutters,orwhenmountingandre-mounting

motor.

17.

18.

19.

20.

21.

22.

AVOIDACCIDENTALSTARTING

Makesureswitchisin"OFF"positionbeforepluggingin

cord.

USERECOMMENDEDACCESSORIES

Consulttheowner'smanualforrecommendedaccessories.

Useofimproperaccessoriesmaybehazardous.

NEVERSTANDONTOOL

Seriousinjurycouldoccurifthetoolistippedorifthecutting

toolisunintentionallycontacted.

CHECKDAMAGEDPARTS

Beforefurtheruseofthetool,aguardorotherpartthatis

damagedshouldbecarefullycheckedtoensurethatitwill

operateproperlyandperformitsintendedfunction-check

foralignmentof movingparts,bindingof movingparts,

breakageofparts,mounting,andanyotherconditionsthat

mayaffectitsoperation.Aguardorotherpartthatisdamaged

shouldbeproperlyrepairedorreplaced.

DIRECTIONOFFEED

Feedworkintoabladeorcutteragainstthedirectionof

rotationofthebladeorcutteronly.

NEVERLEAVETOOLRUNNINGUNATTENDED.TURN

POWEROFF.Don'tleavetooluntilitcomestoacomplete

stop.

Theoperationofanypowertoolcanresultinforeignobjects

beingthrownintotheeyes,whichcanresultinsevereeye

damage.AlwayswearsafetygogglescomplyingwithANSIZ87.1

(shownonPackage)beforecommencingpowertooloperation.

SafetyGogglesareavailableatSearsretailorcatalogstores.

TABLE OF CONTENTS

GENERAL SAFETY RULES FOR POWER TOOLS ............ 2, 3

UNPACKING AND CHECKING CONTENTS .................. 4

SAFETY RULES FOR JOINTER-PLANER ...................... 5

ASSEMBLY .......................................... 5-7

Depth of Cut Hand Knob .................................. 5

Chip Deflector ............................................ 5

Checking Cutter Blades ................................... 6

Fence .................................................. 6, 7

Fence Extension .......................................... 7

INSTALLING THE JOINTER-PLANER ......................... 8

CONTROLS AND ADJUSTMENTS ....................... 8-9

Depth of Cut Hand Knob ................................ 8, 9

Fence Adjustment ........................................ 9

Cutter Guard ............................................. 9

ON/OFF Switch ........................................... 9

BASIC JOINTER-PLANER OPERATION ................... 10-12

Feeding the Workpiece .................................. 10

Using Holddown/Push Blocks ............................ 11

Beveling, Chamfering ................................. 11, 12

Using a Wet/Dry Vac ..................................... 12

MAINTENANCE ........................................ 12, 13

Timing Belt Replacement ................................ 12

Cutter Guard Return Spring .............................. 12

Blade Replacement and Adjustment ...................... 13

General Maintenance .................................... 13

REPAIR PARTS ......................................... 14, 15

TROUBLE SHOOTING ...................................... 16

How to Order Replacement Parts ......................... 16

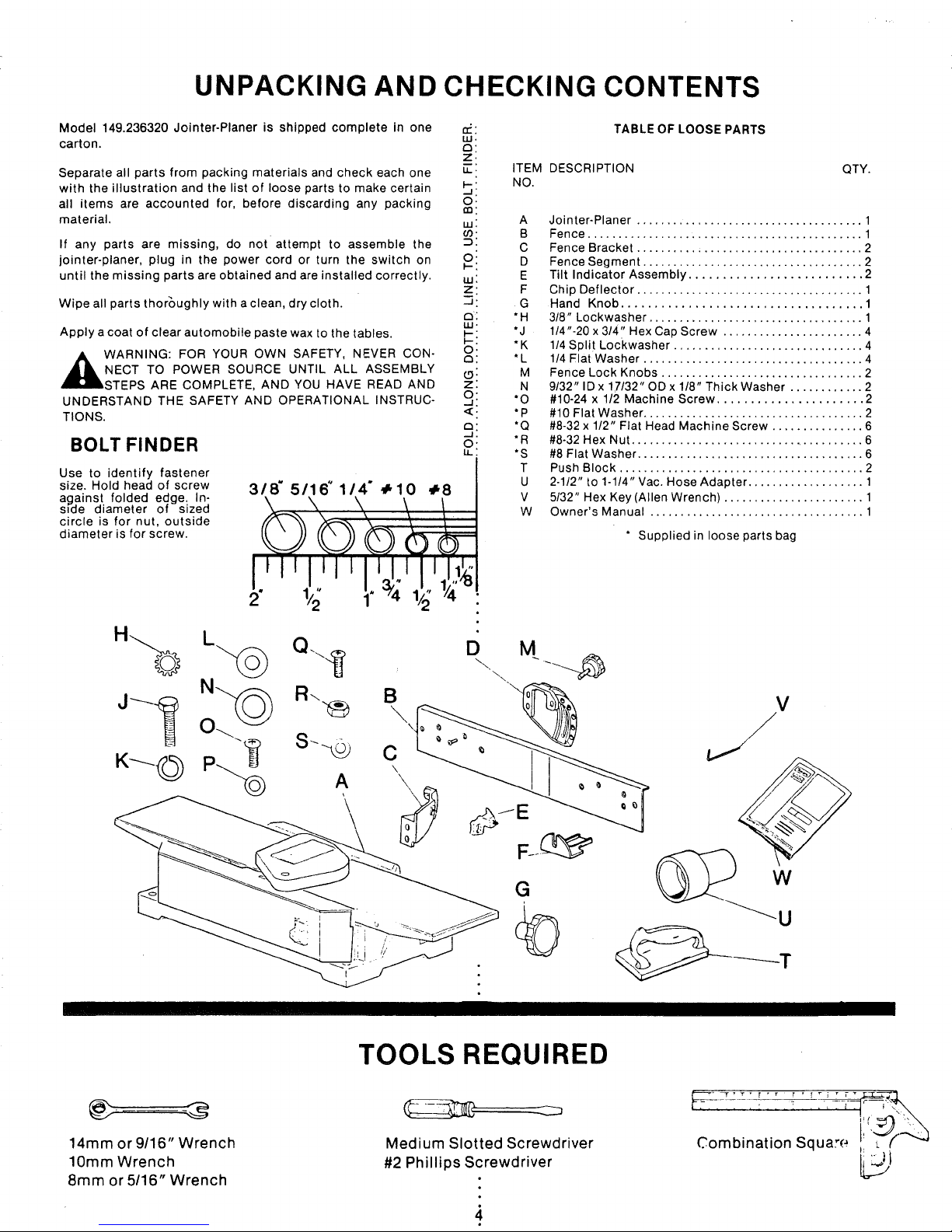

UNPACKING AND CHECKING CONTENTS

Model 149.236320 Jointer-Planer is shipped complete in one

carton.

Separate all parts from packing materials and check each one

with the illustration and the list of loose parts to make certain

all items are accounted for, before discarding any packing

material.

If any parts are missing, do not attempt to assemble the

jointer-planer, plug in the power cord or turn the switch on

until the missing parts are obtained and are installed correctly.

Wipe all parts thoroughly with a clean, dry cloth.

Apply a coat of clear automobile paste wax to the tables.

,_WARNING: FOR YOUR OWN SAFETY, NEVER CON-

NECT TO POWER SOURCE UNTIL ALL ASSEMBLY

STEPS ARE COMPLETE, AND YOU HAVE READ AND

UNDERSTAND THE SAFETY AND OPERATIONAL INSTRUC-

TIONS.

BOLT FINDER

Use to identify fastener

size. Hold head of screw

against folded edge. In-

side diameter of sized

circle is for nut, outside

diameter is for screw.

318' 5/16" 114" ÷10 ÷8

LU.

Z.

I.

LL.

F-'

O.

,-n:

LU:

Cf)"

o:

uJ:

z:

a:

I._.

O.

a:

2::

a:

-J.

O'

TABLE OF LOOSE PARTS

ITEM DESCRIPTION QTY.

NO.

A Jointer-Planer ..................................... 1

B Fence ............................................. 1

C Fence Bracket ..................................... 2

D Fence Segment .................................... 2

E Tilt Indicator Assembly .......................... 2

F Chip Deflector ..................................... 1

G Hand Knob .................................... 1

*H 318" Lockwasher ................................... 1

*J 1/4"-20 x 314" Hex Cap Screw ....................... 4

*K 1/4 Split Lockwasher ............................... 4

*L 1/4 Flat Washer .................................... 4

M Fence Lock Knobs ................................. 2

N 9132"lDx1_7132"ODx118"ThickWasher ............ 2

*O #10-24 x 1/2 Machine Screw ...................... 2

*P #10 Flat Washer .................................... 2

*Q #8-32 x 112" Flat Head Machine Screw ............... 6

*R #8-32 Hex Nut ....................................... 6

*S #8 Flat Washer ..................................... 6

T Push Block ........................................ 2

U 2-1/2" to 1-1/4" Vac. Hose Adapter ................... 1

V 5/32" Hex Key (Allen Wrench) ....................... 1

W Owner's Manual ................................... 1

* Supplied in loose parts bag

1/2" 1/_'4

B

\

\

C

\

\

D

M

G

14mm or 9/16" Wrench

10mm Wrench

8mm or 5/16" Wrench

TOOLS REQUIRED

_.......3

Medium Slotted Screwdriver

#2 Phillips Screwdriver

Combination Squa,-e i L'_

SAFETY RULES FOR JOINTER--PLANER

Safety is a combination of operator common sense and alertness at all times when the Jointer--Planer is being

used. Study these rules and general safety rules before operating and retain them for future use.

1. WEAR EYE PROTECTION.

2. NEVER MAKE JOINTING OR PLANING CUT DEEPER THAN

1/8 INCH -- PER PASS.

3. FEED WORKPIECE AGAINST ROTATION OF CUTTER.

4. KEEP FINGERS AWAY FROM REVOLVING CUTTER -- use

fixtures when necessary.

5. NEVER PERFORM JOINTING OR PLANING OPERATION

WITH CUTTER HEAD GUARD REMOVED.

6. NEVER FORCE CUTTING ACTION. Stalling or partial stalling

of motor can cause major damage. Allow motor to reach full

speed before cutting.

7. NEVER - Attempt to perform an abnormal or little used

operation without study and the use of adequate hold down

/push blocks, jigs, fixtures, stops, etc.

8. NEVER - Attempt to cut small pieces.

9.

ALWAYS - Use hold down/push blocks for jointing material

narrower than 3 inches, or planing material thinner than 3

inches.

10.

ALWAYS- Keep cutter sharp.

11.

NEVER- Use in an explosive atmosphere. Normal sparking of

motor may ignite fumes.

12.

OUTDOOR EXTENSION CORD USE - When tool is used

outdoors, use only extension cords suitable for use outdoors.

Outdoor approved cords are marked with the sL'ffix W-A, for

example- SJTW-A or SJOW-A.

13. ALWAYS use identical replacement parts when servicing.

14.This tool is intended for RESIDENTIAL USE ONLY.

WARNING: DO NOT ALLOW FAMILIARITY (GAINED FROM

FREQUENT USE OF YOUR JOINTER--PLANER) TO BECOME

COMMONPLACE. ALWAYS REMEMBER THAT A CARELESS

FRACTION OF A SECOND IS SUFFICIENT TO INFLICT SEVERE

INJURY.

WARNING: DO NOT AT ANY TIME LET BRAKE FLUIDS, GASOLINE, PENETRATING OILS, ETC.

,_ CONTACT WITH PLASTIC PARTS. THEY CONTAIN CHEMICALS THAT CAN DAMAGE

COME IN

AND/OR DESTROY PLASTICS.

ASSEMBLY

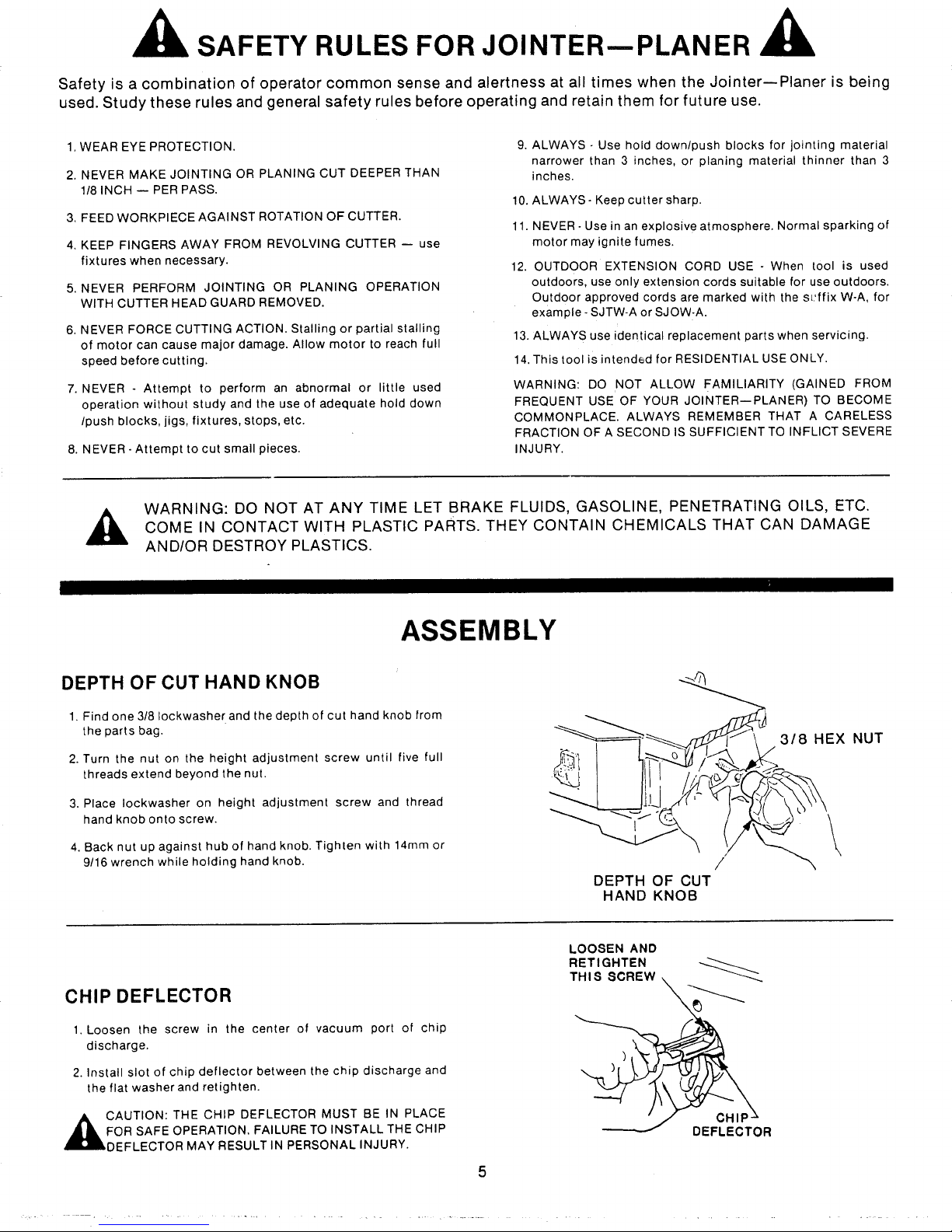

DEPTH OF CUT HAND KNOB

1. Find one 3/8 lockwasher and the depth of cut hand knob from

the parts bag.

2. Turn the nut on the height adjustment screw until five full

threads extend beyond the nut.

3. Place Iockwasher on height adjustment screw and thread

hand knob onto screw.

4. Back nut up against hub of hand knob. Tighten with 14ram or

9/16 wrench while holding hand knob. t

DEPTH OF CUT

HAND KNOB

LOOSEN AND

RETIGHTEN

CHIP DEFLECTOR

1. Loosen the screw in the center of vacuum port of chip

discharge.

2. Install slot of chip deflector between the chip discharge and

the flat washer and retighten.

T H I S SCREW _..........._.

3/8 HEX NUT

,_CAUTION: THE CHIP DEFLECTOR MUST BE IN PLACE

FOR SAFE OPERATION. FAILURE TO INSTALL THE CHIP

DEFLECTOR MAY RESULT IN PERSONAL INJURY.

DEFLECTOR

Loading...

Loading...