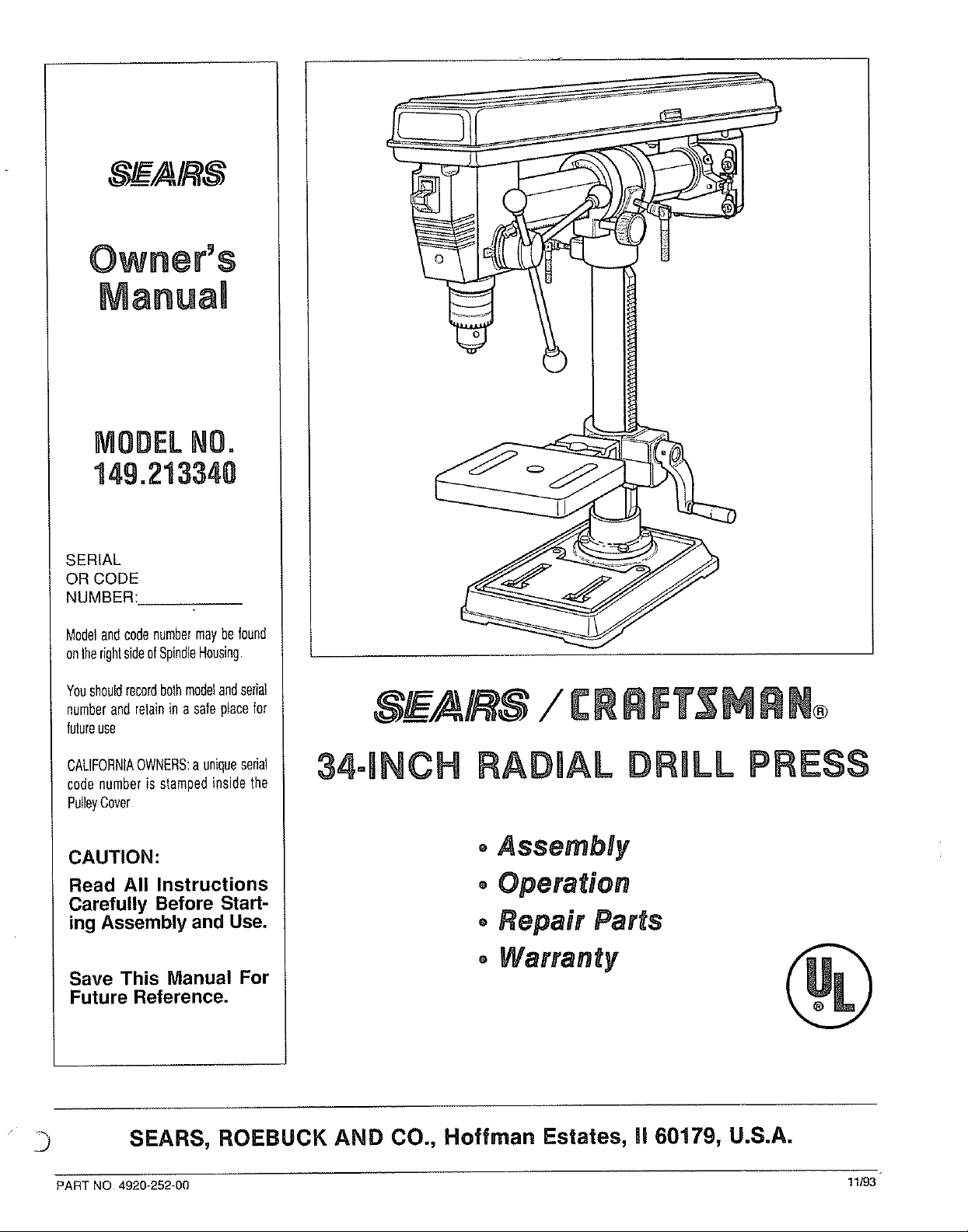

Page 1

SERIAL

OR CODE

NUMBER:

Modelandcodenumbermaybefound

on1herightsideofSpindieHousing

Youshouldrecordbothmodelandserial

numberandretainina satepiacefor

futureuse

/ CRAFT M AN®

CALIFORNIAOWNERS:a uniqueserial

codenumberis stampedinsidethe

PulleyCover

CAUTION:

Read All Instructions

Carefully Before Start-

ing Assembly and Use.

Save This Manual For

Future Reference.

SEARS, ROEBUCK AND CO., Hoffman Estates, la 60179, U.S.A.

PART NO 4920-252_00

34om

OH RADmAL DRULL

oAssembly

° Operation

o Repair Parts

o Warranty

11193

Page 2

FULL ONE-YEAR WARRANTY ON CRAFTSMAN RADIAL DRILL PRESS

If within one year from date of purchase, this Craftsman RADIAL DRILL PRESS fails due to a defect in materi-

al or workmanship, Sears will repair it, free of charge

WARRANTY SERVICE IS AVAILABLE BY CONTACTING THE NEAREST SEARS STORE OR SERVICE

CENTER IN THE UNITED STATES,

. This warranty gives you specific legal rights and you may also have other rightsthat vary from state to state

Sears, Roebuck and Co., 13/817WA, Hoffman Estates, IL 60179.

GENERAL SAFETY RULES FOR POWER TOOLS

KNOW YOUR POWER TOOL

For your own safety, read the owner's manual carefully

Learn the application and limitations as well as the specific

hazards peculiar to this tool

2 GROUNDING INSTRUCTIONS

A. All grounded, cord-connected tools:

In the event of a malfunction or breakdown, grounding pro-

vides a path of least resistance for electric current to

reduce the risk of electric shock This tool is equipped with

an electric cord having an equipment-grounding conductor

and a grounding plug The plug must be plugged into a

matching outlet that is properly installed and grounded in

accordance with all local codes and ordinances

Do not modify the plug provided - if it will not fit the outlet,

have the proper outlet installed by a qualified electrician

Improper connection of the equipment-grounding conduc*

tot can result in a risk of electric shock The conductor with

insulation having an outer surface that is green with or

without yellow stripes is the equipment-grounding conduc-

tor If repair or replacement of the electric cord or plug is

necessary, do not connect the equipment-grounding con-

ductor to a live terminal

Extension Cords suitable for use with your Radial Drill

Press are available at your nearest Sears Catalog Order or

Retail Store

Repair or replace damaged or worn cord immediately

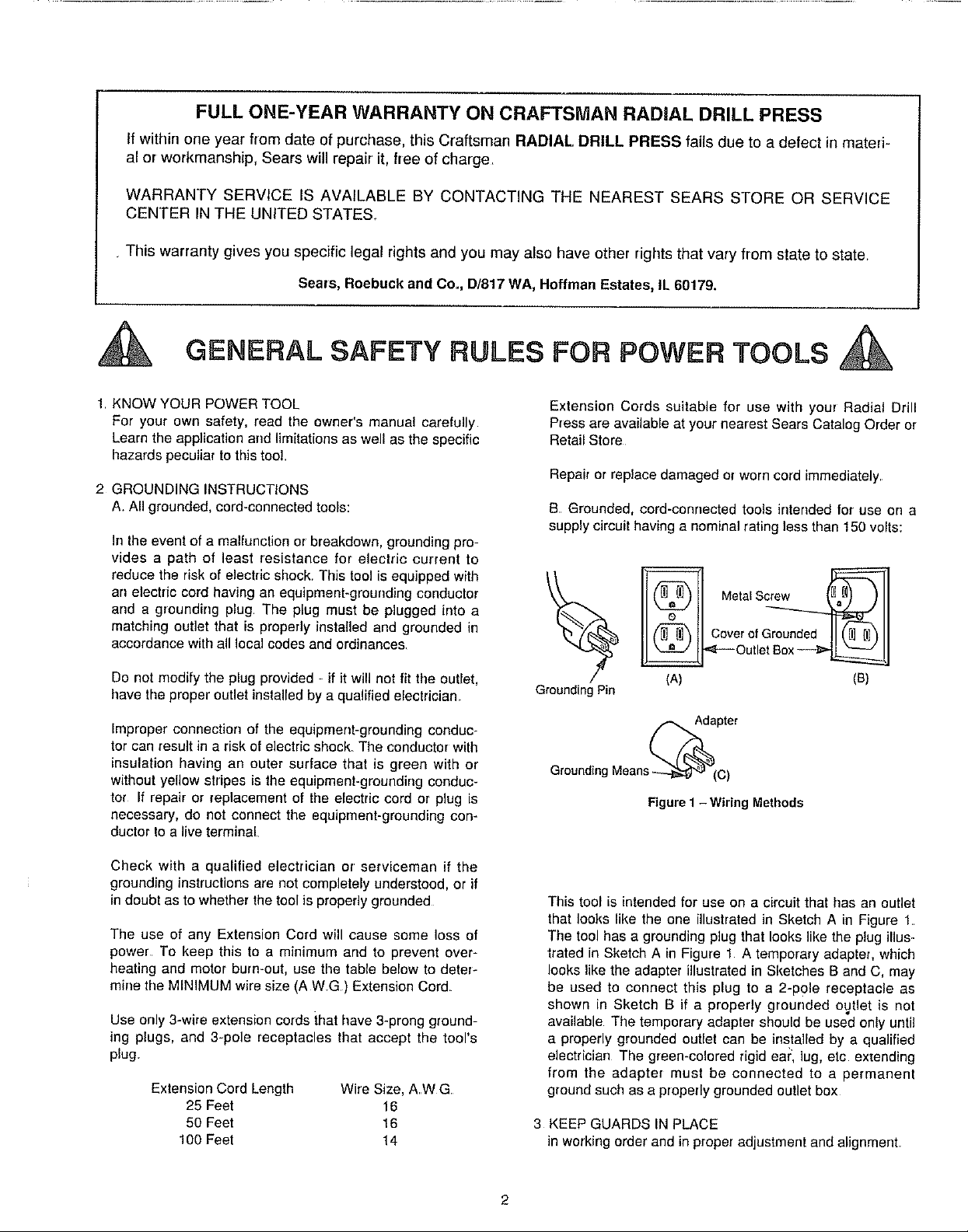

S Grounded, cord-connected tools intended for use on a

supply circuit having a nominal rating less than 150 volts:

MetalS_

rofGroundedII ['1)II

utlet Box

{A) (a)

Grounding Pin

Adapter

Groundin(

Figure I - Wiring Methods

Check with a qualified electrician of serviceman if the

grounding instructions are not completely understood, or if

in doubt as to whether the tool is properly grounded

The use of any Extension Cord will cause some loss of

power To keep this to a minimum and to prevent over-

heating and motor buro-out, use the table below to deter÷

mine the MINIMUM wire size (A W.G ) Extension Cord

Use only 3-wire extension cords :_hathave 3-prong ground-

ing plugs, and 3-pole receptacles that accept the tool's

plug

Extension Cord Length Wire Size, AW G

25 Feet 16

50 Feet 16

100 Feet 14

This tool is intended for use on a circuit that has an outlet

that looks like the one illustrated in Sketch A in Figure 1,

The tool has a grounding plug that looks like the plug illus-

trated in Sketch A in Figure 1 A temporary adapter, which

looks like the adapter illustrated in Sketches B and C, may

be used to connect this plug to a 2-pole receptacle as

shown in Sketch B if a properly grounded outlet is not

available The temporary adapter should be used only until

a properly grounded outlet can be installed by a qualified

electrician The green-colored rigid ea_:,lug, etc extending

from the adapter must be connected to a permanent

ground such as a properly grounded outlet box

3 KEEP GUARDS IN PLACE

in working order and in proper adjustment and alignment,

2

Page 3

4 REMOVEADJUSTINGKEYSANDWRENCHES

Formhabitofcheckingtoseethatkeysandadjusting

wrenchesareremovedfromtoolbeforeturningon

17, REDUCE RISK OF UNINTENTIONAL STARTING

Make sure switch is in "OFF" position before plugging in

cord,

5 KEEPWORKAREACLEAN

Clutteredareas and beeches invite accidents

6 DON'T USE IN DANGEROUS ENVIRONMENT

Don't use power tools in damp or wet locations, or expose

them to rain Keep work area well illuminated_

7 KEEP CHILDREN AWAY

All visitors should be kept a safe distance from work area

8_MAKE WORKSHOP KID PROOF

with padlocks, master switches, or by removing starter

keys

9 DON'T FORCE TOOL

It will do the job better and be safer at the rate for which it

was designed

10 USE RIGHT TOOL

Don't force tool or attachment to do a job for which it was

not designed

11 WEAR PROPER APPAREL

No loose clothing, gloves, neckties, nngs, bracelets, or

jewelry to get caught in moving parts. Nonslip footwear is

recommended Wear protective hair covering to contain

long hair

18 USE RECOMMENDED ACCESSORIES

Consult the owner's manual for recommended acces-

sories Use of improper accessories may be hazard6us

19 NEVER STAND ON TOOL

Serious injury could occur if the tool is tipped or if the cut-

ting tool is unintentionally contacted

20 CHECK DAMAGED PARTS

Before further use of the tool, a guard or other part that is

damaged should be carefully checked to ensure that it

will operate properly and perform its intended function -

check for alignment of moving parfs, binding of moving

parts, breakage of parts, mounting, and any other condi-

tions that may affect its operation A guard or other part

that is damaged should be properly repaired or replaced

21 DIRECTION OF FEED

Feed work into a blade or cutter against the direction of

rotation of the blade or cutter only

22 NEVER LEAVE TOOL RUNNING UNATTENDED TURN

POWER OFF Don't leave tool until it comes to a com-

plete stop

12 ALWAYS WEAR SAFETY GLASSES

Also use face or dust mask if cutting operation is dusty

Everyday eyeglasses only have impact resistant lenses

They are NOT safety glasses

13 SECURE WORK

Use clamps or a vise to hold work when practical It's

safer than using your hand and frees both hands to oper-

ate tool,

14_DON'T OVERREACH

Keep your proper footing and balance at all times.

15 MAINTAIN TOOLS IN TOP CONDITION

Keep tools sharp and clean for best and safest perfor-

mance, Follow instructions for lubricating and changing

accessories_

16 DtSCONNECT TOOLS FROM POWER SOURCE

before servicing and when changing accessories such as

blades, bits, cutters, or when mounting and re-mounting

motor

The operation of any power tool can result in foreign objects

being thrown into the eyes, which can result in severe eye

damage_ Always wear safety goggles complying with ANSI

Z87,1 before commencing power tool operation. Safety

Goggles are available at Sears retail or catalog stores

3

Page 4

SAFETY RULES FOR DRILL PRESSES

1 DO NOT USE until unit is completely assembled and installed

according to instructions

2 USE ONLY CHUCK KEY PROVIDED WiTH YOUR RADIAL

DRILL PRESS It is equipped with a self-ejecting pin that elimi-

nates hazard of leaving key in chuck

3 ALWAYS WEAR EYE PROTECTION

4 DO NOT WEAR Gloves, necktie or loose fitting ciothing

5 BE SURE DRILL BIT or cutting tool is securely locked in chuck

6 USE RECOMMENDED SPEED for drill accessory and workpiece

material

7 ADJUST TABLE OR DEPTH STOP to prevent drilling into table

work surface

8 NEVER USE YOUR HANDS TO HOLD workpiece during drilling

Clamp it to work surface or use a vise to secure workpiece and

prevent rotation

9 NEVER OPERATE drill press if any part is damaged or broken

until it is properly repaired or replaced

10 NEVER pLACE YOUR FINGERS in a position where drill or cut-

ting tool could contact them if part should shift unexpectedly

11 NEVER PERFORM LAYOUT, assembly or setup work on drill

press with cutting tool rotating

12 SHUT OFF POWER, remove drill or cutting too!, and clean table

before leaving machine

TABLE OF CONTENTS

WARRANTY ................................................................. 2

GENERAL SAFETY RULES FOR POWER TOOLS .............. 2, 3

SAFETY RULES FOR DRILL PRESSES ................................... 4

TOOLS REQUIRED .................................................................. 5

UNPACKING AND CHECKING CONTENTS ........................... 5

TABLE OF LOOSE PARTS ........................................................... 5

ASSEMBLY ............................................................................................6, 7

INSTALLING RADIAL DRILL PRESS ........................................ 7

CONTROLS AND ADJUSTMENTS ............................................ 8-11

On/Off Switch .................................................................... 8

Table Adjustment ......................................................... 8

Depth Stop Adjustment ............................................. 8

Spindle Return Spring Adjustment ...................................... 8, 9

Spindle Speeds ............................................................... 9

Changing Speeds ....................... ' ............................ 9

Belt Tension Adjustment ............................................. 9, 10

Tilting Drill Head .................................................... 10

Rotating Drill Head .......................................... 10

Moving Drill Head In or Out ..................................... 10

Adjusting Spindle Perpendicular to Table ....................... 11

Alignment of Motor Pulley to Spindle Pulley .................. 11

OPERATION ..................................................................12

Correct Drilling Speeds ................................................ 12

Drilling Wood ........................................................... 12

Drilling Metal ............................................................... 12

MAINTENANCE ........................................................ 12

ACCESSORIES ...................................................... 13

REPAIR PARTS ........................................................... 14, 15

TROUBLESHOOTING ................................................. 16

HOW TO ORDER REPLACEMENT PARTS ...................... 16

Page 5

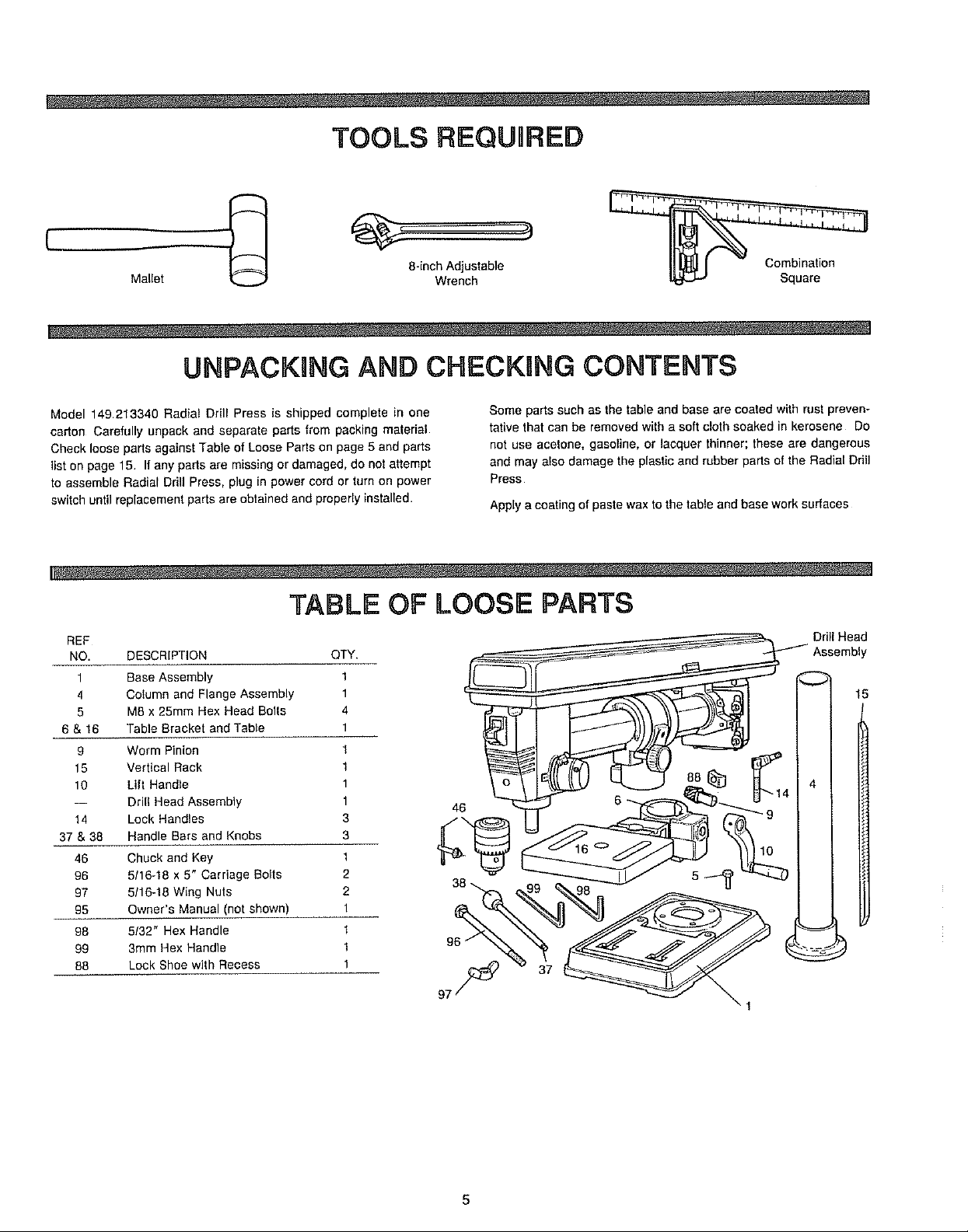

TOOLS REQUmRED

8-inch Adjustable

Mallet Wrench

UNPACKRNG AND CHECKUNG CONTENTS

Model 149213340 Radial Drill Press is shipped complete in one

carton Carefully unpack and separate parts from packing material

Check loose parts against Table of Loose Parts on page 5 and parts

list on page 15 If any parts are missing or damaged, do not attempt

to assemble Radial Drill Press, plug in power cord or turn on power

switch until replacement parts are obtained and properly installed

I

TABLE OF LOOSE PARTS

REF

NO. DESCRIPTION QTY.

1 Base Assembly 1

4 CoIumn and Flange Assembly 1

5 M8 x 25mm Hex Head Bolls 4

6 & !6 Table Bracket and Table 1

9 Worm Pinion 1

15 Vertical Rack 1

10 Lig Handle 1

-- Drill Head Assembly 1

!4 Lock Handles 3

37 & 38 Handle Bars and Knobs 3

46 Chuck and Key 1

96 5/16-18 x 5" Carriage Bolts 2

97 5/16-18 Wing Nuts 2

95 Owner's Manual (not shown) 1

98 5/32" Hex Handle 1

99 3mm Hex Handle 1

88 Lock Shoe wilh Recess 1

Some parts such as the table and base are coated with rust preven-

tative that can be removed with a soft cloth soaked in kerosene Do

not use acetone, gasoline, or lacquer thinner; these are dangerous

and may also damage the plastic and rubber parts of the Radial Drill

Press

Apply a coating of paste wax to the table and base work surfaces

Drill Head

15

46

Page 6

ASSEMBLY

WARNING: FOR YOUR OWN SAFETY, NEVER CONNECT

THE RADIAL DRILL PRESS TO A POWER SOURCE UNTIL

ALL ASSEMBLY STEPS ARE COMPLETE_ AND YOU HAVE

READ AND UNDERSTOOD SAFETY AND OPERATIONAL

INSTRUCTIONS=

CAUTION: Do NOT ALLOW BRAKE FLUIDS_ GASOLINE,

PENETRATING OILS 1 ETC,_ TO COME IN CONTACT WITH

PLASTIC PARTS, THESE SOLUTIONS CONTAIN CHEMICALS

THAT CAN DAMAGE AND/OR DESTROY PLASTICS,

1 Assemble Column and Flange Assembly (REF 4) to Base

Assembly (REF 1) using four 8mm x 25mm bolts (REF 5).

Bracket making sure that the teeth are engaged in the

Table Lift Gear inside bracket Slide rack and bracket

assembly onto column until angled end at bottom of rack

fits into top of column flange

Place Lift Handle (REF 10) on Worm Pinion Shaft extending

from Table Bracket Align flat on pinion shaft with set

screw (REF 11) and tighten

NOTE: Before installing drill head assembly, find a per-

manent location for radial drill press and fasten base

down using Carriage Bolts (REF 96) and Wing Nuts (REF

97) provided. BE SURE BOLTS PASS ENTIRELY

THROUGH MOUNTING SURFACE. (See Installing Radial

Drill Press section on page 7,)

4 Race Lock Shoe (REF 88) from loose parts bag into cast

pocket in Column Head Assembly (REF 83) then slide

Column Head Assembly with Drilt Head Assembly down

onto Column as shown Be very careful to hold Lock Shoe

in place during assembly to prevent it from falling down

inside column Be sure to engage Vertical Rack with angle

on bottom of Column Head Drill head should rotate freely

around column

2 Slide Worm Pinion (REF 9) into Table Bracket (REF 6) until

shaft extends from hole and teeth engage with Table Lift

Gear (REF 7) Lower Vertical Rack (REF 15) into Table

Lift

Handle

Lock

Lock

Handle

Handle

Bar

Lift

5 Attach one Lock Handle (REF 14) to Table Bracket and

two Lock Handles to Column Head_

Table Bracket

6, Attach three Handle Bars (REF 37) into threaded holes

on head of Feed Shaft Assembly (REF 34)

Page 7

I

7 Make sure bottom of Spindle Shaft (REF 42) and bore of

Chuck (REF 46) are clean and free of grease Press

Chuck up onto Spindle Shaft_

NOTE: To avoid damage to Chuck, rotate Chuck barrel

until jaws are fully open.

8 Using a mallet or a block of wood and hammer, firmly tap

Chuck upward into position onto Spindle Shaft

f

nNSTALUNG RADUAL DRULLPRESS

WARNING: BEFORE USING RADIAL DRILL PRESS_

MAKE SURE IT IS ATTACHED TO A FIRM AND STABLE SUP-

PORT SURFACE USING CARRIAGE BOLTS AND WING

NUTS PROVIDED.

1 Choose an area that allows sufficient clearance to take

full advantage of the Radial Drill Press's lateral, rota-

tional, and tilt motions

2 Bolt Radial Drill Press to a firm and stable surface using

Carriage Bolts and Wing Nuts provided, Be sure bolts

pass entirely through mounting surface and are at least

5/16-18 standard strength_ Tighten all bolts and wing nuts

securely

3/8" Diameter

2 Hotes

6 1/4"

12 3/4" Fore and Aft Travel

Head Tilts 45"

C_ockwise and 90"

Counter-clockwise

360" Rotation

Use Carriage Bolts and

Wing Nuts Provided

7

Page 8

CONTROLS AND ADJUSTMENTS

_ WARNING: MAKESURESWITCHIS IN OFF POSmON

AND POWER CORD IS UNPLUGGED BEFORE PERFORMING

CHECKS= ADJUSTMENTS I OR SETUP PROCEDURES,

On-Off Switch

The ON-OFF switch (REF 59) is located on front of Drill Head

and has operating positions clearly marked_ Push switch up

to turn tool ON and down to turn it OFF. The switch has a

Switch Key (REF 60) that, when removed, allows switch to

be locked in OFF position. To activate locking feature, push

switch to OFF and pull Switch Key out of switch.

Switch Key Switch

2. Table Rotation - To rotate table, first loosen Lock Handle.

The table can be rotated from side to side or completely

out from under Spindle Shaft to allow work surface on

base to support workpiece_

Depth Stop Adjustment

When it is desirable to drill holes to an exact depth, the built-

in depth stop can be set

1 With Radial Drill Press turned OFF, adjust table height

until driUbit barely touches workpiece at spot to be drilled,

and lock into position

2. Loosen Depth Stop Butterfly Set Screw (REF 36) and

rotate Depth Gauge Assembly (REF 35) until desired drill

depth on Scale aligns with Pointer on Spindle Housing

(REF 25). Tighten Butterfly Set Screw_

Butterfly Set Screw

Table Adjustment

1_ Table Height - To raise or lower Table, loosen Lock

Handle on back of Table BrackeL Crank Lift Handle to

raise or lower Table, then lock position with Lock Handle

Depth Scale

Pointer

Depth Scale

Spindle Return Spring Adjustment

An automatic spindle Return Spring (REF 28) is installed in

Drill Head to return spindle to full up position. This spring

was preset at the factory and should not be readjusted

unless absolutely necessary. Adjust Return Spring as fol-

lows:

1 Loosen two Nuts (REF 29 & 30) on side of Spring

Assembly (REF 28) about 1/4" NOTE: Do not remove

these nuts from Feed Shaft (REF 34).

2 Hold Spring Assembly firmly and pull it out away from

side of Drill Head Rotate Spring Assembly until next

notctl engages with cast tab on side of Drill head.

8

Page 9

I Cast Tab

spindle speeds are required for different materials, different

types and sizes of drills, and different cutting tools

Spring

Assembly /_ ))_

Feed Shaf< _ )

Lock'Nuts

3 Check operation of Return Spring for proper tension and

full return

4 Nuts must be tightened before use Be very careful; the

nuts hold Spring Assembly in position and should NOT be

tightened flush against Spring Assembly A small gap is

necessary for proper operation of Spindle Housing Lock

the two nuts together using separate wrenches and make

sure Spindle Housing moves freely up and down

Spindle Speeds

Your Radial Drill Press has a 1725 RPM motor with five spin-

dle speeds available through a pulley/belt drive The various

Refer to the V-belt placement illustration on this page fo_ the

five available spindle speeds Maximum speed is obtained

when V-belt is on largest step of pulley at motor end and

smallest step of pulley at spindle end

Changing Speeds

_ WARNING: DISCONNECT RADIAL DRILL PRESS FROM

1 Open Pulley Cover (REF 48)

2 Position V-belt (REF 73) on desired steps of Spindle

3 A chart (REF 51) of drill speeds and pulley steps is pro-

POWER SOURCE BEFORE CHANGING SPEEDS,

Pulley (REF 19) and Motor Pulley (REF 71) When posi-

tioning V-belt, always start by moving the end of the belt

that will go from a larger step to a smaller step first

vided below and inside Pulley Cover for convenience

Belt Tension Adjustment

NOTE: The Radial Drill Press is shipped with the V-belt

installed, Check V-belt adjustment for proper tension

before use.

PulleyCover

\

Butterfly Set Screw

SPnNDLE SPEED CHART

SPINDLE MOTOR

1, Open Pulley Cover (REF 48)

2 Loosen belt tension Butterfly Set Screw (REF 36) located

on right side of Cover Mount (REF 75)

3_ Select speed for drilling operation by referring to Speed

Chart (REF 51) inside Pulley Cover or on bottom of page

Move V-belt to correct position for desired speed

4 Push motor towards rear of machine until V-belt sides are

straight between pulleys

9

Page 10

Angle Gauge (REF 85) on Column head and full length

scored V groove on Horizontal Tube (REF 81) to set desired

angle Lock in position using Lock Handle When returning

to vertical position, turn Vertical Lock plunger and allow it to

snap down onto Horizontal Tube When vertical position is

reached, plunger will pop into milled slot on Horizontal Tube

Tighten Lock Handle to lock position

Rotating Drill Head

Belt Tension

Butterfly Set

Screw

NOTE: When properly tensioned, V-belt should deflect

about 1/2" under thumb pressure at mid-point between

pulleys.

5 Tighten belt tension Butterfly Set Screw and close Pulley

Cover

Tilting Drill Head

The Drill head can be tilted to drill up to 45 degrees clockwise

and 90 degrees counter-clockwise of vertical To tilt Drill

head, loosen Lock Handle on right side of Column head and

pull out and turn plunger of Vertical Lock (REF 87) Use

Scored

V Groove

Lock

Handle

The Drill head can rotate 360 degrees around the Column

Take care when mounting Radial Drill Press to allow suffi-

cient clearance for full use of this feature. Loosen Lock

Handle on left lower area of Column Head. Rotate to desired

position and lock in place with Lock Handle

Tilt Lock

Handle

Rotation Lock Horizontal

Handle Feed Knob

Moving Drill Head In or Out

The Drill head can move in or out along Horizontal Tube

(REF 81) to drill large objects or move between holes without

unclamping workpiece. Loosen same Lock Handle as for tilt-

ing Drill head above Use Horizontal Feed Knob (REF 89) to

move Drill head in or out to desired position Lock in place

with Lock Handle before drilling to prevent drill bit from "walk-

ing" along the wotkpiece surface

Vedical

Lock

10

Page 11

Adjusting Spindle Perpendicular to Table

The Radial Drill Press was factory-adjusted and set with

Spindle Housing perpendicular to table No further adjust-

ment should be necessary However. normal shipping and

handling may have changed the setting Check and adjust

as follows:

1 DISCONNECT FROM POWER SOURCE! Never make

any adjustments while the tool is plugged in

2 Be sure the Vertical Lock plunger (REF 87) is engaged in

Horizontal Tube slot (REF 81).

3 Mount a 3" long precision round steel rod or a large,

straight drill bit into Chuck and place a combination

square on Table Check alignment between rod and

Table as shown

NOTE: Combination square must be "true," Check for

accuracy as illustrated below.

Straight Edgeof

Draw Light _'-.- / Board 3/4"

Boardalong Must Be Perfectly

Edge of Straight

4 If out of square, loosen two Set Screws (REF 26) that

attach Spindle Housing Assembly (REF 25) to Horizontal

Tube Tilt Spindle Housing Assembly until rod is exactly

90 degrees to Table Tighten both Set Screws

5 Check V-belt tension after this adjustment and readjust if

required

Scale >

I /

FlipSquare Over to Dotted Position--Edge of

Scale Should Align Perfectly with Drawn Line

Alignment of Motor Pulley

to Spindle Pulley

Check pulley alignment by sighting between tops of Spindle

Pulley (REF 19) and Motor Pulley (REF 71)

1 Should they need adjustment, loosen screws on Cover

Mount (REF 75) and turn motor assembly until pulleys

align,

2 Tighten screws and adjust V-belt tension if needed

Precision

Steel Rod

11

Page 12

OPERATaON

Correct Drilling Speeds

See "Changing Speeds" section under "Controls and

Adjustments" and Speed Chart inside Pulley Cover for cor-

rect drilling speeds Always disconnect tool from power

source before making any adjustments Care must be taken

when setting speed for any cutting tool or accessory not list-

ed on chart Read and follow any speed instructions supplied

with cutting tool or accessory Rules for judging drilling

speed for materials not listed in chart are:

1 A small size drill requiresfaster cutting speeds than a

larger size

2. Soft material requires faster speeds than hard material

See "Accessories" section for a listing of items authorized for

use with this tool.

Drilling Wood

Many types of drill bits designed for drilling or boring wood

can be used with this machine_ Standard high speed twist _.

drills intended primarily for metal drilling work very well on

wood_ Spur bits, sometimes referred to as forstner bits, are

best for woodworking because they cut a clean-sided, flat

will lift the workpiece from the table and could easily cause

bottom surface, slow feed even more to prevent splintering

or a burr to bottom face of workpiece Always use a piece of

scrap wood under workpiece to reduce splintering and to pro-

tect drill bit and work table

drilling operations If a method of clamping is not used, brace

back-up material against left side of column to prevent work-

piece from spinning

Drilling Metal

Although primarily a woodworking tool, this Radial Drill Press

can be used to drill metal. Always firmly clamp or use a

drill press vise bolted to work table when drilling metal.

bottomed hole Be careful NOT to use any SCREW TIP

hand drill bit At even the slowest drill press speeds, this style

injury.

Feed bit slowly through wood As bit is about to cut through

Use of clamps or a work vise is recommended for most

WARNING: NEVER HOLD A METAL WORKPIECE IN A

BARE HAND DURING DRILLING. FIRMLY CLAMP WORK-

PIECE TO TABLE OR USE A DRILL PRESS VISE BOLTED TO

TABLE WHENEVER DRILLING METAL, FAILURE TO DO THIS

COULD RESULT IN PERSONAL INJURY,

MAINTENANCE

POWER AND DISCONNECT TOOL FROM POWER SOURCE

WARNING: FOR YOU OWN SAFETY_TURN OFF

BEFORE PERFORMING ANY MAINTENANCE.

Periodically clean dust accumulation from machine Apply a

light coat of paste wax to table, base work surfaces, and ver-

tical and horizontal columns. This will help to keep them

clean and working smoothly=

All of the ball bearings are packed with grease at the factory

and require no further lubrication The Quill and Spindle Rack

should be lubricated periodically with a light machine or pen-

etrating oil Open Pulley Cover and spray a light coat of oil

on Spindle Shaft splines (REF 42) as you move spindle up

and down Avoid getting any oil on the drive belt Also, with

spindle in fully down position, spray a light coat of oil on Quill

(REF 40). A small amount of grease on Table Lift Gear (REF

7) and Horizontal Feed Gear (REF 90) will keep these two

mechanisms moving freely Wipe excess grease from racks

to prevent dust buildup in teeth

12

Page 13

ACCESSORUES

Mortising Kit Vises and Clamps

Although not designed specifically for mortising, the variety of

possible drill angles and feed lengths with the Radial Drill

Press make possible some formerly impossible operations

Use Sears Model 9 BT 25255 Mortising Chisel Housing and

Model 9 BT 29506 Drill Press Mortising Kit with the accompa-

nying made-to-fit bits available through Sears Catalog and

Retail Stores

Forstner Bits

A large variety of sizes and types of drill press vises and

clamps are available through Sears Catalog and Retail

Stores The work table has slots that will align with most

vises

A selection of standard size forstnar bits is available to fit the

1/2" capacity chuck of the Radial Drill Press Sears Check

with your local Catalog and Retail Stores

13

Page 14

CRAFTSMAN 344NCH RADIAL DRILL PRESS MODEL No. 149.213340

REPAnR PARTS

72 71

53

89 :

7 14

---i 87

14/__ 6

12 17 5 J

4 I

I\

34

54

88

30 29

15

3

14

Page 15

CRAFTSMAN 34-iNCH RADIAL DRULL PRESS MODEL No. 149.213340

PARTS LIST

REF

NO,

1

2

3

4

8

6

7

8

9

10

11

12

!3

14

15

18

17

18

!9

2O

21

22

23

24

25

281

27

28

29

30

31

32

33

34

35

36

37

3R

39

4O

41

42

43

44

45

46

46A

47

48

49

5O

PARTNO.

4910-001-951

4910-001-70

4910-252-70

4910-162-70

1737-200-00

4910-013-70

4910-014-70

4910-015-70

4910-016-70

4910-053-70

1709-004-00

BTD541025

1726-050-00

4910-057-70

4910-164-70

4910-012-70

ST0525010

!784-007-00

4910-081-70

4910-049-90

i4910-094-70

STD315235

4910-087-70

1695-069-00

4910-095-70

STD503102

1737-130-00

4910-123-70

STD541350

ST0541150

1784-200-00

1737-185-00

4910-124q0

4910-096-70

4910-062-70

4910-054-70

4910-055-70

4910-056-70

4910-091-90

4910-091-70

4910-092-70

4910-093q0

ST0315215

STD315225

1695-062-00

4910-190-70

4910-192-70

4920-041-90

4920.042-70

4910-045-70

4920-251-00

DESCRIPTION QTY.

BASEASSEMBLY (INCLUDES2 & 3) 1

BASE 1

TIPPINGWARNINGLABEL 1

COLUMNAND FLANGEASSEMBLY 1

MR X 25ram HEX HEAD BOLTS 4

TABLE BRACKET 1

GEARTABLE LIFT 1

GEARSHAFT 1

WORMPINION 1

LIFT HANDLE 1

M6 X lOmm SOCKETHEADSET SCREW 1

1/4-20 HEX NUT 1

1/4-20 X 1 1/8" STUD 1

LOCKHANDLE 2

VERTICALRACK 1

TABLE 1

122"X 1" HEX HEADBOLT 1

PULLEYSET NUT 1

SPINDLEPULLEY 1

DRIVESLEEVEASSEMBLY (INCLUDES21-24) 1

DRIVESLEEVE t

BALL BEARINGS(6203Z) 2

SEARINGSPACERCOLLAR 1

EXTERNALRETAININGRING(A-17) 1

SPINDLEHOUSINGASSEMBLY 1

5/16-18 X 1/4" SET SCREWS 4

M8 X 8ram SOCKETHEADSET SCREW 1

SPRING.CAP, AND RETAINERASSEMBLY t

1/2-20 HEX NUT (SPRING.JAM NUT) 1

!/2-20 HEX NUT (SPRINGNUT) 1

MRHEX NUT 1

MRX 22mm DOGPOINTSET SCREW 1

STOPPIN 1

FEEDSHAFTASSEMBLY 1

DEPTHGAUGEASSEMBLY 1

M8 BUTTERFLYSET SCREWS 2

HANDLEBARS 3

HANDLEBAR KNOBS 3

QUILL ASSEMBLY (INCLUDES40-45) 1

QUILL 1

RUBBERWASHER 1

SPINDLESHAFT I

gALL BEARING(6201Z) 1

BALL BEARING(6202Z) 1

EXTERNALRETAININGRING(A-11) 1

CHUCKAND KEY (WITH EJECTIONPIN) 1

CHUCKKEY (ORDERFORKEY ONLY)

PULLEYCOVERASSEMBLY (INCLUDES48-51) 1

PULLEYCOVER 1

RBBBERBUMPERS 2

CRAFTSMANLABEL 1

BEF

NO.

51

4910-253-00

52

4920-050-70

53

ST0511003

54

ST0551210

55

STD55!010

56

1789-015-00i

57

STD511007

58

4920-040q0

59

2292-067-00

60

2292-068-00

61

STD364949

62

t708-100-00

4910-350-00

86 i

4910-351-00

65

STD375005

66

4910-353-70

87

4910-354-00

88

4910-355-00

80

4910-220-00

70

STD580100

71

4910-080-70

78

1709-125-00

73

STD303590

74

4910-031-70

75

4910-030-09

70

4910-050-70

77

49!0-120-70

78

79

80

4910q61-70

81

82

4910-166-70

83

4910-020-95

4910-020-09

04

85

4910-021-70

88

1785-050-00

87

4910-059-70

88

1175-000-00

89

4910-051o70

90

49t0-017-70

91

98

1697-010-00

93

94

4920-250-00

4920-252*00

95

98

97

98

2288-000-00

99

4910-19!-00

100

1175-001-00

PARTNO.

ST05231!0

STD541431

ST0551031

STD501002

STD582037

ST0533150

ST0541631

DESCRIPTION

i BELTSPEEDLABEL

PULLEYC0VERKNOB

810-24 X 3/8" PAN HEADSCREWS

810 STARWASHER

810 FLATWASHERS

810 RUBBERWASHERS

8t0-24 X 3/4" PAN HEADSCREWS

SWITCHCOVER

DPSTSWITCH (INCLUDES60)

SWITCHKEY(ORDERFORKEYONLY)

POWERCORD

M5 X 8ram PAN HEADSCREWS

WIRECLAMPS (HEYCO#3355)

RIGHTANGLE BUSHING(HEYCO81327)

WIRE NUT

SWITCHCORD

CABLETIES

FULL INSUL FEMALE TERM,90 DEGFLAG

MOTOR.EMERSON1/3 HP MAXIMUM

1/8 X 1" SQUAREDRIVEKEY

MOTORPULLEY

M6 X 6mm SOCKETHEADSET SCREW

V-BELT..._

MOTORBRACKET

COVERMOUNT

PUSHTEE

SPRING

5/16-17X I" HEX HEAD BOLTS

5/16-18HEX LOCK NBTS

5/16FLAT WASHERS

HORIZONTAL TUBE

HORIZONTAL RACK

COLUMN HEAD ASSEMBLY (INCLUDES53.84.85

COLUMN HEAD

ANGLE GAUGE

M16 HEXJAM NUT

VERTICALLOCK

LOCkSHOEWlTH RECESS

HORIZONTALFEEDKNOWASSEMBLY

HORIZONTALFEEDGEAR

810-24 X 1/4" SOCKETBETSCREW

EXTERNALRETAININGRiNG

#4 X 1/4" DRIVESCREWS

WARNINGLABEL/DATA PLATE

OWNER'SMANUAL

5/t6q8 X 5" CARRIAGEBOLTS

5/16-18WING NUTS

5/32" HEX HANDLE

3mm HEX HANDLE

LOCKSHOE

QTY.

1

1

8

1

4

4

3

1

1

1

3

3

2

1

1

2

!

1

I

1

1

1

1

1

1

!

6

6

13

1

1

1

1

1

1

1

1

1

1

1

t

4

1

1

2

2

1

1

1

15

Page 16

TROUBLESHOOTING CHART

TROUBLE PROBABLE CAUSE REMEDY

Noisy operation 1 Incorrect V-belt tension 1_ Adjust tension

2 Dry spindle shaft 2. Lubricate spindle shaft See "Maintenance"

3 Loose Spindle shaft or 3 Tighten Lock Nut (left hand thread) or pulley

Motor Pulley set screw,

Bit burns or smokes 1 Incorrect spindle speed. 1, Change spindle speed

2 Chips not coming out of hole 2. Retract bit frequently to clear chips

3 Dull bit 3, Sharpen or replace biL

4 Feed rate too slow 4 Feed faster,

5. Bit not lubricated (metal working) 5 Lubricate bit

Excessive ddll bit 1, Bent bit. 1 Replace bit

runout or wobble 2 Chuck not properly installed 2 Remove chuck and install properly.

3 Bit not properly installed 3 Remove bit and install properly_

4 Worn or loose chuck, 4 Replace chuck

5 Worn spindle bearings 5, Replace beadngs

Drill binds in 1. Improper V-belt tension. 1. Adjust V-belt tension=

workpiece 2. Workpiece twisting or moving 2_ Support or clamp workpiece.

3. Excessive feed pressure_ 3 Reduce pressure and clamp workpiece,

Workpiece torn 1 Not properly supported or 1_Support and clamp workpiece

loose front hands clamped.

section

34-BNCH RADBAL DRILL PRESS

Now that you have purchased your Radial Drill Press should a need ever

exist for repair parts or service, simply contact any Sears Service'Center

or most Sears, Roebuck and Co stores, Be sure to provide all pertinent

facts when you call or visit

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE THE FOLLOWING

INFORMATION:

• PART NUMBER • PART DESCRIPTION

• MODEL NUMBER

149o213340

All parts listed may be ordered from any Sears Service Center and most

Sears stores

If the parts you need are not stocked locally, your order will be electroni-

cally transmitted to a Sears Repair Parts Distribution Center for handling

SEARS, ROEBUCK AND CO., Hoffman Estates, IL 60179, U.S.A.

• NAME OFITEM:

34-1NCHRADIALDRILLPRESS

Printed in USA

Loading...

Loading...