Page 1

S£/ J:kS

operator's

manual

MODEL NO. 143.998003

SOLID STATE IGNITION

CAUTION:

Read RULES for

Safe OPERATION

and INSTRUCTIONS

Carefully

NGIN

• Operating

• Maintenance

• Repair Parts

d_lb California Proposition 65 WARNING: the engine exhaust from this product contains chemicals

known to the State of Caliibrnia to cause cancer, birth defects or other reproductive harm.

Sold by SEARS, ROEBUCK AND CO., CHICAGO, IT, 60684 U.S.A.

and SEARS CANADA, INC., TORONTO, ONTARIO, CANADA

Printedin U.S.A. 5/1199 181-1202-11

Page 2

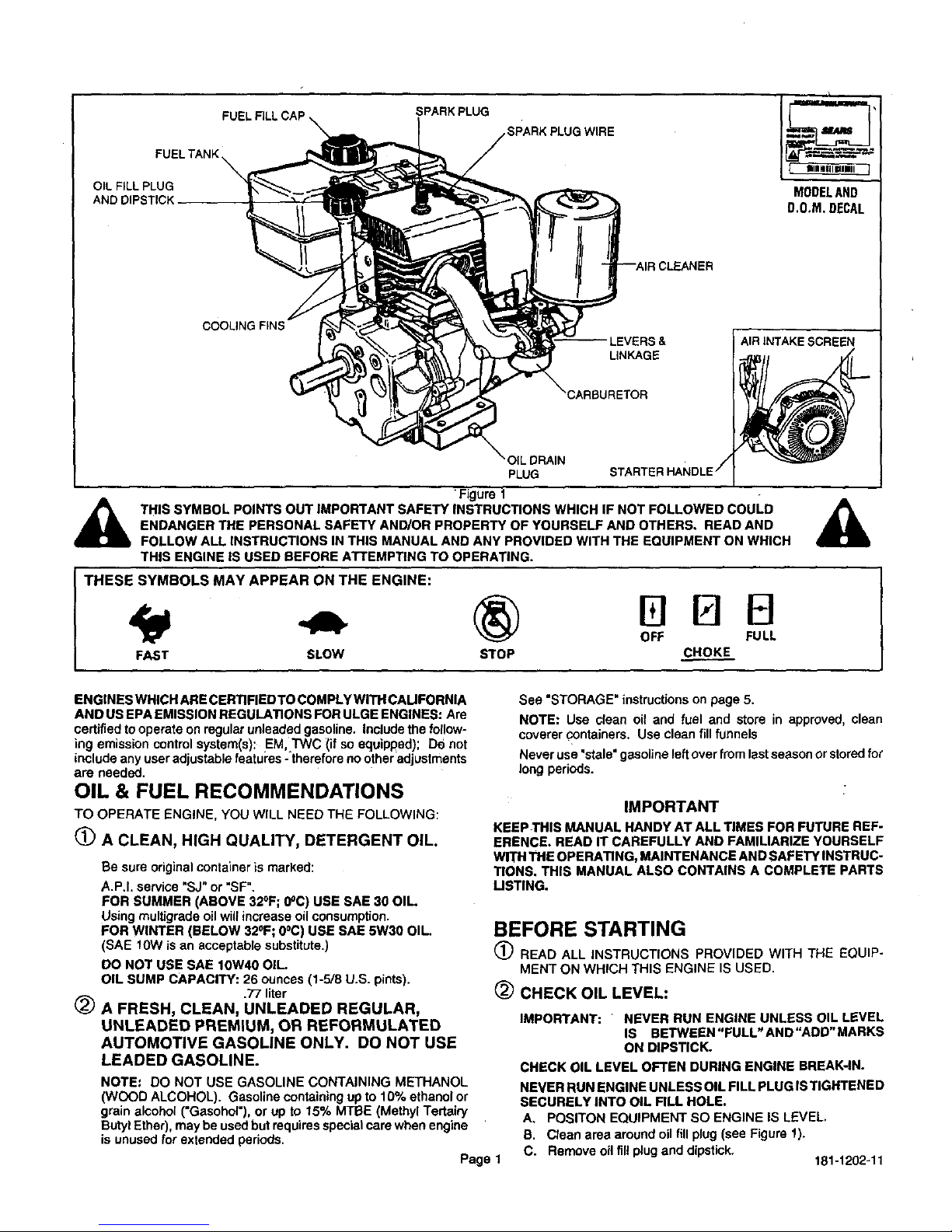

OIL FILL PLUG

AND DIPSTICK

SPARK PLUG

SPARK PLUG WIRE

MODELAND

D.O.M. DECAL

COOLING FINS

LINKAGE

OIL DRAIN

PLUG

'Figure t

THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH IF NOT FOLLOWED COULD

ENDANGER THE PERSONAL SAFETY AND/OR PROPERTY OF YOURSELF AND OTHERS, READ AND

FOLLOW ALL INSTRUCTIONS IN THIS MANUAL AND ANY PROVIDED WITH THE EQUIPMENT ON WHICH

THIS ENGINE IS USED BEFORE ATTEMPTING TO OPERATING.

I THESE SYM4 BOLS MAY APPEAR ON THE ENGINE:

FAST SLOW

liBEl

OFF FULL

STOP CHOKE

AIR INTAKE SCREEN

ENGINES WHICH ARE CERTIFIEDTO COMPLYWITH CAUFORNIA

AND US EPA EMISSIONREGULATIONS FOR ULGE ENGINES: Are

certified to operate on regularunleadedgasoline. Includethe fo{Iow-

ing emission controlsystem(s): EM TWC {if so equipped); De not

{ncludeany user adjustablefeatures - thereforeno0theradjustments

are needed.

OIL & FUEL RECOMMENDATIONS

TO OPERATEENGINE.YOUWILL NEEDTHEFOLLOWING:

(_) A CLEAN, HIGH QUALITY, DETERGENT OIL.

Be sure original container is marked:

A.P.I. service "SJ"or "SF",

FOR SUMMER (ABOVE 32°F; 0°C) USE SAE 30 OIL.

Using multigrade oil wiUincrease oilconsumption.

FOR WINTER (BELOW 32°F; 0°C) USE SAE 5W30 OIL.

(SAE 10W is an acceptable substitute.)

DO NOT USE SAE 10W40 OIL.

OIL SUMP CAPACITY: 26 ounces (1-5/8 U.S. pints).

.77 liter

(_ A FRESH, CLEAN, UNLEADED REGULAR,

UNLEADED PREMIUM, OR REFORMULATED

AUTOMOTIVE GASOLINE ONLY. DO NOT USE

LEADED GASOLINE.

NOTE: DO NOT USE GASOLINE CONTAINING METHANOL

(WOOD ALCOHOL). Gasoline containing upto 10% ethanolor

grain alcohol ('Gasohol"), or up to 15% MTBE (Methyl Tertairy

ButylEther), may beused but requiresspecialcare when engine

is unused for extended periods.

Page 1

See "STORAGE" instructions on page 5.

NOTE: Use (::leanoil and fuel and store in approved, clean

coverer containers. Use clean fill funnels

Never use "stale" gasoline leftover from last season or stored for

long periods.

IMPORTANT

KEEPTHIS MANUAL HANDY AT ALL TIMES FOR FUTURE REF-

ERENCE. READ IT CAREFULLY AND FAMILIARIZE YOURSELF

WITH THE OPERATING, MAINTENANCE AND SAFETY INSTRUC-

TIONS. THIS MANUAL ALSO CONTAINS A COMPLETE PARTS

LISTING.

BEFORE STARTING

READ ALL INSTRUCTIONS PROVIDED WITH THE EQUIP-

MENT ON WHICH THIS ENGINE IS USED.

(_ CHECK OIL LEVEL:

IMPORTANT: NEVER RUN ENGINE UNLESS OIL LEVEL

IS BIETWEEN"FULL" AN D"ADD" MARKS

ON DIPSTICK.

CHECK OIL LEVEL OFTEN DURING ENGINE BREAK-IN.

NEVER RUN ENGINE UNLESS OIL FILL PLUG ISTIGHTENED

SECURELY INTO OIL FILL HOLE.

A, POSITON EQUIPMENT SO ENGINE IS LEVEL,

B. Clean area around oil fill plug (see Figure 1).

C. Remove oil fill plug and dipstick,

181-1202-11

Page 3

BEFORE STARTING (Continued)

D. Wipe dipstickclean, insert it into oil rill hole and tighten

securely.

E. Remove oil fill plug and check oil level. If level is notup to

"FULL" mark on dipstick,add recommended oil, until it is.

POUR SLOWLY.

Wipe dipstickclean each time oil level is checked.

DO NOT FILL ABOVE "FULL"MARK ON DIPSTICK.

F. Replace oil fill plugand tighten_je_urely.

See "MAINTENANCE" section for any future oil level and oil

change instructions(see Page 2).

(_ FILL FUEL TANK

with gasoline as specified in the preceding"OIL & FUEL

RECOMMENDATIONS" item 2.

NEVER MIX OIL WITH GASOLINE

Never use"stale" gasolineleftoverfrom last seasonorstoredfor

longperiods.

_IL EVER FILL FUEL TANK INDOORS. NEVER FILL FUELTAN K ]

WHEN ENGINE IS RUNNING OR HOT. DO NOT SMOKE

WHEN FILLILNG FUEL TANK.

_1 EVER FILL FUEL TANK COMPLETELY. FILL TANK TO 1/2" ]

BELOW BOTTOM OF FILLER NECK TO PROVIDE SPACE

FOR FUEL EXPANSION. WIPE ANY FUEL SPILLAGE FROM

ENGINE AND EQUIPMENT BEFORE STARTING ENGINE, /

ANY LIQUIFIED PETROLEUM (LPG)OR NATURAL GAS FUEL I

SYSTEM MUST BE LEAKPROOF AND MEET ALL APPLICA-

BLE CODES AND REGULATIONS.

(_ CHECK THE FOLLOWING:

STARTING (Continued)

_11=KEEP HANDS, FEET, HAIR AND LOOSE CLOTHING AWAY I

FROM ANY MOVING PARTS ON ENGINE AND EQUIPMENT.]

_1 WARNING: TEMPERATURE OF MUFFLER AND NEARBY

AREAS MAY EXCEED 150°F (65°C). AVO D THESE AREAS.

REWIND STARTER:

A.

Movechoke leverto FULL CHOKE POSITION.

NOTE: IF RESTARTING A WARM ENGINE AFTER A

SHORT SHUTDOWN, MOVE CHOKE LEVER TO "NO

CHOKE POSITION."

B. Moveequipmentcontrelto START (seaequipmentmanufac-

turer'sinstructions).

C. Gresp starter handle(see Figure2) and pullrepe out,slowly,

untilitpullsslightlyharder. Letrope rewindslowly.Then pull

ropewith a rapidfull arm stroke. Let rope rewindSLOWLY.

Do not let starterhandle snap back againststarter.

D. Repeat instructionC until enginefires. When enginestarts,

move choke lever to 1/2 CHOKE until engine runs smoothly

and then to NO CHOKE POSITION.

NOTE: If engine fires, but does not continueto run, move

choke leverto NO CHOKE POSITION and repeatinstruction

C untileng!nestarts.

Ifangine again fires, butdoes notcontinuetorun,movechoke

lever to FULL CHOKE POSITION and repeat instructionsC

and D untilengine starts.

(_ ELECTRIC STARTER (see Figures 2 and 3):

,_ A. BE SURE EQUIPMENT IS IN NEUTRAL GEAR WITH]

CLUTCHES, BELTS, CHAINS AND SAFETY SWITCHES

DISENGAGED. (FOLLOW EQUIPMENT MANUFACT- I

URER'S INSTRUCTIONS.) THIS SHOULD PLACE ANY

SAFETY SWITCHES IN SAFE STARTING POS TION.

B. Be surespark plugwire isattachedto sparkplug (see Figure

1).

C. Be sure anyignitionswitchon engine orequipment isin ON,

RUN or START position.

1- RECOIL 2 -ELECTRIC _

START IGNITIONSWITCHKEY

Figure2

CHOKE LEVER

NO CHOKE POSITION

_ITION

Figure 3

STARTING

A

NEVER RUN ENGINE INDOORS OR IN ENCLOSED, POORLY J

VENTILATED AREAS. ENGINE EXHAUST CONTAINS CAR- J

BON MONOXIDE, AN ODORLESS AND DEADLY GAS (CAR- I

BON MONOXIDE IS ALSO PRESENT IN ENGINE EXHAUST I

FROM LIQUID PETROLEUM (LPG) AND NATURAL GAS FUEL

SYSTEMS).

Page 2

A, Move choke lever to FULL CHOKE POSITION.

a.

C.

D,

NOTE: IF RESTARTING A WARM ENGINE AFTER A

SHORT SHUTDOWN, MOVE CHOKE LEVER TO

"NO CHOKE POSITION,"

MoveequipmentcontroltoSTART (see equipmentmanufac-

turer'sinstructions).

Pushstarterbuttonofturn ignitionswitchkey(see equipment

manufacturer'sinstructions)tocrank engine.

Crank engine until it fires. When it starts, release starter

button or ignitionswitch key and move choke lever to 1/2

CHOKE until engine runssmoothlyand thento NO CHOKE

POSITION.

Ifengine falters, move chokelever to1/2 CHOKE untilengine

runs smoothlyhand then to NO CHOKE POSITION.

NOTE: If engine fires, but does not continueto run, move

chokeleverto NO CHOKE POSITION and repeat instruction

C and D untilengine starts.

STOPPING

I_ Move equipmentcontrolor any ignitionstopswitchonengine

STOP or OFF (see equipment manufacturer's instructions).

(_ AFTER ENGINE IS STOPPED:

_,IA. DISCONNECT SPARK PLUG WIRE FROM SPARK PLUG I

AND KEEP IT AWAY FROM SPARK PLUG. I

_klB. TURN IGNmON SWITCH KEY (IF SO EQUIPPED) TO I

"OFF" POSITION AND REMOVE KEY FROM SWITCH. I

THIS WILL REDUCE THE POSSIBILITY OF UNAUTHO- I

RIZED STARTING OF ENGINE WHILE EQUIPMENT ISNOT

N USE. J

_IL NEVER STORE ENGINE WITH FUEL IN TANK INDOORS I

OR INENCLOSED, POORLY VENTILATED AREAS, WHERE I

FUEL FUMES MAY REACH AN OPEN FLAME, SPARK OR J

PILOT LIGHT AS ON A FURNACE, WATER HEATER,

CLOTHES DRYER OR OTHER GAS APPLIANCE.

181-1202-11

Page 4

MAINTENANCE

_ ARNING: TEMPERATUREOF MUFFLER AND NEARBYI

AREASMAY EXCEED150OF(65°C).AVOIDTHESEAREAS.

CHECK OIL LEVEL:

Check oillevel every five (5) operating hours or each time engine

is used. See "2CHECK OIL LEVEL" in "BEFORE STARTING" on

Page 1.

@ CHANGE OIL:

Change oil after first two (2) operating hours and every 25

operatinghours thereafter, more often if operated in extremely

dusty or dirty conditions.

Change oil while engine isstill warm from recentrunning.

_IA. DISCONNECT SPARK PLUG WIRE FROM SPARK PLUG 1

AND KEEP IT AWAY FROM SPARK PLUG, |

B. Clean area around drain plug (see Figure1).

C. Positionequipmentso engineoildrain plugislowestpointon

engine,

D. Remove oil drain plug and oil fill plug to drain oil

E. Replace oil drain plugand tighten securely,

F. Fill oil sump with recommended oil. See "OIL & FUEL REC-

OMMENDATIONS" and =CHECK OIL LEVEL" on Page 1.

G. Replace oil fill plug and tighten securely.

H. Wipe up any spilled oil.

(_AIR CLEANER

IMPORTANT: NEVER RUN ENGINE WITHOUT COMPLETE

AiR CLEANER INSTALLED ON ENGINE.

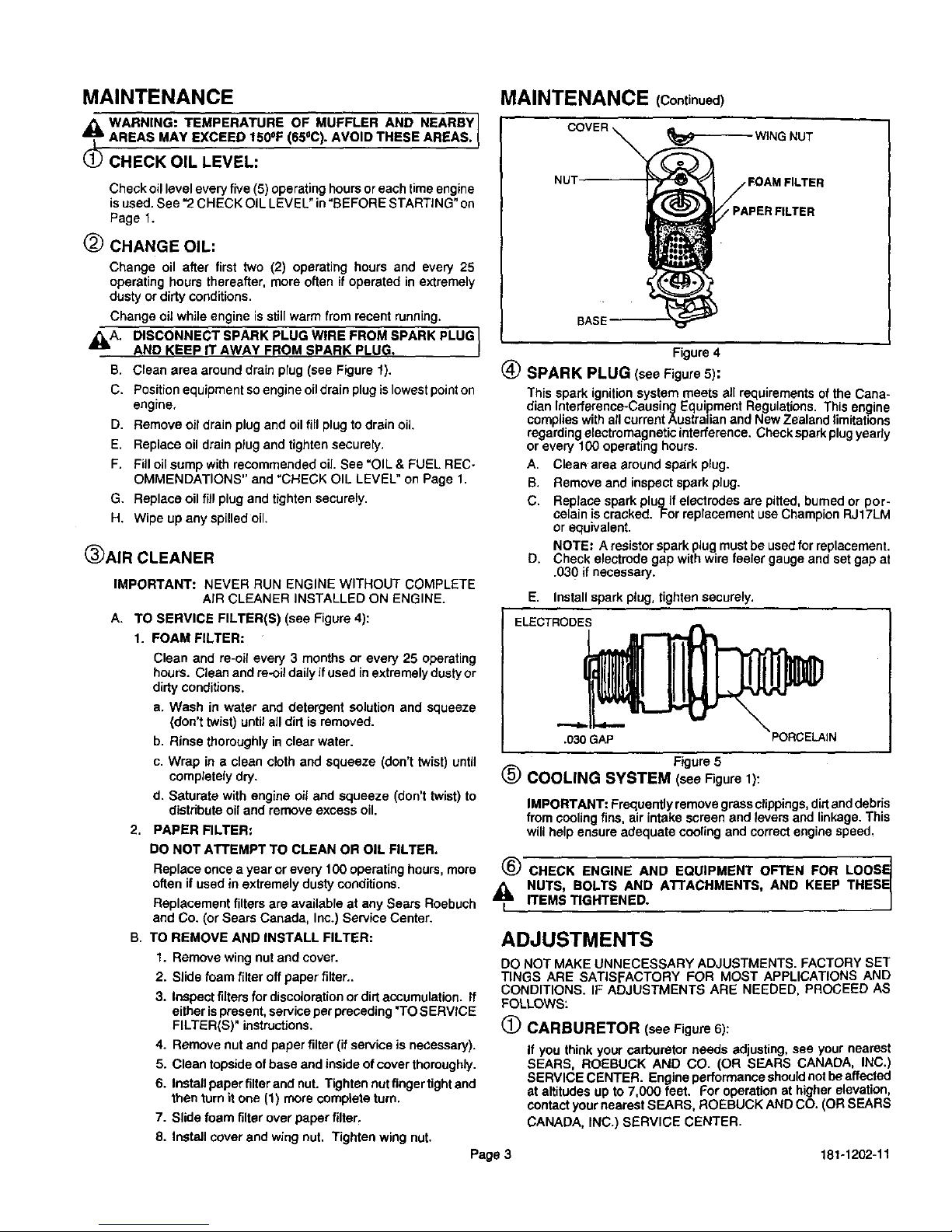

A. TO SERVICE FILTER(S) (see Figure 4):

1. FOAM FILTER:

Clean and re-oil every 3 months or every 25 operating

hours. Clean andre-oil daily if used in extremely dusty or

dirty conditions.

a, Wash in water and detergent solution and squeeze

(don't twist) until all dirt is removed.

b. Rinsethoroughly in clear water.

c. Wrap in a clean cloth and squeeze (don't twist) until

completely dry.

d. Saturate with engine oil and squeeze (don't twist) to

distributeoil and removeexcess oil.

2. PAPER FILTER:

DO NOT ATTEMPT TO CLEAN OR OIL FILTER.

Replace once a year or every t00 operatinghours,more

oftenif usedin extremely dusty conditions.

Replacement filters are available at any Sears Roebuch

and Co. (or Sears Canada, Inc.) Service Center.

B. TO REMOVE AND INSTALL RLTER:

1. Remove wing nut and cover.

2. Slidefoam filteroffpaper filter..

3. Inspectfilters for discolorationor dirtaccumulation. If

eitherispresent,serviceperpreceding"TO SERVICE

FILTER(S)" instructions.

4. Remove nut and paperfilter (if service is necessary).

5. Clean topside of base and inside ofcover thoroughly.

6. Installpaper filter and nut. Tightennut fingertightand

then turn it one (1) more completeturn.

7. Slidefoam filter over paper filter,

8. Installcover and wing nut. Tighten wing nut.

Page 3

MAINTENANCE (Continued)

_WING NUT

NUT

BASE--

Figure4

(_ SPARK PLUG (seeFigure5)=

This spark ignitionsystem meets al[ requirementsofthe Cana-

dianInterference-CausingEquipment Regulations. This engine

complieswithall currentAustralianand New Zealand limitatiOns

regardingelectromagneticinterference. Check spark plugyeady

or every 100 operatinghours.

A. Clean area around spark plug.

B. Remove and inspect spark plug.

C. Replace spark plugif electrodes are pitted,burnedor por-

celain is cracked. For replacementuse ChampionRJ17LM

or equivalent.

NOTE: A resistorspark plug mustbe usedfor replacement.

D. Check electrode gap with wire feeler gauge and setgap at

.030 if necessary.

E. Install spark plug,tightensecurely.

ELECTRODES

.030 GAP

Figure5

(_ COOLING SYSTEM (seeFigure1):

IMPORTANT: Frequentlyremovegrassclippings,dirtand debris

fromcooling fins, air intake screen and levers and linkage. This

willhelp ensure adequate cooling and correctenginespeed.

(_)'CHECK ENGINE AND EQUIPMENT OFTEN FOR LOOSE]

_1= NUTS, BOLTS AND AI"FACHMENTS, AND KEEP THESE_

I ITEMS TIGHTENED.

ADJUSTMENTS

DO NOT MAKE UNNECESSARY ADJUSTMENTS. FACTORY SET

TINGS ARE SATISFACTORY FOR MOST APPLICATIONS AND

CONDITIONS. IF ADJUSTMENTS ARE NEEDED, PROCEED AS

FOLLOWS:

(_ CARBURETOR (see Figure6):

If you think your carburetor needs adjusting, see your nearest

SEARS, ROEBUCK AND CO. (OR SEARS CANADA, INC.)

SERVICE CENTER. Engine performanceshouldnotbe affected

at altitudesup to7,000 feet. For operation at higher elevation,

contactyour nearest SEARS, ROEBUCK AND CO. (OR SEARS

CANADA, INC.) SERVICE CENTER.

18t-1202-11

Page 5

ADJUSTMENTS (Continued)

(_ REMOTE CONTROL (seeFigure7):

Forsatisfactoryengine performance,engine and remote equip

ment controlsmustbeadjusted properly.Tocheckenginecontrol

adjustments,proceed as follows:

A. Set remoteequipmentcontrolat FAST or HIGH SPEED and

keep inthis position.

In this position,engine CONTROL LEVER should touch

HIGH SPEED STOP. If itdoes, the controlsare adjustedcor

rectly and no further adjustmentshouldbe necessary.

NOTE: Ifengine CONTROL LEVER does nottouch HIGH

SPEED STOP, proceed toinstructionB.

B. Loosen CLAMP SCREW so REMOTE CONTROL CABLE

can be moved in CABLE CLAMP (do not remove CABLE

CLAMPfrom CONTROL BRACKET ordisconnectREMOTE

CONTROL CABLE from CONTROL LEVER.)

C. Move engine CONTROL LEVER so _t is touching HIGH

SPEED STOP and hold it inthis position.

D. Tighten CLAMP SCREW securely so CABLE CLAMP will

holdREMOTE CONTROL CABLE inplace when equipment

controlisused.

The engine controlsshould now be adjusted correctly.

If additional control adjustments are necessary, contact your

nearby Sears Roebuck and Co. (Sears Canada, Inc.) Service

Center.

(_) ENGINE SPEED:

_1 NEVER TAMPER WITH ENGINE GOVERNOR WHICH IS FAC- I

TORY SET FOR PROPER ENGINE SPEED. OVERSPEEDING I

ENGINE ABOVE FACTORY HIGH SPEED SETTING CAN BEI

DANGEROUS. I

CHANGING OF ENGINE-GOVERNED SPEED WILL VOID

ENG NE WARRANTY.

FOR ANY MAJOR ADJUSTMENTS OR REPAIRS, CONTACT

YOUR NEARBY SEARS ROEBUCK AND CO. (OR SEARS

CANADA, INC.) SERVICE CENTER.

CARBURETOR

BOWL DRAIN_

Figure 6

CONTROL CONTROL

BRACKET _ SCREW

STORAGE

A

NEVER STORE ENGINE WITH FUEL IN TANK INDOORS OR1

INENCLOSED, POORLY VENTILATED AREAS, WHERE FUEL|

FUMES MAY REACH AN OPEN FLAME, SPARK OR PILOT/

UGHT AS ON A FURNACE, WATER HEATER, CLOTHES/

DRYER OR OTHER GAS APPLIANCE. |

IF ENGINE IS TO BE UNUSED FOR 30 DAYS OR MORE,

PREPARE AS FOLLOWS:

(!) DRAIN FUEL SYSTEM:

A. Remove all gasoline from carburetorand fuel tank to prevent

gum deposits from forming on these parts and causing possi-

ble malfunction of engine.

_L DRAIN FUEL INTO APPROVED CONTAINER OUTDOORS,1

WAN ?O"oO; NFLAMESESUREE"G'"E'SCOOL/

B. Run engine until fuel tank is empty and engine stops due to

lack of fuel.

NOTE: Fuel stabilizer (such as STA-BIL) is an acceptable

a_ternative in minimizing the formation of fuel gum deposits

dudngstorage. Addstabilizertogasoline in fueltank or storage

container.Always follow mix ratio found on stabilizercontain-

er, Run engine at least 10 minutes after adding stabilizerto

allow it toreach carburetor.

(_) CHANGE OIL:

Changeoilifithasnotbeenchangedinthelastthree(3)months.

See"CHANGEOIL"instructionsin "MAINTENANCE"sectionon

Page3.

(_) OIL CYLINDER BORE:

A. Remove spark plug. Squirfone (1) oz. (30 ml)of clean engine

oil into spark plug hole.

B. Crank engine over, slowly, several times.

_ AVOID SPRAY FROM SPARK PLUG HOLE WHEN CRAN K-

ING ENGINE OVER SLOWLY.

C. Replace spark plug.

(_ CLEAN ENGINE:

Removeanyclippings,dirt,orchafffromexteriorofengine.

GENERAL

Justas yourautomobile needsprofessionalmechanicalmaintenance

fromtimetotime, sodoes yourCraftsmanengine. Replacementofthe

spark plug and air cleaner is made necessary by NORMAL use.

ProfessionalAir-Ceeled Engine Service isas close as your nearest

Sears Roebuckand Co. (orSears Canada, Inc.) Service Center.

A yearly check-up or tune-up by Sears is a good idea to avoid

breakdownsor delay.., do it at the end of the season, then you're

ready for the next. We even prepare it forstoragefor you.

Figure 7

Page 4 181-1202-11

Page 6

TROUBLESHOOTING

THE FOLLOWING MAY HELP AVOID A DELAY IN YOUR WORK OR

SAVE THE EXPENSE OF A SERVICE CALL,

ENGINE FALLSTO START OR STARTS WITH DIFFICULTY

CAUSE

Controlsnot in start position.

Spark plug wire disconnected from spark plug.

Spark plug fouled.

Spark plug porcelaincracked,

Insufficientfuel.

Water ordirt in fuel.

Improper carburetoradjustment

ENGINE LACKS POWER

CAUSE

Dirtyair cleaner.

Impropercarburetoradjustment.

Lack of lubricaiton.

ENGINE MISSES UNDER LOAD

CAUSE

Spark plug fouled,

Spark plug porcelain cracked.

Improperspark pluggap,

Impropercarburetoradjustment

REMEDY

Move ENGINE CONTROL or equipment controlto "HI"or

START postien. See "STARTING" instructionsinthis

manual.

Connect SPARK PLUGWIRE toSPARK PLUG,

Remove SPARK PLUG and clean it. See "SPARK PLUG"

instructionsin "MAINTENANCE" section in this manual.

Installnew spark plug.

FillFUEL TANK per "BEFORE STARTING" instructions,

Drain FUEL TANK andre-fill withclean, freshgasoline. See

"BEFORE STARTING" instructionsinthis manual.

Adjust carburetor(if applicable). See "ADJUSTMENTS"

section in thismanual.

REMEDY

Replace or clean air cleaner per "AIR CLEANER"

instructionsin "MAINTENANCE" section inthis marluaL

Adjust carburetor(if applicable). See "ADJUSTMENTS"

sectionin this manual.

'Filloil sump to proper level. See "BEFORE STARTING"

instructions section in this manual.

REMEDY

Remove SPARK PLUG and clean it, See "SPARKPLUG"

instructionsin "MAINTENANCE" section in this manual,

Installnew SPARK PLUG,

!Regap SPARK PLUG electrodes, See "SPARK PLUG"

instructions in "MAINTENANCE" section inthis manual.

Adjustcarburetor (if applicable). See "ADJUSTMENTS"

section nth s manua.

181-1202-11

Page 5

Page 7

SEARS, ROEBUCK AND CO.

Federal and California Emission Control Systems Limited Warranty

Utility and Lawn and Garden Engines

CALIFORNIA & US EPA EMISSION CONTROL

WARRANTY STATEMENT

The U S Environmental Protection Agency (*EPA'), the California Air Resources

Board ('CARB') and Sears, Roebuck andCo, are pleased to explain the Federal

and California Emission Controt Systems Warranty on yournew utility or lawn and

garden equipment engine. In California, new 1995 and later utiEtyand lawn and

arden equipment engines must be designedt bailsand equipped to meet the

_fata's stringent anti-smog standards. In other states, new 1997 and later model

year engines must be designed, built and equipped, at the time of sale. to meet

the U.E. EPA regulabons for small non-road engines Sears Roebuck and Co

will warrant the emission control system on your utility or lawn and garden

equipment engine for the periods of time listod below, provided there has been no

abuse, neglect, unapproved modification, orimproper maintenance of your utility

or lawn and garden equipment engine

Your emission control system may include parts such as the carburetor, ignition

system and exhaust system, Also inoluded may be the compression release

system and other emission-related assemblies¸

Where a warrantable condition exists, Seats. Roebuck and Oo. will repair your

utility ot lawn and garden equipment engine 8t no cost to you for diagnosis, parts

and labor

MANUFACTURER'S EMISSION CONTROL SYSTEM

WARRANTY COVERAGE

Emission control systems on 1995 and later model year California ubliltyand fawn

and garden equipment engines are warranted for two years as hereinafter noted

In other states, 1997 and later model year engines are also warranted for two

years. If, during such warranty period, any emission-related part on your engine

=sdefective in materials or workmanship, the part witl be repaired or replaced by

Sears, Roebuck and Co.

OWNER'S WARRANTY RESPONSIBILITIES

As the utilityor lawn and garden equipment engine owner, you are responsible for

the performance of the required maintenance listed in your Owner's Manual. but

Sears Roebuck and Co will not deny warranty solely due to the lack of receipts

or for your failure to provide wr tten evidence of the pedormance of all scheduled

maintenance.

As the utilityot lawn and garden equipment engine owner, you should, however,

be aware that Sears, Roebuck and Co may deny you warranty coverage if your

utilityor lawn and garden equipment or a part thereof has failed due to abuse.

neglect, improper maintenance or unapproved modifications

You are responsible for presenting your utilityor lawn and garden equipment

engine to a Sears. Roebuck and Do. Authorized Service Outlet as soon as a

problem exists. The warranty repairs soduld be completed Jna reasonable

amount oftime, not to exceed 30 days

Warranty service can be arranged by contacting either a Seat=, Roebuck and Co.

Authorized Service Outlet, or bycontacting Sears, Roebuck and Co at 1-800*

473-7247¸

IMPORTANT NOTE

This warranty statement explains your rights and obligations under the Emission

Contrbl System Warranty ('ECS Warranty') which is provided to you by Sears.

Roebuck and Co, pursuant to Oatifornia law. See also the Sears, Roebuck and

CO. Limited Warranties for Sears. Roebuck and Co, which is enclosed therewith

on a separate sheet and also is provided to you by Sears, Roebuck and Co, The

ECS Warranty applies only to the emission control system of your new engine,

TO the extent that there is any conflict in terms between the ECS Warranty and

the Sears. Roebuck and Co. Warranty, the ECS Warranty shaft apply except in

any circumstances in which the Sears, ROebuck and Co Warranty may provide a

longer warranty period. Both the ECS Warranty and the Sears, Roebuck and Co,

Wa_anty describe important rights and obligations with respect to your new

engine.

Warranty service can only be performed by a Sears, Roebuck and Co. Authorized

Service Outlet, At the time of requesting warranty service, evidence must be

presented ofthe date of sale to the original purchaser. The purchaser shall pay

any charges for makin_ servJcecallsandlorfortransporfingthe pfroducts to a_ld

from the place where the inspection and/or warranty work is performed. The

purchaser shall be responsible for any damage or loss incurred in connection with

the transportation of any engine or any pert(s) thereof submitted for inspection

and/or warranty work,

If you have any questions regarding your warranty rights and responsibilities, you

should contact Sears, Roebuck and CO. at 1-500-473-7247

EMISSION CONTROL SYSTEM WARRANTY

Emission Control System Warranty "ECS Warranty" for 1995 and later model

year California utilityand lawn and garden equipment engines for other states.

1997 and later model year engines):

A. APPLICABILITY: This warranty shall apply to 1995 and later model year

California utilityand lawn and garden equipment engines for other states. 1997

and later model year engines). The ECS Warranty Pedod shaft begin on the date

the new engine or equipment is defivered to its original, end-use purchaser and

shall continue for 24 consecutive months thereafter.

R. GENERAL EMISSIONS WARRANTY COVERAGE: Sears, Roebuck and CO.

warrants to the original, end-use purchaser of the new engine or equipment and

to each subsequent purchaser that each of its utifityand lawn and garden

equipment engines is:

1 Designed. built and eduipped so as to conform with all applicable

regulations adopted by the Air Resources Eoard pursuant to its authority in

Chapters 1 and 2, Part 5. Division 26 of the Health and Safety Code, and

2 Free from defects in materials and workmanship which, at any time duhng

the ECS Warranty Period, will cause a warranted emissions*related part to

fair to be identicat in all material respects to the part as described in the

engine manufacturer's application rbr certification

C. The ECS Warranty only pertains to emissions-relatad parts on your engine, as

follows:

1. Any warranted, emissions-related partswhich are not scheduled for

replacement as required thblntena nce in the Owner's Manual shall be

warranted for the ECS Warranty Period If any such part fails during the

ECS Warranty Period, itshall be repaired or replaced by Sears, Roebuck

and Co according to Subsection 4 below Any such part repaired or

replaced under the ECS Warranty shall be warranted for any remainder of

the ECS Warranty Period,

2,

Any warranted, emissions-refatad part which is scheduled only for regular

inspection as specified in the Owner's Manual shall be warranted for the

ECS Warranty Period A statement in such written instructions to the

effect of "repair or replace as necessary', shall not reduce the ECS

Warranty Period Any such part repaired or replaced under the ECS

Warranty shall be warranted for the remainder of the ECS Warranty

Period.

Any warranted, emissions-related part which is scheduled for replacement

as required maintenance inthe Owner's Manual. shall be warranted for the

period of time prior to the first scheduled replacement point for that part. If

the part fails pdor to the first scheduled replacement, the part shallbe

repaired or replaced bySears, Roebuck and Co according to Subsection

4 below Any such emissions-related part repaired or replaced under the

ECS Warranty, shall be warranted for the remainder of the ECS Warranty

Period prior to the first scheduled replacement point for suchemissions-

related part.

4 Repair or replacement of any warranted, emissions-related part under this

ECS Warranty shall be performed at no charge to the owner at a Sears,

Roebuck and Co. Authorized Service Outlet

fi The owner shall not be charged for diagnostic fabor which leads to the

determination thata part covered by the ECS Warranty is in fact defective,

provided that such diagnostic work is performed at a Sears, Roebuck and

CO. Authorized Service Outlet

5 Sears, Roebuck and Co. shall be fiable for damages to otheroriginbl

engine components or alp|provedmodifications proximately caused bya

failure under warranty of an emission-related part covered by the ECS

Warranty,

7. Thro_Jghoutthe ECS Warranty Period. Sears. Roebuck and Co shall

maintain a sgppty of warranted emission-related parts sufficient to meet

the expected demand for such emission-related parts,

8 Any Sears, Roebuck and Co. authorized and approved emission*refated

replacement part may be used in the performance of any ECE Warranty

maintenance or repaJr and will be provided without chaa_a to the owner¸

Such use shall not reduce Sears, Roebuck and Co ECS Warranty

obligations.

9,

Unapproved edd-on or modified parts may not be used to modify or repair

a Sears. Roebuck and Co. engine. Such use voidsthis ECS Warranty and

shall be sufficient grounds for disallowing an ECS Warranty claim. Seats,

Roebuck and Oo. shall not be Jiable hereunder for failures of any

warranted pads of a Sears. Roebuck and CO. engine caused by the use of

such an unapproved add-on or modified part.

EMISSION-RELATED PARTS INCLUDE THE FOLLOWING:

1. Carburetor Assembly and its Internal Components

a) Fuel filter

b) Carburetor gaskets

c) Intake pipe

2, Air Cleaner Assembly

a) Air filter e_ement

3. Ignition System. including:

a) Spark plug

b) Ignition module

C) Flywheel assembly

4 Catalytic Muffler (if so equipped)

a) Muffler gasket (if so equipped)

b) Exhaust manifold (if SOequipped)

5 Crankcase Breather Assembly and its Components

_,) _.reather co_nectk_n t_be

12297 Ep,VCAR]_

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

Page 6 181o1202-11

Page 8

CRAFTSMAN 4-CYCLE ENGINE MODEL:143.998003

/.

Jr/

lOl

182

245A

Page 7 181-1202-11

Page 9

CRAFTSMAN 4-CYCLE ENGINE MODEL:143.998003

Ref. Part

No. No.

1

2

15

15A

15B

16

17

18

19

2O

25

26

28

30

35

36

37

38

40

40

41

41

42

42

43

45

47

48

49

5O

6O

65

69

70

71

72

75

8O

81

82

83

84

86

87

89

90

92

93

100

101

102

103

110

119

120

125

125

126

126

127

128

130

130A

130B

35385

27652

30599C

30700

650494

33454

29916

651028

34663

35319

36460

650561

30322

35372A

29826

29918

29216

29642

40011

40012

40009

40010

40013

40014

27888

36897

651033

34034

36896

35375

33273A

650128

"35262A

35376

35377

27642

35319

31845

30590A

35378

30588A

29193

650833

650832

32589

611091

650880

650881

35135

610118

651024

651007

35187

*36448

36449

27878A

27880A

34035

34036

650691

650690

650694A

650727

651055

Ref. Part

Part Name No. No.

Cylinder (Incl. 2, 20 & 72) 135

Dowel Pin 139

Governor Rod (,Incl. 15A & 15B) 140

Governor Y5ke 149

Screw, 6-40 x 5/16" 149A

Governor Lever 150

Governor Lever Clamp 151

Screw, Tom "1"-15,8-32 x 3/8" 169

Speed Control Spring 170

Oil Seal 171

Blower Housing Baffle 172

Screw, 1/4-20 x 5/8" 173

Lock Nut, 8-32 173A

Crankshaft 174

Screw, 10-32 x 3/4" 178

Lock Washer 182

Lock Nut, 10-32 184

Retaining Ring 185

Piston, Pin & Ring Set (Std.) 186

Piston, Pin & Ring Set (.010" OS) 200

Piston & Pin Ass'y. (Std.) (Incl. 43)

Piston & Pin Ass'y. (.010" OS) (Incl. 203

43) 204

RingSet (Std.) 206

RingSet (.010" OSi 207

Piston Pin Retaining Ring 209

Connecting Rod Aas'y. (Incl. 47 & 49) 210

Connecting Rod Bolt 211

Valve Lifter 223

Oil Dipper 224

Camshaft (MCR) 227

Blower Housing Extension

Screw, 10-24 x 1/2" 228

Cylinder Cover Gasket 229

CylinderCover (Incr.71, 75 & 80) 232

Crankshaft Bushing

Oil Drain Plug 235

Oil Seal 238

Governor Shaft 239

Washer 239A

GovernorGear Ass'y. (Incl. 81) 241A

Governor Spool 242

Retaining Ring 245

Screw, 1/4-20 x 1-3/16" 245A

Screw, 1/4-20 x 1-11/16" 250

Flywheel Key 251

Flywheel 260

Lock Washer 261

Flywheel Nut 262

Solid State Ignition 264A

Spark Plug Cover 265

Solid State MountingStud 281

Screw, Tcrx To15, 10-24 x 15/16" 282

Ground Wire 285

Cylinder Head Gasket 287

Cylinder Head 290

ExhaustValve (Std.) (Incl. 151) 291

ExhaustValve (1/32" OS) (IncL 151) 292

IntakeValve (Std.) (Incl. 151)

Intake Valve (1/82" OS) (Incr. 151)

Washer

Belleville Washer

Screw, 5/16-18 x 2"

Screw,5/16-18 x 1-3/4"

Screw, 5/16-18 x 5/8"

Page 8

33636

33369

650836

27882

35862

27881

32581

"27896A

28423

28424

28425

34696

32446

650128

2975_

30088A

*33263

34707

34667

34664

31342

651029

610973

33878

650821

27793

28942

650378

"27915A

35044

650851

650852

30675

650163

"27272A

"34698A

37279

34699

34700A

34703

34702

659886

34833S

650788

29747B

650802

33272S

33013

650760

359858

29752

29774

30962

26450

Part Name

Resistor Spark Plug (RJ17LM)

Govemcr Gear Bracket

Screw, 10-24 x 1/2"

Valve Spring Cap

Valve Spring Cap

Valve Spdng

IValve Spring Keeper

Breather Gasket

Breather Body

Breather Element

Valve Cover

Breather Tube

Breather Tube Grommet

Screw, 10-24 x t/2"

Nut & Lock Washer, 1/4-28

Screw, 1/4-28 x 1"

Carburetor To Intake Pipe Gasket

In_ke Pipe

Governor Link

Control Bracket (Incl. 19, 203, 204 &

209)

Compression Spring

Screw, Torx "1"-10,5-40 x 7/16"

Terminal

Throttle Link

Screw, 10-32 x 1/2"

Conduit Clip

Screw, 10-32 x 3/8"

Screw, Torx T-30, 5/16-18 x 1-1/8"

Intake Pipe Gasket

Air Cleaner Elbow (Incl. 228, 229,

234, 239 & 242)

Stud, 1/4-20 x 8.1

Nut, 1/4-20

Pop Rivet (1/8=Dia.)(Purehase

Locally)

Air Cleaner Elbow Fitting

Screw, 10-32 x_7/8"

Air Cleaner Gasket

Air Cleaner Gasket

Air Cleaner Collar

Air Cleaner Bracket

Air Cleaner Filter

Air Cleaner Filter

Air Cleaner Cover

Wing Nut, 1/4-20

Blower Housing

Screw, 5/16-18 x 3/4"

Screw, Torx T-40, 5/16-24 x 21/32"

Screw, 1/4-20 x 5/8"

Cylinder Head Cover

Starter Bubble Cover

Screw, 8-32 x 3/8"

Starter Cup

Nut & Loc;kWasher, 1/4-28

Fuel Line

Fuel Line

Fuel Line Clamp

*Indicates Parts Included in

Gasket Set, Ref. No. 400.

181-1202-11

Page 10

CRAFTSMAN 4-CYCLE ENGINE MODEL:143.998003

Re[ Part

No. No.

293 35807

294 35791

298 650665

300 34156A

301 36246

303 32958

305 35554

307 35499

308 35540

310 36205

325 29443

327 35392

340 34154

341 34155

342 650561

370E 37O89

370G 35274

Pad Name

Pulse Pump

Pulse Pump Repair Kit

Screw, 1/4-15 x3/4"

Fuel Tank (IncL 292 & 301)

Fuel Cap

FuelFitting

Oil Fill Tube

"O" Ring

Fill Tube Clip

Dipstick

Wire Clip

Starter Plug

Fuel TankBracket

Fuel TankBracket

Screw, 1/4-20 x 5/8"

Air Cleaner Decal

Oil InstructionDecal

Ref.

No.

380

390

400

90O

900

Part

No.

640153

590746

36450B

181-1202-11

Part Name

Carburetor (Incl. 184)

Rewind Starter

(NOTE: This engine could have

been built with 590704 starter.)

Gasket Set (Incl. Items Marked *)

Replacement Engine 756335, Order

From 71-999

Replacement Short Block, 756316A

Order From 71-999

Operator's Manual

*Indicates Parts Included in

Gasket Set, Ref. No. 400.

RPM High 3450 to 3750

RRM Low 1700

CARBURETOR NO. 640153

, 1o

I 30

,_27 //

/

/I

/ 86

Ref. Part

No. No. Pert Name

640153 Carburetor (incl. 184 of Engine Parts List

1 631776,_ Throttle Shaft & Lever Assembly

2 631970 Throttle Return Spring

4 631184 Dust Seal Washer

5 631183 Dust Seal (Throttle)

6 640109 Throttle Shutter

7 650506 Shutter Screw

10 632177 Choke Shalt& Lever Assembly

11 632043 Choke Return Spring

• 12 631184 Dust Seal Washer

13 631183 Dust Seal (Choke)

14 631753 Choke Shutter

15 630735 Choke Positioning Spring

16 631807 Fuel Fitting

17 651026 Throttle Crack Screw/idle Speed Screw

18 630766 Tension Spring

20 640027 Idle Restdctor Screw

20A 640053 Idle Restdctor Screw Cap

25 631867 Float Bowl

27 631024 FLoatShaft

28 632019 Float

29 631028 Float Bow1"O" Ring

30 631021 inlet Needle, Seat & Clip (incl. 31)

31 631022 Spring Clip

36 640113 Main Nozzle Tube

37 632547 Main Nozzzle Tube "O" Ring

40 640114 High Speed Bowl Nut

44 27110 Bowl Nut Washer

47 630748 Welch Plug. Idle MixtureWell

48 631027 Welch Plug. AtmosphericVent

Page 9 181-1202-11

Page 11

REWIND STARTER NO. 590746

12

"8

¢p-.4

1

Rof. Part

No. NO, Part Name

590746

1 590599A

2 590600

3 590679

4 590601

5 590678

6 590680

7 590412

8 590661

11 590747

12 590535

13 590701

Recoil Starter

Spring Pin(Incl. 4)

Washer

Retainer

Washer

Brake Spring

Starter Dog

Dog Spring

Pulley & Rewind SpringAss'y.

Starter HousingAss'y.

Starter Rope ( 98"X 9/64" dia.)

Starter Handle

STARTER NO, 590704

/

13

12

8

_--5

O--2

Ref, Part

No. No. Part Name

590704 Recoil Starter

1 590599A Spring Pin (Ind+ 4)

2 590600 Washer

3 590696 Retainer

4 590601 Washer

5 590697 Brake Spdng

6 590698 Starter Dog

7 590699 Dog Spring

8 590700 Pulley & Rewind Spring Ass'y,

t 1 590705 Starter Housing Ass'y.

12 590535 Starter Rope ( 98' x 9/64" dia.)

13 590701 Starter Handle

Page 10 181-1202-!1

Page 12

operator's

manual

MODEL NO. 143.998003

SOLID STATE IGNITION

CAUTION:

Read RULES for

Safe OPERATION

and INSTRUCTIONS

Carefully

How to ORDER Repair Parts

The Model Numbercan be found on a decal on the blower

housing (See Figure 1). Always mention the Model Number

when requesting service or repair parts for your Craftsman

Engine.

All parts listed herein may be ordered from any SEARS, ROE-

BUCK AND GO. or SEARS CANADA, INC. retailor catalog store.

Ifthe partsyou need are not stocked locally,yourorder willbe

electronicallytransmittedtoa Sears Repair Parts Distribution

Centerfor expedited handling.

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE THE

FOLLOWING INFORMATION AS SHOWN IN THIS LIST.

1. The PART NUMBER

2. The PART DESCRIPTION

3. The MODEL NUMBER

4. The NAME OF ITEM - ENGINE

"Your Sears merchandise has addedvalue when you considerthat Sears has

service units nationwide staffed with Sears trained technicians.., professional

technicians specifically trained on Sears products, having the parts, tools and

equipmentto insure thatwe meet our pledge to you ... we service what we sell."

Sold by SEARS, ROEBUCK AND CO., CHICAGO, IL 60684 U.S.A.

and SEARS CANADA, INC., TORONTO, ONTARIO, CANADA

t81-1202-11

Loading...

Loading...