Page 1

For Future Reference

i/Save This Manual _'_''\

MODEL NO,

113,244501

10-INCH BAND SAW

Se;iot.....

Number

Model and serial numbers

may be found on the back

of the saw

You should record both

modet and serial number in

a safe place for future use

FOR YOUR

SAFETY:

READ ALL

INSTRUCTIONS

CAREFULLY

/

O-IN©H

e assembUy

® operating

repair parts

../ j

SEARS, ROEBUCK AND CO., Hoffmann Estates, IL 60179 U.S.A.

Part No_ SP5640 Printed in Taiwan

Page 2

FULLONEYEARWARRANT ONCRAFrSMA.BENCHTOPTOOLS

If this Band Saw fails due to a defect in material or workmanship, within one years from the '

date of purchase, RETURN IT TO THE NEAREST SEARS SERVICE CENTER IN THE UNITED

STATES, and Sears will repair it, free of charge.

If this Band Saw is used for commercial or rental purposes, this warranty will apply for ninety

days from the date of purchase.

This warranty applies only while this product is in the United States,

This warranty gives you specific legal rights, and you may also have other rights which vary

from state to state.

Sears, Roebuck and Co., D/817 WA Hoffman Estates, IL 60179 ._

Safety Instructions for Band Saw

Safety is a combination of common sense, staying • Assembly and alignment. (See pages 7-13).

alert and knowing how your band saw works. Read

this manual to understand this saw.

Safety Signal Words

DANGER: means if the safety information is not fol-

lowed someone will be seriously injured or killed

WARNING: means if the safety information is not fol-

lowed someone could be seriously injured or killed.

CAUTION: means if the safety information is not fol-

lowed someone might be injured_

BEFORE USING THE SAW:

• Learn the use and function of the ON-OFF

switch, table lock knob, blade guides, backup

bearings, upper slide lock knob, blade guard,

tension catch, and tracking screw. (See pages

14 & 15)

• Review and understand all of the safety instruc-

tion and operating procedures in this manual

• Review the maintenance methods for this saw.

(See page 19)

Read the following WARNING labels found on the

front of the saw:

i ,,,,,,,,,,i,,,,,, i,iH,

WARNING: To avoid mistakes that could cause

serious, permanent Injury, do not plug the saw

in until the following steps are completed,

WARNING

WHEN INSTALLING OR MOVING THE SAW.

AVOID DANGEROUS ENVIRONMENT Use the saw

in a dry, indoor place protected from rain, Keep work

area well lighted.

To avoid injury from unexpected saw movement:

• Put the saw on a firm level surface where there is

plenty of room for handling and properly support-

ing the workpiece

• Support the saw so the table is level and the saw

does not rock.

• Bolt the saw to the support surface if it tends to

slip, walk, or slide during operations like cutting

long, heavy boards.

• Turn saw off and unplug cord before moving the

saw.

To avoid injury or death from electrical shock:

• GROUND THE SAW This saw has an approved

3-conductor cord and a 3-prong grounding type

plug Use only 3-wire, grounded outlets rated

120 volts, 15 amperes (amps). The green con-

ductor in the cord is the grounding wire_To avoid

electrocution, NEVER connect the green

wire to a live terminal

DANGER

• Make sure your fingers do not touch the plug's

metal prongs when plugging or' unplugging the

saw,.

NEVER STAND ON TOOL. Serious injury could

occur if the tool tips or you accidentally hit the cutting

tool, Do not store anything above or near the tool

where anyone might stand on the tool to reach them.

BEFORE EACH USE:

Inspect your saw.

DISCONNECT THE SAW To avoid injury from acci-

dental starting, unplug the saw, turn the switch off

and remove the switch key before changing the

setup, opening covers, removing guards, or'blade_

CHECK FOR DAMAGED PARTS. Check for:

, alignment of moving parts,

o binding of moving parts,

o broken parts,

• stable mounting, and

- any other conditions that may affect the way the

saw works.

Page 3

Ifanypartis missing,bent,orbrokenin anyway,or

anyelectricalpartdoesn'tworkproperly,turnthesaw

offandunplugthesaw REPLACEdamaged,miss-

ing,orfailedpartsbeforeusingthesawagain

MAINTAINTOOLSWiTHCAREKeepthesawclean

forbestandsafestperformanceFollowinstructions

forlubricating

REMOVEADJUSTINGKEYSANDWRENCHES

fromtoo!beforeturningiton

Dress for safety,

WEAR YOUR

To avoid injury from jams, slips or thrown pieces:

• Choose the right size and style blade for the

material and the type of cutting you plan to do

• USE ONLY RECOMMENDED ACCESSORIES

(See page 18) Consult this owner's manual for

recommended accessories FoIlow the instruc-

tions that come with the accessories The use of

improper accessories may cause risk of injury to

persons

• Make sure the blade teeth point downward,

toward the table

• Make sure the blade guides and thrust bearings

are properly adjusted

• Make sure the blade tension is properly adjusted,

. Make sure the table lock knob is tight and no

parts have excessive play

. To avoid accidental blade contact, minimize

blade breakage and provide maximum blade

support, always adjust the upper blade guide and

blade guard to just clear the workpiece

• KEEP WORK AREA CLEAN Cluttered areas

and benches invite accidents Floor must not be

slippery

To avoid burns or other fire damage, rlever use the

saw near flammable liquids, vapors or gases

Plan ahead to protect your eyes,

hands, face, ears.

KNOW YOUR SAW Read and understand the

owner's manual and labels affixed to the tool_ Learn

its application and limitations as well as the specific

potential hazards peculiar to this tool

To avoid injury from accidental contact with moving

parts, don't do layout, assembly, or setup work on the

saw while any parts are moving.

AVOID ACCIDENTAL STARTING Make sure switch

is"OFF" before plugging saw into a power outlet

Plan your work.

• USE THE RIGHT TOOL Don't force tool or

attachment to do a job it was not designed to do

• Use this band saw to cut onty wood, wood like

products, and plastics

Any power saw can throw foreign objects into the

eyes This can cause permanent eye damage Wear

safety goggles (not glasses) that comply with ANSI

Z871 (shown on package) Everyday eyeglasses

have only impact resistant lenses They are not safe-

ty glasses Safety goggles are available at Sears

retait catalog stores Glasses or goggles not in c0m_

pliance with ANSI Z87 ! could seriously hurt you

when they break

• Do not wear Ioose clothing, gloves, neckties or

jewelry (rings, wrist watches) They can get

caught and draw you into moving parts

• Wear nonslip footwear

• Tie back long hair

• Roll long sleeves above the elbow

• Noise levels vary widely To avoid possible hear-

ing damage, wear ear plugs or muffs when using

your saw for hours at a time

• For dusty operations wear a dust mask along

with the safety goggles

Inspect your workpiece_

Make sure there are no nails or foreign objects in the

part of the workpiece to be cut

Use extra caution with large, very small or awk-

ward workpieces:

• Use extra supports (tables, saw horses, blocks.

etc ) for any workpieces large enough to tip when

not held down to the table top

• NEVER use another person as a substitute for a

table extension, or as additional support for a

workpiece that is longer or wider then the basic

saw table, or to help feed, support or pull the

workpiece

• When cutting irregularly shaped workpieces, plan

your work so it will not pinch the blade. A piece

of molding, for example, must lay flat or be held

by a fixture or jig that will not let it twist, rock or

slip while being cut

. Properly support round materiat such as dowel

rods, or tubing They have a tendency to roll dur-

ing a cut, causing the blade to "bite" To avoid

this, always use a "V" block or clamp the work to

the miter gage

• Cut only one workpiece at a time

• Clear everything except the workpiece and relat-

ed support devices off the table before turning

the saw on

Page 4

Plan the way you will hold the workpiece from

start to finish,

Do not hand hold pieces so small that your fingers

will go under the blade guard Use jigs or fixtures to

hold the work and keep your hands away from the

blade

Avoid awkward operations and hand positions where

a sudden slip could cause fingers or hand to move

intothe blade

DON'T OVERREACH Keep good footing and balance

WHENEVER SAW IS RUNNING.

WARNING: Don't let familiarity (gained from

frequent use of your band saw) cause a

careless mistake. A careless fraction of a

second is enough to cause a severe injury.

Before starting your cut, watch the saw while it runs If it

makes an unfamiliar noise or vibrates a tot,stop imme-

diately Turn the saw off Unplug the saw Do not restart

until finding and correcting the problem

KEEP CHILDREN AWAY Keep all visitors a safe dis-

tance from the saw Make sure bystanders are clear of

the saw and workpiece

DON'T FORCE TOOL. It will do the job better and safer

at its designed rate Feed the workpiece into the saw

blade only fast enough to let it cut without bogging

down or binding

Before freeing any jammed material:

• Turn switch "OFF"

• Remove switch key

. Unplug the saw

. Wait for all moving parts to stop

When backing up the workpiece, the blade may

bind in the kerf (cut). This is usually caused by

sawdust clogging up the kerr or because the

blade comes out of the guides. If this happens:

• Turn switch "OFF"

° Remove switch key

• Unplug saw

• Wait for all moving parts to stop

• Open band saw cover

• Stick flat blade screwdriver or wedge into the

kerf

• Turn the upper wheel by hand while backing up

the workpiece

Before removing loose pieces from the table, turn

saw off and wait for all moving parts to stop.

BEFORE LEAVING THE SAW:

Wait for a!l moving parts to stop

Make workshop child-proof. Lock the shop

Disconnect master switches Remove the yellow

switch key Store it away from children and others not

qualified to use the tool

gnossaty of terms for woodworking

Beveling

An angle cutting operation through the face of the

board

Crosscut

A cutting operation made across the width of the

workpiece

Compound Cutting

A simultaneous bevel and miter cutting operation

FPM

Feet per minute Used in reference to surface speed

of blade

Freehand (as used for band saw)

Performing a cut without the workpiece properly sup-

ported on the work table

Gum

A sticky, sap-based residue from wood products

Kerf

The material removed by the blade in a through cut or

the slot produced by the blade in a non-through or

partial cut

Leading End

The end of the workpiece which is pushed into the

cutting tool first

Mitering

An angle cutting operation made across the width of

the workpiece

Push Stick

A device used to feed the workpiece through the saw

during narrow ripping type operations so the opera-

tot's hands are kept well away from the blade.

Resaw

A cutting operation to reduce the thickness of the

workpiece to make thinner pieces

Resin

A sticky, sap-based substance that has dried

Ripping

A cutting operation along the length of the workpiece

Sawblade Path

The area of the worktable or workpiece directly in line

with the saw blade

Set

The distance the tip of the saw blade tooth is bent

outward from the face of the blade

Tracking

Adjusting the upper wheel so the bandsaw blade runs

in the center of the wheels

Trailing End

The workpiece end last cut by the saw blade

Workpiece

The item or] which the cutting operation is being per-

formed The surfaces of a workpiece are commonly

referred to as faces, ends, and edges

Worktable

The surface on which the wofkpiece rests while per-

forming a cutting operation

Page 5

motor specifications and eRectrBcanrequBrements

This machine isdesigned to use, and is equipped with,

a 1725 RPM motor It iswired for operation on 120

volts, 60 Hz., alternating current (TOOL MUST NOT

BE CONVERTED TO OPERATE ON 230 VOLT)..

For replacement motor refer to parts list inthis manual.

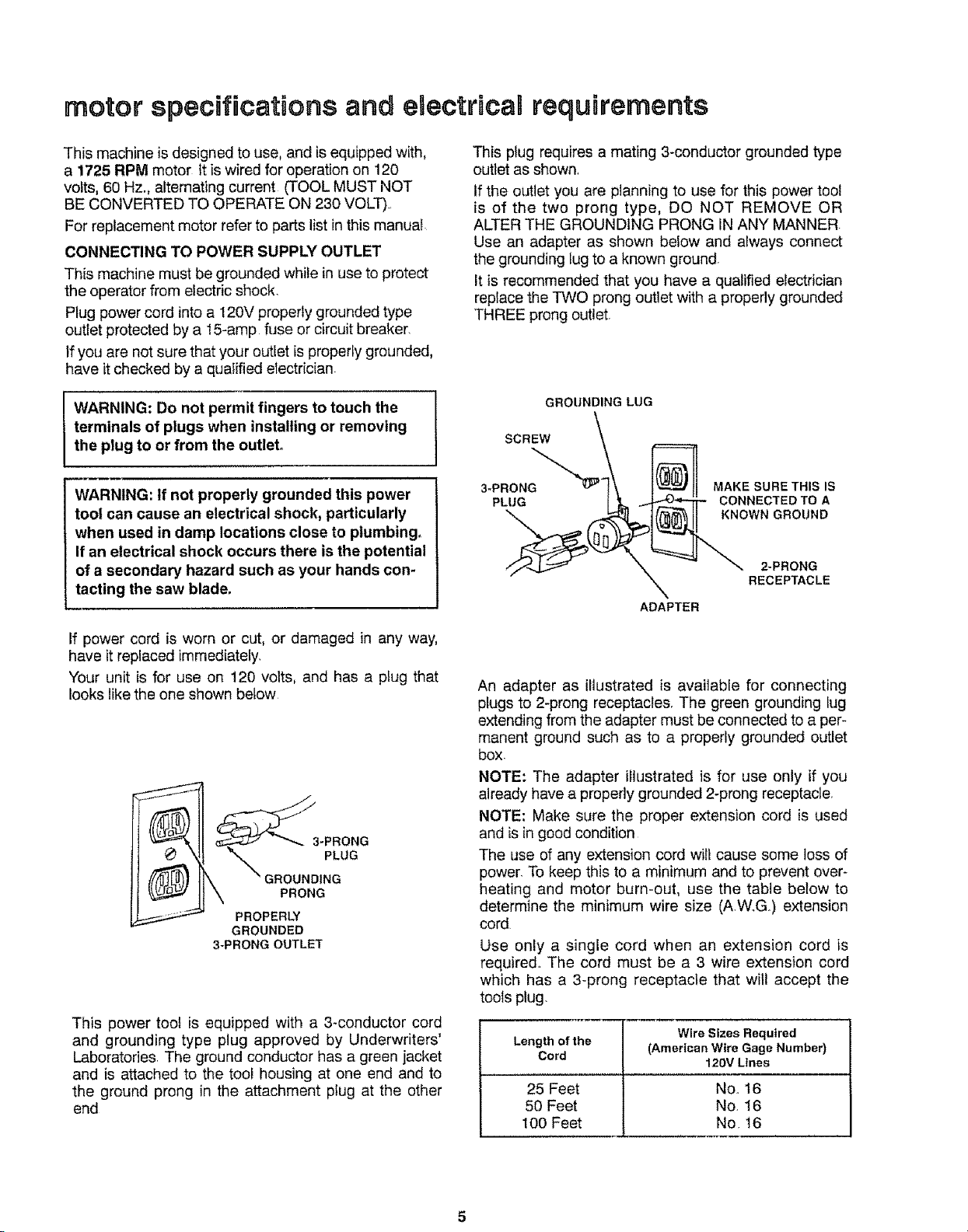

CONNECTING TO POWER SUPPLY OUTLET

This machine must be grounded while in use to protect

the operator from electric shock.

Plug power cord intoa 120V properly grounded type

outlet protected by a 15-amp fuse or circuit breaker.

ifyou are not sure that your outlet is property grounded,

have it checked by a quafified electrician.

WARNING: Do not permit fingers to touch the

terminals of plugs when installing or removing

the plug to or from the outlet.

WARNING: If not properly grounded this power

tool can cause an electrical shock, particularly

when used in damp locations close to plumbing,

If an electrical shock occurs there is the potential

of a secondary hazard such as your hands con-

tacting the saw blade.

This plug requires a mating 3-conductor grounded type

outlet as shown.

If the outlet you are planning to use for this power tool

is of the two prong type, DO NOT REMOVE OR

ALTER THE GROUNDING PRONG iN ANY MANNER

Use an adapter as shown below and always connect

the grounding tug to a known ground.

It is recommended that you have a qualified electrician

replace the TWO prong outlet with a properly grounded

THREE prong outlet.

GROUNDING LUG

PLUG I _. _-_ CONNECTED TO A

//,')_ _ " "_ 2-PRONG

RECEPTACLE

ADAPTER

If power cord is worn or cut, or damaged in any way,

have it replaced immediately.

Your unit is for use on !20 volts, and has a plug that

looks like the one shown below

3-PRONG

PLUG

PRONG

PROPER_

GROUNDED

3-PRONG OUTLET

This power toot is equipped with a 3-conductor cord

and grounding type plug approved by Underwriters'

Laboratories. The ground conductor has a green jacket

and is attached to the tool housing at one end and to

the ground prong in the attachment plug at the other

end

An adapter as illustrated is available for connecting

plugs to 2-prong receptacles. The green grounding lug

extending from the adapter must be connected to a per-

manent ground such as to a properly grounded outlet

box

NOTE: The adapter illustrated is for use only if you

already have a properly grounded 2-prong receptacle.

NOTE: Make sure the proper extension cord is used

and is in good condition

The use of any extension cord will cause some loss of

power. To keep this to a minimum and to prevent over-

heating and motor burn-out, use the table below to

determine the minimum wire size (A.W.,G) extension

cord

Use only a single cord when an extension cord is

required.. The cord must be a 3 wire extension cord

which has a 3-prong receptacle that will accept the

tools plug.

Length of the

Cord

25 Feet

50 Feet

100 Feet

Wire Sizes Required

(American Wtre Gage Number)

120V Lines

No..t6

No. 16

No. 16

Page 6

contents

POWER TOOL WARRANTY ..................................... 2

SAFETY INSTRUCTIONS FOR BAND SAW ..............2

GLOSSARY OF TERMS FOR WOODWORKING ....4

MOTOR SPECIFICATIONS AND ELECTRICAL

REQUIREMENTS ............ ............................................. 5

UNPACKING AND CHECKING CONTENTS .......... 6

ASSEMBLY

Mounting Band Saw to Workbench ................ 7

Installingthe Table ............................... 8

Installing the Blade ........................................ 9

Tensioning the Blade ..................................... 10

BASIC BAND SAW OPERATION ...................... 15

MAINTENANCE ......................................... 18

RECOMMENDED ACCESSORIES ................... 18

TROUBLESHOOTING ...................... 19

REPAIR PARTS ............................ 20

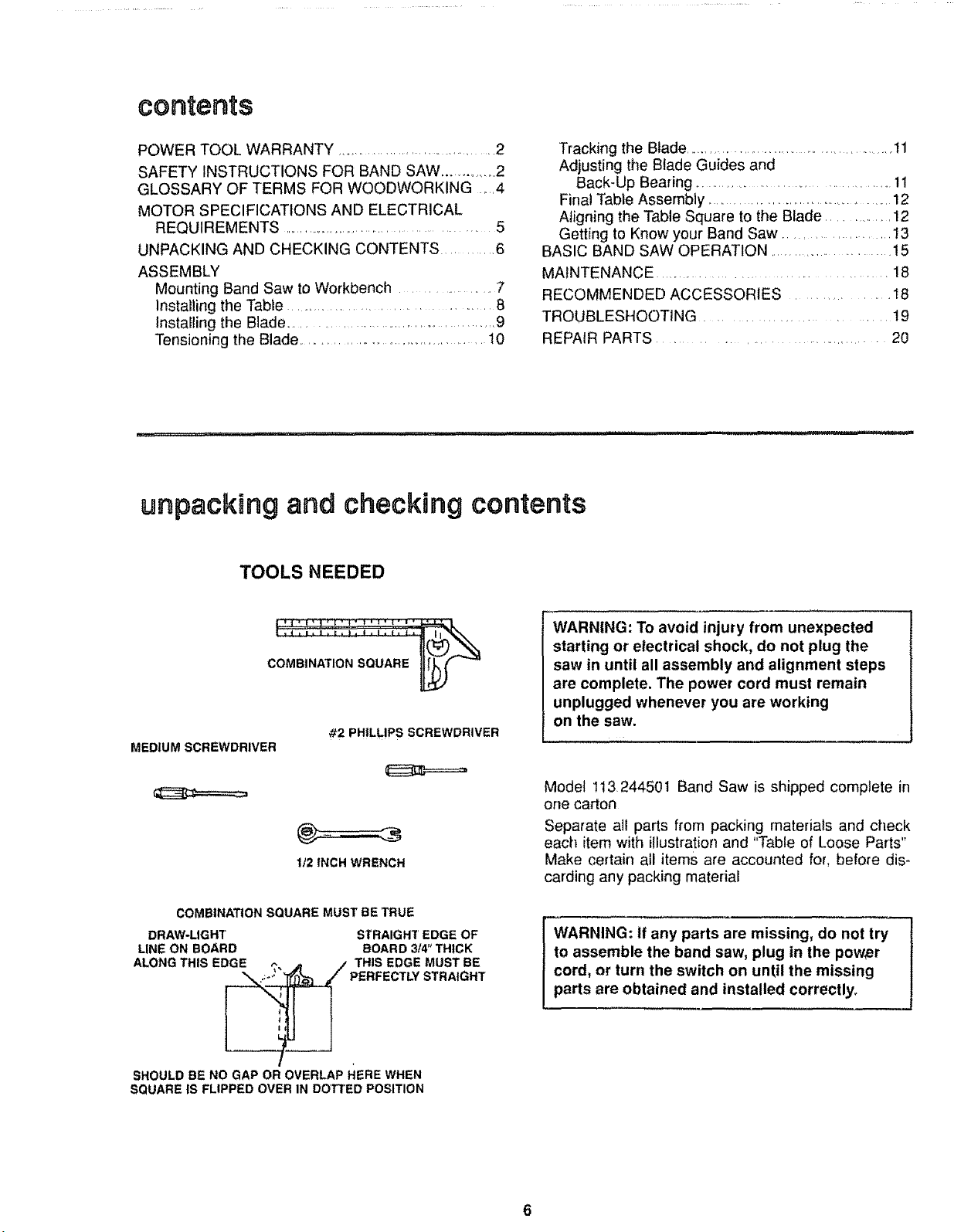

unpacking and checking contents

TOOLS NEEDED

Tracking the Blade .............................................. 11

Adjusting the Blade Guides and

Back-Up Bearing .................................... 1!

Final Table Assembly ........................................... 12

Aligning the Table Square to the Blade ............ 12

Getting to Knew your Band Saw .......................... 13

[,','",q", I" • =- i'"1"_"_"'_" '

COMBINATION SQ

#2 PHILLIPS SCREWDRIVER

MEDIUM SCREWDRIVER

1/2 INCH WRENCH

COMBINATION SQUARE MUST BE TRUE

DRAW-LIGHT STRAIGHT EDGE OF

LINE ON BOARD BOARD 314"THICK

ALONO 1.,S

WARNING: To avoid injury from unexpected

starting or electrical shock, do not plug the

saw in until all assembly and alignment steps

are complete. The power cord must remain

unplugged whenever you are working

on the saw.

Model 113244501 Band Saw is shipped complete in

one carton

Separate all parts from packing materials and check

each item with illustration and "Table of Loose Parts"

Make certain all items are accounted for, before dis-

carding any packing material

WARNING: tf any parts are missing, do not try

to assemble the band saw, plug in the power

cord, or turn the switch on until the missing

parts are obtained and installed correctly,

SHOULD BE NO GAP OR OVERLAP HERE WHEN

SQUARE tS FLIPPED OVER IN DOn"ED POSITION

Page 7

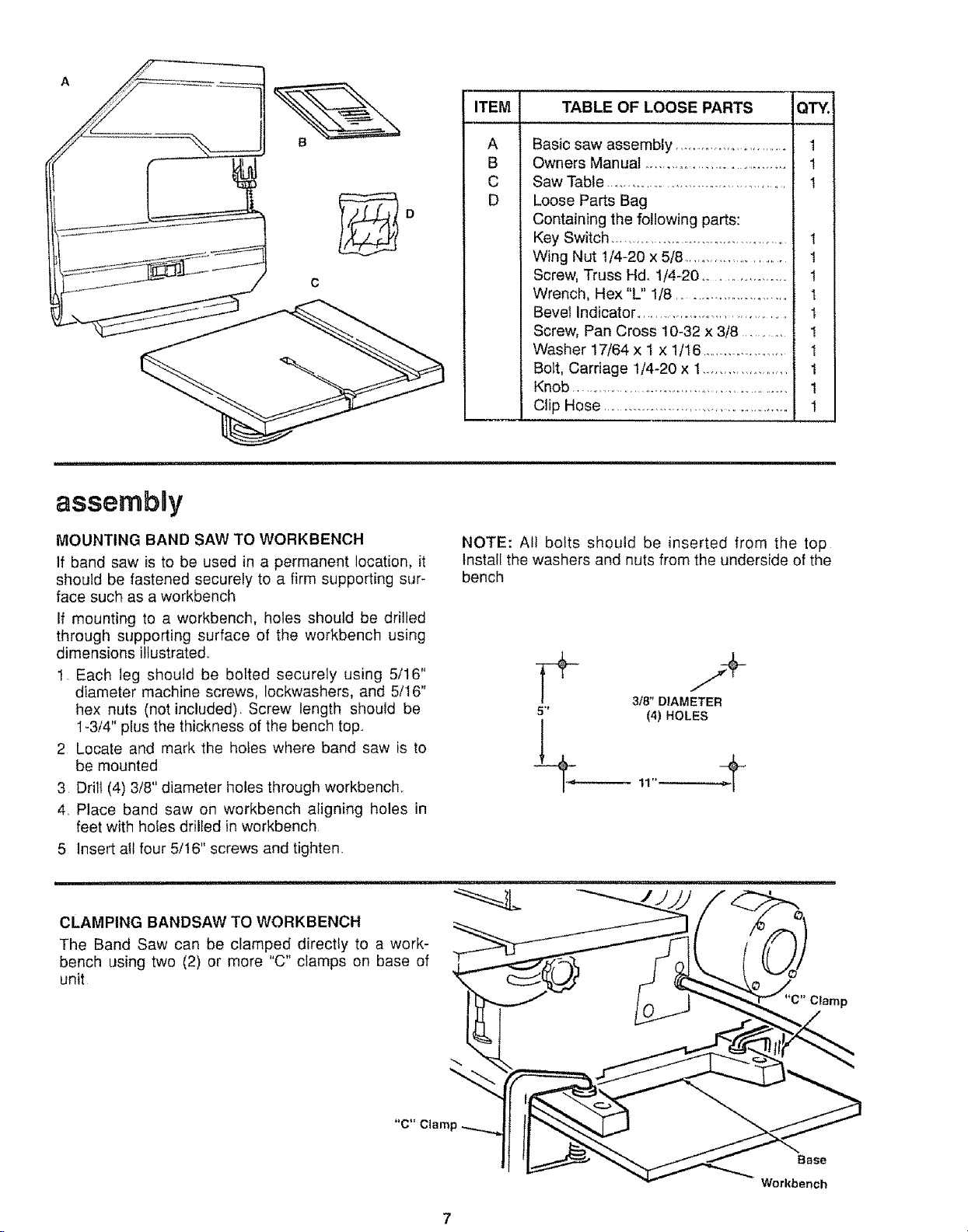

assernbBy

ITEM

=

A

B

C

D

TABLE OF LOOSE PARTS QTY.

Basic saw assembly ............................ 1

Owners Manual ..................................... 1

Saw Table ........................................... t

Loose Parts Bag

Containing the following parts:

Key Switch ......................................... 1

Wing Nut t/4-20 x 5/8 .......................... 1

C

Screw, Truss Hdo 1/4-20 .................. 1

Wrench, Hex "L" 1/8 ......................... 1

Bevel Indicator .................................... 1

Screw, Pan Cross 10-32 x 3/8 ............ 1

Washer 17/64 x 1 x 1/16 ..................... 1

Bolt, Carriage I/4-20 x 1.................... 1

Knob ...................................................... 1

Clip Hose .............................................. 1

MOUNTING BAND SAW TO WORKBENCH

If band saw is to be used in a permanent location, it

should be fastened securely to a firm supporting sur-

face such as a workbench

If mounting to a workbench, holes should be drilled

through supporting surface of the workbench using

dimensions illustrated,

1 Each leg should be bolted securely using 5/16"

diameter machine screws, Iockwashers, and 5/16"

hex nuts (not included)Screw length should be

1-3/4" plus the thickness of the bench top,

2 Locate and mark the holes where band saw is to

be mounted

3 Drill (4) 3/8" diameter holes through workbench,,

4, Place band saw on workbench aligning holes in

feet with holes drilled in workbench

5 Insert all four 5/16" screws and tighten,

i i i ii 1,1,, , ii ,,11,i,l,ll,llr

CLAMPING BANDSAW TO WORKBENCH

The Band Saw can be clamped directly to a work-

bench LJsingtwo (2) or more "C" clamps on base of

unit

NOTE: All bolts should be inserted from the top

tnstall the washers and nuts from the underside of the

bench

3/8" DIAMETER

5"' (4) HOLES

"C" Clamp

Workbench

Page 8

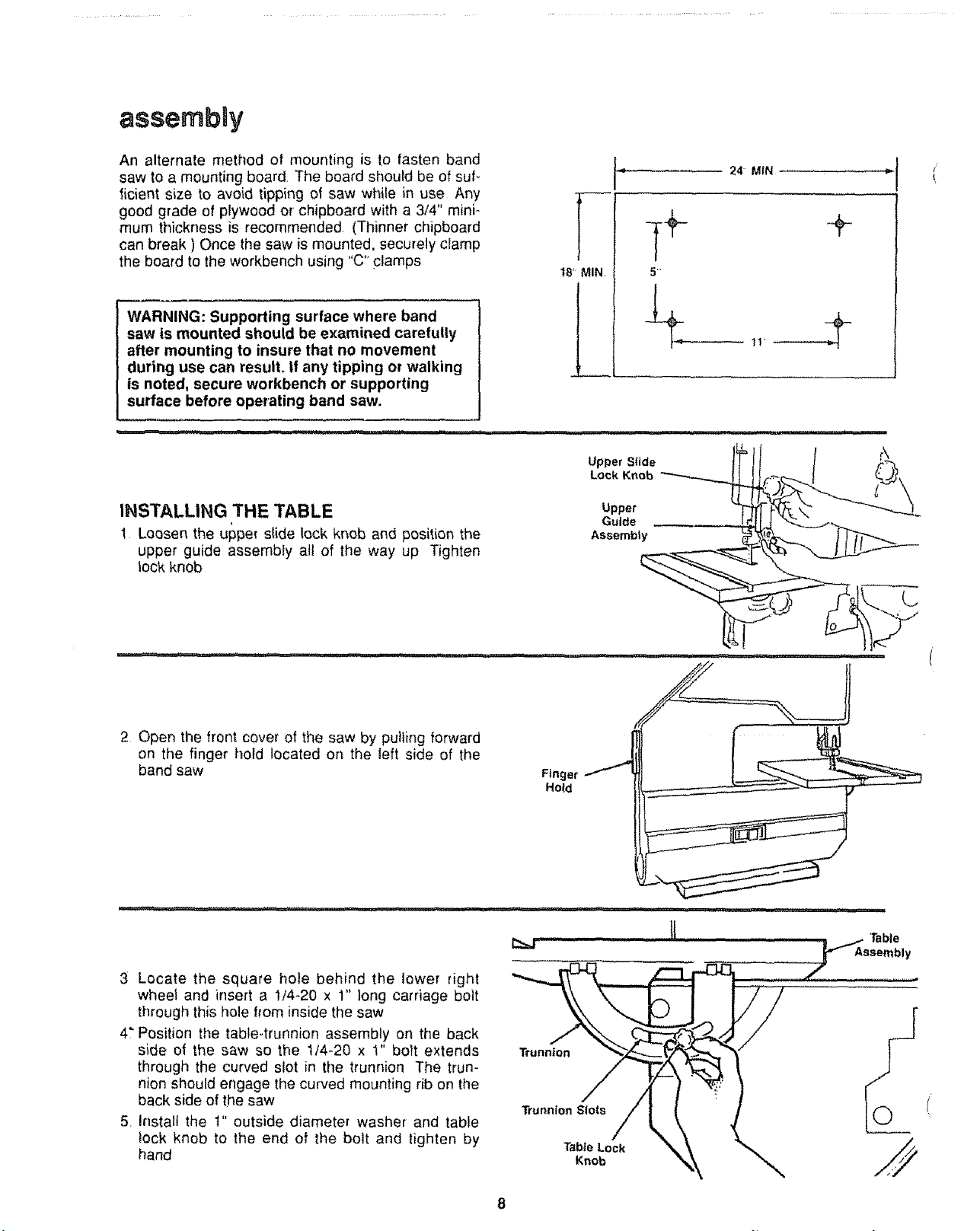

assembOy

An alternate method of mounting is to fasten band

saw to a mounting board The board should be of suf-

ficient size to avoid tipping el saw while in use Any

good grade of plywood or chipboard with a 3/4" mini-

mum thickness is recommended, (Thinner chipboard

can break ) Once the saw is mounted, securely clamp

the board to the workbench using "C" ;:lamps

WARNING: Supporting surface where band

saw is mounted should be examined carefully

after mounting to insure that no movement

during use can result, tf any tipping or walking

is noted, secure workbench or supporting

surface before operating band saw.

INSTALLING THE TABLE

1 Loosen the upper slide lock knob and position the

upper guide assembly atl of the way up Tighten

lock knob

24 MIN ...... .......

t

18' MIN,

Upper Slide

Lock Knob

Upper

Guide ,

Assembly

2 Open the front cover of the saw by pulling forward

on the finger hold located on the left side of the

band saw

3 Locate the square hole behind the lower right

wheet and insert a 1/4-20 x 1" long carriage bolt

through this hole from inside the saw

4" Position the table-trunnion assembly on the back

side of the saw so the 1/4-20 x l" boit extends

through the curved slot in the trunnion The trun-

nion should engage the curved mounting rib on the

back side of the saw

5, Install the t" outside diameter washer and table

lock knob to the end of the bolt and tighten by

hand

Finger

Ho_d

Trunnion

Trunnion Slots

Table Lock

Knob

[

/

!o

Page 9

INSTALLING THE BLADE

and unplug saw before removing or installing

I ARNING:Turn off saw, remove switch key

blade°

I Loosen the upper slide lock knob and position the

guide assembly about half way between the table

and the frame Tighten the !ock knob

2 Open th_ front cover of the saw by pulling forward

on the finger hold located on the left side of the

band saw

3 Remove the blade guard by loosening the screw

located on the side of the guard using a #2 phiffips

screwdriver Slide the guard up and pull forward to

remove it from the blade guide support

4 Unscrew the upper blade guides using a !/8 inch

hex "L" wrench and separate them about I/8 inch

Repeat this step for the lower blade guides

NOTE: There is a patch on the blade guide(s)

threads that makes them difficult to turn This is nec-

essary to prevent rotation of the guides during opera-

tion of the saw

Upper Slide

Lock Knob

Upper

Guide

AssembI

Guide

Blade _'_'_"(_

5 Loosen the setscrew which locks the upper blade

guide support (located on the left side of the sup-

port behind the bearing) Push the support all the

way back Loosen the setscrew holding the upper

back-up bearing (Located on the right side of the

upper slide) Push the bearing all the way back

With the guide support and back-up bearing

pushed back, slightly tighten both set screws

6 Loosen the setscrew which locks the lower blade

guide support (accessed through notch in frame

located below table) Push the support all the way

back Loosen the setscrew holding the lower back-

up bearing Push the bearing all the way back

With the guide support and back-up bearing

pushed back, tighten both set screws,

i , ilillilill illiq; lil/ i lii liiiiiiilll ,

Upper Slide _

Upper Blade

Guide Support

Set Screw Upper

Bearing

BLADE GUARD Guide Support

REMOVED FOR

CLARITY

=m.llJ i.=..,i == N.=..,,I =,,.

Set Screw

k-Up Bearing

Set Screw

Bac Blade

L LowerBack-UpBearing

P

.....

Table Removed For

Visual Clarity

Page 10

7 The upper wheel needs to be placed in its lowest

position Locate the tension lock knob on the

back of the saw and turn it counterclockwise

approximately two turns Lift the tension catch

away from the teeth and move it to its lowest

position

CAUTION: To avoid being scraped, if the blade

should suddenly uncoil, wear safety goggles.

Carefully uncoil the blade holding it at

arms length.

8 Uncoil the blade

9_ Slide the blade into the slot of the table with the

teeth facing forward and down toward the table

10 Place the blade on all three wheels Center the

blade on the rubber tires

ill,,!lii,l,l,,,llll,i

Tension

Catch

Drive Wheel!

illlll.......................................

TensionWheel

Slot in Table

1

r Wheel

WARNING: Turn off saw, remove switch key

and unplug before making arty adjustments.

TENSIONING THE BLADE

1._With one hand on the knob and the other on the

tension catch, lift up on the tension assembly until

the slack in the blade is eliminated. Note which

notch the top of the tension catch is closest to.

2_ Continue to pult up on the tension assembly until it

has moved two or three notches above where the

blade first straightened out. Engage the teeth on

the catch into the notches. This is the proper ten-

sion for a !/4" blade.

NOTE: If using an 1/8" blade the tension assembly

should be positioned one to two notches above the

point where the blade first straightened out.

3. Tighten the tension lock knob in order to hold the

tension assembly in place,

Tension /

Aot..,,ng

Tension

Lock Knob

NOTE: Over tensioning of blade carl cause excessive

wear of wheel bearings and motor and shorten blade

life.

10

Page 11

WARNING: Turn off saw, remove switch key |

and unplug before making any adjustments°

TRACKING THE BLADE

Blade tension must be properly adjusted before

tracking the blade.

1 Slowly turn the upper wheel clockwise by hand

and watch the blade on the tire If the blade moves

away from the center of the tire the tracking will

have to be adjusted

2 Insert a 1/8" hex wrench into the tracking adjust-

ment screw located on the back of the saw behind

the upper wheel

3 a If the blade moved toward the front of the saw

turn the adjustment screw in (clockwise) while

turning the wheel by hand, until the blade rides

in the center of the tire

b If the blade moved away from the front of the

saw turn the adjustment screw out (counter

clockwise) while turning the wheel by hand, until

the blade rides in the center of the tire

4 Check the position of the btade on the other tires

The blade should be completely on the tire If not,

adjust the tracking until the blade is on all three

tires

5 Rotate the upper wheel by hand in a clockwise

direction for a few more turns Make sure the blade

stays in the same location on the tires Readjust if

necessary, until blade is tracking properly

m ii M I'll I I'I'IH'II, II

]

J

Tracking Adjustment

Set Screw

WARNING: Turn off saw, remove switch key ]

and unplug before making any adjustments.

ADJUSTING THE BLADE GUIDES AND

BACK-UP BEARING

NOTE: The upper and lower blade guides and back-

up bearings support the band saw blade during cut-

ting operations The adjustment of the guides and

bearings should be checked whenever a different

blade is installed

1 Ad)ust the back-up bearing first Loosen the rear

set screw using a 1/8" hex wrench (This set screw

is located on the right side of the upper slide for

the upper bearing and on the right side of the

frame just below the table for the lower bearing )

2 Move the back-up bearing to within 1/32" of the

b{ade Tighten the rear set screw Repeat on the

other back-up bearing

NOTE: The back-up bearing is to support the back

edge of the blade while cutting The blade should not

contact the bearings when you stop cutting

3 Adjust the position of the blade guide support next

Loosen the front set screw using a 1/8" hex

wrench (This set screw is located on the left side

of the support for the upper guides and the right

side for the lower guides )

4 Slide the b_ade guide support on the shaft until the

front edge of the blade guides are about 1/32"

behind the gullet of the blade Tighten the set

screw Repeat for the other guide

J

Thrust

Bearing

11

Page 12

NOTE: Letting the blade teeth hit the blade guides

while using the band saw will ruin the blade° The set

of the teeth and the sharpened edge of the teeth

would be damaged Proper adjustment of the upper

and lower blade guide assemblies wil! prevent this

from happening

5 Adjust the blade guides last Use a 1/8" hex

wrench to turn the blade guides in or out to where

they just clear the side of the blade Do this for all

four guides

NOTE: There is a patch on the blade guide threads

that makes them difficult to turn This is necessary to

prevent rotation of the guides during operation of the

saw

6 Reinstall blade guard and tighten screw

7 Close the front cover of the saw

WARNINGI Never start the saw with the cover

pen. Thrown blades can cause injury,

Saw

Biade

Blade

Guides

FINAL TABLE ASSEMBLY

1 Close the front cover of the band saw and snap in

place

2, Locate a 1/4-20 x 5/8 truss head screw, and a 1/4-

20 wing nut in loose parts Insert screw into hole in

table top as illustrated

3 From the underside of the table, install wing nut

onto the truss head screw and tighten finger tight

This will keep the table flat and in alignment

unplug before making any adjustments.

WARNING:Turn off saw, remove switch key and

ALIGNING THE TABLE SQUARE

TO THE BLADE

1 Loosen the upper slide lock knob and position the

guide assembly all the way up Tighten the lock

knob

2 Loosen table lock knob

3 Place a small square on the table beside the blade

as illustrated,

4 Holding the teft edge of the table (near the zero

stop set screw), tilt the table up or down to align

tabte 90 degrees to blade (0 degree position)

Tighten lock knob

5 Adjust the zero stop set screw using a 1/8" hex

wrench until the set screw just touches the frame

6 Check squareness of blade to table Make

readjustments if necessary

Combination

,_.._ TrussHead

Screw

Nut

Zero Stop

Screw

12

Page 13

7 Locatethebevelindicatorand10-32x 3/8"long

panheadscrewinloosepartsbag,

8 Usea #2phillipsscrewdriverto attachthebevel

indicatorto thebackof the frame,in thesmall

recessbelowthetrunnion,withthe 10-32x 3/8"

screw

9 Alignthebevelindicatorwiththe"0"degreemark

onthetrunnionandtightenthescrew

INSTALLING THE HOSE CLIP

! Locate the Hose Clip in the loose parts bag

Identify the barbs on the clip

2, Open the front cover of the saw by pulling forward

on the finger hold located on the left side of the

band saw, Locate the notch in the Frame at the

sawdust ejection port

,I,I ,.dlc o.

....i i ul, ll,,i,Ul ,i,

Barbs

3 Position the Hose Clip with the barbs to the back

side of the band saw Slide the Hose Clip into the

notch Push the clip until it is fully seated on the

Frame The Hose Clip will secure a Wet/Dry vac

hose in place for sawdust collection,

Notch

Hose Clip

13

Page 14

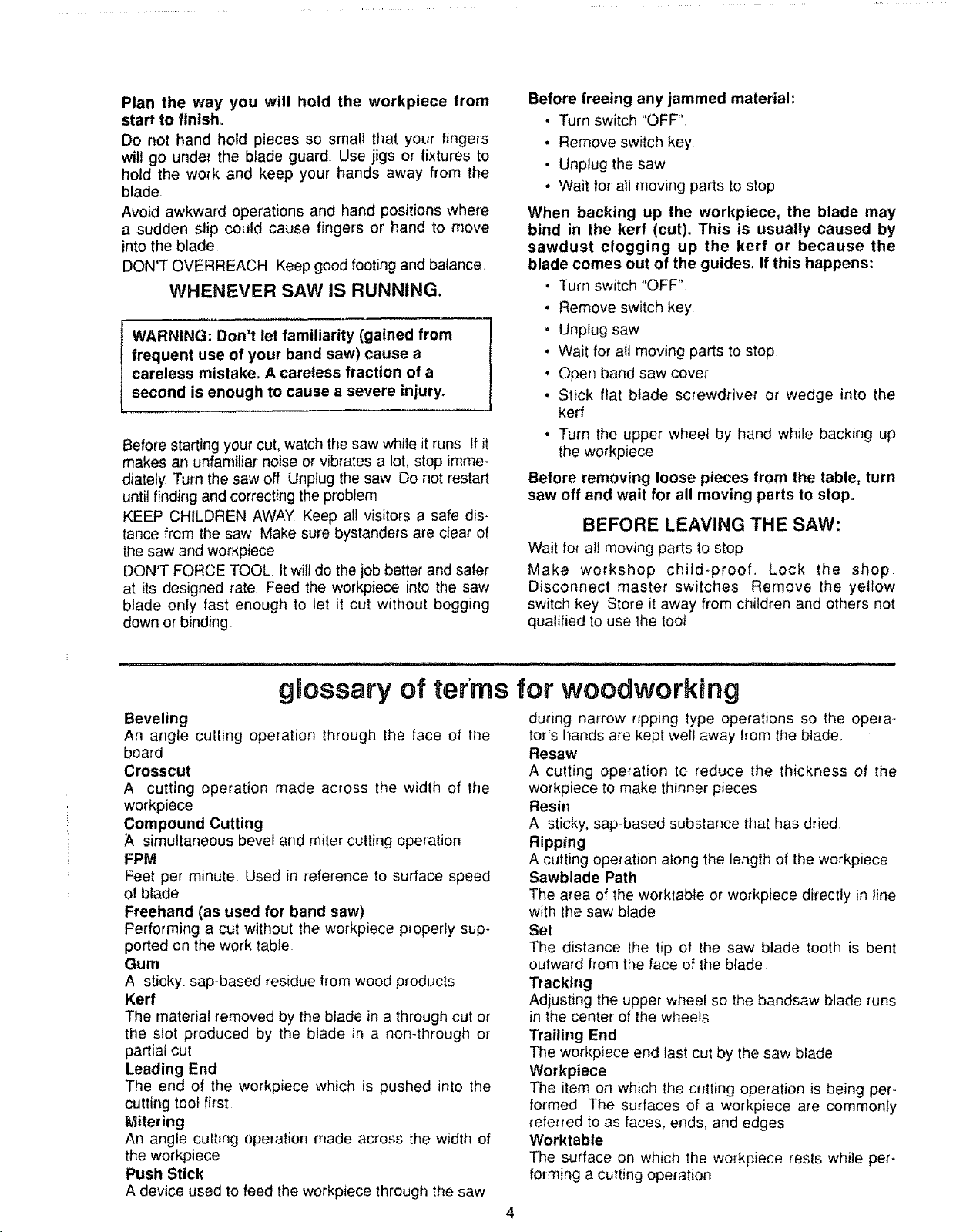

getting to know your band saw

Frame

Tension

Catch

Cover

9 Wrench Holder

2 Upper Slide

Lock Knob

.Table

Tracking Adjustment

Set Screw

5 Tension

Lock Knob

10 On-Off

Switch

7 Sawdust Hose Clip

Ejection

Port

NOTE: Cover shown open for clarity

.................................................. =r,H,,=l= =ll,i H=

1,.Blade Guides.. Supports the blade and keeps it

from twisting during operation, An adjustment is

necessary when blades are changed or replaced

2. Upper slide lock knob , The upper' blade guide

assembly should just clear the workpiece while

cutting Always adjust the upper guide assembly

and lock the upper slide by tightening the upper

slide lock knob before turning on the band saw,

3 Table lock knob , , Loosening the knob allows

the table to be tilted and tightening the knob locks

the table in place.

8 Cover Hinges

1 Blade

Guides

4 Beve

Scale Bevel

indicator

3 Table

Lock

Knob

= ii H =H== ,i = ill= ,i,i =f,l= ................

4, Tilt (bevel) scale • Shows degree table is t/Ited

for bevel cutting

5 Tension Lock Knob • • controls the amount of

blade tension when changing blades

6 Tracking Adjustment Set Screw _ ,, adjust to

keep blade running in center of wheels,

7 Sawdust Ejection Port , sawdust is eliminated

from inside of machine Also. makes an exceJlent

hook-up for a Wet/Dry vac

8 Cover Hinges allows front cover to be opened

for making adjustments to machine

14

Page 15

9 WrenchHolder Keeps1/8"Hex'L" Wrench

convenientlylocatedforbladeguideadjustments

10 ON-OFFSWITCH.TheOn-OffSwitchhasalock-

ing feature THIS FEATURE IS INTENDED TO

HELP PREVENT UNAUTHORIZED AND POSSI-

BLY HAZARDOUS USE BY CHILDREN AND

OTHERS

a To turn machine on, insert key into switch

NOTE: Key is made of yellow plastic; locate in Ioose

parts bag

b Insert finger under switch lever and putt end of

switch out

c To turn machine OFF PUSH lever in

NEVER LEAVE THE MACHINE UNATTENDED

UNTIL IT HAS COME TO A COMPLETE STOP.

..... i, i, , ,i iiiii

d To lock switch in OFF position . hold switch IN

with one hand REMOVE key with other

hand

WARNING: For your own safety, always lock

the switch "OFF" when machine is not in

use.,, remove key and keep it in a safe

place.,, also. ,, in the event of a power failure

(all of your lights go out) turn switch off. _.

remove the key and store it away from

band saw. This will prevent the machine

from starting up again when the power

comes back onr

\

\

15

Page 16

Basic Saw Operations

BEFORE EACH USE:

Inspect your saw.

DISCONNECT THE SAW To avoid injury from acci-

dental starting, unplug the saw, turn the switch off

and remove the switch key before changing the

setup, opening covers, removing guards, or blade

CHECK FOR DAMAGED PARTS. Check for:

• alignment of moving paris,

• binding of moving parts,

• broken parts,

• stable mounting, and

• any other conditions that may affect the way the

saw works.

If any part is missing, bent, or broken in any way, or

any electrical part doesn't work properly, turn the saw

off and unplug the saw REPLACE damaged, miss-

ing, or failed parts before using the saw again

MAINTAIN TOOLS WITH CARE Keep the saw clean

for best and safest performance

REMOVE ADJUSTING KEYS AND WRENCHE, S

from tool before turning it on

To avoid injury from jams, slips or thrown pieces:

• Choose the right size and style blade for the

material and the type of cutting you plan to do

• USE ONLY RECOMMENDED ACCESSORIES

(See page 18) Consult this owner's manual for

recommended accessories Follow the instruc-

tions that come with the accessories The use of

improper accessories may cause risk of injury to

persons.

• Make sure the blade teeth point downward,

toward the table

• Make sure the blade guides and thrust bearings

are properly adjusted

• Make sure the blade tension is properly

adjusted

. Make sure the table lock knob is tight and no

parts have excessive play

• To avoid accidental blade contact, minimize btz

breakage and provide maximum blade supp_

always adjust the upper blade guide and bla,

guard to just clear the workpiece

• KEEP WORK AREA CLEAN Cluttered areas an

benches invite accidents Floor must not be slip

pery

To avoid burns or other fire damage, never use the saw

near flammable liquids, vapors or gases

Plan ahead to protect your eyes, hands,

face, ears.

KNOW YOUR SAW Read and understand the owner's

manual and labels affixed to the tool Learn its applica:

tion and limitations as well as the specific potential haz-

ards peculiar to this tool

To avoid injury from accidental contact ,with moving

parts, don't do layout, assembly, or setup work on the

saw while any parts are moving

AVOID ACCIDENTAL STARTING Make sure switch is

"OFF" before plugging saw into a power outlet

Plan your work.

• USE THE RIGHT TOOL Don't force tool or attach-

ment to do a job it was not designed to do

• Use this band saw to cut only wood, wood like

products, and plastics

Dress for safety.

Any power saw can throw foreign objects into the eyes

This can cause permanent eye damage Wear safety

goggles (not glasses) that comply with ANSI Z87 1

(shown on package) Everyday eyeglasses have only

impact resistant lenses The are not safety glasses

Safety goggles are available at Sears retail catalog

stores Glasses or goggles not in compliance with ANSI

Z87.1 could seriously hurt you when they break

• Do not wear loose clothing, gloves, neckties or

jewelry (rings, wrist watches) They can get caught

and draw you into moving parts

• Wear nonslip footwear

• Tie back long hair

- Roll long sleeves above the elbow

16

Page 17

• Noise levels vary widely To avoid possible hear-

ing damage, wear ear plugs or muffs when using

your saw tot hours at a time

• For dusty operations, wear a dust mask along

with the safety goggles

Inspect your workpiece,

Make sure there are no nails or toreign objects in the

part of the workpiece to be cut

Use extra caution with large, very small or awkward

workpieces:

• Use extra supports (tables, saw horses, blocks,

etc ) for any workpiece large enough to tip when

not held down to the table top

• NEVER use another person as a substitute for a

table extension, or as additional support for a

workpiece that is longer or wider then the basic

saw table, or to help feed, support or pull the work-

piece

• When cutting irregularly shaped workpieces, plan

your work so it will not pinch the blade A piece of

molding, for exampfe, must lay flat or be held by a

fixture or jig that will not let it twist, rock or slip while

being cut

Properly support round materiai such as dowel

rods, or tubing They have a tendency to roll during

a cut, causing the blade to "bite" To avoid this,

atways use a 'V' block or clamp the work to the

table

• Cut only one workpiece at a time

• Clear everything except the workpiece and retated

support devices off the table before turning the

saw on

Plan the way you will hold the workpiece from start

to finish.

WHENEVER SAW iS RUNNING.

WARNING: Don't let familiarity (gained from

frequent use of your band saw) cause a care-

less mistake. A careless fraction of a second is

enough to cause a severe injury.

Before starting your cut, watch the saw while it runs If it

makes an unfamiliar noise or vibrates a lot, stop imme-

diately, Turn the saw off Unplug the saw Do not restart

unlit finding and correcting the problem

KEEP CHILDREN AWAY Keep all visitors a safe dis-

tance from the saw Make sure bystanders are clear of

the saw and workpiece

DONT FORCE TOOL It will do the job better and safer

at its designed rate Feed the workpiece into the saw

blade only fast enough to let it cut without bogging

down or binding

Before freeing any jammed material:

• Turn switch "OFF"

• Remove switch key

• Unplug the saw

• Wait for all moving parts to stop

When backing up the workpiece, the blade may

bind in the kerf (cut). This is usually caused by

sawdust clogging up the kerf or because the blade

comes out of the guides. If this happens:

• Turn switch "OFF"

• Remove switch key

, Unplug saw

• Wait for all moving parts to stop

- Open band saw cover

• Stick flat blade screwdriver or wedge into the kerf,

• Turn the upper wheel by hand while backing up the

workpiece

Do not hand hold pieces so small that your fingers will

go under the blade guard Use jigs or fixtures to hold

the work and keep your hands away from the blade

Avoid awkward operations and hand positiondwhere a

sudden slip could cause fingers or hand to move into

the blade

DON T OVERREACH Keep good footing and balance

Before removing loose pieces from the table, turn

saw off and wait for all moving parts to stop.

BEFORE LEAVING THE SAW:

Wait for all moving parts to stop

Make workshop child-proof Lock the shop Disconnect

master switches Remove the yellow switch Key Store

it away from children and others not qualified to use the

tool.

17

Page 18

basic band saw operation

A band saw is basically a "curve cutting" machine It

is also used for straight-line cutting operations such

as cross cutting, ripping, mitering, beveling, com-

pound cutting, and resawmg It is not capable of

doing inside cutting,

This band saw is designed to cut wood and wood

like products only,

For general type scroll cutting, follow the pattern lines

by pushing and turning the workpiece at the same

time Don't try to turn the workpiece while engaged in

the blade without pushing it; the workpiece could bind

or twist the blade

A curve cut is best performed by keeping the pattern

line in line with the blade while turning the workpiece

before the radius of the curve is cut,. The blade

should cut in the middle of the pattern line (saw kerf)

since wood cutting band saw blades are thin

NOTE: Blade guard is raised and right hand removed

for clarity of picture only

Saw

Kerr

Workplece

?

Pattern Line Blade

RIGHT - Planning ahead by turning workpiece for

cutting a curve

NOTE: Blade guard is raised and right hand removed

for clarity of picture only

Workptece

WARNING: To avoid blade contact, adjUst the

upper guide assembly to just clear the

workpiece,

l r,Use both hands while feeding the work into the

blade, Hold the workpiece firmly against the table,

Use gentle pressure Do not force the work, but

allow the blade to cuL

2 The smallest diameter' circle that can be cut out is

, determined by the width of the blade,, A 1/4" wide

blade will cut a minimum diameter' of approximate-

ly 1-1/2" A 1/8" wide blade will cut a minimum

diameter of approximately 1/2",

Relief cuts are made when an intricate curve (too

small a radius for the blade) is to be cut buL A relief

cut is made by cutting through the scrap section of

workpiece to curve in pattern line, then carefully

backing blade out Several relief cuts should be made

for intricate curves, then follow pattern line as sec-

tions are cut off of curve "relieving" blade pressure,

Pattern Line

Blade

WRONG - Not planning ahead for cutting a curve

could bind or twist blade if workpiece is forced

NOTE: Blade guard is raised and right hand removed

for clarity of picture only

Workplece

\

Blade

Relief Cuts

/

PatternLine

NOTE: Blade guard is raised and right hand removed

for clarity of picture only,

18

Page 19

maintenance

WARNING: For your own safety, turn switch

"OFF", remove switch key and remove plug

from power outlet before maintaining

or lubricating your band saw.

TIRES

Pitch and sawdust that accumulates on the tires

should be removed with a stiff brush or scraped off

with a piece of wood Do not use a sharp knife or any

kind of solvent

GENERAL

Keep your Band Saw clean

Remove sawdust from the inside frequently

Do not allow pitch to accumulate on the table, blade

guides, or thrust bearings Clean them with

Craftsman Gum and Pitch Remover

Apply a thin coat of automobile-type wax to the table

top so the wood slides easily while cutting Also apply

wax to the inside surfaces of the trunnion

MOTOR/ELECTRICAL

Frequently vacuum or blow out any sawdust from the

motor

Wiring Diagram

{ co,a ,lo,t

White While

Black

.J__Green

Ground Screw

or damaged in any way, have it

f WARNING: If the power cord is worn, cut,

replaced immediately.

WARNING: To avoid fire or electrocution,

reassemble electric parts with only approved

service parts. Reassemble exactly as

originally assembled.

LUBRICATION

A!t of the BALL BEARINGS are permanently lubricat-

ed They require no further lubrication

_, i i IM I1,,I,' III I_ It1 III I I Ir I IIII '1I

sears recommends the following accessories

Sears may recommend other accessories not listed in

manual

See your nearest Sears Store or Catalog Department

for other accessories

Do not use any accessory unless you have received

and read complete instructionsfor its use

Item Cat. No.

Miter Gauge ............................................... _)-24214

Blades (56-7/8" length) ......................... See Catalog

Leg Set ................................................... 9-22244

Power Toot Handbook .............................. 9-29117

19

Page 20

troubleshooting

WARNING: For your own safety, turn switch

"OFF", remove switch key and remove plug

from power outlet before readjusting or

aligning your band saw.

TROUBLE REMEDY

Motor will not run. 1

PROBABLE CAUSE

t Damaged On-Off switch

Damaged power cord

2 Motor Damaged,

Replace damaged parts before using

Band Saw again

2

Consult Sears Service, Any attempt to repair this

motor may create a HAZARD unless repair

is done by a qualified service technician Repair

service is available at your nearest Sears Store.

Blade does not run in

the approximate center

1 Not tracking properly

.

Adjust tracking, see Assembly Section,

"Tracking the Blade"

of the upper wheel.

Band Saw slows down

when cutting.

mm

Blades breaking=

1, Cutting too small a radius

2 Dutl blade,

1, Too much tension,

Stop feeding, and back up the material slightly,

until the band saw speeds up,

Replace blade,

14

Adjust tension, See Assembly section

"Tensioning The Blade,"

v

Kink in blade caused by

cutting too small a radius

2,

Use correct cutting technique° See Basic

Band Saw Operation Section.

or turning the material too

fast when cutting

Saw is noisy when

running.

1 Too much blade tension

.,

Adjust blade tension. See Assembly section

"Tensioning The Blade"

Blade will not cut

straight.

Blade guides will

not stay in position

2, Blade guides and back_up

bearings are in contact with

the blade.

1 Blade guides and bearings

not,properly adjusted.

2, Worn or damaged blade,

Patch on blade guide

threads has deteriorated

allowing them to rotate

with the blade,

20

.

Adjust upper and lower blade guides and

bearings. See assembly section "Adjusting the

Blade Guides and Back-up Beating,"

Adjust upper and lower' blade guides and

bearings See Assembly section "Adjusting

Guides and Back-up Bearing,."

Replace blade

1,

Replace blade guides,

Page 21

repair parts

4

FOR 10-INCH BAND SAW 113.244501

Always order by Part Number - Not by Key Number

2

NO

1

2

3

4

5

6

7

Part

No.

820286

STD601103

817899

STD502502

820279

820281

820284

4

6

FIGURE 1

Description

i,in,,ll,,=

Guard Blade

. Scr Pan HD TY "TT"

10-32 x 3/8

Scr Soc Set 1/2 Dog Pt

1/4-20 x 1/2

" Scr Soc Set 1/4-20 x 114

Support Guide

Shaft w/Bearing

Slide Upper

Key

NO,,,II,

1

2

3

4

5

6

Pad

No,

u

60323

817935

820874

817915

815865_2

817149

5

FIGURE 2

Description

, i, i1,, i,i, i .... i,i ii1,1,lilt

Scr Truss 1/4-20 x 5/8

Table

Nut Wing Low Profile I/4-20

Trunnion

Scr Hx Hd TYTT 1/4_20x 5/8

Scr Locking Set 1/4-20

Page 22

40

:E FIGURE 2

18

FOR 10-INCH BAND SAW 113.244501

Always order by Part Number- Not by Key Number

45

_,..1 23

., 6 7

. _ _ 10

6 "_" 11

=m=lm

9

[

"_l 24

to

6

32

31

48

FIGURE 3

23

22

15

SEE FIGURE 1

46

SEE FIGURE 1 \_

7 _ 12

10

6

11

14

13

.... 47

Page 23

FOR IO-INCH BAND SAW 113.244501

Always order by Part Number- Not by Key Number

FIGURE 3

Key

No

1

3

4

5

6

7

8

9

10

11

12

!3

14

15

16

17

18

19

20

21

22

23

24

25

Part

820288

STD541031

STD551131

820269

816087

818146

820266

9-28137

9-26653

817911

817453-2

821725

817943

STD551037

820277

STD541025

STD551225

STD551025

820265

STD522507

STD551210

STD541110

820264

STD532510

STD502502

Description

=nil n,,

Pin Hinge

Nut, Hex 5/16-18

Lockwasher5/16

Support Wheel (Includes Key

No?s 2, 3 & 23)

ScrTr Cr Hd 1/4-20 x 1/2

Washer Nylon

Wheel tdler (Includes

Key No, 10)

* Wrench, Hex L 1/8

tBand Saw Blade 56-7/8

BandsawTire

Retaining Ring

Cover Front

(includes Key No. 46)

* NUt3/8-16 L.H.

* Washer 3/8 x 3/4 x 1/32

Wheel Drive (Includes

Key No. 10)

* NUt, Hex 1/4-20

* Lockwasher 1/4

*Washer 17/64 x 1 x 1/16

Foot Frame

* Screw Hex Hd 1/4-20 x 3/4

* Lockwasher Int NtO

* Nut, Hex 10-32

Shaft - Wheel

* Belt Crge 1/4-20xl

*Screw Soc. Set t/4-20 x 1/4

Key

No

26

27

28

29

3O

31

32

33

34

35

36

37

38

39

4O

41

42

43

44

45

Pad

NO,

,mn,,,n,,=l

820272

STD532525

820088

817944

STD511103

820493

816464

813989-1

STD375006

820273

9-22256

816113

STD600803

820274

61400

817149

820276

69164

STD512505

82I 679

46 821157

47 STD551237

48 821288

- SP5640

Description

Spring Blade Tension

* Bolt Crge 1/4-20 x 2-1/2

Catch Blade Tension

Indicator Bevel

* Screw Pan HD

! 0-32 x 3/8

Clip Hose

Latch Cover

Cord w/Plug

* Connector Wire

Motor

t Key Switch

Switch Locking

* Screw Pan HD TY 'TF"

8-32 x 3/8

Capacitor

Knob 1-3/8 Dia.

Screw Lock Set 1/4-20

Plate Cover

Relief-Strain

Screw Pan HD

1/4-20 x 1/2

Frame (includes Key No,'s

2, 3 & 23)

', Gasket

Lockwasher 3!8

Washer 1/2 x I x ,039

Owners Manual

(Not tUustrated)

t_

-t-Stock item - May Be Secured Through The Hardware Department Of Most Sears Retail Stores Or

Catalog Order Houses.

*Standard Hardware item - May Be Purchased Locally.

Page 24

MODEL NO.

1

For the repair or replacement parts you need

Call 7 am - 7 pm, 7 days a week

t -800-366-PART

(1-800-365-7278)

For in-home major brand repair service

Call 24 hours a day, 7 days a week

t =800=4=REPAIR

(1-800-473-7247)

The model number of your

10-Inch Band Saw will be

found on a plate located on

the back of the Band Saw

below the motor.

When requesting service or

ordedng parts, always

provide the following

Information:

° Product Type

* Model Number

• Part Number

• Part Description

j j

Forthe location of a

Sears Repair Service Center in your area

Call 24 hours a day, 7 days a week

1=800..488- t 222

For information on purchasing a Sears

Maintenance Agreement or to inquire

about an existing Agreement

Ca!l 9 am - 5 prn, Monday-Saturday

t =800=827=6655

America's Repair Specialists

SEARS,ROEBUCK AND CO., Hoffmann Estates, IL60179 U.S.A.

Part No, SP5640 Form No, SP5640 -t Printed in Taiwan 3/96

Loading...

Loading...