Sears 113.244200 Owner's Manual

OWNERS

MANUAL

MODEL NO.

113.244200

CAUTION"

Read Rules for

Safe Operation

and Instructions

Carefully

,___/A/_8

10" BAND SAW

Introduction

Operation

Maintenance

Repair Parts

i,i

®

SOLD BY SEARS, ROEBUCK AND CO , Chicago, IL 60684 U S A

PART NO, SP4998 PRINTED IN U S A

f

FULL ONE YEAR WARRANTY ON CRAFTSMAN 10" BAND SAW

tf this CRAFTSMAN 10" BAND SAW fails due to a defect in material or workmanship within one year from date of

purchase, Sears will repair it free of charge, This warranty applies only while this product is in use in the United States.

WARRANTY SERVICE IS AVAILABLE BY SIMPLY RETURNING THE TOOL TO THE NEAREST SEARS STORE

OR SERVICE CENTER THOUGHOUT THE UNITED STATES.

This warranty gives you specific legal rights and you may also have other rights which vary from state to state.

SEARS, ROEBUCK AND CO., DEPT, 698/731A SEARS TOWER, CHICAGO, IL 60684

"READ ALL INSTRUCTIONS" Failure to follow the SAFETY RULES listed L___-

BE LOW, and other basic safety precautions, may result in serious personal injury,

J

GENERAL SAFETY RULES

1, KEEP WORK AREAS CLEAN. Cluttered areas and

benches invite accidents,,

2. AVOID DANGEROUS ENVIRONMENT. Don't use

power tools in damp or wet locations. Keep work area

well lit+ Do not expose power tools to rain+ Do not

use tool in presence of flammable liquids or gases.

3, KEEP CHILDREN AWAY. Do not let visitors contact

tool or extension cord. All visitors should be kept

away from work area.

4. STORE IDLE TOOLS. When not in use, tools should

be stored in dry, high or locked up place-out of the

reach of children,

5+DON'T FORCE TOOL. It will do the job better and

safer at the rate for which it was designed

6. USE THE RIGHT TOOL. Don't force small toot or

attachment to do the job of a heavy-duty tool+ Don't

use tool for purpose not intended-for example; don't

use circular saw for cutting tree limbs or logs.

7. DRESS PROPERLY° Do not wear loose clothing or

jewelry. They can be caught in moving parts° Rubber

gloves and non-skid footwear are recommended when

working outdoors, Wear protective hair covering to

contain long hair.

8_USE SAFETY GLASSES+Also face or dust mask if

cutting operation is dusty.

9, DON'T ABUSE CORD. Never carry tool by cord or

yank it to disconnect from receptacle, Keep cord

from heat, oit, and sharp edges,

10. SECURE WORK. Use clamps or a vise to hold work,

It's safer than using your hand and it frees both hands

to operate tool+

11°DON'T OVERREACH+ Keep proper footing and

balance at all times,,

12. MAINTAIN TOOLS WITH CARE. Keep tools sharp

and clean for better and safer performance+ Follow

instructions for lubricating and changing accessories,,

Inspect tool cords periodically and if damaged, have

repaired by authorized service faciIity+ Inspect exten+

sion cords periodically and replace if damaged. Keep

handles dry, clean and free from oil and greaser

13, DISCONNECT TOOLS. When not in use; before

servicing; when changing blades, bits, cutters, etc+

14. REMOVE ADJUSTING KEYS AND WRENCHES.

Form habit of checking to see that keys and adjusting

wrenches are removed from toot before turning it on

15. AVOID ACCIDENTAL STARTING, Don't carry

plugged in tool with finger on switch. Be sure switch

is OFF when plugged in,

16, OUTDOOR USE EXTENSION CORDS, When tool is

used outdoors, use only extension cords suitable for

use outdoors and marked with suffix W+A (for UL),

or W (for CSA)o

17,

18+

AVOID GASEOUS AREAS, Do not operate portable

electric tools in gaseous or explosive atmospheres.

Motors in these tools normally spark, and the sparks

might ignite fumes.

DO NOT ALTER OR MISUSE TOOL These tools

are precision built. Any alteration or modification

not specified is misuse and may result in a dangerous

condition,

19, GUARD AGAINST ELECTRIC SHOCK, Prevent

body contact with grounded surfaces. For example;

pipes, radiators, ranges, refrigerator enclosures+,

20. STAY ALERT. Watch what you are doing. Use

common sense Do not operate tool when you are

tired.

21+

22+

CHECK DAMAGED PARTS. Before further use of

the too!, a guard or other part that is damaged should

be carefully checked to determine that it wit1 operate

property and perform its intended function+ Check

for alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any other

conditions that may affect its operation+ A guard or

other part that is damaged should be properly re+

paired or replaced, Have defective switches replaced°

Do not use tool if switch does not turn it on or off.

E_efore connecting the tool to a

power source (receptacle, outlet,

etc.) be sure the voltage supplied is the same as that

specified on the nameplate of the tool, A power

source with voltage greater than that specified for the

tool can result in SERIOUS INJURY to the user-as

well as damage to the tool If in doubt, DO NOT

PLUG IN THE TOOL. Using a power source with

voltage Iess than the nameplate rating is harmfu+ to

the motor.

\--- {"SAVE THESE INSTRUCTIONS"} ...."1"

r BAND SAW SAFETY RULES

@

For your own safety, do not attempt

to operate your band saw until it is

completely assembled and installed according to the

instructions . _ _ and until you read and understand

the following:

• GENERAL SAFETY INSTRUCTIONS..SeePage2

• BAND SAW SAFETY RULES ............ See Page3

@ GETTING TO KNOW YOUR BAND SAW See Page6

® OPERATIONS ......................... SeePage 9

® ADJUSTMENTS ................. See Pages 12 & 13

• MAINTENANCE ................. See Page t0

STABILITY OF SAW

• YOUR BAND SAW MUST BE BOLTED SECURELY

TO A STAND OR WORK BENCH In addition, if

there is any tendency for the band saw to tip over or

move during certain operations such ascutting long

heavy boards, bolt your band saw stand or work_

bench to the floor

LOCATION

• This band saw is intended for indoor use only..

0

@

@

@

0

0

When cutting a large piece of material, make sure

it is supported at table height.

Hold the work firmly against the table

Do not feed the material too fast while cutting. Only

feed the material fast enough so that the blade win

cut, Keep fingers away from the blade.

Use caution when cutting off material which is irreg-

ular in cross section which could pinch the blade

before the cut is completed. A piece of molding for

example must lay flat on the table and not be

permitted to rock while being cut

Use caution when cutting off round material such

as dowel rods, or tubing. They have a tendency to

roll while being cut causing the blade to "bite",

Always use a "V" block, or clamp round material to a

miter gauge.

When backing up the workpiece, the blade may bind

in the cut ....... this is usually caused by sawdust

clogging up the cut or because the blade comes out

of the guides. If this happens:

Turn off the band saw.., remove plug from power

source outlet , _remove cover from band saw, Insert

a screwdriver or wedge in the cut . _ . rotate the

wheels by hand while backing up the workpiece.

PROTECTION: EYES, HANDS,

FACE, EARS AND BODY

e Wear safety goggles and a face shiefd if operation is

dusty_ Wear ear plugs or muffs during extended

periods of operation. Do not wear gloves.. _rott tong

steeves above the elbow.

O Do not cut pieces of material too small to hold by

hand.

O Avoid awkward hand positions where a sudden slip

could cause a hand to move into the blade.

e Never turn your band saw "ON" before clearing the

table of all Obiects (tools, scraps of wood, etc.)

except for the workpiece and related feed or support

devices for the operation planned,

e Make sure the blade runs downward toward the table.

Always adjust tracking wheel correctly so that the

blade does not run off the wheels°

O

O

o

Never leave the band saw work area with the power

on, before the machine has come to acomplete stop,

or without removing and storing the switch key.

Never operate band saw with cover removed_

Do not perform layout, assembly, or setup work on

the table while the cutting toof is rotating.

Turn saw "off" and remove plug from power supply

outlet before installing or removing an accessory or

attachment.

Should any part of this band saw be missing, bent,

or fail in any way, or any electrical component fail to

perform properly, shut off power switch and remove

plug from power supply outlet_ Replace damaged,

missing, and/or failed parts before resuming opera-

tion.

THINK SAFETY

o Safety is a combination of operator common sense

and alertness whenever the band saw is in operation,

O Always adjust blade tension correctly.

O ALWAYS adjust the upper blade guide and blade

guard to just clear the workpiece to protect the

operator, to keep blade breakage to a minimum, and

to provide maximum support for blade°

O

Do not alfow familiarity (gained

from frequent use of your band

saw) to become commonplace. Always remember

that a careless fraction of a second is sufficient to

inflict severe injury.

J

Page 3

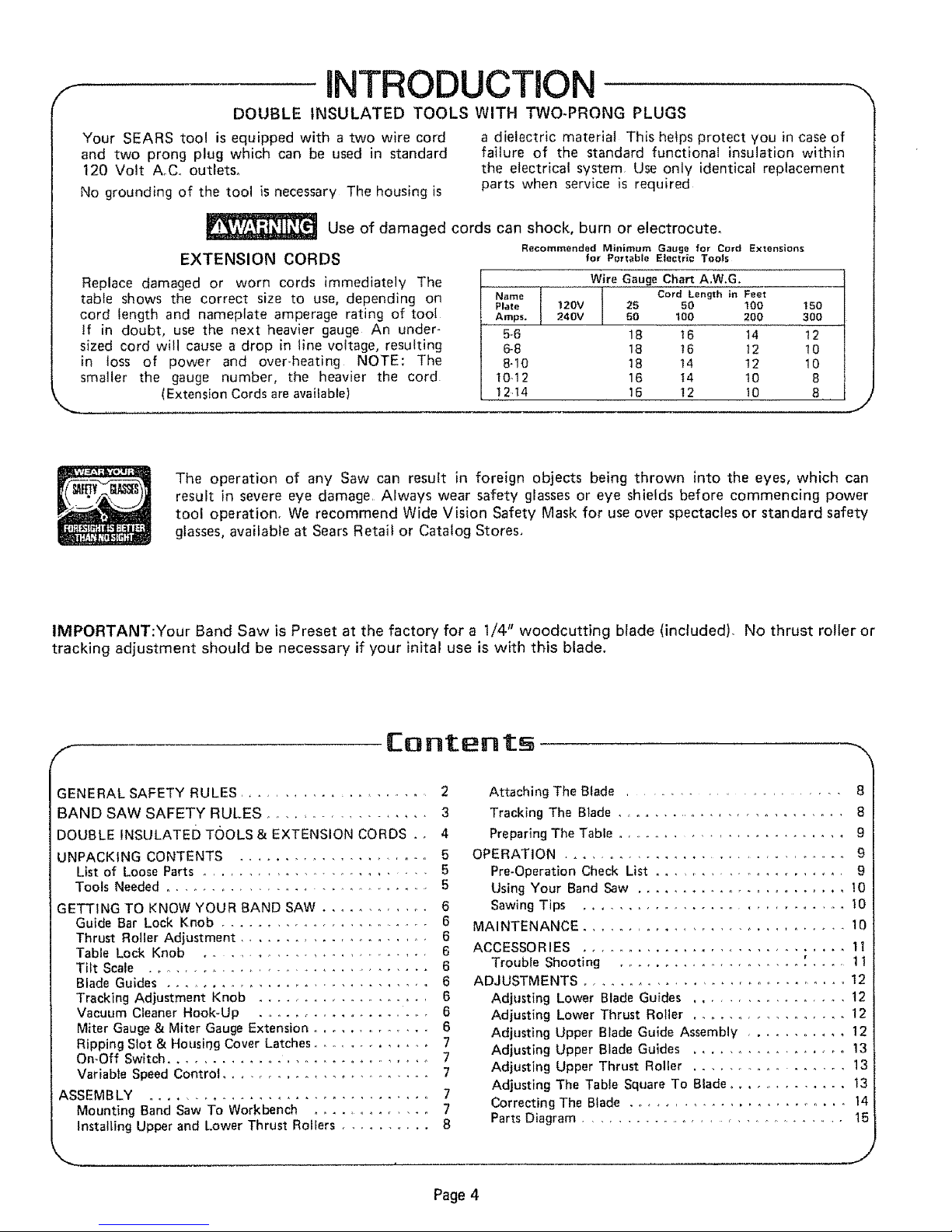

iNTRODUCTiON

DOUBLE INSULATED TOOLS WITH TWO-PRONG PLUGS

Your SEARS tool is equipped with a two wire cord

and two prong plug which can be used in standard

120 Volt A,C, outletso

No grounding of the tool is necessary The housing is

a dielectric material This helps protect you in case of

failure of the standard functional insulation within

the electrical system Use only identical replacement

parts when service is required

Use of damaged

EXTENSION CORDS

Replace damaged or worn cords immediately The

table shows the correct size to use, depending on

cord Iength and nameplate amperage rating of tool

tf in doubt, use the next heavier gauge An under-

sized cord will cause a drop in tine voltage, resulting

in loss of power and over-heating NOTE: The

smaller the gauge number, the heavier the cord

(Extension Cords are available)

cords can shock, burn or electrocute,

Recommended Minimum Gauge for Cord Extensions

for Portable Electric Toots

Wire Gauge Chart A.W.G.

Name Cord Length in Feet

Plate 12OV I 2s so 10o t5o

,,, Amps. 240V 50 100 200 300

5.6 18 t6 14 t2

6-8 18 !6 12 10

8-10 18 t4 t2 10

10.12 16 t4 10 8

12.14 16 12 10 8

J

The operation of any Saw can result in foreign objects being thrown into the eyes, which can

result in severe eye damage, Always wear safety glasses or eye shields before commencing power

tool operation, We recommend Wide Vision Safety Mask for use over spectacles or standard safety

glasses, available at Sears Retail or Catalog Stores,

IMPORTANT:Your Band Saw is Preset at the factory for a 1/4" woodcutting blade (included), No thrust rolfer or

tracking adjustment should be necessary if your inital use is with this blade.

GENERAL SAFETY RULES ..................... 2

BAND SAW SAFETY RULES ................... 3

DOUBLE INSULATED TOOLS& EXTENSION CORDS . , 4

UNPACKING CONTENTS ...................... 5

List of Loose Parts .......................... 5

Tools Needed ............................. 5

GETTING TO KNOW YOUR BAND SAW ............ 6

Guide Bar Lock Knob ......................... 6

Thrust Roller Adjustment .................... 6

Table Lock Knob ........................ 6

TiltScale ............................... 6

Blade Guides ............................. 6

Tracking Adjustment Knob ................... 6

Vacuum Cteaner Hook-Up .................... 6

Miter Gauge & Miter Gauge Extension ............. 6

Ripping Slot & Housk)g Cover Latches ............ 7

On-Off Switch .............................. 7

Variable Speed Control ....................... 7

ASSEMBLY ............................... 7

Mounting Band Saw To Workbench ............. 7

Installing Upper and Lower Thrust Rollers .......... 8

Attaching The Bfade ....................... 8

Tracking The Blade ........................... 8

Preparing The Table ......................... 9

OPERATION ................................ 9

Pre.Operation Check List ..................... 9

Using Your Band Saw ....................... 10

Sawing Tips ................................ 10

MAINTENANCE .............................. 10

ACCESSORIES ............................. 11

Trouble Shooting .................... [ ..... 1 1

ADJUSTMENTS .............................. 12

Adjusting Lower Blade Guides ................. 12

Adjusting Lower Thrust Roller ................. 12

Adjusting Upper Blade Guide Assembly ........... 12

Adjusting Upper Blade Guides ................. 13

Adjusting Upper Thrust Roller ................. 13

Adjusting The Table Square To Blade .............. 13

Correcting The Blade ........................ 14

Parts Diagram .................. .............. 15

_J

Page 4

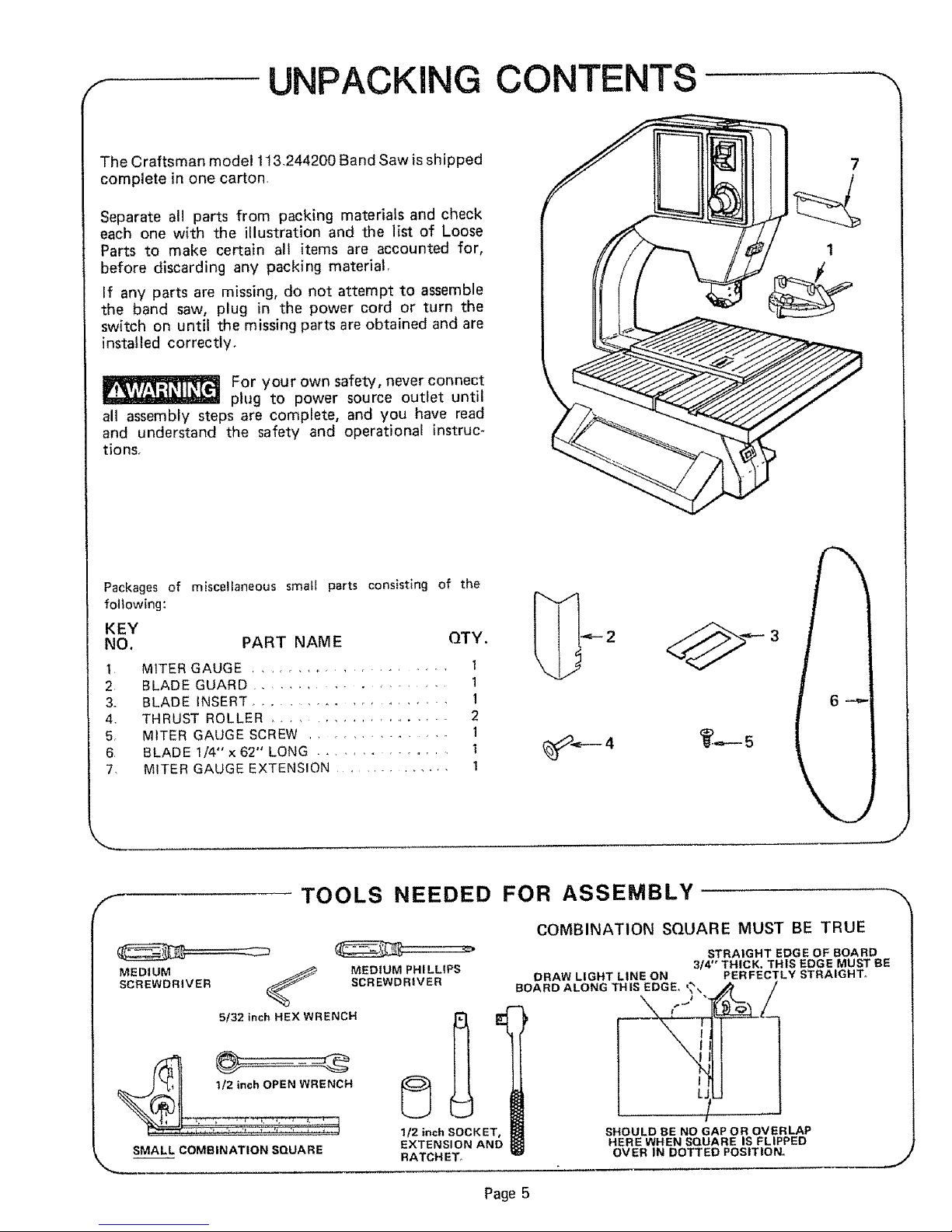

F UNPACKING CONTENTS

The Craftsman model 113,244200 Band Saw is shipped

complete in one carton,

Separate all parts from packing materials and check

each one with the illustration and the list of Loose

Parts to make certain all items are accounted for,

before discarding any packing material,

If any parts are missing, do not attempt to assemble

the band saw, plug in the power cord or turn the

switch on until the missing parts are obtained and are

installed correctly,

For your own safety, never connect

plug to power source outlet until

all assembly steps are comptete, and you have read

and understand the safety and operational instruc-

tionsr

7

Packages of miscelfaneous small parts consisting of the

following:

KEY

NO, PART NAME QTY.

1 MITER GAUGE .......... , .......... I

2 8LADE GUARD ................... 1

& BLADE INSERT ..................... 1

4. THRUST ROLLER .................... 2

5, MITER GAUGE SCREW .............. 1

6 BLADE 1/4" x 62" LONG ............... 1

7. MITER GAUGE EXTENSION .............. I

3

f

TOOLS NEEDED FOR ASSEMBLY

MEDIUM

SCREWDRIVER SCREWDRIVER

5132 inch HEX WRENCH

MEDIUM PHILLIPS

1/2 inch SOCKET,

EXTENSI ON AND

RATCHET_

COMBINATION SQUARE MUST BE TRUE

STRAIGHT EDGE OF BOARD

314" THICK. THIS EDGE MUST BE

DRAW LIGHT LINE ON PERFECTLY STRAIGHT.

BOARD ALONG THIS EDGE_?,,._, _t/_

I

L.

I

SHOULD BE NO GAPOR OVERLAP

HERE WHEN SQUARE IS FLIPPED

OVER IN DOTTED POSITION.

t2 inch OPEN WRENCH

SMALL COMBINATION SQUARE

J

Page 5

Loading...

Loading...