Page 1

Ii Future Reference

_AIRS

MODEL O.

113.236150

Serial

Number

Model and serial number may be

found attached to the rightside of

arm housing.

You should record both model

and serial number ina safe place

for future use.

i ii llllINNI ' II ................

FOR YOUR

SAFETY:

Read ALL

iNSTRUCTIONS

carefully

16 INCH RIABLE

SPEED SCROLL SAW

, assembly

• operating

repair parts

........... , ......... J _ ........................

Sold by SEARS, ROEBUCK AND CO., Chicago, IL. 60684 U.S.A.

Part No_SP5641

Page 2

Safer

SCROLL SAW

Scroll Saw fails due to a defect in material or work-

RETURNING:THE CRAFTSMAN SCROLL SAW TO THE

E CENTER/DEPARTMENT IN THE UNITED

':IS USED IN THE UNITED STATES.

'ights which vary from state to state.

IL: 60195

Safety is a combination of common sense, staying alert

and knowing how your scroll saw works. Read this man,

ual to understand this saw.

_Safety Signal Words

DANGER: means ifthe safety information is not followed

someone will be seriously;injured or killed.

WARNING: means if the-safety information isnot fol-

lowed someone could be seriously injured orkilled.

CAUTION: means ifthe safety information is not followed

someone might be injured.

Before Using The Saw

the following steps are: corn pleted.

Assembly and alignment (See pages 7-12)

Learn the:;:::useand function of the speed control ON-

OFF knob, bevel: lock knob, blade holders, blade sup,

port, hold down, tension knob, and blade guard. (See

pages14:16)

• Review and Understand at! safety instructions and

operating procedures in this manual.

• Review of the maintenance:meth0ds for this saWi:(See

page 20)

" Read the WARNING tabeJ!Seiow,found_n t_eba_eof

the saw.

, WARNING

To Avoid Injury from Unexpected Saw Movement:

• Turn saw off and unplug cord before moving the saw.

• Put the saw on a firm level surface where there is

plentyof room for handling and properly supporting the

workpiece.

• Support the saw so the table is level and the saw does

not rock.

= Boltthe sawto the work surface ifit tends to slip, walk,

or slide during operations like cutting long heavy

boards, or when using an auxiliary table.

o NEVER STAND ON TOOL. Serious injury could occur

if the tool tips or you accidentally hitthe cuttingtool. Do

not store anything above or near the tool where any-

one might stand on the too! to reach them.

To Avoid Injury or Death from Electrical Shock:

° GROUND THE SAW, This saw has an approved 3 con-

ductor cord and a 3-prong grounding type plug. Use

only:3-wire, grounded outlets rated 120 volts, 15

amperes (amps), The green conductor in the cord is

the grounding wire. :To avoid electrocution, NEVER

connect the green wire to a live terminal.

• Make sure your fingers do not touch the plug's metal

prongswhen plugging or unpluggingthe saw.

Before Each Use:

InsPect your saw,

DISCONNECT THE SAW. To avoid injury from accidental

starting, unplug the saw, turn the switch off and lock out

the switch before changing the setup, removing covers,

guards or blade.

CHECK DAMAGED PARTS. Check for:

- Alignment of moving parts.

• Bindingof movingparts.

• Broken parts.

• Stable mounting.

° Any other conditions that may affect the way the saw

works.

If any part is missing, bent or broken in any way, or an_

When Installing or Moving The Saw

dry indoor _place, prote=_edfrom rain:i Keep work area parts before using the saw again.

well lighted.

electrical parts don't work properly, turn the saw off aria

unplug the saw. REPLACE damaged, missing or failed

Page 3

Maintain Tools with Care, Keep the saw clean

for best and safest performance. Follow instruc-

ns for lubricating.

move adjusting keys and wrenches from tool before

turning it on.

To avoid injury from jams, slips or thrown pieces:

• Choose the right size and style blade for the material

and the type of cutting you plan to do.

• Use Only Recommended Accessories.

(See page 21). Consult this owners manual for recom-

mended accessories. Follow the instructions that come

with the accessories. The use of improper accesso-

ries may cause risk of injury to person.

• Make sure the blade teeth point downward, toward

the table.

• Make sure the blade tension is properly adjusted.

, Make sure the bevel lock knob is tight and no parts

have excessive play.

• To avoid accidental blade contact, minimize blade

breakage and provide maximum blade support, always

adjust the work and blade guard to just clear the work-

piece.

• Keep Work Area Clean. Cluttered areas and benches

invite accidents. Floor must not be slippery.

To avoid burns or other fire damage, never use the saw

._nearflammable liquids, vapors or gases.

!tan Ahead to Protect Your Eyes, Hands,

Face and Ears

, Know Your Saw. Read and understand the owners

manual and labels affixed to the tool. Learn it's appli-

cation and limitations as well as the specific potential

hazards peculiar to this tool.

° To avoid injury from accidental contact with moving

parts, don't do layout, assembly, or setup work on the

saw whi;_eany parts are moving.

• Avoid Accidental Starting. Make sure switch is

"OFF" before plugging saw into a power outlet.

Plan Your Work.

• Use The Right Tool. Don't force tool or attachment to

do a job it was not designed to do.

• Use this scroll saw to cut only wood, wood-like prod-

ucts, plastics and non-ferrous metals.

CAUTION: This saw is NOT designed for cutting fer-

rous metals like iron or steel. When cutting non-fer-

rous metals (brass, copper and aluminum, etc.),

metal shavings can react with wood dust and start a

fire. To avoid this:

°Remove all traces of wood dust from on and

round the saw.

Remove all metal shavings from on or around the

I saw before sawing woo d again,

Dress for safety.

Any power saw can throw foreign objects into the eyes.

This can cause permanent eye damage. Wear salety

goggles (not glasses) that comply with ANS! Z87.1

(shown on package). Everyday eyeglasses have only

impact resistant lenses. They are not safety glasses.

Safety goggles are available at Sears Retail Stores.

Glasses or goggles not in compliance with ANSI

Z87.1 could seriously hurt you when they break.

• Do not wear loose clothing, gloves, neckties or jewelry

(rings, wristwatches). They can get caught and draw

you into moving parts.

° Wear nonslip footwear.

• Tie back long hair.

• Roll long sleeves above the elbow.

° Noise levels vary widely. To avoid possible hearing

damage, wear ear plugs or muffs when using saw for

hours at a time.

° For dusty operations, wear a dust mask along with the

safety goggles.

Inspect Your Workpieceo

Make sure there are no nails orforeign objects in the part

of the workpiece to be cut.

Use Extra Caution with Large, Very Small or Awkward

Workpieces:

• Never use this too! to finish pieces too small to hold by

hand.

° Use extra supports (tables, saw horses, blocks, etc.)

for any workpieces large enough to tip when not held

down to the table top.

° Never use another person as a substitute for a table

extension, or as additional support for a workpiece or

to help feed, support or pull the workpiece.

• When cutting irregularly shaped workpieces, plan your

work so it will not pinch the blade. A piece of molding,

for example, must lay flat or be held by a fixture or jig

that will not let it twist, rock or slip while being cu_.

° Properly support round material such as dowel rods or

tubingJhey have a tendency to roll during a cut, caus-

ing the blade to "bite". To avoid this, always use "V"

block.

• Cut on!y one workpiece at a time.

• Clear everything except the workpiece and related

support devices of_the table before turning the saw on.

WEAR YOUR

Page 4

Y_U Wilti Holld the Workpiece Before Leaving the Saw:

in'i_h,:,_: ' ° Waitforall rnovingparts to stop.

•Donot handhc

sudden slip €_i

ithe blade.

o_:Don,t Overreach. Keep good footing and balance.

° Keep your face and body to one side of the blade, out

oftine with a possible thrown piece if the blade should

break.

:l:pieces s_:ismall thatyour:fingers will...... Make Workshop Child-proof. Unplug the saw. Lock

i_gula_.:iOse jigs or fixtures to :hold the shop or ONIOFF knob. Store the key away from

ipyo_r_hands away from the blade: children and others not qualified to use the toot.

;_e_ati_ns and hand positions where a

d cause fingers or hand to move into

Whenever Saw Is Running:

WARNING: Don't let familiarity (gained from fre-

quent use of your scroll saw) cause a careless

mistake. A careless fraction of a second is

enough to cause a Severe injury,

• Before starting your cut, watCh the saw while it runs. If

it makes an unfamiliar noise or Vibrates excessively,

stop' immediately Turn the saw off:Unplug the:saw:_Do

not restart untilfindingand correctin gthe problem,

• Keep Children Away. Keep;all:visitors a:saf edistance

i from :the saW.:Make,sure bystanders are:clear of the

saw and wo_tSieCei:i :

• Don-t;ForCe::T_l::it better and safer at

its designed rate. Feed the workpiece intothe saw

blade only fast enough to let ,it cut without:bogging

down or binding.=

Before Freeing Any Jammed Materia !,

• Turn switch"OFF"

• Unplug the saw.

• : Waitfor all moving parts to:stop.

When backing up the workpiece, the blade may bind

in the kerf (cut),This iiS usually caused by Sawdust

clogging up the kerr. If this happens:

• Turn switch "OFF".

• Unplug the saw.

° Wait forall moving padsto stop.

- With a flat blade screwdriver, turn motor shaft by hand,

by inserting into the slotted end of motor shaft located

at the center of the motor housing. Do this while back-

ing up the workpiece:

Before removing loose pieces from the table, turn

sawoff and wait foraU moving parts to stop:

Page 5

Motors, Specifications and Electricat Requirements , ....

This machine is equipped:witha var able speed motor_ It

_ired for operation on 120V, 60Hz, alternating current.

CAUTION: A direct current motor is used in thisj

saw. Changes to the internal wiring will create a fire I

hazard and may also create a shock hazard. ]

For replacement motor and control board, refer to parts

list in this manual.

Connecting To Power Supply Outlet

If power cord is worn or cut, or damaged in any way,

have it replaced immediately.

WARNING: if not properly grounded, this power tool

can cause an electrical shock, particularly when

used in damp locations close to plumbing. If an

electrical shock occurs there is potential of a sec-

ondary hazard, such as your hands contacting the

saw blade.

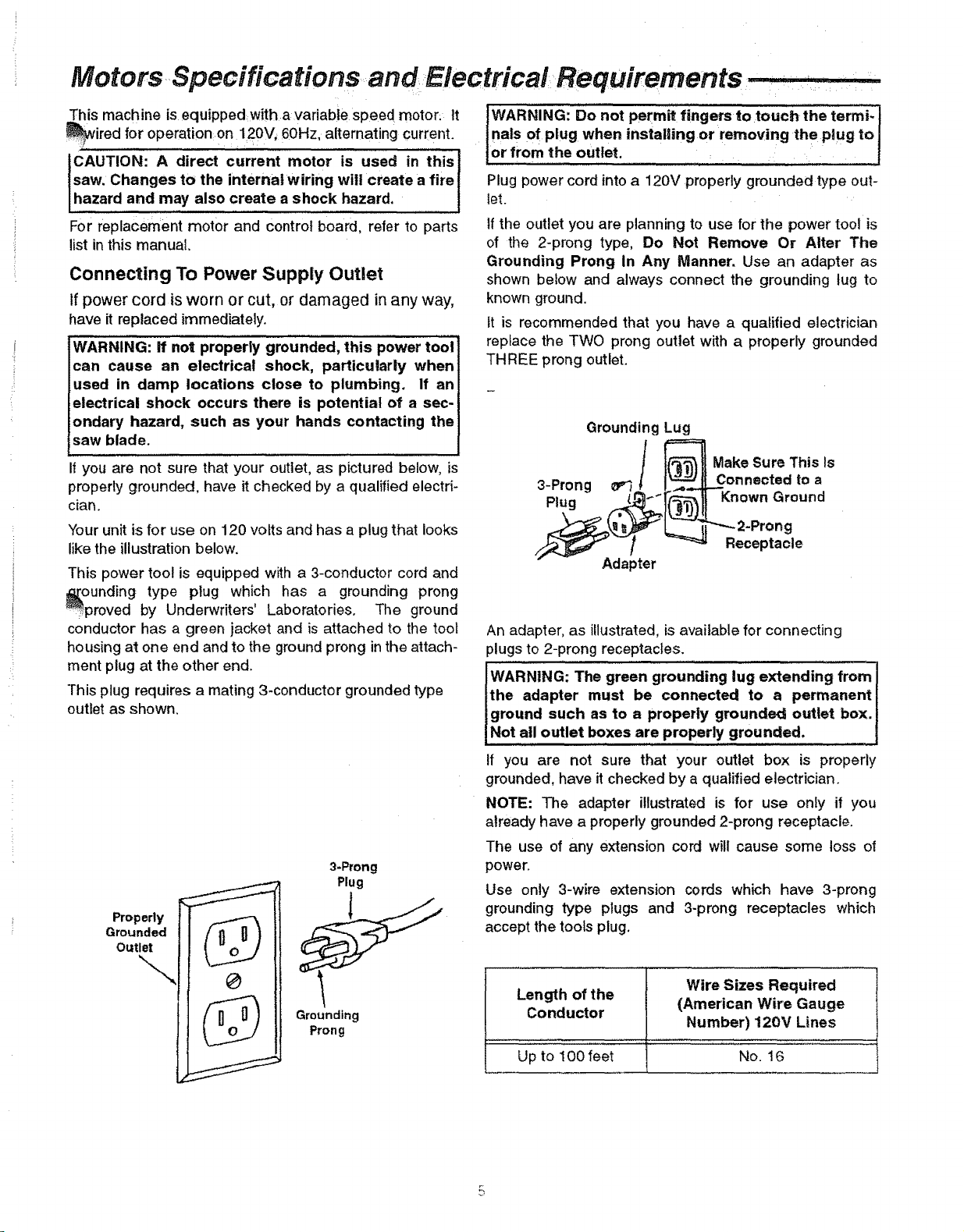

If you are not sure that your outlet, as pictured below, is

properly grounded, have it checked by a qualified electri-

cian.

Your unitis for use on 120 volts and has a plug that looks

like the illustration below.

This power tool is equipped with a 3-conductor cord and

_[ounding type plug which has a grounding prong

_v

._proved by Underwriters' Laboratories. The ground

conductor has a green jacket and is attached to the tool

housing at one end and to the ground prong in the attach-

ment plug at the other end.

This plug requires a mating 3-conductor grounded type

outlet as shown.

3-Prong

Plug

Properly

Grounded

Outlet

--..,

0

U

Grounding

Prong

WARNING: Do not permit fingers to touch the termi-

nals of plug when installing or removing the plug to

or from the outlet.

Plug power cord into a 120V properly grounded type out-

let.

Ifthe outlet you are planning to use for the power tool is

of the 2-prong type, Do Not Remove Or Alter The

Grounding Prong In Any Manner. Use an adapter as

shown below and always connect the grounding tug to

known ground.

It is recommended that you have a qualified electrician

replace the TWO prong outlet with a properly grounded

THREE prong outlet.

Grounding Lug

Make Sure This Is

3-Prong _ Connected to a

Plug Known Ground

,g

Receptacle

Adapter

An adapter, as illustrated, is available for connecting

plugs to 2-prong receptacles.

The

the adapter must be connected to a permanent

ground such as to a properly grounded outlet box.

IWARNING: green grounding lug extending from

Not all outlet boxes are properly grounded.

If you are not sure that your outlet box is properly

grounded, have it checked by a qualified electrician.

NOTE: The adapter illustrated is for use only if you

already have a properly grounded 2-prong receptacle.

The use of any extension cord will cause some loss of

power.

Use only 3-wire extension cords which have 3-prong

grounding type plugs and 3-prong receptacles which

accept the tools plug.

Wire Sizes Required

Length of the (American Wire Gauge

Conductor

Up to 100 feet No. 16

Number) 120V Lines

Page 6

Ke_:::; th_!s|ot::c_t!iby :th_ibiade:_ = ::!: :::::=:: 5,:Blade Tooth Set:-::the distance:that the edge of th_

2.:LeadlngEdge:_!_= ...... g ............. p .................: : _. ....... ........... : )

:/::.puShed:intotheibiade:first: : : ::::the:b!ade_::: ::::::::::_:!_,: ::: .....

.... 0fthework 6 Trailing Edge;:; the work iece ed e last cut b the

3_:Sawbtm:fe Path:,- the area : : p ..... y ..... ..... ......... .......P g . y

toward the sawbiade edge:;::: :i:Sawblade. : ,

:4-1:Bevel' -:the blllty'.....to slantthetable to make ........angie cuts. 7 , Wor:kp:iece :- the item :onWhichthe cutting operation is

:: angle cuttir_goperati0nl through the face:of the being performed.

board.

work' _:_wh:iCh is: : : saWblade tOothisb_ni (orset Outward fromthes,det

-::Contents

W_rranty Information.... ........................... ...................... 2

ety Instructions for Scroll Saws :...... i.. ..:i ::..:.. 2

Motor Specs and Electrical Requirements .................. :. 5

Glossary of Terms for Woodworking .................... .....:..:6

Unpacking and Checking Contents ............................... 6

Assembly and Alignment ............................................... 7

Setting Table for Horizontal or Bevel Cutting ..........8

Aligning the Bevel Indicator .................................... 8

Removing and Installing Blades ....................... ..,._..:.._10

Adjusting Work Hold-Down Foot. ...................... .,.L.... 12

Dust Blower .................................................................. 12

Blade Guard: ...................................... :......................... 12

Mounting the Scroll Saw ............................................. 13

Getting to Know Your Scroll Saw................................. 14

Operation .................................................................... 17

Maintenance ................................................................ 20

Wiring Diagram ........................................................... 2I

Troubleshooting ........................................................... 21

Service Information ....................................... Back Cover

i ....

Speed Control/On-OFF Knob ............................... 15

Choice of Blade and Speed .................................. 16

Making Interior Cuts ............................................. 19

Recommended Accessories ....................................... 21

Repair Parts ................................................................ 22

Unpacking and Checking Contents ........

Tools Needed

::j_ COMBINATION

MEDIUM STANDARD SCREWDRIVER

WARNING: For your own safety never connect plug

to power sou rce outlet until all assembly iStepsare

complete, and you have read and understand the

safety and operating instructions.

IMPORTANT: Never lift this saw by the arm which hotds

the blade or damage will occur to your saw.

Separate all parts from packaging materials and check

each item with illustration and "Table of Loose Parts".

Make certain all items are accounted for before discard-

ing any packaging material.

If any parts are missing, do not attempt to assemble the

Scroll Saw, plug in the power cordor turn the switch on

until the missing parts are obtained and installed cor-

rectly.

MEDIUM PHILLIPS SCREWDRIVER

Table of Loose Parts Qty

A 16" Scroll Saw (Completely Assembled) ............. 1

B Owner's Manual .................................................. 1

C Loose Parts Bag containing:

Blade ................................................................... 1

Hex "T" Handle Wrench ...................................... 1

"L" Shaped Blade Change Rod ........................... 1

NOTE: Hardware to mount thisscroll saw to a bench or

leg set isNOT supplied. See mounting instructionsfor

recommended hardware size.

Page 7

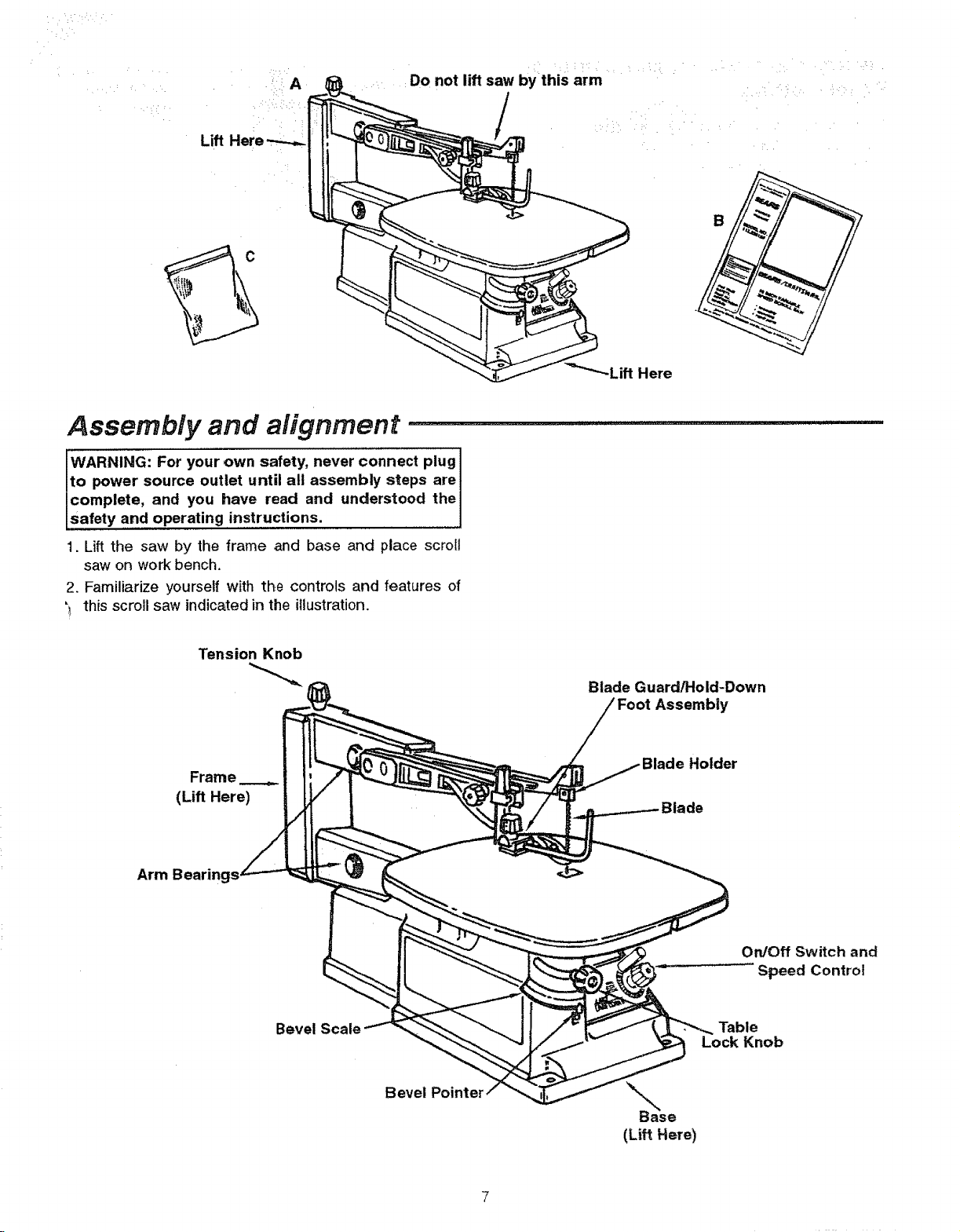

Do not lift saw by this arm

Lift

C

Here

Assembly and alignment ...............................................

WARNING: For your own safety, never connect plug

to power source outlet until all assembly steps are

complete, and you have read and understood the

safety and operating instructions.

1. Lift the saw by the frame and base and place scrolt

saw on work bench.

2. Familiarize yourself with the controls and features of

'_ this scroll saw indicated in the illustration.

Tension Knob

Frame

(Lift Here)

Arm Bearings _

Bevel

Blade Guard/Hold-Down

Assembly

Holder

de

On/Off Switch and

Speed Control

Table

Lock Knob

Bevel

Base

(Lift Here)

Page 8

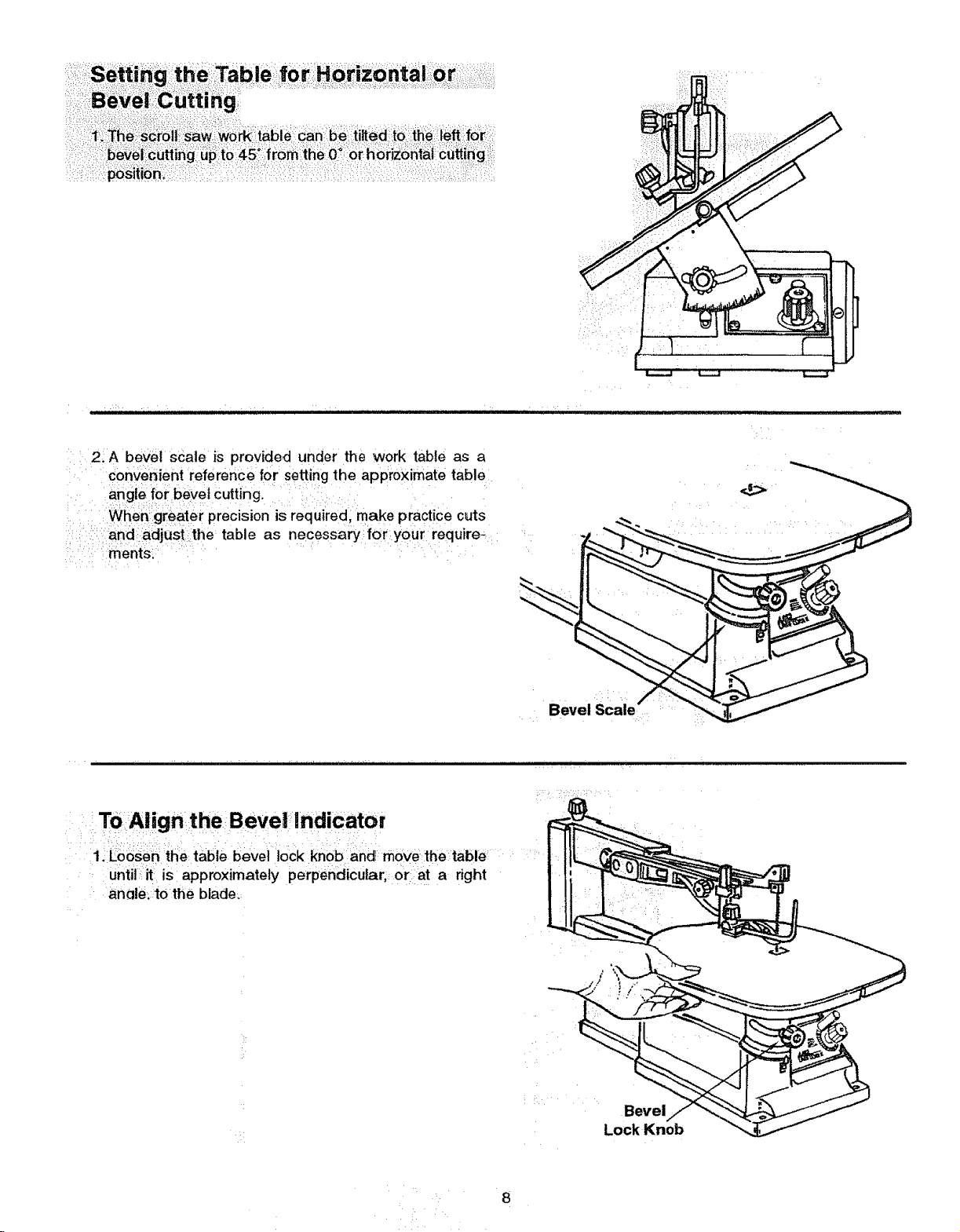

ng

2. A bevel scale is provided under the work table as a

convenient reference for setting the approximate table

angle for bevel cutting.

When greater precision is requiredl make practice cuts

and :adjust the table as necessary:for your require-

: .... ments.

ToAlign the Bevel indiCator

11Lo_n_ttle table bevei lock knob an_ move,the:table ::

until iti is approximately perpehdicutar;_ Or:iat a right

anale:to the blade,:

L¸

• J

Bevel

Lock Knob

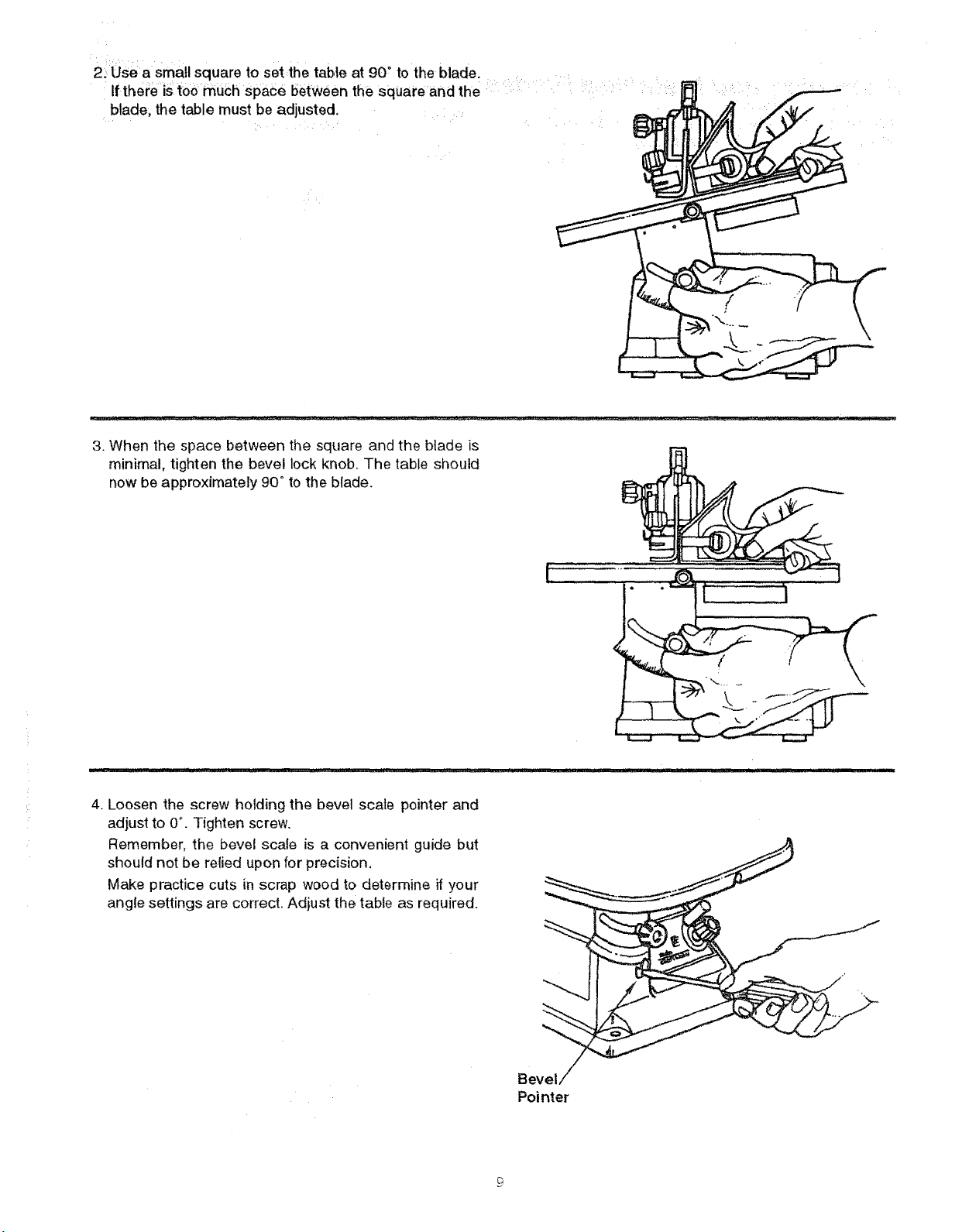

Page 9

2_Use a small square to set the table at 90" to the blade.

If there is too much space between the square and the

blade, the table must be adjusted.

3. When the space between the square and the blade is

minimal, tighten the bevel lock knob, The table should

now be approximately 90° to the blade,

4. Loosen the screw holding the bevel scale pointer and

adjust to 0°. Tighten screw.

Remember, the bevel scale is a convenient guide but

should not be relied upon for precision,

Make practice cuts in scrap wood to determine if your

angle settings are correct. Adjust the table as required.

.......

Bevel

Pointer

Page 10

Removing Pin End Blades

1: UnP!ug=powercord from outlet and Checkthat switch is

ofL

2. Loosen tension on blade by turning tension knob coun-

terclockwise _ about three full turns.

3. Remove blade from the lower blade holder by pushing

down on the upper arm, releasing the blade/pin from

the lower blade holder. Remove blade from the upper

blade holder by slightly lifting up on the blade and pull-

ingforward.

NOTE: Thesaw comes from the factory already setup

for pin end blades.

1. Pin End Blade Set Up: Insert the blade change rod

through the holeabove the upper blade holder. Use

the "T' handle wrench to loosen the h ex socket screw

and clamp from the upper blade holder. Install the

Clamp so that the boss goes into the recess in the

blade holder: The "V" notcheSmust line up.

2. Tighten_he hex socket screw:

3_Repeat this prOcb_e_i:_n t_heIowgi_blade holder.

:4'iCheck that the tension knob is loose:

5!instal{ the blade throughlthe insert opening with the

teeth pointing down, Engage the pin into the "V" notch

of :thelower blade:holder:

6. Pullup on the blade and engage the upper pin in the

notch of the upper blade holder.

7. Carefully tighten the blade tension by turning the ten-

sion knob clockwise _ until you feel the slack in

the blade is removed.

8. Check to see that the pins are properly located in the

slots. Turn the tension knob an additional two full turns

clockwise. This amount of blade tension should do

well for most cutting operations and blades. The num-

ber of turns Will be approximately two full turns. This

will vary depending on blade :thiCkness and blade type.

9. Make sure the blade is properly installed. Before apply-

Ing power, rotate the motor shaft by hand using a

screwdriver in the motor shaft slot as shown,

Knob

Blade Change Rod

"T" Wrench

Upper

Blade Holder

J

NOTE: Teeth pointing downward.

Lower

Blade Holder

ecess

%

Blade Clamp Upper Blade Holder

Boss _)

"V"

Notches Recess

Blade Clamp Lower Blade Holder

II

injury

remove the blade change rod and all tools from the

IWARNING: To avoid from thrown

saw.

objects,

10

Page 11

IWARNING: To avoid,injury from accidental starting,

lalways turn switch' OFF"and unplug power cord

• • i _

lfrom outlet before removing or,replacing the blade.

OTE: Saw comes set up, for pin end blades. For plain

=end blades, the blade clamp needs to be reinstalled with

the flat surface placed against the blade holder.

Removing Plain End Blades

1. Unplug power cord from outletand check that switch is

off.

2. Loosen tension on blade byturning tension knob coun-

terclockwise _ about three full turns.

3. Insert the blade change rod through the hole above the

blade holder and loosen the hex socket screw of the

blade holder with the "T" wrench.

4. Remove blade from upper blade holder.

5. Loosen the lower blade holder hex socket screw in the

same way as the upper blade ho]der in step 3.

6. Remove blade from lower blade holder.

Installing Plain End Blades

:NOTE: For plain end blades, the flat surface of the blade

ctamp needs to be positioned against the blade holder.

1. Plain End Blade Set Up: insert the blade change rod

through the hole above the upper blade holder. Use

the "T" handle wrench to loosen the hex socket screw

and clamp from the upper blade holder. Install the

clamp so that the flat surface is against the blade

holder.

.... 2. Replace the he>(socket screw.

3. Repeat this procedure on the lower blade holder.

4. Install the blade through the hole in the table and into

the lower blade holder. The blade teeth should point

down. Position the blade end at the bottom of the blade

clamp and against the hex socket screw.

5. Tighten the hex socket screw, using the "T" wrench,

while holding the blade change rod in position.

6. Use the same procedure to install the blade into the

upper blade holder. Before tightening the socket hex

screw, adjust the position of the upper blade holder by

turning the blade tension knob until the end of the

blade isnear the top of the blade holder.

7. Remove the "T" wrench and the blade change rod from

the blade holder.

8. Tighten the blade tension knob clockwise

until the blade is tensioned. The number of turns will

be approximately two full turns. This will vary depend-

ing on blade thickness and blade type.

9. Make sure the blade is properly installed. Before apply-

ing power, rotate the motor shaft by hand using a

screwdriver in the motor shaft as shown on page 10.

JWARNING: To avoid injury from thrown objects,!

PIremove the blade change rod and all tools from the

l saw.

ion Knob

Blade Change Rod

"T" Wrencl_

Blade Change

Rod

Blade Clamp

Blade Holder

Lower Birdie

BRod

Upper BladeHolder

l

Lower

Holder

I

Surface '-_

11

Blade C!am£

LowerB!_de _.o!de_

Page 12

wARNING: To avoid i'njury from accidental starting,

alwwsturn switch:"OFP and unplug power cord ;,

fromoutlet before removing or replacing the blade;

The purpose of the work hold_down foot is to hold the

work against the table so that it:isless likelyio liftwith:the

up stroke of the blade, tt should lie flat on the work with

the front prongs straddling the blade.

1. The work hold-down foot is attached to the blade guard

wire. The height ofthe work hold-down foot is adjusted

by loosening the height adjustment knob and moving

the guide post up or down. The work hold-down foot is

adjusted front to back and left-to-rightby loosening the

hold-down knob located on the bracket, as illustrated

2. When the table is tilted, the work hold-down foot can

be adjusted by loosening the height adjustment knob

and adiustingthe foot to the same angle as the table.

The work hold-downfoot should always be adjusted as

close to the blade as: possible without touching and

positioned directlyon the surface of the workpiece.

breakage _iScaused by:the following:

';_tensi_n orunde_tension:

;i:_iuse::!i_biade iiife :exiiausted;

;rAggressive_ Feeding of the workpiece into the

:te bygoing too:fast,

OOT

Height

AdjustmentKnob

Hold-Down

Knob _

Hold-Down

Foot

Adjust

Hold-Down

Foot to

Same Angle

as Table

Dust Blower

The dust blower will direct air to the most effective point

on the cutting line when the hold down is adjusted. No

adjustment is necessary to the blower.

Blade Guard

The blade guard will always be positioned parallel to the

blade. No adjustment is necessary,

i__ iil -- B/oUSter

Page 13

Mounting the Scroll Saw to a Bench

ii ,I,L±I_lji, , _i i,li, ilrli ,11 ,

1. When mounting this saw to a workbench a solid

wood bench is preferred over a plywood bench

where noise and vibration will be more noticeable.

2, Hardware to mount this saw to a workbench is Not

supplied with the saw. However, we recommend the

hardware used be not smaller than the following.

Description Qty.

Hex Head Screw, 1/4-20 x length required .................... 3

Flat Washers, 1/4 I.D..................................................... 6

Lock Washers, 1/4 i.D................................................... 3

Hex Nuts, 1/4-20 ........................................................... 6

3. A soft foam pad to place between your scroll saw and

workbench is NOT supplied with the saw. However,

we highly recommend the use of such a pad to

reduce noise and vibration.

Description Qty.

Soft foam pad such as carpet padding,

24"x 12" x 1/2"........................................................ I

Do NOT over tighten mounting bolts - leave some cush-

ion in the foam pad for absorbing noise and vibration.

Scroll Saw Base

] _% •

Top View

Hex Head Screw

Workbench /

Scroll Saw Base ._

Hex Head Screw X

Flat Washer -_"\

1/2" Foam Pad. _'N_

(Optional) '__ Side View

Workbench

FtatWasher

Lock Washer___=

Hex Nut Jam Nut

,

If you prefer to mount your saw to a leg set, we rec-

ommend the leg set for bench top tools which is

available through Sears Retail Stores. The number of

this leg set is 9-22244. This leg set is an optional

accessory and instructions to mount the scroll saw to

this leg set are included in the leg set package.

13

Page 14

Upper Blade Holder

2. Work Hogd-Down

5. Bevel Scale

Blade Support

7. BladeGuard

8. Blade Storage

Drawer

Speed Control/

On-Off Knol_

4. Bevel Lock Knob

3, Lower Blade Holder

1. Tension Knob ... Tightening the knob (clockwise) will

increase the tension on the blade. Loosening it (coun-

terclockwise) will deCreaSe the tension.

2. Work Hold-Down and Blade Support ... Provides

added control of work-p!ece, protection for operator

and support for the blade_

3. Blade Holders ... Retain and position the blade,

4. Bevel Lock Knob ... Loosening knob allows the table

to tilt up to 45 ° for bevel cuts.

5. Bevel Scale .. Shows angle table is tilted for bevel

cutting.

6. Speed Control!On-Off Knob ... For speed control set-

ting, refer to the "Choice of Blade and Speed" table.

The On-Off knob has a locking feature, This Feature

Is Intended To Help Prevent Unauthorized Use By

Children And Others.

7. Blade Guard ... Defines area of moving blade.

8. Blade Storage Drawer ... Used to stere blades, "T'

handle wrench, and "L" shaped rod.

14

Page 15

Speed Control/On-Off Knob

1.:Toturn machine 'On', place fingers on Speed Control/

On-Off Knob and pull out.

2. To turn machine 'OFF', push in Speed Control/On-Off

Knob. Never Leave The Machine Unattended Until It

Has Come To A Complete Stop.

The variable speed control may be adjusted to the

approximate speeds identified on the contro! panel. Sug-

gested speeds are identified under "Choice of Blade and

Speed". Turn the control knob clockwise (,_"_'_)

strokes per minute and counterclockwise (_"_)

to reduce the strokes per minute.

\,,.

3. To lock knob in 'Off' position, install a padlock through

the post above the knob as illustrated, and lock the

padlock. (Padlock is not supplied withthe saw.)

WARNING: For your own safety, always push the

knob 'Off' when machine is not in use, Also, in the

event of a power failure (all of your lights go out),

push knob 'Off'. 'Lockout' your knob with a padlock

as shown. This will prevent the machine from start-

ing up again when the power comes back on.

Push

Rotate

15

Page 16

3. Use a blade that will have at least 2 teeth in the mate-

dal at ailtimes.

4, Use thin, narrow blades for tight radius work, and thi¢_

wide blades for large curves and straight cuts.

Listed below are examples of some blades and their intended uses: ....

Pin and Plain end Biades

:'Teeth/inch Width Thickness

Speed : _ _ Application

20 .__2 .012"

i, .... ha-

15 : _110_'..... .0t 8"

12:5

11.5

10

.038"

.053'_

.110"

!

+:+o666'

.0i8"

:,018"

500-600 Tight radius work; 3/32" to 1/8' wood veneer, wood,

bone, fiber, plastics, non-ferrous metals, etc.

600-1200

Close radius cutting in materials 3/32" to 1/2" thick.

Good for hard and soft wood, bone, horn, plastics, etc.

1200-1700

For hard and soft woods and woodlike products

3/16" to 2".

16

Page 17

Basic Saw Operations- ................

=_lease, read and understand the following items about

bur scroll saw before attempting to use the saw.

1. The saw does not Cut wood by itself. You allow the

saw to cut wood by guiding the wood into the blade

as it moves.

2. The blade teeth cut wood _ on the down stroke.

3. You must guide the wood into the blade slowly

because the teeth of the blade are very small and

they can only remove wood when they are on the

down stroke.

4. There is a learning curve for each person who wants

to use this saw. During that period of time it is

expected that some blades will break until you learn

how to use the saw and receive the greatest benefit

from the blades.

5. Best results are achieved when cutting wood less

than one inch thick.

6. When cutting wood thicker than one inch the user

must guide the wood very, very slowly into the blade

and take extra care not to bend or twist the blade

while cutting in order to maximize blade life.

7. Teeth on scroll saw blades wear out and as such

must be replaced frequently for best cutting results.

Scroll saw blades generally stay sharp for 1/2 hour to

', 2 hours of cutting.

8. To get accurate cuts, be prepared to compensate _or

blade's tendency to follow the wood grain as you are

cutting.

9. This scroll saw is intended to cut wood, wood like

products, plastics and non-ferrous metals.

10. When choosing a blade to use with your scroll saw,

consider the following carefully.

o Very fine, narrow blades should be used to scroll cut

in thin wood 1/4 inch thick or less.

• To cut wood over 1/4 inch thick, use wider blades.

o Most blade packages state the size or thickness of

wood which that blade is intended to cut, and the

radius, size of curve, which can be cut with that

blade.

• Wider blades can't cut curves as tight or small as

thinner blades.

• Narrower blades work well only on thinner wood

material.

This saw uses 5 inch long, pin end type, blades only.

See your Sears Retail Store for accessory blades.

Blades wear taster when cutting plywood, which is

very abrasive; when sawing wood which is thicker

than the 7/8 inch blade stroke; and when sawing

hardwood, or when side pressure is placed on the

blade.

Before Each Use:

inspect your saw.

Disconnect The Saw. To avoid injury from accidental

starting, turn the switch "OFF", unplug the saw before

changing the setup, removing covers, guards or blade.

CHECK DAMAGED PARTS. Check for:

o Alignment of moving parts.

o Binding of moving parts.

° Broken parts.

o Stable mounting.

o Any other conditions that may affect the way the saw

works.

If any part is missing, bent or broken in any way, or any

electrical parts don't work properly, turn the saw off and

unplug the saw. Replace damaged, missing or failed

arts before using the saw again. Keep Guard In Place

nd in working order

Maintain Tools With Care

Keep the saw clean for best and safest performance.

Follow instructions for lubricating.

Remove Adjusting Keys And Wrenches from toot

before turning iton.

To avoid injury from jams, slips or thrown pieces:

• Choose the right size and style blade for the material

and the type of cutting you plan to do.

° Use Only Recommended Accessories. (See page

21). Consult this Owner's manual for recommended

accessories. Follow the instructions that come with the

accessories. The use of improper accessories may

cause risk of injury to persons.

° Make sure the blade teeth point downward, toward the

table.

o Make sure the blade tension is properly adjusted.

° Keep Work Area Clean. Cluttered areas and benches

invite accidents. Floor must not be slippery,

To avoid burns or other fire damage, never use the saw

near flammable liquids, vapors or gases.

17

Page 18

Usel extra caution With :/large, very smal] or

awkward workpieces:

owners

Neve!_uSethis:t00t t0 finish pieces too small to hold bv

ha a - ....

Use extra supports (tables, _saw horses, blocks etc.)

for:any workpiece large enough to tip when not held

down to the table top.

while

Av'oid Accidental Starting.: Make sure switch is "OFF"

before plugging Saw into a power outlet.

Plan your work;

o Use The Right Tool, Don't force tool or attachment to

doa job it Wasnot designed todo.

,*use this scrolt saw to cut only wood, wood-like prod-

ucts, plastics and non-ferrous metals.

CAUTION: This saw is NOT designed for cutting fer-

rous metals like iron or steel. When cutting non-fer-

rous metals (brass, :copper and aluminum, etc.),

metal shavings can react with wood dust and start a

fire. To avoid this:

-Remove all traces of wood dust from inside the

saw.

•Remove all traces of metal dust from on or around

the saw before sawing wood again;

Dress for safety.

Any power saw can throw foreign objects into the eyes.

This can cause permanent eye damage. Wear safety

goggles (not glasses) that comply with ANSI Z87.1

(shown on package), Everyday eyeglasses have only

impact resistant lenses. They are not safety glassesi:: ....with_apossible thrown piece if the blade should break.

Safety goggles: are available :at Sears Retail Stores.

Glasses or goggles not in compliance with ANSi Z87.1

could seriously hurt you when they break_

• Do not wear loose clothing, gloves, neckties or jewelry

(rings, wristwatches). They can get Caught anddraw

you into moving parts,

"* Wear non-slip footwear.

• Tie back long hair.

° Roll long sleeves above the elbow,

° Noise levels vary widely. To avoid possible hearing

damage, wear ear plugs or muffs when using saw for

hours at a time.

• For dusty operations, wear a dust mask along with the

safety goggles.

Inspect your workpiece.

Make sure there are no nails or foreign objects in the part

of the workpiece to be cut.

o Never use another person as a substitute for a table

extension, or as additional support for a workpiece or

to help feed, support or pull the workpiece

o When cutting irregularly shaped workpieces, plan you r

work so it will not pinch the blade. A piece of molding,

for example, must lay flat or be held by a fixture or jig

that will not let it twist, rock or slip while being cut.

• Properly support round material such as dowel rods or

tubing. They have a tendency to roll during a cut,

causing the blade to "bite". To avoid this, always use a

"V" block,

° Cut only one workpiece at a time.

° Clear everything except the workpiece and related

support devices off the table before turning the saw on.

Plan the way you will hold the workpiece from start to

finish.

Do not hand hold pieces so small that your fingers will go

under the blade guard. Use jigs or fixtures to hold the

work and keep your hands away from the blade.

Avoid awkward operations and hand positions where a

sudden slip could cause fingers or hand to move Ontothe!

blade.

Don't Overreach. Keep good footing and balance.

Keep your face and body to one side of blade, out of line

18

Page 19

Whenever Saw Is Running

iWARNING: Don't let familiarity (gained from fre- I

quent use of your saw) cause a careless mistake. A I

icareless fraction of a second is enough to cause

l

Isevere injury.

Before starting your cut, watchthe saw while it runs. If it

makes an unfamiliar noise or vibrates a lot, stop immedi-

ately. Turn the saw off. Unplug the saw. Do not restart

until finding and correcting the problem.

Keep Children Away. Keep all visitors a safe distance

from the saw. Make sure bystanders are clear of the saw

and workpiece.

Don't Force Tool. It will do the job better and safer at its

designed rate. Feed the workpiece into the saw blade

only fast enough to let it cut without bogging down or

binding.

Before freeing any jammed material:

• Turn switch "OFF".

o Unplug saw.

• Wait for al! moving parts to stop.

a I

When backing up the workpiece, the blade may bind

in the kerr (cut). This is usually caused by sawdust

clogging up the kerf. If this happens:

* Turn switch "OFF".

- Unplug saw.

o Wait for al! moving parts to stop.

o With a flat blade screwdriver, turn the motor by hand

while backing up the workpiece.

Before removing loose pieces from the table, turn

saw off and wait for all moving parts to stop.

Before Leaving The Saw:

° Wait for all moving parts to stop.

Make Workshop Child-proof. Unplug the saw. Lock the

shop or ON/OFF knob, Store the key away from children

and others not qualified to use the tool.

Making interior Scroll Cuts

1. One of the features of this saw is that it can be used to

make scroll cuts on the interior of a board without

breaking or cutting into the outline or perimeter of the

board.

WARNING: To avoid injury from accidental starting,

always turn switch "OFF" and remove plug from

power source outlet before removing or replacing

the blade.

2,To make interior cuts in a board, remove the scroll saw

blade as explained in the Assembly section,

3. Drill a 1/4" or larger hole in the board you wil! use to

make interior cuts.

4. Place the board on the saw table with the hole in the

board over the access hole in the table.

5. Install the blade through the hole in the board and

adjust blade tension.

6.When finished making the interior scroll cuts, simply

remove the blade from the blade holders, as described

in the Assembly section, and remove the board from

the table.

19

Page 20

pastewax onthe wo_k:tabte will

cut _to'glide:smooth y across the

i

The motor bearings are permanently lubricated and

require no further lubrication,

D0not attempt to oil the motor bearings or service the

m0t0rinternalpartsi

WARNING: ifthe power cord is worm, cut or dam- i

aged inany way, have it replaced immediately.

t WARNING: To avoid fire or electrocution, reassem- i

I bie electric parts with only approved service parts._

[Reassemble exactly as originally assembled. |

Arm Bearings

Lubricate the arm bearings after 10 _ours of use. Re-oil

after every 50 hours of use or whenever there is a squeak

coming from the bearings_

1. Turnsaw on its side. _

2_Squirt a generous amount 0f SAE 30 oil around the

-::shaft end and bronze bearing._

3_Let tl_e:oil soak inoVernight in this condition.

4;Next day repeat the above procedure for::theopposite

with this saw are

designed to give long service life. When one or both

brushes become shorter than 1/4", replace both brushes.

1. Remove the brush cap using a 1/4" flat blade screw-

driver.

NOTE: The brushes are spring loaded and may push

against the brush cap as it releases.

2. Install the new brush assembly and reinstall the brush

cap.

3. Use the cap to push the spring and brass end of the

assembly into the rectangular hole as the cap is tight-

ened. Be sure that the brush cap is fully seated in the

brush hoider.

4. Repeat the procedure for the ether brush.

i

\

\,

Brush Cap

Brush

20

Page 21

Wiring Diagram ...........

/ARNING: To avoid fire or shock, use only recom-

_ended service parts and reassemble exactly as

[originally assembled.

Sears recommends the following accessories

_J

Item Sears Number

Leg Set ............................................................... 9-22244

Blades ....................... See Sears Retail Store for 5" long

Plain End/Pin End blades

Sears may recommend other accessories not listed in

manual, See your nearest Sears Store for other accesso-

ries.

Troubleshooting ..............................................

power source outlet before troubleshooting your scroll saw.

t WARNING: For your own safety, turn switch "OFF", and remove plug from I

L PROBLEM PROBABLE CAUSE

Breaking B'iades, 1.

Motor will not run.

Vibration

NOTE: There will always be

some vibration present when

the saw is running because of

the blade and arm movement,

Wrong tension

2. Over working blade.

3. Wrong btade application.

4. Twisting blade in wood.

1, Damaged cord or plug.

2, Damaged motor or control

board.

1, Improper mounting of the

saw.

2. Unsuitable mounting sur-

face.

3. Loose table

4. Loose motor mounting.

........................ ' "i

1. Adjust blade tension.

2. Reduce feed rate.

3. Use narrow blades for cutting thin wood, wide

blades for thicker wood.

4. Avoid side pressure on blade.

1. Replace damaged parts before using saw

again.

2. Consult Sears Service. Any attempt to repair

this motor or control board may create a HAZ-

ARD unless repair is done by a qualified ser_

vice technician. Repair service is available at

your nearest Sears Store.

1. See mounting instructions in this manual for

proper mounting technique.

2. The heavier your workbench is, the less vibra-

tion will occur, A plywood workbench wiltnot

be as good a work surface as the same size

solid lumber. Use common sense in choosing

a mounting surface.

3. Tighten table lock knob.

4. Tighten motor mounting screws,

REMEDY SCHEDULED

Motor stops during cuts 1:Aggressive feeding causes

Current Protector to shut

motor off.

21

1. Turn machine "OFF" and then back "ON" to

continue cutting.

2. Slow down the feed rate ot material into blade.

Page 22

48

J

51

Po

P_

J

J

13 12

15 _10 " 14

11

4O

/I

3O

32 38

39

1S

16

18

19

22 20

21

\ 23

10 '\ 11

37

28

10

25

27

24 10

1 F

Page 23

PARTS LIST FOR CRAFTSMAN 16" , RIABLE SPEED SCROLL SAW

MODEL NO. 113.236150

Always Order By Part Number-Not By Key Number

t',.3

O3

Key

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

!7

18

19

20

2!

22

23

24

25

26

27

28

29

3O

3t

32

Part No.

820733

820333

822426-1

820376-2

821673

813249-131

821701

821708

821707

STD852005

821389

821702

STD851006

821697

820322

820324

822428

821712

821985

821675

821720

819293

821719

821672

817450-5

821722

821677

821151-1

820249-1

STD852006

821683

82t697q

Description

Rod, Blade Change

Wrench, "T" Handle, 4ram

Housing (includes Key #4 & 41)

Screw Pan Hd Ty"TT" M4 x 0,7-28

Table

Pin, Roll M5 x 25

Screw, Support

Guide, Drawer

Drawer

Lockwasher, M5

Screw, Pan Hd M5 x 0,8-8

Support, Scale

* Washer, 6mm

Knob

Brush

Cap, Brush

o Motor

Cord with Plug

Housing, Control (includes label)

Knob

Gasket

Grommet

Board, Controller

Cover, Switch Box

Screw, Pan Hd Self Tap M4 x 18

indicator, Tilt

Base (Includes Labels)

Screw Hex Hd M5 x 0.8-15

Screw Hex Hd M6 x 1.0-20

* Lockwasher, M6

Support, Hold Down

Knob

Standard hardware item - may be purchased locally.

t Stock item - may be secured through the Hardware department

of most Sears Retail Stores

Key l

No. i

33 1

34 i

35 1

36 1

37 i

38 I

39 I

4O t

41 i

42 1

43 !

44

45 t

46 i

47 I

48 I

49 I

5O I

51 I

52 I

53 I

54 I

55 i

56 i

57 I

58 I

59 t

6o 1

61 1

62 l

63 {

Part No. Description

821690

821692

821693

821691

818471-6

821689

821716

820379-1

821717

821704

816018

816017

821675-1

821666

66061

821668

818468

818469

817450-1

46-58600-3

821706

813249-127

820317

818471

821709

820314

9-26877 t

820316

819248-1

8217O3

820315

SP5641

Support, Plate

Spring, Hold Down

Guard, Blade

Clamp, Hold Down

Screw, Hex Soc Set,M5 x 0.8-5

Support Bar

Plate Clip

Screw, Hex Soc Cap, M5 x 0.8-8

Bearing, Flanged

Bolt, Tension

Wedge, Tension

Nut, Tension

Knob

Arm, Upper

Spring

Arm, Lower

Bearing, Ball 625ZZ

Screw, Hex Soc Cap, M5 x 0.8-16

Screw, Pan Hd Serf Tap M4 x 16-8

* Washer, 4.2 x 10 x 0.9

Link, Arm

Pin, Roll M5 x 14

Clamp, Lower Blade

Screw, Hex Soc Set, M6 x 1.0-6

Coupling, Eccentric

Holder, Lower Blade

Blade, Scroll Saw

Clamp, Upper Blade

Hose

Bellows

Holder, Upper Blade

Owner's Manual (Not Illustrated)

;-A_'attempt to repair this motor may create a hazard unless

repair is done by a qualified service technician. Repair service

is available at your nearest Sears store.

Page 24

your owner's manual for future reference

packed with your scroll saw. The instructionsand illustrationsshown on

blades.

scroll saw owner's manual for safety instructions and proper use of the scroll saw.

rBlades

IWARNING :_To avoid i_iju_:from accidental starting, i

lahNays 1urn switch _:,!OFF and :unplug power cord I

Ifrom_:outletbefore removing or replacing the blade, I

NOTE: Saw comes Set :uplfor pin end blades, tf you are

going:to use plain end blades, refer to the instructions

under:_'installingPlain End Blades".

Removing Pin End Blades

:1;,Unplug power cordfrom outlet and check that switch is

0ffii_....

2_Loosen tension onblade byturning tension knob coun-

temlockwise_ aboutthreefull turns.

3, Remove-blade ftorn :the iiower Blade holder by pushing

down on the upper arm, releasing the blade!pin from

the lower blade holder_:Remove blade from the upper

btade holdei_by slightly;lifting, up on tt_e blade and pull-

ing forward,

113.236150

Knob

Page 25

Installing Pin End Blades

NOTE: The saw comes from the factory already set up

for pin end blades.

4i, Pin End Blade Set Up: Insert the blade change rod

through the hole above the upper blade holder, Use

the "T" handle wrench to loosen the hex socket screw

and clamp from the upper blade holder, Install the

clamp so that the thick boss goes into the recess in the

blade holder. The "V" notches must line up.

2. Tighten the hex socket screw,

3. Repeat: this procedure on the lower blade holder.

4. Check that the tension knob is loose.

5. Install the blade through the insert opening with the

teeth pointing down. Engage the pin ir_tothe "V" notch

of the lower blade holder.

6. Pull up on the blade and engage the upper pin in the

"V" notch of the upper blade holder.

7. Carefully tighten the blade tension by turning the ten-

sion knob clockwise _ until you feel the slack in

the blade is removed.

8, Check to see that the pins are properly located in the

slots, Turn the tension knob an additional two full turns

clockwise. This amount of blade tension should do

well for most cutting operations and blades. The num-

ber of turns will be approximately two full turns. This

will vary depending on blade thickness and blade type.

9. Make sure the blade is properly installed, Before apply-

-'_ ing power, rotate the motor shaft by hand using a

screwdriver in t:he motor shaft slot as shown,

Blade Change Rod

Upper

Blade Holder

\

NOTE: Teeth pointing downward.

"T" Wrenct

Blade Change

Rod

Lower

Blade Holder

WARNING: To avoid injury from thrown objects,[

remove the blade change rod and all toots from the[

saw.

Notches

Blade

Thin Clamp_

Boss

thick Boss

t

Blade

Holder

Blade

Clamp Thick

Notches

,Boss

Holder

Upper Blade Holder

Lower Blade Holder

Page 26

tel:clockwise _ about three full turns.

3, Insert the blade change rod through the hole above the

blade holder and loosen the hex socket screw of the

blade holder with the "T" wrench.

4!.Remove bladefrom upper blade holder.

5i:Loosen th:e lower blade holder he× socket :screw in the

sarnewayaS the upper blade holder in step 3.

61Remove blade from lower blade holder.

Upper

Blade Holder

Knob

Blade Change Rod

"T" Wrench

Z

.... T":Wrencl_

i

:: :Blad_Chang_.:-,

Rod ::!::::::

:: =:: :

___lower

Blade Holder

\.

NOTE: Teeth pointing downward.

Note:Teeth

Pointing

Holder

Hex Socket

Screw

Blade Change Rod

Blade

Page 27

Installing Plain End B|ades ..................

NOTE: For plain end blades, the thin boss of the blade

_.l_mp needs to be positioned against the blade holder.

Plain End Blade Set Up: Insert the blade change rod

through the hole above the upper blade holder. Use

the "T" handle wrench to loosen the hex socket screw

and clamp from the upper blade holder. Install the

clamp so that the thin boss isagainst the blade holder,

and the beveled edge is in the corner of the blade

holder. The thin boss side of the blade clamp can be

identified by a circular impression placed on the sur-

face.

2. Replace the hex socket screw.

3. Repeat this procedure on the lower blade holder.

4. Install the blade through the hole in the table and into

the lower blade holder. The blade teeth should point

down. Position the blade end at the bottom ofthe blade

clamp and against the he× socket screw.

5. Tighten the hex socket screw, using the "T" wrench,

while holding the blade change rod in position.

6. Use the same procedure to install the blade into the

upper blade holder. Before tightening the socket hex

screw, adjust the position of the upper blade holder by

turning the blade tension knob until the end of the

blade is near the top of the blade holder.

7. Remove the "T' wrench and the blade change rodfrom

._._the blade hotder.

Tighten the blade tension knob clockwise

until the blade is tensioned. The number of turns will

be approximately two full turns. This wil! vary depend-

ing on blade thickness and blade type.

9, Make sure the blade is properly installed. Before apply-

ing power, rotate the motor shaft by hand using a

screwdriver in the motor shaft as shown on the previ-

ous page.

Blade Change Rod

!

Upper

Blade Holder

\

NOTE: Teeth pointing downward.

Lower

8lade Holder

Note: Teeth

Pointing Down _ Blade

Holder

Hsx Socket

Screw

WARNING: To avoid injury from thrown objects,

remove the blade change rod and all tools from the

saw.

Beveled Edge

Circular ImiDression

Blade Clam_ / t (_ _i_}B_l_d: r

Thin Boss

Upper Blade Holder

Form No. SP5766

Blade Clamp

Beveled

Circular

Edge Impression

Lower Blade Hotder

Printed in U.S.A. 7:,'94

Btade

Holder

Page 28

SERVICE

MODEL NO.

18 iNCH VARIABLE

SPEED SCROLL SAW

Now that you have purchased your scroll saw, should a need

ever exist for repair parts or service, simply contact any Sears

Service Center and most Sears, Roebuck and Co. stores, Be

sure to provide all pertinent facts when you call or visit.

113.236150

HOW TO ORDER

REPAIR PARTS

The model number of your scroll saw will be found attached to

the right side of the arm housing.

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE THE FOL-

LOWING INFORMATION:

PART NUMBER PART DESCRIPTION

MODEL NUMBER

113.236t50

All parts listed may be ordered from any Sears Service Center

and most Sears stores. If the parts you need are not stocked

locally, your order will be electronically transmitted to a Sears

Repair Parts Distribution Center for handling.

NAME OF ITEM

t6 INCH VARIABLE

SPEED SCROLL SAW

4p_... i iiiiiiiiiiiiii iiii _ _ ..................... iiii ii i i¸111111111/i/11 ii ii , iii

Sold by SEARS, ROEBUCK AND CO., Chicago, II. 60684 U.S.A.

Part No. SP5641 Form No. SP5641

J

i,

4194

Loading...

Loading...