Page 1

Sears

owners

manual

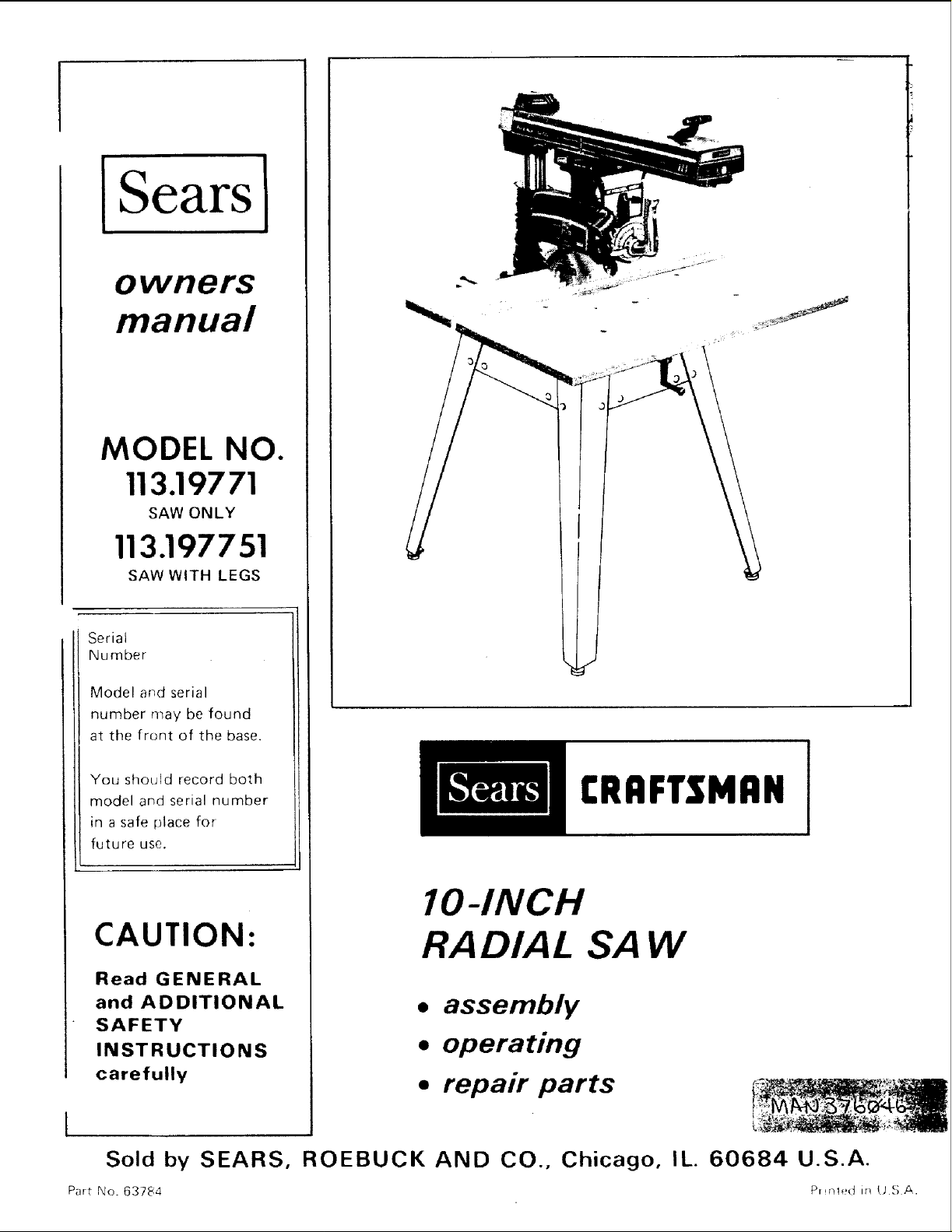

MODEL NO.

113.19771

SAW ONLY

113.197751

SAW WITH LEGS

Serial

Number

Model ar,d serial

number may be found

at the front of the base.

You should record both

model and serial number

in a safe place for

future use.

CAUTION:

Read GENERAL

and ADDITIONAL

SAFETY

INSTRUCTIONS

carefully

1

£RRFTSMRN

IO-INCH

RADIAL SAW

• assembly

• operating

• repair parts

Sold by SEARS,

Part No. 63784

ROEBUCK AND CO., Chicago, IL. 60684 U.S.A.

Pr riled in USA.

Page 2

FULL ONE YEAR WARRANTY ON CRAFTSMAN RADIAL SAW

If within one year from the date of purchase, this Craftsman Radial Saw fails due to a defect in material or

workmanship, Sears will repair it, free of charge.

WARRANTY SERVICE IS AVAILABLE BY SIMPLY CONTACTING THE NEAREST SEARS STORE

OR SERVICE CENTER THROUGHOUT THE UNITED STATES.

This warranty gives you specific legal rights, and you may have other rights which vary from state to state.

SEARS, ROEBUCK AND CO., Sears Tower, BSC 41 3, Chicago, IL 60684

general safety instructions for power tools

1. KNOW YOUR POWER TOOL

Read and understand the owner's manual arrd labels

affixed to the tool. Learn its applications and limitations

as well as the specific potential hazards peculiar- to this

tool.

2. GROUND ALL TOOLS

This tool Is equipped with :rn approved 3 conductor

cord and a 3-prong grounding type i)log to fit tile

[)roper g_o*mding type receptacle The g_een con(Joctor

in the cor I _s the grounding wire. Never connect the

green wire !o a live terminal.

3. KEEP GUARDS IN PLACE

in worMug order, and in proper adjustment and

atigrlment.

4. REMOVE ADJUSTING KEYS

AND WRENCHES

Form habit of checking to see that keys and adjusting

wrenches _re removed from tool before tLJrnH]g it on

5. KEEP WORK AREA CLEAN

Cluttered teas and benches nvite accidents Floor

must not bp slippery due to wax or sawdust,

6. AVOID DANGEROUS ENVIRONMENT

Don't use power tools in damp or wet locations or

expose them to rain. Keep work area well bighted.

Provide adequate surrounding work space.

7. KEEP CHILDREN AWAY

All visttor,, should be kept a safe distance from work

area

8. MAKE WORKSHOP KIDPROOF

with p_tdlocks, master switches, or by ,emoving

starter key_

9. DON'T FORCE TOOL

It will do rhe job bette_ and safer at the rate for which

_t was designed.

10. USE RIGHT TOOL

Don't forc_ tool or attacfrment to do a job it was not

designed for.

11. WEAR PROPER APPAREL

Do not wea_ loose clothing, gloves, neckties or jewelry

(rings, wrist watches} to get caught in moving parts.

Nonslip footwear is recommended. Wear protective

hair covering to contain long hair. Roll long sleeves

above the t Ibow.

12. USE SAFETY GOGGLES (Head Protection)

Wear Safety goggles (must comply with ANSI Z87.1)

at all times. Everyday eyeglasses only have impact

resistant lenses, they are NOT safety glasses. Also, use

face or dust mask if cutting operation is dusty, and ear

protectors (plugs or muffs) during extended periods of

operation.

13. SECUREWORK

Use clamps or a vise to hold work when practical. It's

safer than qsing 'your hand, frees both hands to operate

tool.

14. DON'T OVERREACH

Keep proper fooUng and balance at all times.

15, MAINTAIN TOOLS WITH CARE

Keep tools sharp and clean for best and safest

performance Follow *nstructions for lubricating and

changirrg accesso, ies

16. DISCONNECT TOOLS

belgie setvcing; when changing accessories such as

blades, bits. cutters, etc.

17. AVOID ACCIDENTAL STARTING

Make sure switch is in "OFF" position bqfore plugging

in,

18. USE RECOMMENDED ACCESSORIES

Consult the owner's manual for recommended

accessories, Follow the instructions that accompany

the accessories. The use of improper accessories may

cause hazards.

19. NEVER STAND ON TOOL

Serious injury could occur if the toot is tipped or if the

cutting toot is accidentally contacted.

Do not store materials above or near the tool such that

it is necessary to starrd on the toot to reach them.

20. CHECK DAMAGED PARTS

Before further use of the tool, a guard or other part that

is damaged should be carefully checked to ensure that it

will operate properly and perform its intended function.

Check for alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any other

conditions that may affect its operation. A guard or

other part [hat is damaged should be properly repaired

or replaced

21. DIRECTION OF FEED

Feed work into a blade or cutter against the direction

of rotation of the blade or cutter only.

22. NEVER LEAVE TOOL RUNNING

UNATTENDED

Turn power off Don't leave tool until it comes to a

complete stop.

Page 3

additional safety instructions for radial saws

CAUTION: Always disconnect the power cord before between the column & column support, or in the

removing the guard, changing the cutting tool, changing the

set-up or making adjustments. Shut off motor before

performing layout work on the saw table.

WARNING: DO NOT CONNECT POWER CORD UNTIL

THE FOLLOWING STEPS HAVE BEEN

SATISFACTORILY COMPLETED:

I. Assembly and alignment.

II. Examination and operating familiarity with ON-OFF

switch, elevation control, yoke index and lock bevel

index and lock, carriage lock, guard clamp screw,

spreader and antikickback device, and miter index and

lock.

III. Review and understanding of al! Safety Instructions and

Operating Procedures thru-out manual.

INSTAL LATION

1. Set carriage lock before moving the saw.

2. Bolt the saw to the floor if it tends to slip, walk, or

slide during normal operation.

3. Mount the saw so the table is approximately 39" above

the floor.

4. Mount the saw so the arm s!opes slightly downward to

the rear so the carriage will not roll forward due to

gravity.

5. If you attach any kind of table extensions over 24"

wide to either end of the saw, make sure you either bolt

the saw to the bench or floor as appropriate, or support

the outer end of the extension from the bench or floor,

as appropriate.

MINIMIZE ACCIDENT POTENTIAL

Most accidents are caused by FAILURE TO FOLLOW

setup and operating instructions:

(A) GENERAL

-Avoid awkward hand positions, where a sudden slip

cotfld cause a hand to move into a sawblade or other

cutting tool. Never reach in back of or around the

cutting tool with either hand to hold down the

workpiece, or for any other reason; DO NOT place

fingers or hands in the path of the sawblade.

Never saw, dado, mold, or rabbet unless the proper

guard is installed and set up as instructed.

NOTE THE FOLLOWING DANGER LABELS

WHICH APPEAR ON THE FRONT OF THE YOKE

AND GUARD:

READ AND UNDERSTAND OWNER'S MANUAL BEFORE OPERATING MACHINE _OT FEED "

rlANGE_; FOR YOUR OWN SAFETY {NJUnYI_TODO

_ _A_E,v eO_CL[_ 5 e[v_n nE_CH A_OUNO _E _LAOE MATE _+AL

DANGER I

TO AVOID

]

- H any part of this radial saw is missing or should

break, bend or fail in any way, or any electrical

component fail to perform properly, shut off power

switch, remove cord from power supply and replace

damaged, missing and/or failed parts before resuming

operation.

- IF YOUR SAW MAKES AN UNFAMILIAR NOISE

OR IF IT VIBRATES EXCESSIVELY CEASE

OPERATING IMMEDIATELY UNTIL THE

SOURCE HAS BEEN LOCATED AND THE

PROBLEM CORRECTED.

-WARNING: DO NOT ALLOW FAMILIARITY

(GAINED FROM FREQUENT USE OF YOUR

SAW) TO BECOME COMMONPLACE. ALWAYS

REMEMBER THAT A CARELESS FRACTION OF

A SECOND IS SUFFICIENT TO INFLICT SEVERE

INJURY.

Before starting work, verify that no play exists

carriage, and that arm, yoke, and bevel locks/clamps

are tight.

- A large proportion of saw accidents is caused by use

of the wrong type blade, dull, badly set, improperly

sharpened cutting tools, by gum or resin adhering to

cutting tools, and by sawblade misalignment

out-of-parallel with the fence. Such conditions can

cause the material to stick, jam (stall the saw) or

"KICKBACK" at the operator. NEVER ATTEMPT

TO FREE A STALLED SAW BLADE WITHOUT

FIRST TURNING THE SAW "OFF". If the

sawblade is stalled or jammed, shut saw "OFF",

remove workpiece, and check sawblade squareness to

table surface and to the fence, and check for heel.

Adjust as indicated.

-CAUTION: DO NOT cycle the motor switch "ON"

and "'OFF" rapidly, as this might cause the sawblade

to loosen. In the event this should ever occur, allow

the saw blade to come to a complete stop and

re-tighten the arbor nut normally, not excessively.

- Do not leave a long board unsupported so the spring

of the board causes it to shift on the table. Provide

proper support for the workpiece, based on its size

and the type of operation to be performed. Hold the

work firmly against the fence.

Never use a length stop on the free end or edge of the

workpiece whether crosscutting or ripping. Never

hang onto or touch the free end of workpiece when

crosscutting, or a free piece that is cut off while

power is "ON" and/or the saw blade is rotating. In

short, the cut-off piece in any "thru-sawing"

operation must never be confined - it must be

allowed to move laterally.

--Make sure your fingers do not contact the terminals

when installing or removing the plug to or from a live

power source.

- Never climb on the saw, or climb near the saw when

power is "ON". Never leave the saw with power

"'ON", or before the cutting tool has come to a

complete stop. Lock the motor switch and put away

the key when leaving the saw.

-Do not use any blade or other cutting tool marked

for an operating speed lower than 3450 RPM. Never

use a cuttlng tool larger in diameter than the diameter

for which the saw was designed. For greatest safety

and efficiency when ripping, use the maximum

diameter blade for which the saw is designed, since

under these conditions the spreader is nearest the

blade.

Never turn your saw "ON" before clearing the table

or work surface of all objects (tools, scraps of wood,

etc.) except the workpiece and related feed or

support devices for the operation planned.

- DO NOT perform layout, assembly, or setup work on

the table while the cutting tool is rotating.

Never perform any operation "FREE HAND". This

term means feeding the sawblade into the workpiece

or feeding the workpiece into the sawblade or other

cutting tool without using the fence or some other

device which prevents rotation or twisting of the

workpiece during the operation. Never "RIP'" in the

crosscut position. Never make a miter cut with the

arm in the 90 ° crosscut position.

Never lower a revol_ing cutting tool into the table or

a workpiece without first locking the Carriage Lock

Knob. Release the knob only after grasping the Yoke

Handle. Otherwise the cutting too! may grab the

workpiece and be propelled toward you.

The sawblade, dado, or other cutting tool must be

Page 4

additional safety instructions for radial saws

removed from the saw arbor before using the Therefore, rip with the finished side down (next to

accessory shaft (rear end of the saw motor). NEVER the table) and be especially attentive to following

operate the saw with cutting tools iincluding sanding

accessories) installed on both ends of the saw arbor.

(B} RIPPING

Ripping is cutting with the grain or the tong way of the

board - it is performed by pushing the workpiece

along the fence and thru the sawblade (sawblade

parallel to the fence).

1. Never apply the feed force to the section of the

workpiece that will become the cut-off (free) piece.

Feed force when ripping must always be applied

between the saw blade and the fence . . . use a

"PUSH STICK" (see pg. 26) for narrow or short

work.

2. Whenever possible, use the in-rip position - this

provides minimum obstruction for feeding by hand

or push stick as appropriate.

3. Do not release the workpiece before operation is

complete - push the workpiece atl the way past the

rear (outfeed or exit) of the sawblade.

4. Make sure by trial before starting the cut that the

antikickback pawls will stop a kickback once it has

started. Keep points of pawls SHARP!

5. Use a push stick when ripping short (under 12

inches) or narrow (under 6 inches wide) workpieces.

6. CAUTION: Never reposition the Guard or

antikickback with power "ON".

7. A "KICKBACK" occurs during a rip-type operation

when a part or all of the workpiece is thrown back

violently toward the operator. It can occur when

the workpiece closes in on the rear (outfeed side) of

the sawblade (pinching), binds between the fence

and the sawblade (heel), or is grabbed by the

sawblade teeth (wrong-way feed) at the outfeed

side. "PINCHING" is generally avoided by

utilization of the spreader, and a sharp sawblade of

the correct type for the workpiece being cut.

"HEEL" can be avoided by maintaining the

sawblade exactly parallel to the fence. Grabbing by

the sawblade teeth can be caused by heel or by

feeding from the wrong direction (see "DANGER"

warning on guard) - it can be avoided by

maintaining parallelism of sawblade to fence,

feeding into the sawblade from the nose of the

guard only, by positioning the spreader and

antikickback properly, and keeping the workpiece

clown on the table and against the fence.

8. Position the nose of the guard to just clear the

workpiece, and position/adjust the antikickback

and spreader devices as instructed.

9. NEVER cut more than one piece at a time by

stacking workpieces vertically.

10. NEVER feed a workpiece thru the saw with another

piece (butting second piece against trailing edge of

piece being cut), even if of the same thickness. Feed

each workpiece individually thru the sawblade, and

completely beyond the sawblade, before ripping the

next workpiece. Use push stick if the rip cut is less

than 6'" wide.

11, DO NOT pul! the workpiece thru the sawblade

- position your body at the nose (in-feed) side of the

guard: start and complete the cut from that same

side. This will require added table support for long

pieces.

12. Plastic and composition (like hardboard) materials

may be cut on your saw. However, since these are

usually quite hard and slippery, the antikickback

pawls may not stop a kickback.

proper set-up and cutting procedures. Do not stand,

or permit anyone else to stand, in line with a

potential kickback.

13. When sawing 1/4" or thinner materials, follow at!

normal ripping procedures except set sawblade into

table top at least 1/8". DO NOT let go of or stop

feeding the workpiece between the blade and fence

until you have pushed it completely past the

antikickbaek pawls. Otherwise the workpiece could

get into the back of the sawblade and be thrown

violently from the saw in the direction opposite to

the feed direction. This is the same action that

would occur if the instructions of the DANGER

warning on the guard is aborted. Do not stand, or

permit anyone else to stand, in line with the path of

a workpiece that may be thrown from the saw in

this manner.

14. Position the saw so neither you, a helper, or a casuat

observer is forced to stand in line with the

sawblade.

15. Use extra care when ripping wood that has a twisted

grain or is twisted or bowed it may rock on the

table and/or pinch the sawblade.

16. Shaping of wood with a dado head or a molding

head can be performed "top-side" (cutting tool

basically vertical and employing sawblade guard}, or

"edge" (saw arbor vertical -- cutting tool horizontal

- and employing the Accessory molding head

guard).

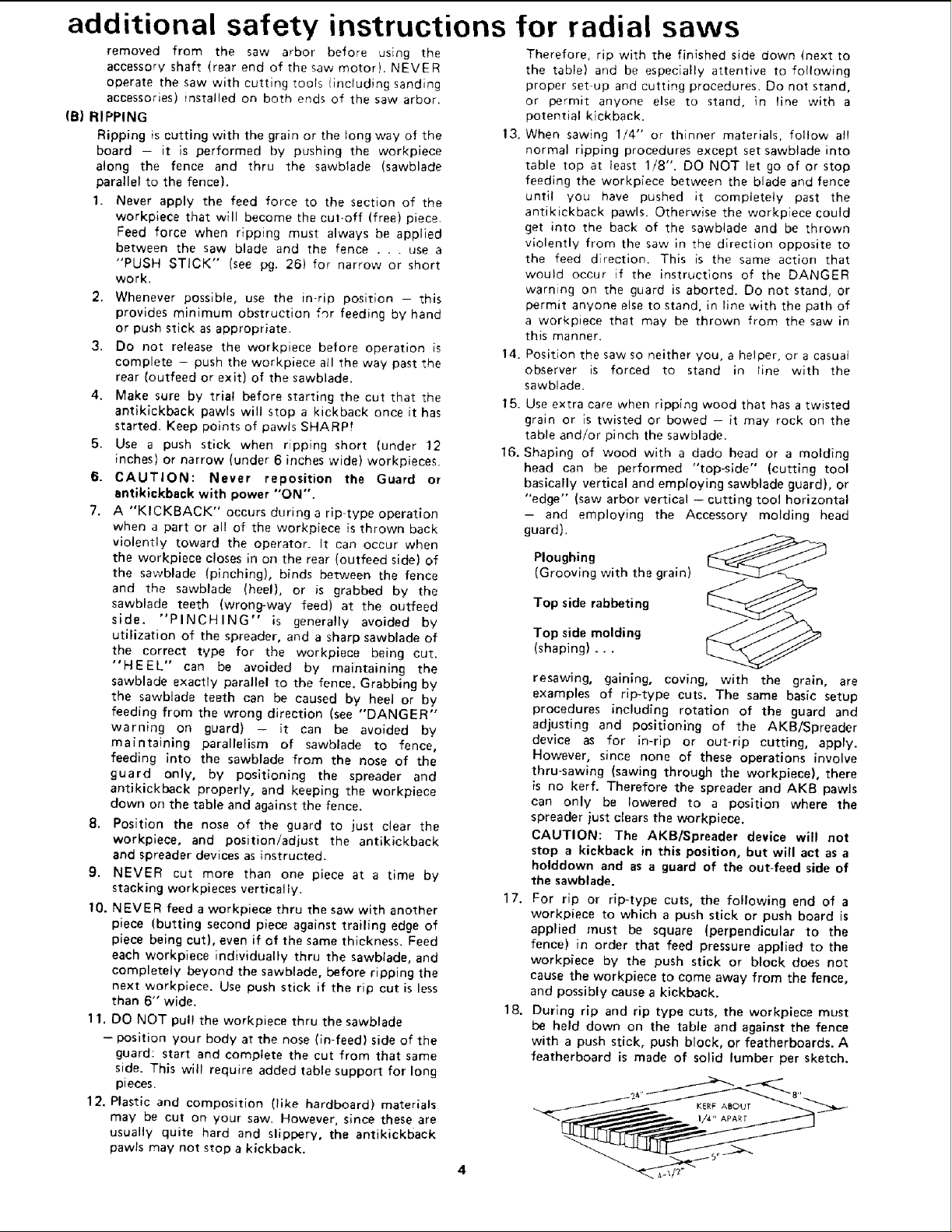

Ploughing

(Grooving with the grain)

Top side rabbeting

Top side molding

(shaping)...

resawing, gaining, coving, with the grain, are

examples of rip-type cuts, The same basic setup

procedures including rotation of the guard and

adjusting and positioning of the AKB/Spreader

device as for in-rip or out-rip cutting, apply.

However, since none of these operations involve

thru-sawing (sawing through the workpiece), there

is no kerf. Therefore the spreader and AKB pawls

can only be lowered to a position where the

spreader just clears the workpiece.

CAUTION: The AKB/Spreader device will not

stop a kickback in this position, but will act as a

holddown and as a guard of the out-feed side of

the sawblade.

17.

For rip or rip-type cuts, the following end of a

workpiece to which a push stick or push board is

applied must be square (perpendicular to the

fence) in order that feed pressure applied to the

workpiece by the push stick or block does not

cause the workpiece to come away from the fence,

and possibly cause a kickback.

18.

During rip and rip type cuts, the workpiece must

be held down on the table and against the fence

with a push stick, push block, or featherboards. A

featherboard is made of solid lumber per sketch.

Page 5

(C)CROSSCUTTING

1. ALWAYSRETURNTHECARRIAGETOTHE

FULLREARWARDPOSITIONATCONCLUSION

OFEACHCROSSCUTTYPEOPERATION.Never

remove your hand from the Yoke Handle unless the

carriage is in this position. Otherwise the cutting

tool may climb up on the workpiece and be

propelled toward you.

2. Place guard in horizontal position and adjust

antikickback pawls to just clear the top of the fence

or workpiece, whichever is higher. This provides

additional guarding.

3. NEVER gang crosscut - lining up more than one

workpiece in front of the fence - stacked vertically,

o_ horizontally outward on the table -- and then

pulling saw thru: the blade could pick up one or

more pieces and cause a binding or loss of control

and possible injury.

4. Do not position the Arm so the operation you are

performing permits the cutting tool to extend

beyond the edges of the Table.

5. -1op-side dadoing or molding across the grain are

examples of crosscut-type cuts. The same basic

procedures including positioning of the

AKB/Spreader device as for crosscutting, apply.

(D) ACC ESSORI ES

1. Use only recommended accessories as listed on page

34.

2. Never operate this saw when equipped with a dado

head or molding head unless the molding head

guard is installed - see listing of recommended

accessories. The only exception is when "top-side"

dadoing or molding, when the sawblade guard must

be used. See detailed instructions that accompany

the dado head, molding head, and molding head

guard.

3. The use of grinding wheels, abrasive or cut-off

wheels, or wire wheels, can be dangerous and is not

recommended. (Abrasive or cut-off wheels are used

to saw many different materials including metals,

stone, and glass.)

4. Drill Chuck: Do not install or use any twist drill

larger than 1/2-inch in dia., or longer than 7 inches

in length or extending more than 6inches beyond

the chuck jaws. Do not install or use any reduced

shank drill except of the spade type (1 inch dia. or

smaller). "Use for drilling WOOD and PLASTIC

only."

NOTE: Do not overtighten arbor nut. Use the arbor wrench

to just "snug" it.

WEAR YOUR

The operation of any power tool can result in foreign

objects being thrown into the eyes, which can result in

severe eye damage. Always wear safety goggles complying

with ANSI Z87.1 (shown on Package) before commencing

power tool operation. Safety Goggles are available at Sears

retail or catalog stores.

electrical connections

POWER SUPPLY

1. Motor Specifications

The ArC motor used in this saw is a capacitor-start,

non-reversible type having the following specifications:

Voltage ............................. 120/240

Amperes .............................. 11/5.5

Hertz (cycles) ............................. 60

Phase ................................ Single

RPM .................................. 3450

Rotation as viewed from saw blade end .... Clockwise

CAUTION: Your saw is wired for 120V operation.

Connect to a 120V, 15-Amp. branch circuit and use a

15-Amp. time-delay fuse or circuit breaker. If the

motor is used for 240V operation, connect to a

15-Amp. branch circuit and use a 15-Amp. time-delay

fuse or circuit breaker.

This machine must be grounded while in use to protect

the operator from electric shock.

IF YOU ARE NOT SURE THAT YOUR OUTLET IS

PROPERLY GROUNDED, HAVE IT CHECKED BY A

QUALI FI ED ELECTR ICIAN.

WARNING: DO NOT PERMIT FINGERS TO TOUCH

THE TERMINALS OF PLUGS WHEN INSTALLING

OR REMOVING THE PLUG TO OR FROM THE

OUTLET.

WARNING: IF NOT PROPERLY GROUNDED THIS

POWER TOOL CAN INCUR THE POTENTIAL

HAZARD OF ELECTRICAL SHOCK.

PARTICULARLY WHEN USED IN DAMP

LOCATIONS IN PROXIMITY TO PLUMBING. IF AN

ELECTRICAL SHOCK OCCURS THERE IS THE

POTENTIAL OF A SECONDARY HAZARD SUCH AS

YOUR HANDS CONTACTING THE SAWBLADE.

IF POWER CORD tS WORN OR CUT, OR DAMAGED

IN ANY WAY, HAVE IT REPLACED

IMMEDIATELY.

If your unit is for use on less than 150 volts it has a

plug that looks like below.

3-PRONG PLUG

PROPERLY

GROUNDED OUTLET

GROUNDING PRONG

This power tool is equipped with a 3-conductor cord

and grounding type plug which has a grounding prong,

Listed by Underwriters' Laboratories. The ground

conductor has a green jacket and is attached to the tool

housing at one end and to the ground prong in the

attachment plug at the other end.

This plug requires a mating 3-conductor grounded type

outlet as shown.

If the outlet you are planning to use for this power tool

is of the two prong type DO NOT REMOVE OR

ALTER THE GROUNDING PRONG IN ANY

MANNER. Use an adapter as shown and always connect

the grounding lug to known ground.

It it recommended that you have a qualified electrician

replace the TWO prong outlet with a properly grounded

THREE prong outlet.

Page 6

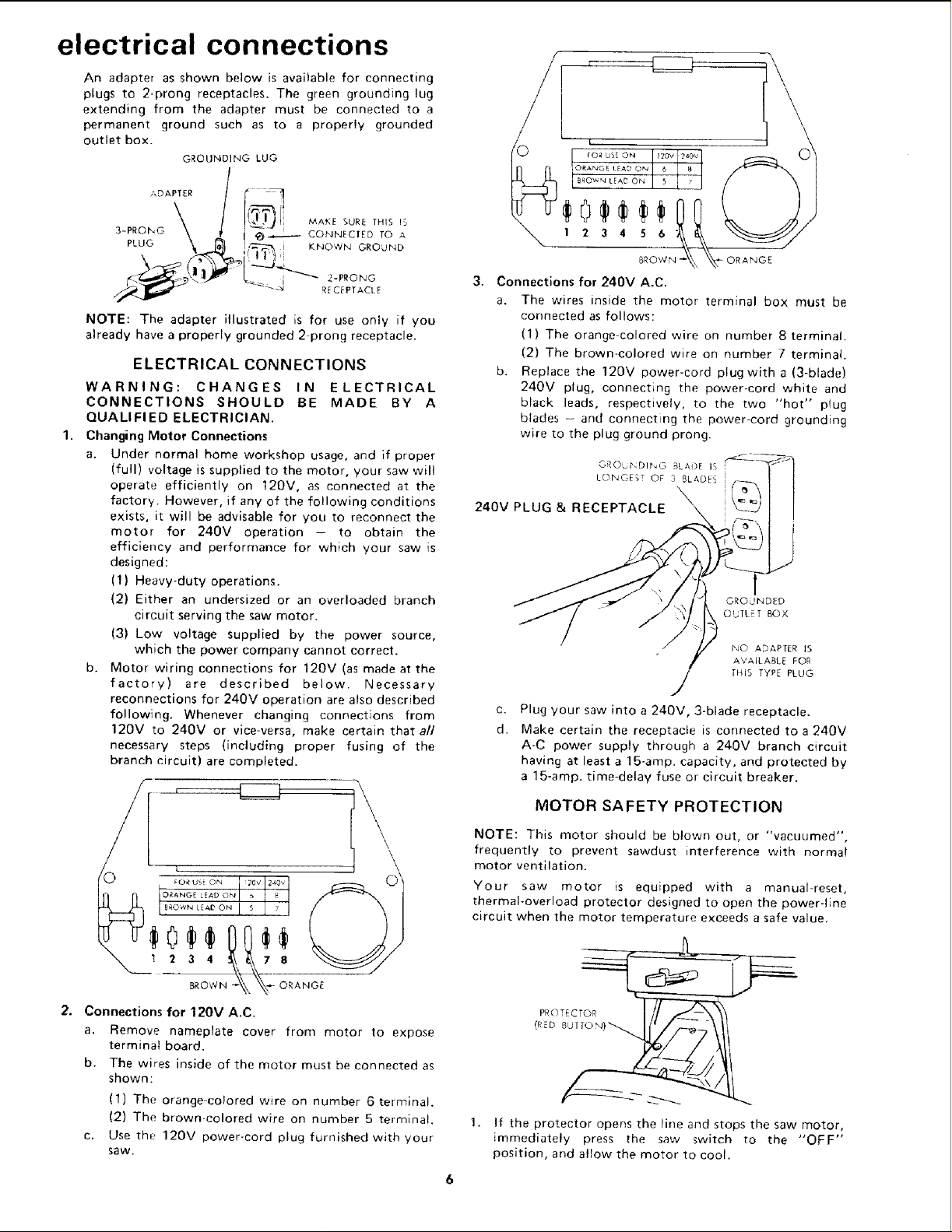

electrical connections

An adapter as shown below is available for connecting

plugs to 2-prong receptacles. The green grounding lug

extending from the adapter must be connected to a

permanent ground such as to a properly grounded

outlet box.

GROUNDING LUG

NOTE: The adapter illustrated is for use only if you

already have a properly grounded 2-prong receptacle.

ELECTRICAL CONNECTIONS

WARNING: CHANGES IN ELECTRICAL

CONNECTIONS SHOULD BE MADE BY A

QUALIFIED ELECTRICIAN.

1. Changing Motor Connections

a. Under normal home workshop usage, and if proper

(full) voltage is supplied to the motor, your saw will

operate efficiently on t20V, as connected at the

factory. However, if any of the following conditions

exists, it will be advisable for you to reconnect the

motor for 240V operation - to obtain the

efficiency and performance for which your saw is

designed:

(1) Heavy-duty operations.

(2) Either an undersized or an overloaded branch

circuit serving the saw motor.

(3) Low voltage supplied by the power source,

which the power company cannot correct.

b. Motor wiring connections for 120V (as made at the

factory) are described below. Necessary

reconnections for 240V operation are also described

following. Whenever changing connections from

120V to 240V or vice-versa, make certain that all

necessary steps (including proper fusing of the

branch circuit) are completed.

/ \

[ ,o,0,Eo.i,,0v/ .0vl o

3. Connections for 240V A.C.

a. The wires inside the motor terminal box must be

connected as follows:

(1) The orange-colored wire on number 8 terminal.

(2) The brown-colored wire on number 7 terminal.

b. Replace the 120V power-cord plugwith a (3-blade)

240V plug, connecting the power-cord white and

black leads, respectively, to the two "hot" plug

blades - and connecting the power-cord grounding

wire to the plug ground prong.

GROUNDED

()bILE/ BOX

NO ADAPTER IS

AVAILABL_ FOR

THIS TYPE PLUG

c. Plug your saw into a 240V, 3-blade receptacle.

d. Make certain the receptacle is connected to a 240V

A-C power supply through a 240V branch circuit

having at least a 15-amp. capacity, and protected by

a 15-amp. time-delay fuse or circuit breaker.

l"\

Jn n IoCZE£o-77 1

2. Connections for 120V A.C.

a. Remove nameplate cover from motor to expose

terminal board.

b. The wires inside of the motor must be connected as

shown:

(1) The orange-colored wire on number 6 terminal.

(2) The brown-colored wire on number 5 terminal.

Use the 120V power-cord plug furnished with your

saw.

I°*°WNLE'_°-I_'I 7 I /

MOTOR SAFETY PROTECTION

NOTE: This motor should be blown out, or "vacuumed",

frequently to prevent sawdust interference with normal

motor ventilation.

Your saw motor is equipped with a manual-reset,

thermal-overload protector designed to open the power-line

circuit when the motor temperature exceeds a safe value.

PROTECT_

(R_D

1. If the protector opens the line and stops the saw motor,

immediately press the saw switch to the "OFF'"

position, and allow the motor to cool.

Page 7

2. Afler coolingto a safeoperatingtemperature,the

overloadprotectorcanbeclosedmanuallybypushing

in theredbuttononthetopofthemotor.If thered

b_ttonwillnotsnapintoplaceimmediately,themotor

isstilltoohotandmustbeallowedtocootforawhile

longer.Insomecasesthismaytake20-30minutes.(An

audibleclickwillindicateprotectorisclosed.)

3, As soonastheredbuttonwill snapinto running

position, the sawmay be startedand operated

normally, by pulling out the saw switch to the "'ON"

position.

4. Frequent opening of fuses or circuit breakers may result

if motor is overloaded, or if the motor circuit is fused

differently from recommendations, Overloading can

occur if you feed to rapidly or if your saw is misaligned

so that the blade heels. Do not use a fuse of greater

capacity without consulting a qualified electrician.

5. Although the motor is designed for operation on the

voltage and frequency specified on motor nameplate,

normal loads will be handled safely on voltages not

more than 10% above or below the nameplate voltage.

Heavy loads, however, require that voltage at motor

terminals equals the voltage specified on nameplate.

6. Most motor troubles may be traced to loose or

incorrect connections, overloading, reduced input

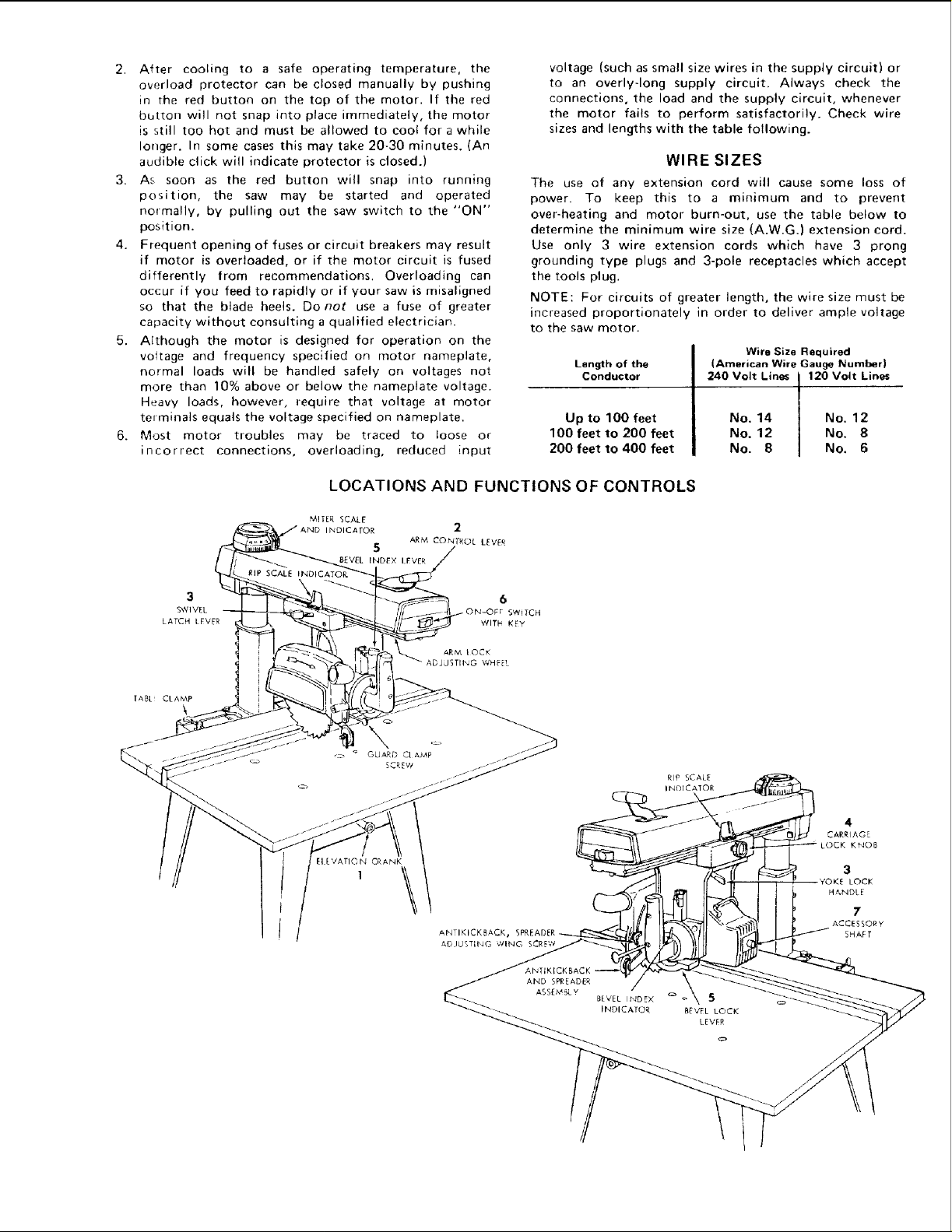

LOCATIONS AND FUNCTIONS OF CONTROLS

voltage (such as small size wires in the supply circuit) or

to an overly-long supply circuit. Always check the

connections, the load and the supply circuit, whenever

the motor fails to perform satisfactorily. Check wire

sizes and lengths with the table following.

WIRE SIZES

The use of any extension cord will cause some loss of

power. To keep this to a minimum and to prevent

over-heating and motor burn-out, use the table below to

determine the minimum wire size (A.W.G.) extension cord.

Use only 3 wire extension cords which have 3 prong

grounding type plugs and 3-pole receptacles which accept

the tools plug.

NOTE: For circuits of greater length, the wire size must be

increased proportionately in order to deliver ample voltage

to the saw motor.

Length of the

Conductor

Up to 100 feet

100 feet to 200 feet

200 feet to 400 feet

Wire Size Required

(American Wire Gauge Number)

240 Volt Lines 120 Volt Lines

No. 14 No. 12

No. 12 No. 8

No. 8 No. 6

LATCH LEVER

[ABL CLAMP

3

SWIVEL

\

6

SWITCH

WITH KEY

RIP SCALE

INDICATOR

3

LOCK

HANDLE

ACCESSORY

SHAFT

7

Page 8

CONTENTS

Guarantee ................................... 2

General Safety Instructions for Power Tools ......... 2

Additional Safety Instructions for Radial Saws ....... 3

Electrical Connections .......................... 5

Assembly and Alignment ........................ 8

Unpacking and Preassembly ..................... 8

Alignment Procedure ......................... 12

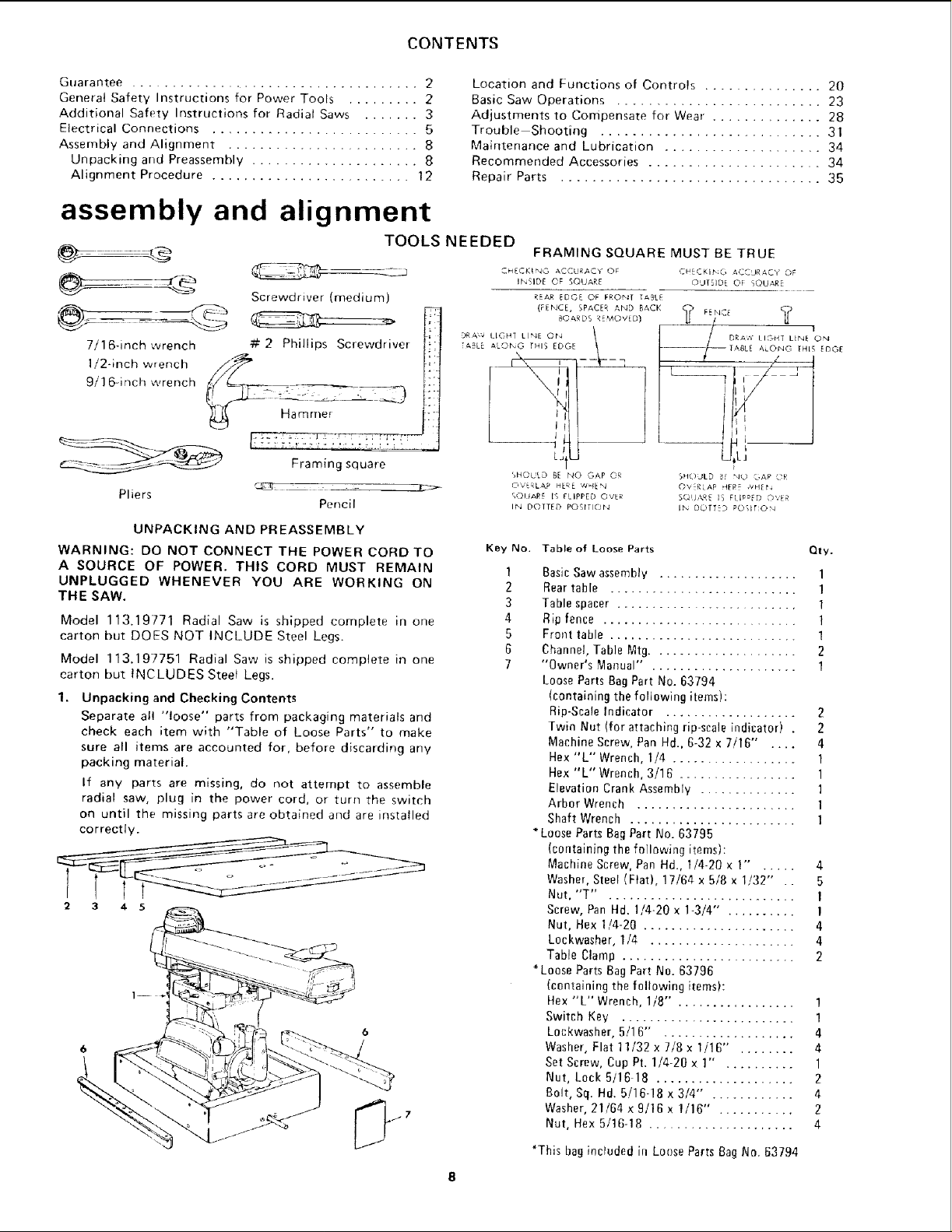

assembly and alignment

..... _÷_ TOOLS NEEDED

Screwdriver (medium)

7/16-inchwrench #2 Phillips Screwdriver [i: _'L[

1/2-inch wrench /_/_ [/

9i16dnch wrench _'//___[_ - _ i:

Framing square

Pliers

UNPACKING AND PREASSEMBLY

WARNING: DO NOT CONNECT THE POWER CORD TO

A SOURCE OF POWER. THIS CORD MUST REMAIN

UNPLUGGED WHENEVER YOU ARE WORKING ON

THE SAW.

Model 113.19771 Radial Saw is shipped complete in one

carton but DOES NOT INCLUDE Steel Legs.

Model 113.197751 Radial Saw is shipped complete in one

carton but INCLUDES Steet Legs.

1. Unpacking and Checking Contents

Separate al! "loose" parts from packaging materials and

check each item with "Table of Loose Parts" to make

sure all items are accounted for, before discarding any

packing material.

If any parts are missing, do not attempt to assemble

radial saw, plug in the power cord, or turn the switch

on until the missing parts are obtained arrd are installed

correctly.

2 3 4 5

Pencil

Location and Functions of Controls ............... 20

Basic Saw Operations .......................... 23

Adjustments to Compensate for Wear . ............. 28

Trouble Shooting ............................ 31

Maintenance and Lubrication .................... 34

Recommended Accessories ...................... 34

Repair Parts ................................. 35

FRAMING SQUARE MUST BE TRUE

CHECKING _CC[JRACY OF CIdECKI_ , ACCURACY OF

I[_SIDE OF SQUARE OUTSIDE OF SQUARE

REAR EDGE OF FRONT TAB£_

(FENCE, SPACE _ ^ND BACK C') __ cm

TIGHT LI_qE ON / DR_-,%" 11_'4 T LINE ON

•_,LOFJO_i__ __ illl /,THIS EDGE ---_ ITAgLE ALONG THIS EDGE

BOARDS R '4DYED) -- _" / "_ I

' *" _--_b;C[

11i! t

SHOULD BE NO GAP 0£ StIOULD 4 NO '_AP R

OV LAP HEre WHE'q Ou RLAP _!FRE ,VHEr4

RQliARE [S FLIPPED OVER B©UAR_ c iS FIID_TD OVER

IN DOTTED POSITION It., DOTTED POSITION

Key No. Table of Loose Parts Qty.

1

Basin Saw assembly .................... 1

2

Rear table ........................... 1

3

Table spacer ......................... 1

4

Rip fence ............................ 1

5

Front table ........................... 1

6

Channel, Table Mtg..................... 2

7

"Owner's Manual" . .................... 1

Loose Parts Bag Part No. 63794

(containing the following items):

Rip-Scale Indicator ................... 2

Twin Nut (for attaching rip-scale indicator) . 2

Machine Screw, Pan Hd.,6-32x7!16" .... 4

Hex "L" Wrench, 1/4 .................. 1

Hex "L" Wrench, 3/16 ................. 1

Elevation Crank Assembly .............. 1

Arbor Wrench ....................... 1

Shaft Wrench ........................ 1

*Loose Parts Bag Part No. 63795

(containing the following items):

Machine Screw, Pan Hd., 1/4-20 x 1'" . .... 4

Washer, Steel (Flat), 17/64 x 5/8 x 1/32" .. 5

Nut,"T" . .......................... 1

Screw, Pan Hd. 1/4-20 x 1-3/4" . ......... 1

Nut, Hex 1,/4-20 ...................... 4

Loekwasher, 1/4 ..................... 4

Table Clamp ......................... 2

*Loose Parts Bag Part No. 63796

(containing the following items):

Hex "L"Wrench, 1/8" . ................ 1

Switch Key ......................... 1

L0ekwasher, 5/16" . .................. 4

Washer, Flat l l/32 x l/8 x li16" . ....... 4

Set Screw, Cup Pt. 1/4-20 x 1" . ......... 1

Nut, Lock 5/16 18 .................... 2

Bolt, Sq. H& 5/16 18 x 3/4" . ........... 4

Washer, 21/64 × 9/16 x 1/16" . .......... 2

Nut, Hex 5/16-18 ..................... 4

*This bag included in Loose Parts Bag No. 63794

Page 9

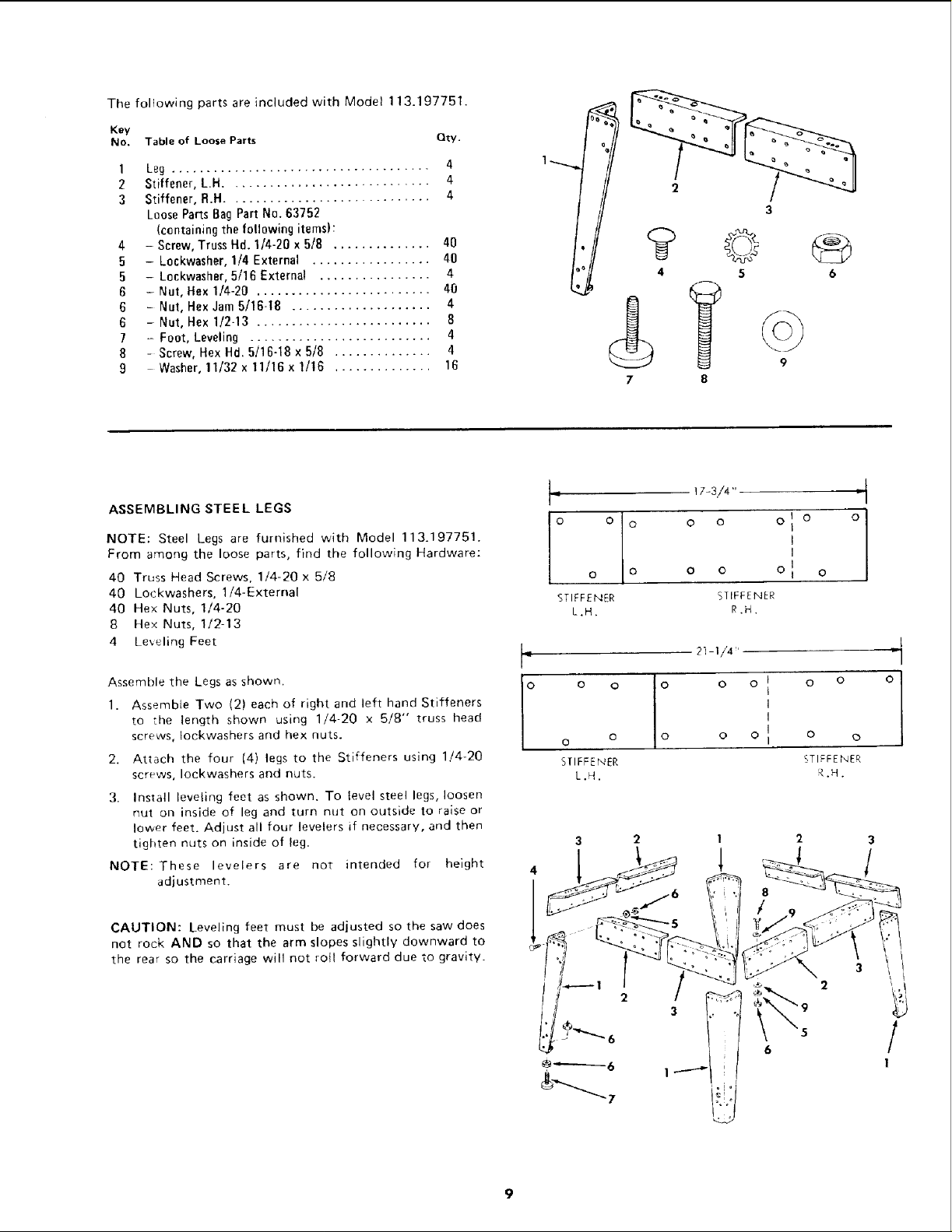

ThefoliowingpartsareincludedwithModel113.197751.

Key

No. Table of Loose Parts Qty.

1 Leg ..................................... 4

2 Stiffener, L.H ............................. 4

3 Stiffener, R.H ............................. 4

Loose Parts Bag Part No. 63752

(containing the following items):

4 - Screw, Truss Hd. 1/4-20 x 5/8 .............. 40

5 - Lockwasher, 1/4 External ................. 40

5 - Lenkwasher, 5/16 External ................ 4

6 - Nut, Hex 1/4-20 ......................... 40

6 - Nut, Hex Jam 5/16-18 .................... 4

6 - Nat, Hex 1/2-13 ......................... 8

7 - Foot, Leveling .......................... 4

8 - Screw, Hex Hd. 5/16-18 x 5/8 .............. 4

9 Washer, 11/32 x 11/16 x 1/16 .............. 16

2

3

4

7

ASSEMBLING STEEL LEGS

NOTE: Steel Legs are furnished with Model 113_197751.

From among the loose parts, find the following Hardware:

40 Truss Head Screws. 1/4-20 x 5/8

40 Lockwashers, 1/4-External

40 Hex Nuts, 1/4-20

8 Hex Nuts, 1/2-13

4 Leveling Feet

Assemble the Legs as shown.

1. Assemble Two (2) each of right and left hand Stiffeners

to the length shown using 1/4-20 x 5/8" truss head

screws, tockwashers and hex nuts.

2. Attach the four (4) legs to the Stiffeners using 1/4-20

screws, Iockwashers and nuts.

3. Install leveling feet as shown. To level steel legs, loosen

nut on inside of leg and turn nut on outside to raise or

lower feet. Adjust all four levelers if necessary, and then

tighten nuts on inside of leg.

NOTE: These levelers are not

adjustment.

CAUTION: Leveling feet must be adjusted so the saw does

not rock AND so that the arm slopes slightly downward to

the rear so the carriage will not rotl forward due to gravity.

intended for height

I-

I°

o o

o

STIFFENER

L.H.

O O

O

SflFFENER

L.H.

3 2

0 0

0 0

STIFFENER

R.H.

0 O t O O

I

I

o

O O II O O

1 2

i

STIFFENER

R.H.

°1

/

1

1

Page 10

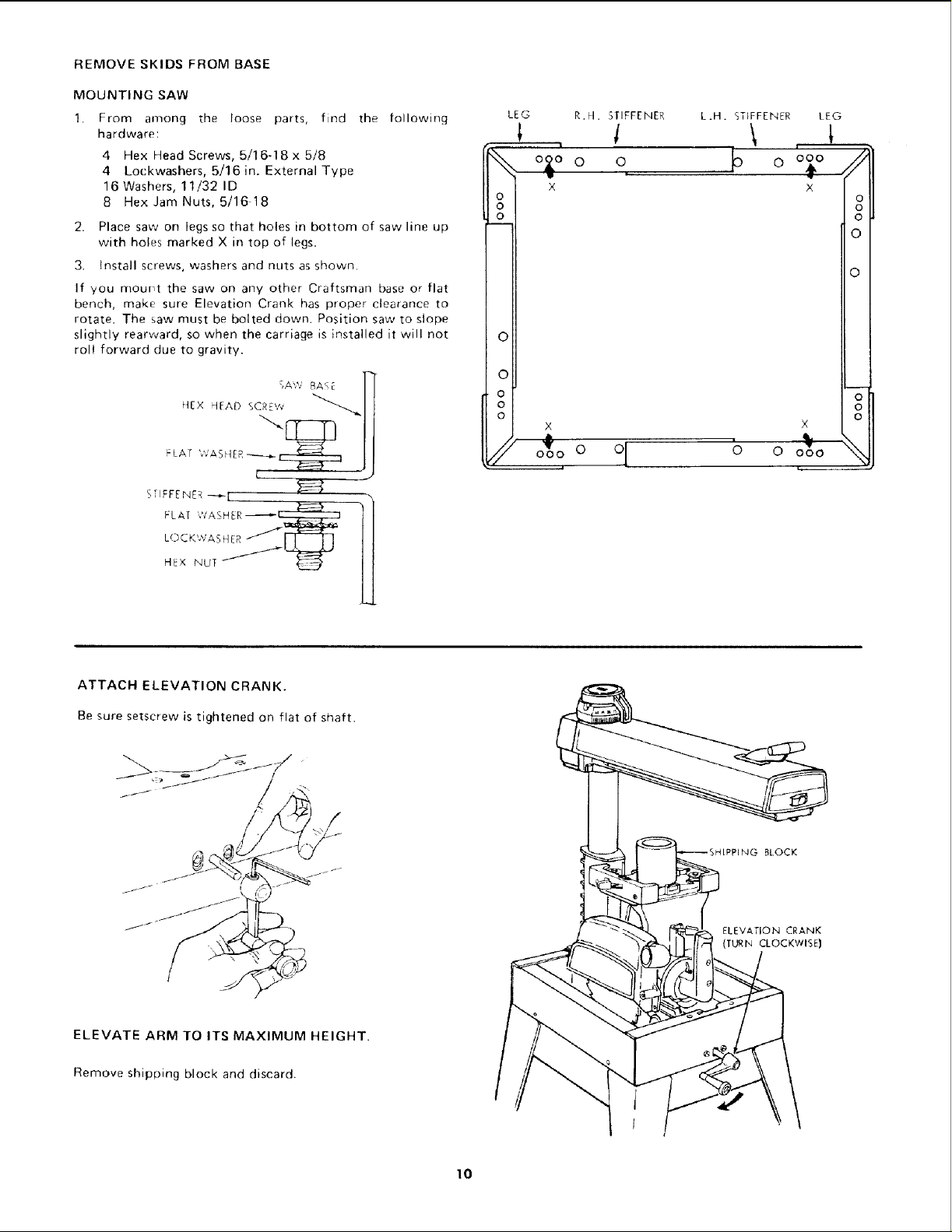

REMOVESKIDSFROMBASE

MOUNTINGSAW

1. Fromamongthe looseparts,find the following

hardware:

4 HexHeadScrews,5/16-18x5/8

4 Lockwashers,5/16in.ExternalType

16Washers,11/32ID

8 HexJamNuts,5/1618

2. Placesawonlegssothatholesinbottomofsawlineup

withholesmarkedXintopoflegs.

3. Installscrews,washersandnutsasshown.

If youmour_tthesawonanyotherCraftsmanbaseorflat

bench,makesureElevationCrankhasproperclearanceto

rotate.Thesawmustbebolteddown.Positionsawtoslope

slightlyrearward,sowhenthecarriageisinstalleditwillnot

rollforwardduetogravity.

LEG

l

R.H. STIFFENER L.H. STIFFENER LEG

1

oloo o Io ooo,oj

x x

i

0

0

o

0

o

SA',\, BABE ]

tFADscC

FLAT W A SH[ P,,---_-_- _ J

STIFFENER_1

HEX NUT /_

ATTACH ELEVATION CRANK.

Be sure setscrew is tightened on flat of shaft.

x x

ooo o oI o o ooo

1

4L

O

O

O

ELEVATE ARM TO ITS MAXIMUM HEIGHT.

Remove shipping block and discard.

BLOCK

ELEVATION CRANK

(TURN CLOCKWISE)

lO

Page 11

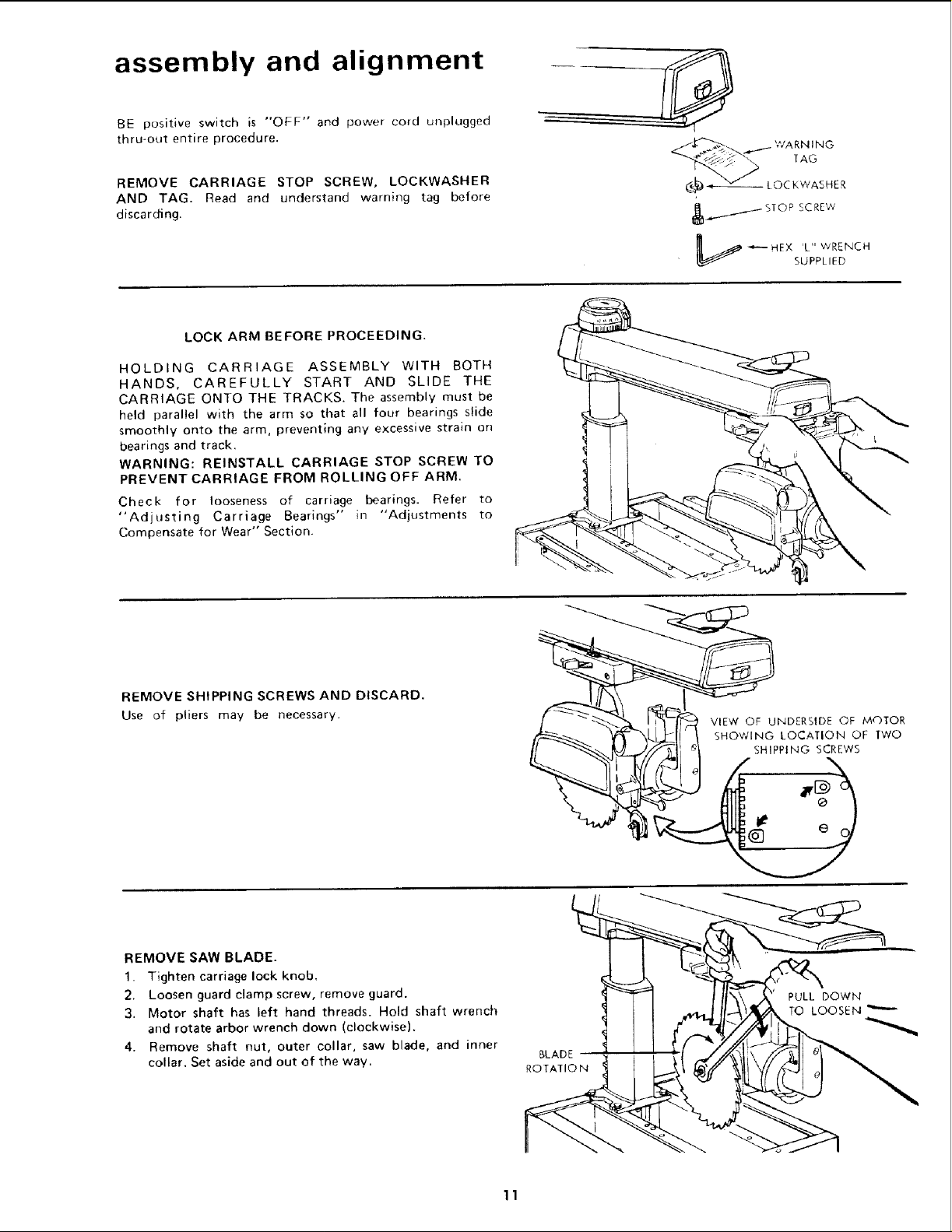

assembly and alignment

BE positive switch is "OFF" and power cord unplugged

thru-out entire procedure.

REMOVE CARRIAGE STOP SCREW, LOCKWASHER

AND TAG. Read and understand warning tag before

discarcfing.

LOCK ARM BEFORE PROCEEDING.

HOLDING CARRIAGE ASSEMBLY WITH BOTH

HANDS, CAREFULLY START AND SLIDE THE

CARRIAGE ONTO THE TRACKS. The assembly must be

held parallel with the arm so that all four bearings slide

smoothly onto the arm, preventing any excessive strain on

bearings and track.

WARNING: REINSTALL CARRIAGE STOP SCREW TO

PREVENT CARRIAGE FROM ROLLING OFF ARM.

Check for looseness of carriage bearings. Refer to

"Adjusting Carriage Bearings" in "Adjustments to

Compensate for Wear" Section.

REMOVE SHIPPING SCREWS AND DISCARD.

Use of pliers may be necessary.

REMOVE SAW BLADE.

1. Tighten carriage lock knob.

2. Loosen guard clamp screw, remove guard.

3. Motor shaft has left hand threads. Hold shaft wrench

and rotate arbor wrench down (clockwise).

4. Remove shaft nut, outer collar, saw blade, and inner

collar, Set aside and out of the way,

NDERSIDE OF MOTOR

LOCATION OF TWO

IL el S.IP,INOSCREWS

PULL DOWN

TO LOOSEN ""'--

BLADE

ROTATION

11

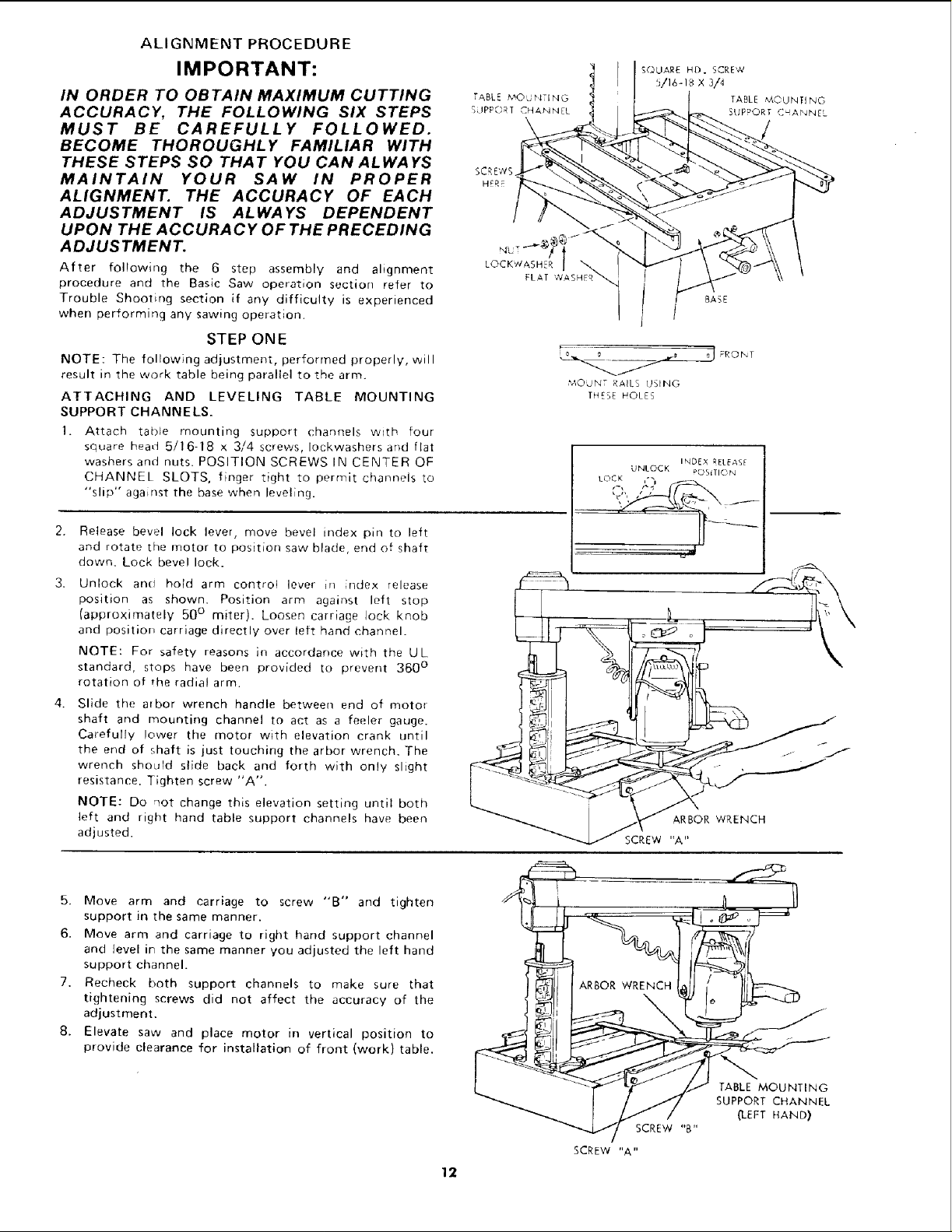

Page 12

ALIGNMENT PROCEDURE

IMPORTANT:

IN ORDER TO OBTAIN MAXIMUM CUTTING

ACCURACY, THE FOLLOWING SIX STEPS

MUST BE CAREFULLY FOLLOWED.

BECOME THOROUGHLY FAMILIAR WITH

THESE STEPS SO THAT YOU CAN ALWAYS

MAINTAIN YOUR SAW IN PROPER

ALIGNMENT. THE ACCURACY OF EACH

ADJUSTMENT IS ALWAYS DEPENDENT

UPON THE ACCURA CY OF THE PRECEDING

ADJUS TMENT.

After following the 6 step assembly and alignment

procedure and the Basic Saw operation section refer to

Trouble Shooting section if any difficulty is experienced

when performing any sawing operation.

STEP ONE

NOTE: The following adjustment, performed properly, will

result in the work table being parallel to the arm.

ATTACHING AND LEVELING TABLE MOUNTING

SUPPORT CHANNELS.

1. Attach table mounting support channels with four

square head 5/16 18 x 3/4 screws, Iockwashers and flat

washers and nuts. POSITION SCREWS IN CENTER OF

CHANNEL SLOTS, finger tight to permit channels to

"slip" against the base when leveling.

TABLE MO r'4TING

S JPPORT CHANNEL

\

SCREWS

HERE

LOCKWASHER

FLAT WASHER

BASE

MOUNT RAILS LJSIING

THESE HOLES

2. Release bevel lock lever, move bevel index pin to left

and rotate the motor to position saw blade, end of shaft

down Lock bevel lock.

Unlock and hold arm control lever n ndex release

position as shown. Position arm against left stop

(approximately 50° miter). Loosen carriage Jack knob

and positior, carriage directly over left hand channel.

NOTE: For safety reasons in accordance with the UL

standard, stops have been provided to prevent 360 °

rotation of the radial arm.

4. Slide the arbor wrench handle between end of motor

shaft and mounting channel to act as a feeler gauge.

Carefully lower the motor with elevation crank until

the end of shaft is just touching the arbor wrench. The

wrench should slide back and forth with only slight

resistance. Tighten screw "A".

NOTE: Do qot change this elevation setting until both

left and right hand table support channels have been

adjusted.

5. Move arm and carriage to screw "B" and tighten

support in the same manner.

6. Move arm and carriage to right hand support channel

and level in the same manner you adjusted the left hand

support channel.

7. Recheck both support channels to make sure that

tightening screws did not affect the accuracy of the

adjustment.

8. Elevate saw and place motor in vertical position to

provide clearance for installation of front (work) table.

o

ARBOR WRENCH

SCREW "A"

ARBOR WRENCH

12

TABLE MOUNTING

SUPPORT CHANNEL

(LEFT HAND)

SCREW "8"

SCREW "A"

Page 13

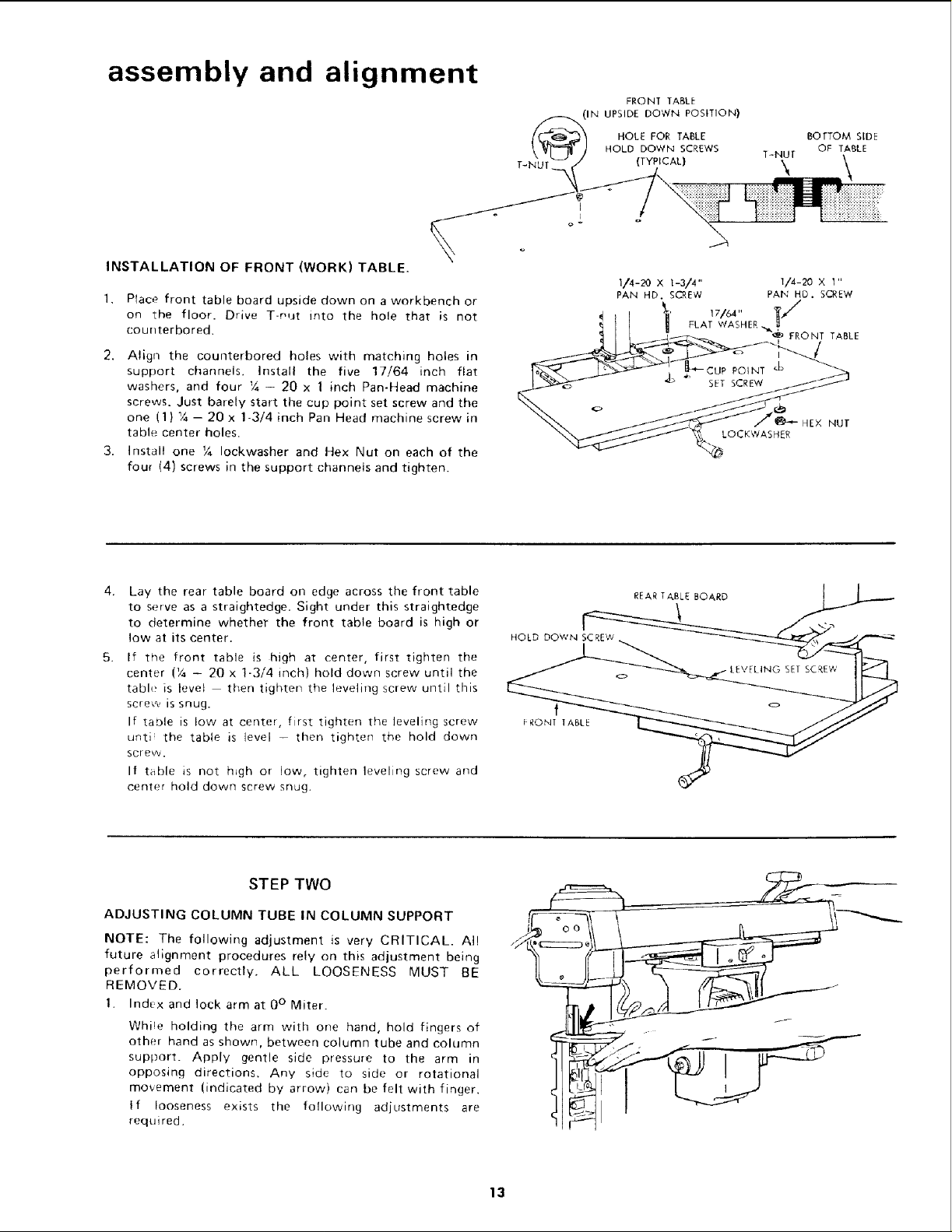

assembly and alignment

INSTALLATION OF FRONT (WORK) TABLE.

Place front table board upside down on a workbench or

on the floor. Drive T-r, ut into the hole that is not

counterbored,

2. Align the counterbored holes with matching holes in

support channels. Install the five 17/64 inch flat

washers, and four 1/4- 20 x 1 inch Pan-Head machine

screws. Just barely start the cup point set screw and the

one ( 1) 1/__ 20 x 1-3/4 inch Pan Head machine screw in

table center holes.

3. Install one ¼ Iockwasher and Hex Nut on each of the

four (4) screws in the support channels and tighten.

,,)

FRONT TABLE

i/__._IN UPSIDE DOWN POSITION)

(_G_ / HOLE FOR TABLE BOTTOM SIDE

"O'hT O, L';REWS,_.0, \ABLE

° ° 2

i/4-20 x I-3/4' i/_-20 x _

PAN HD. SCREW PA_ HD. SCREW

1' FLAT17/64"WASHER --_/

"_? FRONT TABLE

LOCKWASHER

E

NUT

Lay the rear table board on edge across the front table

to serve as a straightedge. Sight under this straightedge

to determine whether the front table board is high or

low at its center.

5.

If the front table is high at center, first tighten the

center (Y, - 20 x t-3/4 inch) hold down screw until the

table is level then tighten the leveling screw until this

screw is snug.

If table is low at center, first tighten the leveling screw

unti the table is level - then tighten the hold down

scre_.

If table is not h_gh or low, tighten leveling screw and

center hold down screw snug.

STEP TWO

ADJUSTING COLUMN TUBE IN COLUMN SUPPORT

NOTE: The following adjustment is very CRITICAL. Al!

future alignment procedures rely on this adjustment being

performed correctly. ALL LOOSENESS MUST BE

REMOVED.

t. Indux and lock arm at 0° Miter.

Whi!e holding the arm with one hand, hold fingers of

other hand as shown, between column tube and column

support. Apply gentle side pressure to the arm in

opposing directions. Any side to side or rotational

movement (indicated by arrow) can be felt with finger.

If looseness exists the following adjustments are

requi red,

REAR TAiLE BOARD

HOLD DOW'N _= J_

FRONT tABLE

13

Page 14

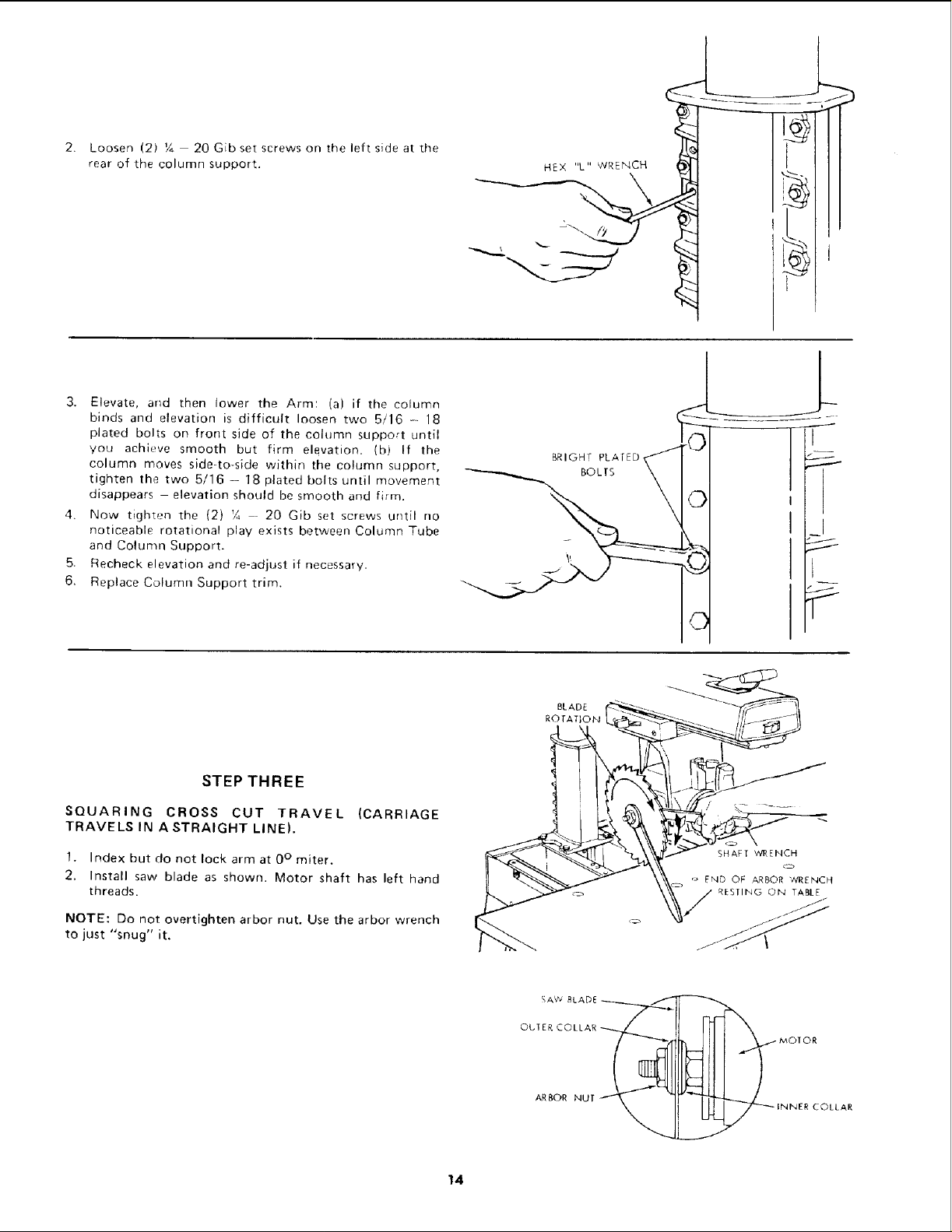

Loosen (2) V4 20 Gib set screws on the left side at the

rear of the column support,

3. Elevate, and then lower the Arm: (a) if the column

binds and elevation is difficult loosen two 5/16 - 18

plated bolts on front side of the column support until

you achieve smooth but firm elevation. (b) If the

column moves side-to-side within the column support,

tighten the two 5/16 -- 18 plated bolts until movement

disappears - elevation should be smooth and firm.

4. Now tighten the (2) Yf, 20 Gib set screws until no

noticeable rotational play exists between Column Tube

and Column Support.

5. Recheck elevation and re-adjust if necessary.

6, Replace Column Support trim.

B ,OH PtArED O

STEP THREE

SQUARING CROSS CUT TRAVEL (CARRIAGE

TRAVELS IN A STRAIGHT LINE).

1. Index but do not lock arm at 0° miter.

2. Install saw blade as shown. Motor shaft has left hand

threads.

NOTE: Do not overtightenarbor nut. Use the arbor wrench

to just "snug" it.

BLADE

ROTATION 1

SHAFT WRENCH

o END OF ARBOR WRENCH

Rf_STING ON TABLE

SAW BLADE _..__

OCTEF_ COLLAR __ iii _._ MOTOR

ARBOR NUT _INNER COLLAR

14

Page 15

assembly and alignment

3. Lower arm until saw blade just clears the front table.

Lock the yoke clamp handle and bevel lock lever.

4. Place a framing square on the table as shown and

position the blade and square until the leg of the square

just contacts a tooth of the blade. Mark this tooth.

NOTE: The framing (or combination) square must be

"true" -- see start of "Assembly and

Alignment" section on p. 8 for checking

method."

5. When the carriage is moved back and forth on the arm,

the marked tooth should just touch the square at all

poults. If marked tooth moves into square or away

from square the following adjustments are required:

a. Loosen (3) 3/8 - 16 set screws in arm latch at rear

of arm.

b. Move the arm in proper direction to make marked

tooth follow edge of square when the saw blade is

moved along arm in a "cross cut" manner.

c. Lock arm latch.

d. RETIGHTEN (3) setscrews in arm latch as tight as

possible and recheck "cross cut" travel.

NOTE: This squaring of the cross cut travel will

simultaneously set BOTH of the 45 ° miter index

positions.

BEVEL LOCK

LEVER

D

_HEX "L" WRENCH

e. Set miter indicator on 0° position as shown.

6.

Position the rip (guide) fence, spacer board and rear

table board behind the front table board as shown.

7.

Install the two table clamps in the holes provided for

them at the rear of the saw base, and tighten them

securely.

NOTE: The life of your saw table will be lengthened

considerably if you will cover the front table with a

fitted piece of 1/4 inch plywood. This should be tacked

in place for easy replacement. Use of such a cover will

allow you to do all cutting into the cover, rather than

your table top.

WASHER

REAR

CLAMP

RIP FENCE

FRONT TABLE

15

Page 16

STEP FOUR

SQUARING SAW BLADE TO {WORK) TABLE

NOTE: If alignment procedure step one was not performed,

this adjustment can not be accomplished.

1. Place a framing square on the table with the short leg

against the saw blade. Do not allow the square to rest

against a "set*out" tooth; it must rest flat against the

blade side.

2. If the saw blade is square with the table top (no visible

gap appears between the saw blade and square) and no

adjustment is required. Set bevel indicator to 0 °

reading. If the square does not touch the saw blade as

shown {with square leg held firm against the table top),

perform the following adjustments:

I J/ I • f/ ,

RIP FENCE

X

SQUARE

TA'_t E WRONG ,VRONO

a. Tighten carriage lock knob. p

b. Remove handle cover by removing two #10 Pan

Head Screws• Remove handle by removing 5116- 18 _ _--'_

socket head screw and Iockwasher.

c. Loosen the four socket head screws with 1/4" Hex

"L" Wrench. Rotate motor while holding square

firmly against saw blade and table top.

d. Slightly tighten each of the four screws and recheck

• . . Now tighten each screw tight.

e. Reinstall handle and adjust indicator on 0° reading.

f. Loosen carriage lock knob.

STEP FIVE

SQUARING BLADE TO RIP (GUIDE) FENCE - BLADE

HEEL ADJUSTMENT.

NOTE: If alignment procedure steps two and four were not

performed, this alignment step cannot be accomplished.

1.

Position cmriage as shown and tighten carriage lock

knob. Place a framing square against the rip fence and

the saw blade, as shown. The long leg of the square

must be hehl firmly against both the fence and the table

top, and the short leg must not touch any of the teeth

on the saw blade. Check at several points of blade

rotabon.

C

LEFT HAND

CARRIAGE COVER

RIP FENCE

RGHT

LOOSEN THESE

FOUR SCREWS

5/16 IN. LOCKWASHER/f

HEX "L" WR ENCH

5/16-18 SOCKET

HEAD SCREW

NO. 10 PAN HD

SCREW

2• If the square does not touch the blade at both of the

two points as shown, a heel condition exists.

FENCE

_OLIARE _ --_

|j WRONG

FENCE

U WRONG

16

I l

H

-%

SQUARE tR [_..L

FENCE

MOFOR

Page 17

assembly and alignment

3. To correct "heel" condition proceed as follows:

a. Remove left hand carriage cover.

b. Loosen the yoke clamp handle.

c. Loosen (slightly) the two hex-head screws.

d Rotate the yoke assembly until gap between the

saw blade and square is eliminated.

e. Lock yoke clamp handle and retighten the two

he× head screws.

f, Recheck for "heel" and install carriage cover.

g Loosen carriage lock knob.

NOTE: This alignment procedure will simultaneously set

both yoke index ng positions for blade in and out rip.

VERTICAL HEEL ADJUSTMENT

1. WiEh sawblade in 90 ° cutoff position, elevate saw and

rotate motor to vertical position (Blade Horizontal) and

c_eck for heel. Make sure bevel lock lever is locked.

2. P_ssition square perpendicular to fence and between

blade and table, as shown lower am1. Do not allow the

square to rest against a "set-out" tooth, it must rest flat

against the blade side.

HEX HEAD SCREWS

LEFT SIDE OF CARRIAGE

, ! I1k

BEVEL,lOCKf " "--T I ol

If the saw blade is parallel with t!le table top {no visible

g,]p appears between the saw blade and square), no

adjustment is requir_:d.

4.

I_ there is a visible gap between saw blade and square, a

bevel heel condition exists and adjustment is required.

a. To correct, unlock bevel lock lever, loosen the rear

motor mount 3/8-16 nut until you can rotate Cam,

and then rotate Can] as shown until gap between

saw blade and square is eliminated.

b. Tighten nut and bevel lock lever and recheck.

c. Reposition motor in crosscut position.

SQUARE

_E_c_NII _q_,

r_[] / _1n

TABLE RIGHT

WRONG

(TURN CAM

COUNTERCLOCKWISE}

17

CLOC

'/TR0 N G

(TUR Iq CAM

CLOCKed1SE}

1

J

Page 18

STEP SIX

1.

INSTALLING AND ADJUSTING RIP SCALE

INDICATORS.

NOTE: The rip scales and pointers are intended to

be used for quick settings. For greater accuracy,

take direct measurement between blade and fence.

a. Pre-assemble indicator and twin nut, loosen but do

not remove the two screws which attach left hand

carriage cover.

b. Tilt carriage cover and install rip indicator as shown.

Tighten carriage attaching screws.

c. Loosen hut do not remove carriage lock knob in

right hand carriage cover. Install rip indicator in the

same mar ner. Tighten carriage attaching screws.

With the fence in its normal position (next to the

front table), loosen the yoke clamp handle, pult on

swivel latch pin knob and rotate the yoke as shown

to index the yoke 90 ° from the cross cut position.

This will !ocate the saw blade between the motor

and the fence. Lock the yoke by tightening the

yoke clamp handle.

SCREW

TWIN NUT

k i i I

Position carriage until the edge of the blade, when

spun by hand, just touches the front face of the

fence. The rip-scale indicator (on the right hand side

of radial arm) should now read "0" inches on upper

portion of the blade "In-Rip" scale. If not, loosen

screws and shift the indicator until it is aligned with

the "0" mark, then tighten the screws.

NOTE: With the saw blade and fence in the position

shown, the upper portion of the blade "In Rip"

scale is used. If the fence is re-located at the

extreme rear position, the lower portion of the

blade "In-Rip" scale would be used.

f. The blade "Out-Rip" scale indicator on the left

hand side of the radial arm is adjusted in essentially

the same manner as the blade "'In-Rip" indicator,

except the blade should be as shown. With 2 inches

measured between the fence and the face of saw

blade, the rip-scale indicator should be positioned

to read 2 inches on the upper portion of the blade

"Out-Rip" scale.

NOTE: With the saw blade and fence in the position

shown, the upper portion of the blade "Out-Rip"

scale is used. If the fence is moved to rear position

(at the rear of rear table) the lower portion of the

blade "'Out-Rip'" scale is used.

g. Loosen the yoke clamp handle, pull on the swivel

latch pin knob and return the blade to the 90 °

position.

TABLE SPACERBOARD

RIP SCALE INDICATOR

. ® O er]

CARRIAGE

LOCK KNOB

2" - MEASURED FROM FENCE

TO NEAREST BLADE TOOTH

I

1

I

18

Page 19

assembly and alignment

ALIGNMENT OF SPREADER FOR RIPPING.

WARNING: NEVER POSITION THE GUARD OR

ANTIKICKBACK ASSEMBLY WITH POWER ON; NOR

POSITION ANTIKICKBACK PAWLS BY GRASPING

PAWLS OR SPREADER.

2. Install Blade Guard.

a. Sight (visually) to check for proper alignment of

spreader with saw blade as shown. If the spreader is

not aligned, adjust it as follows:

(I) Loosen two hex nuts, one on each side of

spreader.

(2) Rotate hex nuts with fingers until the spreader

is directly in line with saw blade.

(3) Tighten both hex nuts firmly.

_ i

",_ WING SCREW

3.

Check and Adjust the spreader as follows:

a. Loosen the antikickback spreader adjusting wing

screw and with the "tab" position the antikickbaek

and spreader assembly near the bottom of the blade

and tighten.

FENCE LOCATIONS

PREADFR

J

ANTI KICKBACK, SPREADER

ADJUSTING WING SCREW

TAB

OUTSIDE VIEW INSIDE VIEW

ANTIKICKBACK PAWLS

Position (A) is used for most cutoff and narrow ripping

operations. Position (B) is used for maximum width

ripping. Position (C) is used to achieve maximum crosscut

capacity in thin work.

Now that you have assembled and aligned your saw, you

are ready to proceed with operating controls section of this

manual. Refer to trouble shooting section if saw does not

perform satisfactorily or any problems should surface after

using the saw.

19

B CA

--

Page 20

locations and functions of controls

The versatility of the Radial Saw is due, in part, to its

controls, and these are the keys to its successful operation.

Learn to use the controls for all operations before actually

start ng to saw.

A series of six diagrams is located on the top surface of the

arm. These designate the controls that must be used in basic

set-ups and operating procedures. You should become

familiar with these diagrams and the operating instructions

that follow, before operating your saw.

MITER SCALE

3

SWIVEL

LATCH LEVER

INDICATOR 2

BEVEL INDEX LEVER

RIP SCALE tNDLCATOP_

' /

ARM CONTROL LEVER

6

SWITCH

WITH KEY

ARM LOCK

ADJUSTING WHEEL

TABLE CLAMP

GUARD CLAMP

ELEVATION CRANK

ANTIKICKBACK,

ADJUSTING WING SCREW

ANTIKICKBACK

AND SPREADER

ASSEMBLY

SCRE'¢V

<--7

BEVEL INDEX

INDICATOR

RIP SCALE

INDICATOR

4

CARRIAGE

KNOB

3

LOCK

HANDLE

7

ACCESSORY

SHAFT

5

BEVEL LOCK

LEVER

2O

Page 21

locations and functions of controls

1. Depth of Cut (Elevation)

a. The diagram shows the elevation crank which is

used to raise and lower the saw blade.

b. Clockwise rotation raises the blade . . .

counterclockwise rotation lowers it. One complete

turn of the handle will raise or lower the saw blade

Ii16-inch.

2. Angle of Cut (Miter)

Proper Indexing Method Experienced operators of

woodworking equipment, such as this Craftsman Radial

Saw, acquire the habit of indexing in one direction

only, whenever a new setting is made in preparation for

a different opeTation.

Example: When moving the arm to a miter index

[_osition move it slightly past the desired index position,

then return to the index position carefully to index and

lock. Yoke indexing and bevel indexing carl be

accomplished in a similar manner. This indexing

technique tends to neutralize any stresses impaired

upon saw components and contributes to the high

degree of accuracy the saw is capable of producing

when operated expertly.

a. The arm control lever locks, unlocks and indexes

the arm for Left and Right Miter cuts.

b. The radial arm has positive index positions at 0 °

and 4E ° Left and Right. The arm is rotated by

pulling arm control lever to index release position.

With arm contro! lever released the arm will

automatically index at 0 ° and 45 ° Left or Right.

After positioning arm to the desired miter angle,

push arm contlol lever to locked position.

saw-blade (bevel) angle, are: bevel lock lever and

bevel-index lever.

b. The bevel-index scale indicates the angular position

of the motor with respect to horizontal, from 0 ° to

90 ° in either vertical position.

c. The bevel index lever automatically indexes the

motor at 0 °, 45 ° and 90 ° . Move bevel index lever

to the left while positioning the blade, then release

it. At any other position it does not engage.

d. The bevel lock lever locks the motor to the yoke

when the motor is in any position. Pull lever to

release and push to lock.

6. Power Switch and Key

a. Insert key into switch lock.

b. Insert finger under end of switch lever and pull end

out, to turn switch on.

UNLOCK INDEX R,ELEASE

LOCK i"_1

3. Yoke Pivot (Ripping)

a. Two controis are used in this operation. They are:

the swivel latch-pin lever and the yoke clamp

handle.

b. A swivel latch lever automatically indexes the yoke

at each 90 ° position, Pull the spring-loaded swivel

latchdever forward to release this pin.

c. The yoke clamp handle locks the yoke to the

carriage in any position. Pu!l the handle forward to

release the yoke; push the handle rearward to secure

the yoke.

4. Carriage Lock

a. The carriage !ock knob is rotated clockwise to lock

the carriage on the radial arm, and counterclockwise

to release it.

b. When performing crosscutting operations the

carriage lock knob must he rotated

counterclockwise until the carriage is free to travel

along the arm. This knob should be tightened until

the operator is ready to grasp the bevel index

handle and make a cut.

5. Blade Angle (Bevel)

a. The two controls used in angular positioning and

indexing of the motor, to provide the desired

c. Push lever in to turn switch off.

d. WARNING: THIS LOCKING FEATURE IS

PROVIDED TO PREVENT UNAUTHORIZED

USE OF YOUR SAW, ALWAYS REMOVE THE

KEY AND KEEP IT IN A SAFE PLACE, TO

REMOVE KEY, HOLD THUMB ON END OF

LEVER TO KEEP SWITCH IN "OFF" POSITION

AND PULL KEY STRAIGHT OUT.

/

/

Page 22

WARNING: FOR YOUR OWN SAFETY ALWAYS

LOCK THE SWITCH "OFF" WHEN SAW IS NOT

IN USE. REMOVE KEY AND KEEP IT IN ASAFE

PLACE . . . ALSO IN THE EVENT OF A POWER

FAILURE (ALL YOUR LIGHTS GO OUT) TURN

SWITCH OFF. LOCK IT AND REMOVE THE KEY

THIS WILL PREVENT THE SAW FROM

STARTING UP AGAIN WHEN THE POWER

COMES BACK ON.

7. Accessory Shaft

Use only the following recommended accessories:

Drill chuck, Sanding drum, and Router adapter.

CAUTION: The sawblade, dado, or cutting toot must

be removed from the saw arbor before using the

accessory shaft. NEVER operate the saw with cutting

tools (including sanding accessories) installed on both

ends of the saw arbor.

POSITIONING GUARD, ANTIKICKBACK AND

SPREADER ASSEMBLY, FOR RIPPING

WARNING: NEVER POSITION THE GUARD OR

ANTIKICKBACK ASSEMBLY WITH THE POWER

ON. NEVER POSITION THE ANTIKICKBACK

PAWLS BY GRASPING THE PAWLS OR

SPREADER.

GUARD

\

INFEED PriCE

DIRECTION d

NOSE OF MINIMUM

GUARD GUARD CLEARANCE

• ni,2 SIDE

)" SCREW

,-' OUTFEED

1. The biade guard is positioned by loosening the guard

clamp screw and rotating the guard so that the nose just

clears the workpiece as shown.

This is necessary:

-to protect operator from accidentally contacting the

sawblade radially from the Infeed direction.

-to hold down the workpiece against the table -

minimizing lifting or fluttering (particularly thin

and/or light workpieces);

--to minimize sawdust thrown toward the operator.

-to minimize the possibility of a thin pusher board

riding up on top of the workpiece with loss of control

of workpiece.

2. The antikickback and spreader assembly is used during

ripping operations and is adjustable to accommodate

the thickness of the board being ripped. A wing screw

in the guard secures the assembly.

These adjustments are necessary:

Antikickback

- to stop a kickback if generated.

Spreader

-to prevent kerf from closing in on sawblade and

possible kickback;

to prevent "wrong-way feed". "Wrong-way feed" is

feeding the workpiece - when sawblade is in a rip

position into the outfeed side of the cutting tool

(sawblade, dado, molding head, etc.), the side

containing the antikickback/spreader. This can be

extremely hazardous because the sawblade may grab

the workpiece and throw it violently toward the nose

of the guard (infeed side of the tool). Danger label on

guard.

"Wrong-way feed" occurs when the teeth themselves

cut, or attempt to cut, a kerf in the workpiece. This

differs from a "kickback" which is generated by the

sides (one or both) of the teeth, because of binding

between the fence (heel), pinching of the sides of the

sawblade (failure to use spreader), and!or inadequate

set of teeth of sawblade.

- to act as a partial guard regarding accidental contact

with the sawbtade at the outfeed side when ripping,

and leading edge when crosscutting.

a.]'he blade guard is positioned by loosening the

guard clamp screw and rotating the guard so that

the "nose" just clears the workpiece as shown.

b. The antikickback and spreader assembly must be

adjusted to accommodate the thickness of the

board being ripped. A wing screw in the guard

secures the assembly.

_. SPREADER

\ PAWL

DIRECTION

OF K

ANTIKICKBACK POSITION

3. Loosen the wing screw and with the tab provided,

ANTIKICKBACK

DIRECTION OF FEED

position the antikickback and spreader assembly until

the pawl assumes approximately the position shown

above. Tighten the wing screw.

(Make sure by trial before starting the cut that the

antikickback pawls will stop a kickback once it has

started). Insert workpiece alongside spreader under

outer set of pawls by approaching pawls in the feed

direction. Push workpiece sharply in the direction of a

kickback (opposite to direction of feed). Readjust

Pawls if they do not stop the kickback motion by biting

into the workpiece.

22

Page 23

HA VE YOU FOLL 0 WED ALL SIX S TEPS OF

THE ALIGNMENT PROCEDURE? IF YOU

HAVE NOT FOLLOWED THEM IN THEIR

PROPER SEQUENCE, YOU CANNOT

EXPECT ACCURATE CUTTING RESULTS.

In addition to the proper alignment of your saw, you must

also become familiar with the following practices in order

to expect the best results.

1. Edge of workpiece which is placed against fence

must be as straight as the long side of your framing

square.

2. Workpiece must be as flat as the front table board

on your saw.

3. There must be no sawdust or other wood chips

between the fence and front table board.

4. There must be no sawdust or other wood chips

underneath workpiece or between workpiece and

fence.

5. Workpiece must be held tightly against fence . ..

this is especially important when making angle cuts

because the workpiece has a tendency to move.

6. Always use the correct Sawblade for the Job ...

Always keep it sharp.

7. When making a fou_ sided frame:

a. The two side pieces must be exactly the same

length.

b. The top and bottom pieces must be exactly the

same length.

c. Always place the same edge of the workpiece

against, the fence . . . turn the workpiece end

for end for the successive cuts and mark a pencit

line on the table for gauging the required length.

THIS EDGE OF BOARD

AGAINST FENCE FOR ALL CUTS FENCE

1

//-,I

" 1

1ST CUT

Turn workpiece over end for end . . . keep same edge

against fence when making successive cuts.

I /% !

PENCIL LINE FOR

GAUGING REQUIRED LENGTH

3RD CUT SCRAP

Deviations from any of the above practices will have an

effect on the accuracy of the cuts that you make.

basic saw operations

Basic saw operations are summarized into six categories,

explained and illustrated in the following paragraphs. A

book entitled "Power Tool Know How Radial Saw" is

available at your nearest Sears Retail Store or Catalog

Store. This book contains considerable data applicable to

the ,adial saw.

NOTE: Refer to paragraphs under "OPERATION" for

illustrations and descriptions of controls.

23

Page 24

basic saw operations

REQUIREMENTS FOR CROSSCUT

Board position (stationary) against rip fence (guide) and

laying flat on table top.

(OPERATIONS 1 THROUGH 4)

1. Arbor nut must be tight and saw blade guard installed

in horizontal position.

2. Arm control lever must be in locked position.

3. Adjust the antikickback assembly so the pawls just clear

the workpiece or the fence, whichever is higher.

4. Work must be held firmly against table and fence, For

workpieces thicker than the fence is high, install a

higher fence (at least workpiece thickness}. Always

place the fence in the most forward position (farthest

from the column support) compatible with the

workpiece being processed and the operation being

performed. With the carriage fully retracted, the blade

must not contact the workpiece when placed against

the fence, within the stated capacities of your saw.

5. Blade should he sharp and correctly set,

6. Hands must be kept well away from saw blade.

7. Yoke clamp handle must be in locked position.

8. Bevel index lever must be locked.

9. Blade should cut into the table or plywood cover not

more than 1/32 inch.

10. Pull the saw forward just far enough to sever the

lumber. It is dangerous if the blade has been pulled too

far out beyond the piece being cut. When it is returned

it can pick up the right hand piece and throw it over the

fence.

11. For operations No. 3 and No. 4, observe additional

instructions under paragraph "Operating Controls"

"Blade Angle".

(SEE ITEM "10" AT LEFT}

PROPER

OPERATION No. 1 - CROSSCUT

Crosscutting is the process of sawing the workpiece by

pulling the saw blade through it and using the fence as a

support for the edge of the workpiece. Never crosscut

free-hand.

WARNING: BEFORE CROSSCUTTING, MAKE SURE

THE ARM CONTROL LEVER, BEVEL LOCK LEVER

AND YOKE CLAMP ARE ALL LOCKED. NEVER USE A

LENGTH STOP OR A FIXED GUIDE ON THE FREE

END OR EDGE OF A WORKPIECE. DO NOT CROSSCUT

WORKPIECES THAT PLACE YOUR HANDS CLOSE TO

THE PATH OF THE SAW BLADE. WHEN MORE

EXPERIENCE IS GAINED BY USING THE SAW, IT

WILL BE NOTICED, THAT WHEN PULLING THE SAW

TOWARD YOU DURING CROSSCUTTING, THE BLADE

TENDS TO FEED ITSELF THROUGH THE WORK DUE

TO THE ROTATION OF THE BLADE AND THE

DIRECTION OF THE FEED. THEREFORE, YOU

SHOULD DEVELOP THE HABIT OF HOLDING YOUR

RIGHT ARM STRAIGHT FROM THE SHOULDER TO

THE WRIST.

IMPROPER

(SEE ITEM "10" AT LEFT}

REPETITIVE CROSSCUTTING

Clamp a "C" clamp (min. 6 inch) using a wood block on

each side of the arm. This will limit the carriage travel

beyond the position necessary to complete the crosscut

operation.

24

Page 25

basic saw operations

OPERATION No. 2 - MITER CROSSCUT

Miter crosscutting is the process of sawing a board at any

angle other than a 90 ° (square} cut. The 45 ° miter angle is

a popular one, since two boards cut to 45 ° can be

assembled to form a 90 ° corner for producing a square or

rectangular frame. The radial arm is set to the desired angle

of cut; yoke and bevel settings indexed at 0° (and locked)

as if] square crosscutting. The board being cut Ts held firmly

against the fence (guide} and the carriage pulled forward

along the radial arm to perform the desired cut. As in

"Operation No. 1", the carriage should be returned to full

rear position and the saw blade allowed to come to a

complete stop before removing the boards from saw table.

OPERATION No. 3 - BEVEL CROSSCUT

Bevel crosscutting is the process of sawing at 90 ° (square}

across the board with the saw blade set at an angle other

than 90 ° to the saw table. The radial arm and yoke are

indexed at 0° and locked, but the bevel is set to the desired

angle of cut. The board is held firmly against the fence and

the carriage pulled forward along the radial arm to produce

the cut. The carriage should be returned to full rearward

position and the saw blade allowed to come to a complete

stop before removing the boards from saw table.

OPERATION No. 4 -- COMPOUND

CROSSCUT

Compound crosscutting is the combination of miter and

bevel crosscuts. The radia! arm and bevel are set to produce

the desired cut; the yoke is indexed at 0 ° and locked. The

board is held firmly against the fence and the carriage

pulled forward along the radial arm to produce the cut.

Again, the carriage should be returned to full rearward

position and the saw blade allowed to come to a complete

stop before removing boards from saw table.

25

Page 26

REQUIREMENTS WHEN RIPPING

(OPERATIONS 5 AND 6)

1. Carriage lock knob must be locked,

2_ Radial arm must be locked in 0 ° position.

3. Work must be held firmly against table and fence while

feeding through.

4. Guard spreader and antikickback (AKB) assembly must

be properly set. OBSERVE INSTRUCTIONS IN

PARAGRAPH, "POSITIONING GUARD, AND

ANTIKICKBACK AND SPREADER ASSEMBLY FOR

RIPPING" UNDER "LOCATION AND FUNCTION

OF CONTROLS".

5. Blade should be sharp and correctly set.

6. When ripping narrow stock, less than 6 inches but more

than 1/4 inch between the guard and the fence (guide),

use a "Push Stick" at least 1/4" thick and at least 16"

long so the workpiece is clear of the blade before your

hand contacts the guard.

SLIGHfLY LESS THAN

TH CKNESS OF WORKPIECE

dP TO B!8"

SUGHILY LESS

THAN 90 °

(l-INCH S©UAR[S)

PLYWOOD

7. Wtlen ripping stock 1/4 inch or less between the blade

and fence (guide) use a Pusher Board.

Pusher board should not be less than 4 inches wide and

16 inches long. Nail or glue a 3/4 x 3/4 x 4 inch block

to one edge of pusher board to be used as a grip.

The pusher board should be fed into the blade behind

the stock being ripped until the stock is clear of the rear

of the blade (not more than 8 inches so as not to strike

antikickback pawls) and then puiled back with use of

the grip.

8. Hands must be kept well away from saw blade.

9. Saw blade MUST be parallel to fence, to minimize

possibility of kickbacks.

t0. For every new width of cut, a new PUSHER BOARD

must be used.

11. The pusher board should be the same thickness as the

workpiece. No thinner for strength, or no thicker since

the nose of the guard must clear the top of tbe

workpiece with minimum clearance.

1/4" OR LESS

OPERATION No. 5 -- OUT-RIPPING

AND IN-RIPPING

Ripping is the process of sawing the workpiece by

feeding it into the saw blade when using the fence as a

guide and as a positioning device to obtain the desired

width of cut. The sawblade is parallel to tbe fence.

WARNING: NEVER RIP FREE-HAND. BEFORE

RIPPING, MAKE SURE THE GUARD, AND

ANTI KICKBACK AND SPREADER ASSEMBLY ARE

SET UP PROPERLY. ALSO, MAKE SURE THE SAW

BLADE IS PARALLEL WITH THE FENCE. NEVER

RIP WORKPIECES SHORTER THAN THE SAW

BLADE DIAMETER.

26

Page 27

2. Since the work is pushed along the fence, it must have a

straight edge in order to make sliding contact with tire

fence. Also, the work must make solid contact with the

table, so that it will not wobble. Provide a straight edge,

even if this means temporarily nailing of an auxiliary

_traight-edged board to the work. If the workpiece is

warped, turn the hollow side down.

3. Always use the saw guard and make sure the spreader is

correctly aligned with the saw kerf and antikickback

pawls properly adjusted. Wood cut with the grain tends

to spring the kerf closed and bind the blade and a

kickback could occur.

4.

Stand a little to one side of center to be clear of work

n case of kickback.

6.

When ripping short or narrow work, always use a push

_tick applied to the section of the workpiece between

the blade and fence . . . push the work past the blade so

t is clear of the blade. This procedure will minimize the

_ossibility of kickbacks.

In-Ripping. The radial arm and bevel are indexed at 0° and

locked, but the yoke is turned g0-degrees in a clockwise

direction (viewed from above) from the crosscut position.

Tht_s, when standing in front of the saw, the blade would

be ,otatmg counterclockwise. After positioning the guard

and antikickback mechanism the workpiece is fed from the

right hand side of the saw. The "Blade In-Rip" scale is on

the right-hand side of radial arm.

Out-Ripping. Tbe radial arm and bevel are indexed at 0°

and locked, but the yoke is turned 90*degrees in a

counterclockwise direction (viewed from above), from the

crosscut position. When standing in front of the saw, blade

would be rotating clockwise. After positioning the guard

and antikickback mechanism the workpiece is fed from the

left-hand side of the saw. The"Blade Out-Rip" scale is on

the left hand side of radial arm.

OPERATION No. 6 - BEVEL RIPPING

Bewg ripping is either in-ripping or out-ripping as described

above, except thf_'saw blade is tilted out of perpendicular to

[he saw table surface. The radial arm is indexed at 0 ° and

locked, the bevel is set to the desired beveI angle and the

yol. e is positioned for in-ripping (saw blade at rear) or

out r_pping (saw blade at front), as required All

requirements and observations applicable to normal iipping

op,_ations also apply to bevel ripping.

DADOING

Instructions for operating the Molding Head are contained

Instructions for operating the Dado Head are contained in

booklet furnished with the Dado Head.