Page 1

OPERATING INSTRUCTIONS

AND

DRILL

r----Model

This

is

the

found

Always

with

...--Instructions

---------

--

All

retail

paid.

ing

on a plate

mention

us

regarding

parts

liSted

store

When

information:

1.

The

2.

The

3.

The

PARTS

LIST FOR

PRESS

Number

model

number

located

thismodelnumberwhencommunicating

your

on

Drill

For

herein

or

mail

ordering

Part

Number.

Part

Name

Model

must

order

repair

and

Number

103.2362

of

your

Drill

the

base

Press

or

when

Ordering

be

ordered

house.

Price.

103.23620.

parts.

Parts

always

near

are

Press.

It

the

column.

ordering

will

parts

be

Parts.----.

through a Sears

shipped'

give

the

pre-

follow-

.

1

UTHOGRAPHED

SOURCE

FORM

IN

26949

U,

This

lili\t

is

obtain

other

valuable.

proper

valuable

parts

papers.

It

will

service.

assure

We

SEARS, ROEBUCK

S.

A.

your

suggest

being

you

keep

and

able

to

it

with

CO.

Page 2

'-,

TABLE

HANDLE

LOC:K

--.11

OPERATING INSTRUCTIONS

FOR DRILL

Model

Number

PRESS

103.23620

AND

PRICE

LIST

You

now

own

one

able

for

wood

and

shop.

The

chining

to

assure

inch.

table,

ing

the

this

accuracy

which

The

away

with

making

tool.

the

various

quickly

or

cover.

The

and

feed

In

its

equaled

tion.

quality

operations

The

and

operating

may

fully

This

and

quiet

accuracy

rigid

the

be

enclosed

the

your

feature

pulley

easily

long

oil

to

price

in

quality,

of

massive

through

performed

projection

drill

the

class,

ASSEMBLING:

Your

drill

press

tested

at

the

factory.

the

following

an

enclosed

Knurled

the

Chuck-The

drills

threads

parts

carton.

Collar-18428-Turn

just

from

5/64

of

the

handiest

metal

drilling

the

material

are

controlled

within a few

steel

column,

box

mechanism

the

floating

press a safer-neater

allows

steps

without

life

porous

moving

we

feel

service,

has

been

To

have

above

standard

inch

and

type

are

wide

on

the

of

the

you

or

even

interference

bronze

parts

that

and

carefully

avoid

been

the

spindle

#33

Jacobs

up

to

drill

presses

in

the

home

the

precision

by

rigid

thousandths

the

sturdy

head

casting

designed

range

drill

spindle

splines

to

change

as

this

convenience

loss

packed

Y2

to

of

press.

design

at

the

remove

from a guard

bearings

it

is

needed.

drill

inspected

during

separately

this

collar

taper.

chuck

inch

in

avail·

work

ma·

tolerances

of

base

and

enclos·

maintain

operations

does

top

thus

appearing

the

belt

the

belt

filter

press

is

of

opera·

and

shipment,

onto

will

hold

diameter.

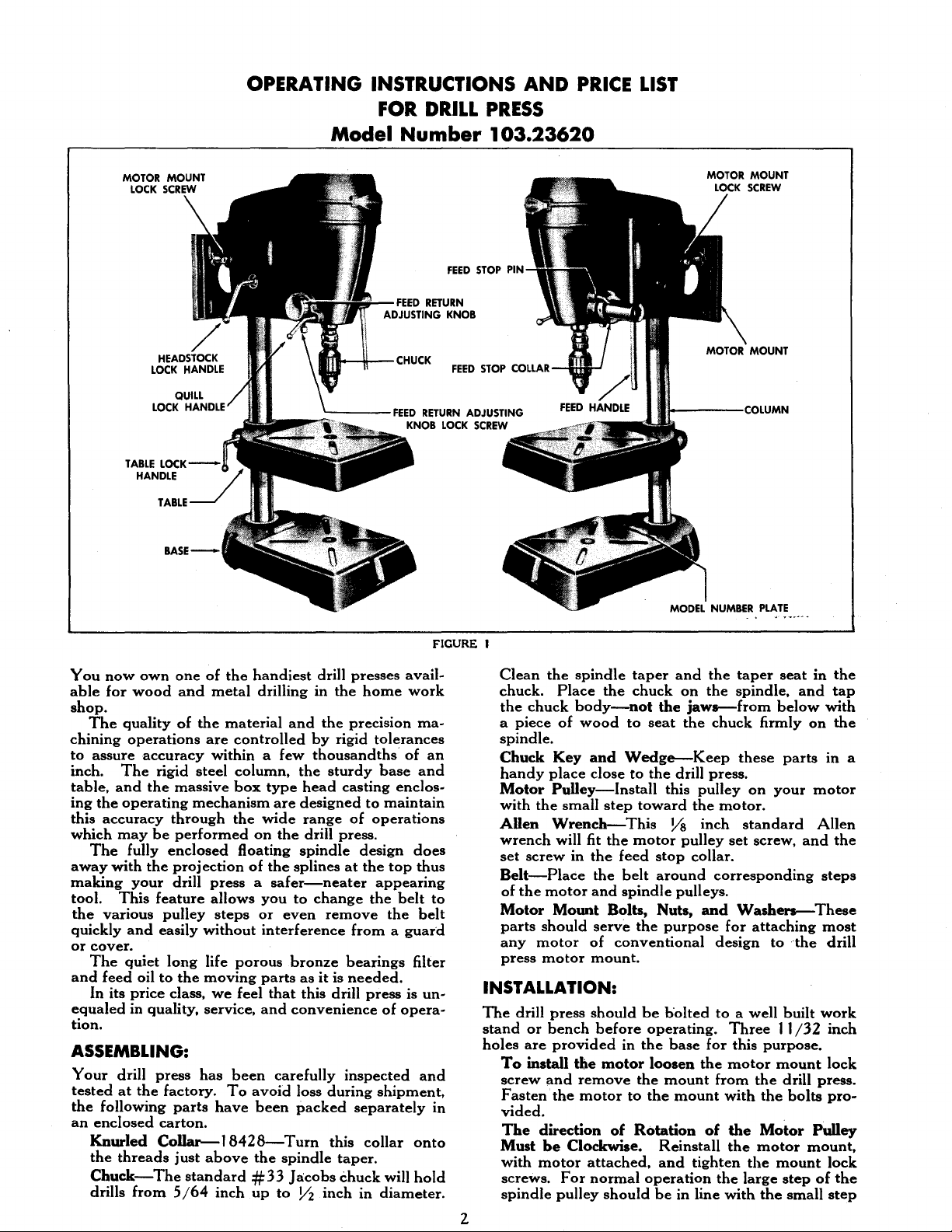

FIGURE I

an

to

un·

in

Clean

chuck.

the

a

spindle.

Chuck

handy

Motor

with

ADen

wrench

set

Belt-Place

Motor

parts

any

chuck

piece

screw

of

the

press

the

Place

of

Key

place

PuDey-Install

the

small

Wrench-This

will fit

motor

Mount

should

motor

motor

INSTALLATION:

The

drill

press

stand

or

bench

holes

are

provided

To

install

screw

and

Fasten

vided.

The

Must

with

screws.

spindle

the

direction

be

motor

For

pulley

2

spindle

the

body-not

wood

in

the

remove

motor

Clockwise.

to

and

Wedge--Keep

close

to

step

the

the

feed

the

belt

and

spindle

Bolts,

serve

of

conventional

mount.

should

before

in

motor

to

of

attached,

normal

should

taper

and

chuck

the

seat

the

drill

this

toward

Va

motor

stop

around

pulleys.

Nuts,

the

purpose

be

holted

operating.

the

base

loosen

the

mount

the

mount

Rotation

Reinstall

and

operation

be

in

the

taper

on

the

spindle,

jawa--from

the

chuck

these

press.

pulley

the

motor.

inch

pulley

set

collar.

corresponding

and

Washers--

for

design

to a well

Three

for

this

the

motor

from

with

of

the

the

tighten

the

line

with

seat

below

firmly

parts

on

your

standard

screw,

attaching

to

built

11/32

purpose.

mount

the

drill

the

bolts

Motor

motor

the

mount

large

step

the

small

in

and

on

motor

Allen

and

These

the

press.

PuUey

mount,

of

the

tap

with

the

in

the

steps

most

drill

work

inch

lock

pro·

lock

the

step

a

..

Page 3

of

the

pulleys

away

lock

screws

tension

during

loads

the

drill

motor

and

from

should

normal

the

tighten

the

securely

motor

press

pulley.

drill

be

operation.

mechanism.

just

and

Place

by

press

to

hold

sufficient

places

the

sliding

head.

this

Excessive

unnecessary

LUBRICATION:

There

good

your

are

four

quality

drill press.

I.

2.

3.

4.

Keep

To

on

wipe

occasionally

Do

automobile

An

oil

directly

An

access

the

3

v..

pulley

hole

in

spindle.

Lower

hole

in

No.

26120.

Apply

spindle.

oil

off

maintain

the

column.

the

exposed

not

drill

points

hole

is

over

hole

inch

through

the

head

the

spindle

the

keyway

oil

to

the

belt.

the

smooth

and

with

holes

at

which

engine

provided

the

pinion

is

located

diameter

which

casting

the

splines

to

surfaces

an

oily

for

oil

you

and

apply

on

the

sliding

prevent

of

rag.

thru

oil.

shaft

step

the

the

MOTOR-SPEED:

A 1

/3

will

press.

set-up

available

ley

step

horsepo~,~JI

provide

in

combinations

sufficient

The

operating

are

shown

by

relation

changing

SPINDLE

R.PM,

4000

2275

1346

765

A

~~

9~

~sg~

~

MOTOR PULLEY RAISED ONE

.-_3i~

MOTOR PULLEY RAISED TWO

750

speed

speeds

in

the

the

to

the

spindle

are

created.

DRILL

PRESS

- -

~

R.P.!\1. baH

and

available

chart.

position

pulley

-

-

CONTROLS:

The

Feed

leverage

Handle

adjustment

is

designed

to

allow

belt

around

the

motor

Tighten

tensioa.

to

you

S.A.E.

in

the

the

prevent

tension

should

No.

head

#26623.

in

the

top

of

the

can

reach

directly

left

at

action

power

Other

behind

oil

through

side

of

the

top

of

rust. it is wise

column

bearings.

bearing

for

with

speeds

of

the

motor

so

that

MOTOR

(1750

-~

..

..

;"~'"

-

GROOVE=:Jl

GROOVES

to

permit

greater

mount

mount

The

belt

slippage

over-

strain

apply

30.

casting

surface

spindle

the

the

quill

of

the

table

and

table

motor

your

normal

different

RPM)

the

on

a

to

of

oil

the

the

the

to

drill

are

pul-

sures

pressure.

also

slide

shaft

clear

in

handle.

The

lows

depth

several

depth

a

fore

tion.

shown

the

The

the

change

table

vent

The

firmly in

fluting.

lower

The

way

be

greater

shifting

changed.

ADJUSTMENTS:

The

counteI:-clockwise will

feed

sluggish

turn

reached.

adjustment.

motor

to

be

ficiency.

may

handle

operation.

«(<;:

~

<~

~

quick

feed

pres-

DRILLS

Quite a variety

in

your

proven

generally

mercial

longer

However.

in

metal

pensive

servIce.

wood.

blind

without

This

allows

through

quickly

work

the

way

Feed

you

to

when

holes

or

when

hole

drilling.

The

by

collar.

Table

grip

of

of

lock

its

dropping.

Quill

Lock

surface

the

spindle

Headstock

as

the

exercised

weight

Tighten

after

Feed

return

loosen

the

adjusting

If

the

headstock

mount

the

motor

changed

The

be

removed

to

lock

Retighten

AND

drill

For

metal

most

give

operation

and

the

home

drilling

carbon

The

standard

This

excessive

design

the

handle

the

and

easily

which

Stop

calibrations

Lock

the

table

handle.

place

table

the

Return

Tighten

of

a fixed

Collar

pre-set

you

wish

to

the

must

See

feed

Handle

barrel-lock

position.

Handle

for

grinding.

while

Lock

lock.

when

of

the

lock

the

spring.

the

before

mount

without

hex

in a new

pulley

might

the

the

depth

be

depth

support

releasing

position

Adjusting

adjusting

knob

the

nut

and

BITS:

of

drills

press.

drilling,

satisfactory.

more

because

may

be

their

greater

shop

unwarranted.

operations

steel

twist

drill

hand

feature

pinion

to

set

illustra-

operations

Handle

parts

handles

If

lock

locking.

lock

set

and

satisfactory

will

r---:C;;:::::;;~

to

to

be

feed

alfeed

drill

same

of

be-

is

on

the

when

on

When

the

when

etc.

the

quill

However.

supported.

of

increase

the

until

lock

handle

screws.

disturbing

in

the

rotated-thus

position.

screws

bits

the

standard

High

they

operated

cost

are

drills will

drill

operate

.--~f--...,

pinion

loosened

the

column

you

table

firmly

tight

holds

such

Never

lock

is tight.

functions

more

this

lock

securely

the

head

Knob

feed

knob

the

screw

or

barrel-lock

are

often

plannea.

may

when

the

tension

return

lock

desired

securely

should

if

it

blocks

the

position

the

after a few

available

twist

Speed

service

hold

at

higher

makes

Unless

give

also

much

lower the

drill to the

planned

depth

of

cut.

Set

quill lock.

-~

shaH

near

releases

to

allow

release

as

attempt

in

due

to

or

screw

locking

causing

Steel

their

the

satisfactory

be

the

to

pre-

the

quill

shaping.

the

same

care

must

to

the

prevent

table

turned

of

the

becomes

and

tension

after

strike

the

access

may

# 1812 1

the

hours

for

use

drill

has

Drills

'for

com-

edge

speeds.

their

extensive

less

used

more

effi-

to

is

is

ef-

use

ex-

in

--,

3

Page 4

ciently

from

degree

sharper

proximately

bit

wood

press.

may

some

center

monly

be

off

adapter

for

the

wood

Solid

to

ceptionally

large

of

large

with

press,

point.

biting

than

cleaner

gum

in

wood,

the

original

angle

angle

Most

may

any

be

drilling

Slight

be

necessary

cases.

wood

used

reworked

the

point

section

The

Spur

wood

drilling

best

qualities

bit.

Its stiffness

Center

Wood

Bit

make a better

smooth

The

Expansive

holes.

large

hole

diameter

any

of

the

screw

This

prevents

into

the

The

Double

the

rosette

and

under

continuous

however,

120

to a much

of

70

degrees.

standard

used

in

the

drill

alterations

The

solid

bit

com-

with

the

for

drill

and

at

the

Machine

with

of

the

Machine

tracking

true

Bit

With

this

sizes

without

drills

the

wood

point

work

and

Lip

Counter

type.

is less

apt

ap-

for

by

Spur

for

the

DRILL SHARPENING:

To

maintain

your

twist drills,

during

equal

length

of

the

gradually

at

the

degrees

the

grinding.

and

drill

behind

heel

of

on a side

accuracy

must

the

extreme

The

their

be

the

cutting

less

in

hand

press

use

cutting

end

of

Bit

is

the

drill

twist

and

Bit

hole

is a

handy

tool

having

each

bits

must

coarse

lifting

for

drill

to

load

operation.

and

care

two

cutting

angle

equal.

cutting

edge

than

at

if

the

point

For

Metal

brace

by

filing

off

the

bit

probably

press.

drill

and

cutting

bit

which

in

wood.

t~ol

you

can

to

hole

size. As is

when

used

be

filed

screw

it

from

sink

is

press

up

cutting

should

in

relation

Relieve

lips

so

is

approximately

the

cutting

can

the

the

shank.

the

It

the

spurs

Double

Counter

drills

for

drill a

buy

in

to a brad

threads

the

more

use.

with

efficiency

be

lips

must

to

that

is

altered

For

Wood

readily

threads

enlarged

best

bit

combines

standard

combine

lip

Sink

an

ex-

drillin~

variety

separate

true

the

drill

from

table.

desirable

It

will

cut

chips

and

of

exercised

be

of

the

axis

the

metal

the

angle

12

lip.

Length

must

OPERATION:

When

advisable

flat

only

vides a surface

guides,

be

danger

metal

piece

under

through

lower

method

through

from

emerges

ness.

quality

tempt

speeds

general

material

drilling

increasing

the

diameter

RP.M.

and

without

hole

In

feed

wears

ting

Likewise

an

are

and

or

same

grooving

table

with

designed

drilling.

Y4

inch

head

increases

used.

If

the

Due

and

drill.

In

wood

over

saws

general,

and

When

edges,

indication

generally

should

A

straight

fence

distance

The

either

the

A

drill

the

drill

to

p.lywood

screws

pivot

This

of

drilling

table.

drill is

it is

advisable

the

work

to

prevent

surface

of

preserving

is

to

the

opposite

on

the

to

variation

grain

of

the

to

establish

for

boring

rule:

the

operation

either

drilling

may

without

cannot

burning.

should

if

speed

drilling

away

at

it

if

the

be

has

many

or

fluting

work

by

drill.

vise

to

hold

Cylindrical

fasten a smooth

slower

the

of

designed

piece

piece

of

Cutting

lips

be

equal

press

is

used

to

the

metal

or

bolts.

the

working

on

pins

auxiliary

and

surface

which

other

table

through

to

pass

completely

to

place a piece

piece

at

splintering

as

the

bit

breaks

the

reverse

lower

of

hole

the

side

'Surface.

in

the

the

material,

desired,

as

bit

a fixed

in

wood.

the

larger

the

the

feed

with a moderate

or

both

after

operations,

generally

burning

generally

be

while

be

Multi-spur

never

be

operated

drill

smokes

to

metal.

the

is

an

drill

too

used

prevent

extreme

burning.

if

indication

chips

on

heavy a feed.

for

high

accordingly

clamped

uses,

as

in

from a common

operations.

should

clamps

is

an

various

or

inexpensive

odd

work

pieces

Heel

Cutting

for

wood

level

table

This

auxiliary

available,

auxiliary

similar

also

the

work

the

point

and

through.

surface,

wood

soon

and

as

pattern,

and

it

is

impractical

table

of

It

is

best

hole

and

and

noting

drills

run

at

bits

Y4

run

over

bits,

expansive

in

the

it

is

noted

outer

corners

of

the

cutting

speed

for

to

the

drilling

edge

be

held

pins

to

and

shaped

such

of

Lip

working

auxiliary

using

countersunk

fences,

units

may

will

reduce

piece

through

of

scrap

of

mutilation

at

drill

drill

the

drill

the

type,

the

depth

drill

feeds

to

follow

the

feed

harder

Start

and

speed.

the

up

to

¥.t

1800

inch

in

2400

over

750

hole,

reduce

that

of

too

much

edge,

Very

small

and

light

best

results.

table

as a guide

several

or

as a guide

securely

prevent

very

handy

work

pieces

as

dowels,

it

is

table

of

table

not

but

pro-

shaping,

easily

the

'into

the

the

work

wood

breaking

of

the

Ano~her

break

through

point

hard-

and

to

at-

and

this

the

any

speed,

effect

on

inch

in

to

3000

diameter

RP.M.

bits

and

RP.M.

the

the

drill

the

cut-

speed.

it

is

drills

feed

holes

the

in

on

the

turning

unit,

for

or

4

Page 5

turned

ficulties

into

their

device.

be

used

If

the

but

its

limit

of

after

the

made.

imum

Holes

greater

by

first

tion

to

possible

and

the

All

work

table

drill

lodge

the

piece

to

the

and

work

A

punch

of

the

center

work

pieces

when

an

centers

The

drill

for

work

drill

is

'penetration

the

chuck.

first

cut

thus

allowing

length.

through

than

the

establishing

the

drill

from

one

hole

completed

metal

work

before

in a piece

from

operator

piece.

mark

proposed

until

the

of

attempt

without

vise

of

this

long

enough

is

the

piece

of

maximum

the

a'

piece.

drill

length

the

center.

side

should

drilling

not

the

operator's

as

well

on

the

hole

drill-spot

various

is

or

a V

type.

limited

may

drill

the

location

then

the

from

be

is

clamped.

as

mutilation

metal

will

tend

is

established.

diameters

made

to

an

adequate

block

to

go

through

by

the

be

feed

to

penetrate

thickness

may

often

of

after

piece

may

the

other

clamped

attempted.

it

grip

resulting

surface

to

drill

should

travel

set

up

depth

be

the

piece

drilling

be

securely

could

of

the

at

keep

present

through

stabilizing

always

the

piece.

or

on a block

has

been

to

its

max-

of

which

completed

in

rela-

as

far

reversed

side.

to

Should

easily

in

injury

drill

press

the

center

the

drill

dif-

or

feed

is

as

the

the

tear

on

Always

breaking

reduces

point

the

and

Avoid

This

will

help

Lubricants

cast

iron

which

oil is a

solution

tection

on

must

rotating

worn

the

parts

This

the

be

The

hair

suitable

of

drill

from

chuck

impressed

power

when

face

or

that

Accessories

tions

may

dovetailing.

finish

or

engine

ing

and

reeding

covering

able.

reduce

through

tendency

thereby

set-ups

minimize

should

sal

soda

press

moving

and

working

should

does

flying

are

be

performed

shaping.

details

the

the

minimizes

which

is

drilled

lubricant.

in

is

designed

parts

drill

upon

tools.

with

be

not

become

chips

available

turn.

and

on

these

feed

pressure

surface

of

the

will

drill

be

used

dry.

water

at

would

the

no

loose

the

kept

away

do

on

routing.

cutting

buffing.

various

of a work

drill

to

bite

drill

breakage.

allow

the

breakage.

on

all

For

most

for

the

may

be

to

give

all

times.

also

operator

clothing

drill

press.

from

entangled

not

injure

with

which

your

drill

carving.

of

plugs

An

interesting

operations

when

the

piece.

deeply

work

to

metals

metals.

harder

used.

maximum

Since a guard

hide

the

that

as

should

the

drill

with

the

operator.

further

press

sanding.

or

dowels.

drill

This

at

spring.

except

metals

pro-

work.

with

so

moving

opera-

such

spot

booklet

is

avail-

is

this

lard

all

be

that

as

flut-

it

a

il

II

Part

No.

18019

18022

18121

18122

18124

1813 I

18217

18221

18421

18428

1851 I

18614

18915

26003

26120

26130

26140

26150

26180

26190

26210

26212

26213

26220

266 I I

26612

26614

26615

26616

This

sheet

accessories

NAME

OF

PART

Pulley

(Spindle)

Pulley

(Motor)

Headstock

Headstock

Pin

..............................

Chuck

Release

Headstock

Ball

Bearing

Washer

Thrust

Adj.

Feed

Feed

Head

Quill

Upper

Feed

Motor

Spindle

Spindle

Chuck

Lock

Table

Base

Column...

Table

Pinion

Headstock

Quill

•.•..••.••.•••.•..•..••.••..•

Collar

Knob

Return

Return

Frame

Assy

Spindle

Stop

Mount

Collar

............................•

and

Shoe

. • . . . • . . . • . . . . . . . . . . . . . . • . . • .

••••....

Lock

Retaining

Lock

is

intended

not

necessarily

........

............••...•.....

and

Table

and

Bushing

••.••.••..••..•..........

Lock

Adj.

Spring

Aaay

.•.•.••••••••............••

Collar & Set

Key

.•.•.•..•.......•.•..•...••

• • • • • • . • • • • . . • . . • . . . . . . •

Handle....................

Lock

Handle

Lock

Table

Lock

Sleeve

Wedge

Nut

and

,........................

for

...............

••.•..•..•..........

..•...........•......

Screw

..••..••.•....•..•

Knob

...•........•....

•.•..•...........•..

.••.••..•..•.......•.

Collar & Set

Screw

•.....•..............•..

Set

Screw

.............•.........

Screw

•••••.••...•..••

Handle

'"

•••••••••••••••..•.•

·Part.

instruction

part

of

this

•

_

...........

..••••••......

........•

Screw

.......•

.••.........

............

..••••.•.••.•

marked

and

repair

tool.

All

PARTS LIST

Prepaid

Selling

Price

(Each)

..

$1.80

1.70

.30

.30

..

· I 5

.20

,

..

.40

.25

.15

.35

• I 5

.65

.25

16.00

2.00

.30

.50

2.50

.

.35

3.75

10.00

.25

.•

10.00

I 1.00

.•

3.00

.35

· I 5

.35

.

20

in

this

manner

parts

only

parts

are

and

is

shipped

5

Part

No.

26617.

26623

26626

26712

267

267

26716

267

267

268

268

268

268

26815

X-164

X-I71

X-I72

X-I73

X-I85

·X-205

·X-322

X-417

·X-566

X-601

·X-1405

X-I457

may

not a packing

I 3

I 4

I 7

I 8

I I

I 2

I 3

I 4

be

purchased

prepaid.

-Splined

Pinion

Feed

Column

Pointer............

Steel

Fibre

Steel

Leather

Snap

Rubber

Feed

Feed

Chuck

NAME

Sleeve

............................

Handle

Plug.......................

Washer

Washer

Disc

.•.

Disc.

Ring.

Washer

Handle

Handle

Key

Set

Screw

Round

Point

Set

Screw

!4-20

Set

Screw

Point

Set

Point

Set

Point

Cap

Mach.

Hex

Mach.

Plain

Allen

V-Belt.

retail

Catalog

All

];4-20 x 5/16

..•.•...•.........•.•........

Screw

.................•..•.......•

Screw

..•....••........

Screw

Bolt

Nut

5/1

Screw

Washer

Wrench

purchase

store

No. 9-I 637

locally.

slip.

The

prices

Prepaid

,...

Cup

Cone

.•••.•

Sears

Ask

may

Hd.

Pt.

Cup

Cup

..•

Hd

for

Selling

(Each)

•

.

..

include

Price

$2.D.O..

2.75 I

.50

.15

• I 5

.15 .

15

• I 5

• I 5

.80

.10

.10

.10

.10

.10

.10

.10

.10

.10

.10

• I 5

notice

OF

PART

..•.

--~.

,

••.

~~----

•.••...•...•••••...••••

•.....••..•••.•••••

.......................

. . . . • . . • . • • • • . . • • • • . • • • • I 5

. • . . . • • • . . . . • • • . . • . • • . . •

. • • • . . . • . . • . . . . . . • . • • • • • . . I 5

Thrust

Snap

........................•

No.

......................

!4-20 x 5/16

Y2-"-

5/

16-

5/16-18

6-18

No.

11/32

or

parts

are

• • . . • • • . . • . • • . • • • I 5

•••...••.•••••••.••.•

Spring

Ring

6-32 x 3/16

x

I 3 x

18

6-32 x 3/1

Vs

Std. • ..•.••..•...•••

from

mail

subject

. . . . . . . • • • . • • I 5

..............

Slotted

Ys

Socket

Hd.

Socket

Socket

1!4

Square

,

........••..•

x ~ Hex

x 2

Am.

•.•.••.••••••.•..

your

order

•....••••..•..•.•

shown

to

Sq.

Std.

house.

and

change

Hd

Hd

...•...•

Reg.

6

Round

nearest

listed

Hd.

Hd.

Hd.

Full

without

il

I

'.j

I

--')11

II

;!

,"

.

Page 6

"

26150-------_

X417

___

X601

X601

26615

---------

X322---------

e.

0

X171-----4E:...-,.

X171-o

-18019

X566

26718

26717

26813

26140

X173

26814

26623

26626

X1457--+I

18022--

X1405

--

26612-----.l)

......

-,

.....

--"'"""-'-"

18122~

26611------

26212-----

26712

•

26190

-----26210

""i~------2681

,-------

-----?6220

5

26213

FIGURE

6

'.,

2

8000-8-50

Loading...

Loading...