Page 1

FT500-Series

FLOW COMPUTER

INSTRUCTIONS

• FT520

• FT522

F T 5 0 0 - S E R I E S F L O W C O M P U T E R I N S T R U C T I O N S

Page 2

Page 1

GENERAL INFORMATION, FEATURES, DIMENSIONS, SPECIFICATIONS

FEATURES

Setting Keys

Cover Screws*

Indicator Lights

The FT500-Series is a batching flow processor with additional

output controls. It is designed for use with Seametrics flow

meters and flow sensors, as well as other manufactuer’s

products which have frequency output proportional to flow.

In addition to batch functions, the FT500-Series indicates

flow rate, and other data in large 3/8” (9.66 mm) digits on

an easily-read, backlit display. Units of measure are user

selectable, and range from milliliters per second to millions

of gallons per day. The unit can be 110 Vac powered with a

standard 3-wire cord (included), 220 Vac powered (optional),

or DC powered through an internal terminal strip (battery not

included).

An analog output of 4-20 mA is available both in active and

passive loop configuration, and in 0-5 Vdc or 0-10 Vdc outputs,

and can be used in applications such as flow rate logging. Two

programmable pulse scaled outputs are also standard, and

can be used, for example, to provide proportional chemical

feed with a pulse-responsive metering pump.

The housing is supplied with two brackets for wall-mount

applications, or the top/bottom housings can be easily

separated and reassembled for panel-mount.

*Can be ordered cross-drilled for seal wire

Display

115 Vac, 50/60 Hz @ 125 mA, (220 Vac optional), 12 Vdc @ 750 mA

32˚ - 130˚ F (0˚ - 55˚ C)

Precision cast aluminum, NEMA 4X, panel or wall mount configuration

Two form C (SPDT) relays, 115 Vac 6A max

100 mA at 60 Vac/Vdc, opto-isolated, open-collector

Non-volatile EEPROM with auto-backup

12 Vdc, 10 mA

Totalizer = 8 digit Rate = 5 digit, backlit

Volume = Gallons, cubic feet, cubic meters, millions of gallons, milliliters, fluid ounces, pounds, liters

Time = Seconds, minutes, hours, days

4-20 mA passive opto-isolated; 4-20 mA active; 0-5 Vdc, or 0-10 Vdc

1-1000 Hz, ESD protected, interfaces to current sinking sensor output

NEMA 4X

Non-volatile EEPROM, auto-backup

Power

Temperature

Enclosure

Batch Outputs

Max Pulse Output

Memory Type

Sensor Power

Display

Units

Analog Output

Sensor Input

Environmental

Setup Memory

SPECIFICATIONS*

*Specifications subject to change • Please consult our website for current data (www.seametrics.com).

6.42"

6.42"

1/2" NPT

5.67"

DIMENSIONS

4.65"

1/2" NPT

5.67"

Page 3

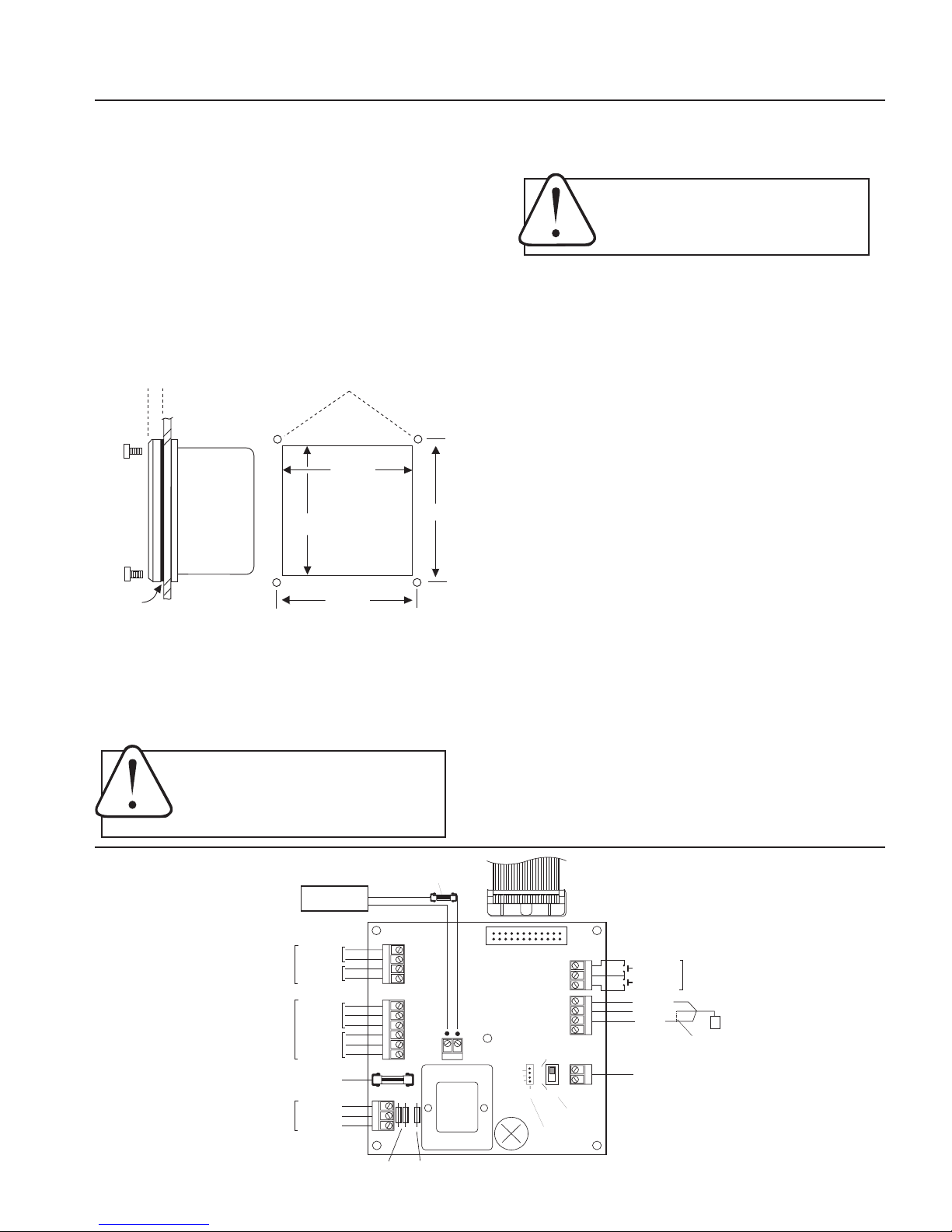

•

•

SEN1

–G

SEN2

Alternate

DC power

Customer Supplies

1A Fuse

Pulse 1

Pulse 2

Pulse Outputs

(for metering pumps)

Regeneration Outputs

AC Power

Relay 1

Relay 2

Main power fuse

250mA

Line

Neutral

Ground

Ribbon connector

from display board

Resume

Start/Stop

Remote

Controls

NO

COM

NC

NO

COM

NC

Resume

COM

BATCH

+12

Power

Signal

Ground

RED

WHITE

BLACK

Meter

Dry contact

0-5 V or

0-10 V or

4-20 mA

Analog Switch*

Analog Header

A

+

-

B

Active

Passive

Jumpers

A

P

5V

10V

4-20mA

An Output

110 Vac

Jumpers

220 Vac

Jumper

*Consult Seametrics before

changing from factory pr eset

Batch Control Connection (if used). Connect the valve or

other device(s) to be controlled for star ting and stopping the

batch to the appropriate relay terminals. Note: if the staged

shutoff (“prewarn”) will not be used, connect to relay one

only. Relay 1 remains energized for the entire batch cycle. If

a staged shutoff is desired, connect the main valve to Relay

2 (early shutoff) and the low-flow valve to Relay 1.

Monitor Alarm Connection (if used). Connect the alarm

devices to the appropriate relay terminals. Note that the

relays have both normally-open (NO) and normally-closed

(NC) contacts.

Analog Connection (if used). This output can be configured

4-20 mA, 0-5 V or 0-10 V by placing a jumper in the correct

position on the analog header. The analog switch next to

the header selects active (powered) or passive (unpowered)

output. NOTE: Consult factory to change internal firmware

when changing switch position. When using the 12 Vdc

powered input you may only select passive output.

Power Connection. Connect AC or DC power as desired

to the appropriate terminals. For safety, if using AC power,

be sure to connect the ground terminal provided to a good

earth ground. If using 12 Vdc, use a 12 Vdc 500 mA power

supply. Replace the front panel, taking care to reconnect

the ribbon cable if it has been disconnected. When power

is switched on, the display should light up immediately with

meaningful letters or digits.

5.50"

gasket

PANEL

CUTOUT

5.50"

6.03"

6.03"

1/4" holes (4 required)

.375"

INSTALLATION, REPAIR, CONNECTIONS

Page 2

Caution: Always disconnect power to the

unit before opening the teminal cover. Do

not reconnect power until all connections

have been made and the teminal cover has

been replaced.

PANEL CUT-OUT

Wall Mounting. Using the four screws provided, attach

the two foot brackets to the sides of the enclosure. Then

attach the unit to any secure surface by inserting screws

through the mounting holes in the foot brackets.

Panel Mounting. Follow the dimensions given for “Panel

Cutout”. Be sure to include the four corner screw holes.

After cutting and drilling, place the front plate on the front

side of the panel with its gasket against the panel, and the

remainder of the square housing on the back side. Slide

the screws through the four holes drilled in the panel, and

into the threaded holes in the housing. Tighten until the

gasket is firmly compressed against the panel.

Expose Terminals. Remove the four screws which hold the

front plate to the lower housing flange. Remove front plate.

The display board is attached to this front plate. It is also

connected to the power board by a ribbon cable. This cable

can be disconnected while making connections. Connections

can be made inside the enclosure, or the terminals can be

unplugged by gentle tugging for easier access.

Caution: When the control is powered up, relay or analog outputs may be present. If this

could be a hazard, wait to make external connections until programming is complete.

Repair

The only field-repairable component on the FT520 is the

fuse. If failure is due to a cause other than a blown fuse,

it is necessary to replace the entire board stack. Contact

your distributor for information.

Connections

Sensor Connection. Follow the “Connections” diagram to

connect either two or three wires from the flow meter or

flow sensor.

Page 4

> FT520 Batch Controller

In Batch Processing Mode, the display indicates a flow rate

on the top line, and one of three user-selectable configurations on the bottom line: an accumulated total flow (resettable), accumulated batch flow, or batch process bar

graph. The batch output is controlled via two relays. The

main relay star ts and stops the batch as a set, or the

auxiliary “prewarn” relay can be used to operate a second

valve. This allows increased accuracy by engaging a staged

shut off at the end of the batch.

Settings

Use left arrow and up arrow keys to change settings. Press

SET to advance to next menu.

- SET Batch Size

Set the batch size for the desired number of units. If the

staged shut-of f feature is not being used, this is the only

setting required for the batch.

- SET Prewarn Size

This is only used for a staged shut-off. The number set is

the number of units early (before the end of the batch) that

Relay 2 will shut off.

- SET Flow/Rate

Select the particular volume unit desired (gallons, liters,

etc.). Then switch to time units and select the time unit

desired (minutes, hours, etc.).

- SET Decimal

Select none, one, or two decimal places on the flow units.

- SET K-Factor

The unit will not function properly until this number is entered. The K-factor is simply the number of pulses which

the flow meter or flow sensor puts out per gallon of liquid.

It is marked on the Model/Serial tag of Seametrics flow

meters and flow sensor fittings. On adjustable depth flow

sensors, the K-factor must be taken from the chart in the

flow sensor instructions, based on pipe size.

- SET Pulse (scaled) Output 1

An output pulse is activated at the selected volume intervals if this feature is in use. If a pulse output is not needed,

pulse out does not need to be set.

- SET Pulse (scaled) Output 2

An output pulse is activated at the selected volume intervals if this feature is in use. If a pulse output is not needed,

pulse out does not need to be set.

- SET 20 mA Rate

The “SET 20mA RATE” programs the maximum flow rate at

which the output is 20 mA full scale, at 5 V or 10 V.

- Clear Total

This function resets the accumulated total back to zero.

It is unrelated to the regeneration function, and can be

ignored unless it is needed.

Operation

Start Batch. Pressing the Start/Stop key starts the batch

by energizing Relay 1. The indicator for Relay 1 will light,

indicating normal operation. The indicator for Relay 2 may

also light, depending on the prewarn setting. If staged

shut-off is being used, the Relay 2 indicator light should go

out before the end of the batch, at the prewarn set point.

The batch will continue on to the set amount unless it is

halted in the middle of the process by pressing the Start/

Stop key again.

Stop Batch/Resume Batch. Pressing the Start/Stop key

anywhere in the batch will stop it. It will remain stopped

until the Resume key is pressed. Pressing the Star t/Stop

key again allows the batch to restart from zero.

Choice of Displays for Batching. When in Operation Mode,

press the UP Arrow to change the type of display. Running

Totalizer (“T”) accumulates a Total Flow until it is reset.

Batch (“B”) accumulates the flow of the present batch only,

then resets. Bar Graph (“❚”) graphically indicates from left

to right, how much of the batch has already accumulated.

Page 4

FT520

STAGED SHUT-OFF APPLICATION

TX Flow Sensor

High-Fl

ow

Valve

Low- Flow

Valve

Tank

FT520

Staged shut-off

at end of batch

High-Flow Valve

Low-Flow V

alve

Relay 1

Relay 2

NC

COM

NO

NC

NO

COM

Po

we

r

Source

+

-

CONNECTION FOR STAGED SHUT-OFF

Page 5

Relay 1

Relay 2

NC

COM

NO

NC

NO

COM

Tank 1

Tank 2

Page 5

FT520-84

> FT520-84 Filter Regeneration

In Filter Regeneration Mode, the display indicates a flow rate

on the top line, and one of two configurations on the bottom

line: an accumulated total flow (resettable), or batch process

remainder. The regeneration process is initiated by setting a

target volume, a value for regeneration time as well. A single

relay or alternate relay setting allows control of either single

tank or alternating dual tank systems.

On the input side, this model can be used with Seametrics

flow sensors and meters, as well as with water meters from

other manufacturers. The output can be used to initiate regeneration in a variety of one-tank and two-tank water treatment systems. In addition to the regeneration functions, this

unit features displays of flow rate and accumulated flow, as

well as programmable pulse output and a 4-20 mA analog

output, for use with remote recorders. There are two regeneration relays, which can be used for alternating regeneration of

two tanks. The outputs remain on for a duration programmed

by the user, depending on the requirements of the regeneration valve being used. A programmable pulse output can be

used as needed to control a chemical metering pump, for

controlled chemical addition to the water stream.

Settings

Use Left Arrow and UP Arrow keys to change settings. Press

SET to advance to next menu.

- SET Flow/Rate

Select the par ticular volume unit desired (gallons, liters, etc.).

Then switch to time units and select the time unit desired

(minutes, hours, etc.).

- SET Decimal

Select none, one, or two decimal places on the flow units.

- SET K-Factor

The unit will not function properly until this number is entered.

The K-factor is simply the number of pulses which the flow

meter or flow sensor puts out per gallon of liquid. It is marked

on the Model/Serial tag of Seametrics flow meters and flow

sensor fittings. On adjustable depth flow sensors, the K-factor

must be taken from the chart in the flow sensor instructions,

based on pipe size.

- SET Pulse (scaled) Output 1

An output pulse is activated at the selected volume intervals

if this feature is in use. If a pulse output is not needed, pulse

out does not need to be set.

- SET Pulse (scaled) Output 2

An output pulse is activated at the selected volume intervals

if this feature is in use. If a pulse output is not needed, pulse

out does not need to be set.

- SET 20 mA Rate

The “SET 20mA RATE” programs the maximum flow rate at

which the output is 20 mA full scale, at 5 V or 10 V.

- Clear Total

This function resets the accumulated total back to zero. It is

unrelated to the regeneration function, and can be ignored

unless it is needed.

- SET Regeneration Volume

This is the volume (in the units you have selected; typically

gallons) at which the relay energizes to initiate a regeneration

cycle.

- SET Regeneration Time in seconds (3 digits)

This is the length of time in seconds, the relay remains energized to initiate regeneration. Enter a value slightly over the

minimum time required by the regeneration valve to begin a

cycle.

- SET Relay Mode to one or alternate relays

Choose between single relay (Relay No. 1) and dual relay (Alternate Relays) operation. In alternate relay mode, the first

regeneration will use Relay 1, the next will use Relay 2, and

successive regenerations will switch between the two.

- Clear Total

This function resets the accumulated total back to zero. It is

unrelated to the regeneration function, and can be ignored

unless it is needed.

Operation

Choice of Displays. When all of the settings have been en-

tered, the next press of the SET Key puts the unit in operation. If a T appears at the left side of the display, the values

shown are flow rate and running total. If there is no T, the

values shown are flow rate and units remaining until regeneration. The total increases with flow, and the regeneration quantity counts down. Use the UP Arrow to choose the preferred

display, usually regeneration quantity.

Regeneration Initiation. When the regeneration quantity number first reaches 0, Relay No. 1 energizes for the length of

time which has been set. The regeneration quantity immediately resets and begins counting down again. If alternating

mode has been selected, the next time it reaches 0, Relay

No. 2 will energize, and the cycle after that, will return to Relay No. 1. An output can be manually forced at any time by

pressing the Start/Stop key. The relay will energize for the set

time, and regeneration volume will return to its original setting

to begin counting down again.

TX Flow Sensor

FT520-84

Tank 1

Tank 2

Alternating Tanks Appliction

Connections for Alternating Tanks

Page 6

> FT520-86 Flowrate Alarm

In Flowrate Alarm Mode, the display indicates a flow rate

on the top line, and on the bottom line, an accumulated

total flow (resettable). The user sets a minimum and maximum flow rate, and if the flow exceeds the min/max paramenter, Relay 1 or Relay 2 will close. The output relay will

stay latched until the flow rate increases/decreases back

between the min/max settings.

Settings

Use Left Arrow and UP Arrow keys to change settings.

Press SET to advance to next menu.

- SET Flow/Rate

Select the particular volume unit desired (gallons, liters,

etc.). Then switch to time units and select the time unit

desired (minutes, hours, etc.).

- SET Decimal

Select none, one, or two decimal places on the flow units.

- SET K-Factor

The unit will not function properly until this number is entered. The K-factor is simply the number of pulses which

the flow meter or flow sensor puts out per gallon of liquid.

It is marked on the Model/Serial tag of Seametrics flow

meters and flow sensor fittings. On adjustable depth flow

sensors, the K-factor must be taken from the chart in the

flow sensor instructions, based on pipe size.

- SET Pulse (scaled) Output 1

An output pulse is activated at the selected volume intervals if this feature is in use. If a pulse output is not needed,

pulse out does not need to be set.

- SET Pulse (scaled) Output 2

An output pulse is activated at the selected volume intervals if this feature is in use. If a pulse output is not needed,

pulse out does not need to be set.

- SET 20 mA Rate

The “SET 20mA RATE” programs the maximum flow rate at

which the output is 20 mA full scale, at 5 V or 10 V.

- SET Low Flow Alarm

Set the desired minimum flow rate at which you want an

alarm to occur. Low alarm corresponds to alarm Relay 1

(see Connections diagram).

- SET Hi Flow Alarm

Set the desired maximum flow rate at which you want an

alrm to occur. High alarm corresponds to alarm Relay 2

(see Connections diagram).

- Clear Total

This function resets the acccumulated total back to zero.

NOTE: The “Star t/Stop” and “Resume” keys are not used

in flow alarm mode.

Operation

The last press of the key returns the unit to operation

mode.

Flow Monitoring. The flow rate and accumulated displays

begin showing current data. The accumulated total increases indefinitely unless it is reset.

Alarms. Alarm Relay 2 activates when flow reaches the

high alarm set point. Because of the built-in hysteresis, the

relay does not deactivate until the flow rate has reached

10% below the high alarm set point. Similarly, alarm Relay

1 activates when flow reaches the low alarm set point, and

does not deactivate until flow returns to 10% above the low

alarm set point.

FT520-86

NC

COM

NO

NC

NO

COM

Alarm 1

Alarm 2

-Autodialer

-Pump

-Alarm

-Valve Shutoff

Page 6

Page 7

> FT522 Usage Monitor

In Usage Monitor Mode, the display indicates one of two

configurations: an elapsed time and elapsed flow, or a flow

rate and accumulated total flow (resettable). A time period is set to monitor for a set maximum total flow. If the

total flow is reached within the set time, an output relay

is closed. The output relay stays latched until the system

either resets automatically after the set time, or is reset

manually via the StartStop button. A reset condition clears

the elapsed time and flow, but not the accumulated total

flow.

The FT522 is a flowmeter monitor with added output and

alarm features. It is designed for use with Seametrics flow

meters and sensors, as well as other units which have a

pulse or frequency output. It displays flow rate and total in

large digits on an easily-read backlit display. Units are user

selectable between gallons, cubic feet, and cubic meters.

The primar y output of this unit is a user-set alarm relay

which signals excessive total flow within a given time period (up to 48 hours). This is typically used to detect an

elevated usage level in a cooling tower or potable water

application. The dual relays can be connected to an alarm,

autodialer, or any other switch-controllable device. In addition to the usage alarm, the FT522 has analog output

(4-20 mA, 0-5 Vdc or 0-10 Vdc) and programmable pulse

output. These can be used with an external data logger or

to provide proportional chemical feed, using an externallycontrolled metering pump.

Settings

Use Left Arrow and UP Arrow keys to change settings. Press

SET to advance to next menu.

- SET Flow/Rate

Select the particular volume unit desired (gallons, liters,

etc.). Then switch to time units and select the time unit

desired (minutes, hours, etc.).

- SET Decimal

Select none, one, or two decimal places on the flow units.

- SET K-Factor

The unit will not function properly until this number is entered. The K-factor is simply the number of pulses which

the flow meter or flow sensor puts out per gallon of liquid.

It is marked on the Model/Serial tag of Seametrics flow

meters and flow sensor fittings. On adjustable depth flow

sensors, the K-factor must be taken from the chart in the

flow sensor instructions, based on pipe size.

- SET Pulse (scaled) Output 1

An output pulse is activated at the selected volume intervals if this feature is in use. If a pulse output is not needed,

pulse out does not need to be set.

- SET Pulse (scaled) Output 2

An output pulse is activated at the selected volume intervals if this feature is in use. If a pulse output is not needed,

pulse out does not need to be set.

- SET Time Period from 01-48 hours

This is the monitoring period at the end of which the unit

will alarm if total flow has exceeded its setting. Set this

monitoring period for 01-48 hours. NOTE: that if the digit to

the right is set to “9”, the digit to the left will only go to “3”

This is because 48 is the maximum setting allowed.

- SET Alarm Reset

Set to automatic or manual.

- SET Alarm Point in Flow (8 digits)

This is the maximum total flow allowed in the time period

set above. Use the same procedure as above to set this

value, up to eight digits. The units are those previously

chosen.

- SET 20 mA Rate

The “SET 20mA RATE” programs the maximum flow rate at

which the output is 20 mA full scale, at 5 V or 10 V.

- Clear Total

This function resets the accumulated total back to zero in

the rate/total configuration. It does not affect the data in

the elapsed time/flow configuration.

Operation

The last press of the key returns the unit to operation

mode. In this mode, pressing either arrow key will toggle

back and forth between two displays, one for flow monitoring and the other for usage monitoring.

Usage Alarm. Pressing the Star t/Stop key will start the

clock and zero the total of the usage monitor. The clock

will increase and the total will accumulate (provided there

is flow) until the end of the monitoring period. At that time,

the usage total and clock will zero automatically and the

cycle will star t over. If the usage total ever reaches its

alarm point within the monitoring time, the usage alarm

relays will energize and remain on until the Resume key is

pressed. If the Resume key is pressed during a monitoring

cycle, it will freeze the cycle at its current point. Pressing it

again allows the cycle to resume where it left off.

Flow Monitoring. The “Rate” indication gives the current

rate of flow. “Total” is a running total of flow which increases indefinitely unless it is reset.

NC

COM

NO

NC

NO

COM

Main

power fuse

250mA

part # 26926

Neut

Hot

Gnd

110 Vac

Alarm 1

Alarm 2

Autodialer

Alarm

Page 7

FT522

Page 8

LT-65200029-A

9/1/10

Se a m e t r ics I n c o rpo r a t e d • 1 9 0 2 6 7 2 n d A ve n u e S out h • K ent , W a s hi n g t o n 98 0 3 2 • U S A

(P ) 2 5 3 .87 2 . 0 2 8 4 • ( F ) 25 3 . 8 7 2 .02 8 5 • 1. 8 0 0 . 9 75. 8 1 5 3 • w w w . s e am e t r i c s.c o m

TROUBLESHOOTING

Problem

Probable Cause Try...

Display blank No power to the unit Check for minimum 12 Vdc at power

terminals

Short in sensor circuit Disconnect sensor, see if display returns

(zero flow rate)

Display missing segments Damaged display module Contact distributor for return/replacement

Display reading meaningless Unit’s microcontroller crashed Disconnect and reconnect power, if problem

characters repeats, contact distributor for

return/replacement

Display reads normally, Wrong k-factor entered Check k-factor, enter proper one if in error

flow rate incorrect

Display reads normally, Wrong pulse output setting Check “SetP” to see if it is set correctly no

(wrong) pulse output

Polarity reversed on pulse output terminals Reverse leads and see if problem corrects

Display reads normally, Wrong 20 mA setting Check “Set 20” to see if it matches target top

no (wrong) 4-20 mA output flow rate

(FT420 only)

Inadequate loop power supply voltage Check voltage. For 4-20 mA applications,

24 Vdc recommended

Polarity incorrect in 4-20 mA loop circuit Compare to Connections diagram

Display reads zero when Flow sensor failed Consult flow sensor manual for how to test

there is flow

Break in flow sensor circuit Check for continuity with multimeter

Display reads flow rate when Long flow sensor wire, running parallel to Reroute wire or switch to shielded wire

there is none power wires

Flow sensor malfunction See flow sensor manual to check

Loading...

Loading...