Page 1

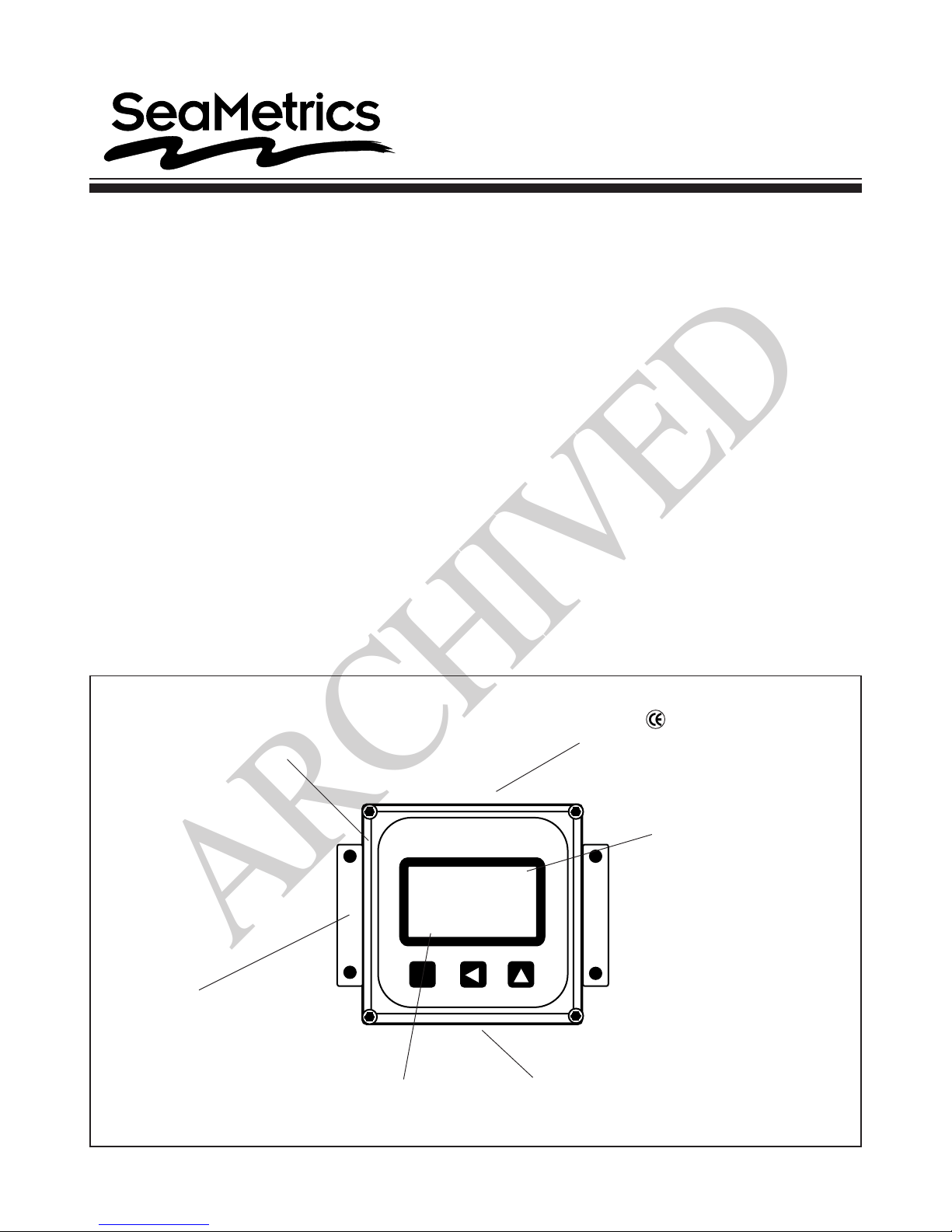

FT415 Flow Computer

ARCHIVED

Instructions

SpecificationsGeneral Information

The FT415 is a microcontroller-based rate/total indicator powered by a lithium battery. It displays rate and

total, and provides a programmable pulse output for use

in metering pump pacing or datalogging.

The rugged cast-aluminum housing is gasketed for maximum environmental protection, and the electronics are

potted into a solid block of urethane. A membrane keypad allows settings to be changed without removing the

cover. The wall mount version comes with brackets for

wall mounting, and a kit (MK10) is available for field installation on TX80-series flow sensors. The FT415 can

also be factory or field installed on a TX100/200 series

sensor or WT meter. (Micropower sensors are required

to prolong battery life.)

The standard output is a programmable 0.1 second opencollector transistor (TTL) pulse which can be used to

trigger most externally-paced metering pumps.

Features

Sturdy gasketed cover

with electronics

potted in

Display

Rate 6-digit autorange, 1/2"

character height

Total 8-digit, 5/16" character

height

Pulse Output 0.1 second open collector

pulse

Input Micro-power GMR sensor

(square wave)

Input Range Minimum: 20 mV peak-peak

Maximum: 6V peak-peak

K factor Range 0.050 - 999999.9

Pulse Output Range 0.1 - 200,000 units/pulse

Battery Type Lithium "C", 3V, replaceable

Normal Battery Life 3-5 years

Temperature 0 C - 70 C

Environmental NEMA 4X

Tested for Immunity

and Emissions standards

Removeable foot brackets

for wall mounting

2341678.9

SET K RESET

SET

Easy set-up

prompts

Large rate numerals

10.5

Triple bosses for

watertight input/output

connections

LT-10621-B

Page 1 of 4

Page 2

Installation

!

ARCHIVED

To mount the FT415W on a wall, hold the unit in the

desired position, mark the holes in the mounting feet,

drill, and mount with screws.

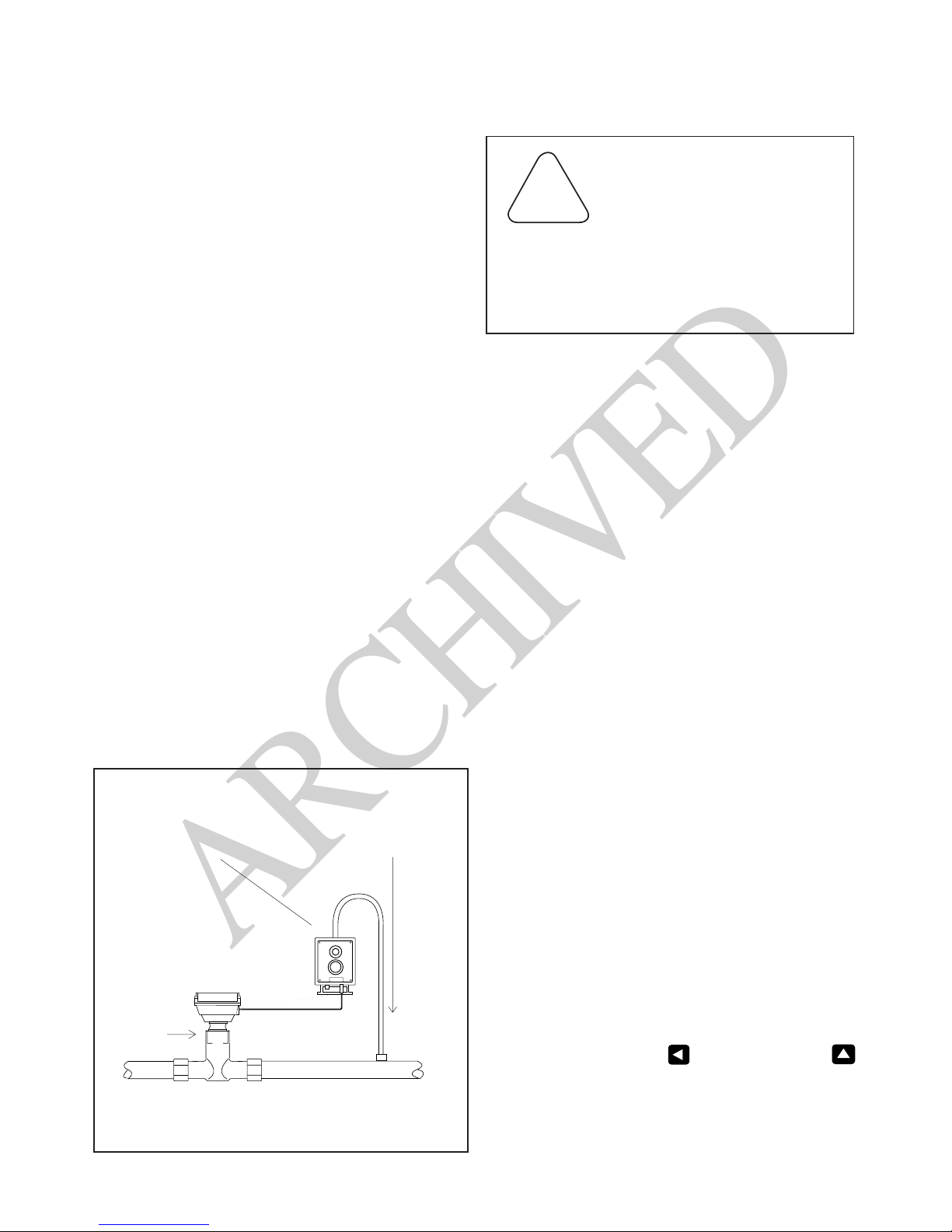

This unit can also be mounted directly on a flow sensor

for local reading. Note that the FT415 requires the

optional micropower sensor, in order to conserve battery life. For loop or other external power, the FT420 is

recommended, and can be installed on any standard

sensor.

If the unit was ordered as an FT415M, factory mounted

to the top of a 100 or 200 Series flow sensor, no further

installation is required.

To mount the unit on a flow sensor, an MK10 mounting

kit is required. Then remove the housing cover. Place

the lower half of the housing in the groove on the top of

the flow sensor. An adapter from the kit is included in

the lower housing, which threads into the top of any 80Series flow sensor. Pull the sensor wires through the

hole in the center of this adapter, then thread the adapter

into place. Tighten the adapter using a screwdriver. (See

diagram). Connect the wires, then replace the housing

cover, orienting it any direction as desired for viewing

convenience.

Connection

To connect to the FT415 to a flow sensor, follow the

diagram marked “Connections”. This diagram also

shows the connections for an external device, such as

a chemical metering pump.

Programming

Caution: If pulse output is being

used to control an external device,

such as a metering pump, do not

connect the pulsed device until pro-

gramming is completed. If malfunction or incorrect programming of the pulse output

could cause personal injury or property damage,

separate safeguards must be installed to prevent

such injury or damage.

At a minimum, every FT415 must be programmed with

the “K-factor”. This is simply the number of pulses per

gallon which the meter or flow sensor produces. (If you

wish the FT415 to read in another unit, enter the number of pulses per that unit. For example, if the desired

units are liters, the K-factor is the number of pulses per

liter that the flow sensor produces.)

To find the K-factor on any SeaMetrics flow sensor fitting or in-line meter, look on the model-serial label. The

line reading K = xxxx is the desired number. For adjustable sensors (101,201,115,215) look in the instruction

manual under your pipe size.

Set K. Begin by pressing the key SET once. The prompt

SET K should appear on the display. The digit to the far

right will be blinking. Use the up arrow key to reach

your desired digit. Then press the left arrow key to move

to the next digit. Repeat the process until the entire number is entered. (Note that the decimal is fixed at three

places. If you only have two decimal places for your Kfactor, enter a zero for the third digit.)

Chemical

FT415

on TX81

Flow

2 of 4

Control Pulses

Proportional

Chemical

Set P. If the pulse output is to be used, set the desired

pulse rate. Note: If the pulse output feature is not

being used, this step can be skipped. The P (pulse

output) setting does not affect anything if it is not

being used. This is the number of gallons (or other

units, if you are using them) between pulses. The second time the SET key is pressed, SET P will appear.

Follow the same process as above to enter the desired

number.

Pressing all three buttons at once will put the unit into

low alarm. Pressing all three again will put the unit into

high alarm.

Press the ARROW LEFT

keys to set the flow rate at which you want to have the

output pulse switch on.

and ARROW UP

Page 3

Sensor Mount: Step 1

ARCHIVED

Sensor Wires

Sensor Mount: Step 2

Sensor Wires

Standard Connections

Red

White

Black

Micropower Sensor Only

Battery Type:

Lithium "C, 3V, replaceable

+

Sensor

Input

s

-

- +

Outputs

- +

Sensor Pulse

To Other

Control

Pulse Responsive

Metering Pump

3 of 4

Page 4

Set Decimal Point. The third time the SET key is

ARCHIVED

pressed, a D prompt appears. Pressing the up arrow

key switches back and forth between no decimal place

and one decimal place.

Set Time Unit. The fourth time the SET key is pressed,

a blinking arrow appears. Press the up arrow key to

select S (seconds), M (minutes), H (hours) or D (days).

Operation

To return to normal operation after entering settings,

press SET for a fourth time. The rate and total indicator

numbers should appear in the display. If the unit is connected to an operating flow sensor, the larger-sized

digits indicate flow rate and the smaller-sized digits indicate total.

Unless the unit has been ordered with the non-reset

option, a RESET prompt is constantly visible in the lower

right corner, above the up arrow key. Press this key at

any time to reset the totalizer to zero.

Battery Change

The expected average life of the battery is approximately

four years, with a range of 3-5 depending on the frequency of the input. Pull the battery from its holder and

replace it with the new one. Note that when the battery

is removed, all of the settings previously entered will

be retained. However, the totalizer will reset to a previous total, which represents the last auto-backup (approximately one hour intervals.) If it is necessary to save

the exact current total at the time of the battery change,

save before removing the battery, by simultaneously

pressing the SET and up arrow keys. Then press SET

again, then again simultaneously press the SET and

up arrow keys.

Dimensions

2341678.9

SET

3.93"

4.52"

10.5

with Wall Mount Brackets

FT415

3.93"

2.06"

FT415

Sensor-Mount

2.57"

2.78"

4 of 4

20419 80th Ave. So., Kent WA. 98032 USA

Phone: 253-872-0284 Fax: 253-872-0285

www.seametrics.com 1-800-975-8153

Loading...

Loading...