Page 1

FT410 Flow Computer

DISCONTINUED

Instructions

SpecificationsGeneral Information

The SeaMetrics FT410 is a compact digital flow monitor

with user-programmed output features. Combined with

an IP Series insertion flow sensor or a WT turbine meter,

it is ideal for flow rate and total indication, chart recording, and proportional chemical feed. It is available in wall

or panel-mount enclosures, or in a round cast-aluminum

housing mounted directly on a SeaMetrics meter. For

wall-mounting, the non-metallic enclosure is splashproof

and has a clear cover. The housing for panel mounting

is standard 1/4 DIN-sized, with gasketed front panel and

membrane switches. Wall and meter-mounted enclosures are NEMA 4X; Panel-mounted enclosures are

NEMA 12.

An eight-digit totalizer is resettable, unless ordered with

non-reset option. Programming prompts simplify set up

by indicating the next step. Pulse output is a programmable 0.1 second open-collector transistor pulse (an

optional dry contact pulse output is available) which is

compatible with electronic metering pumps, PLC's, computer input cards, and SeaMetrics controls. An optional

4-20 mA output feature is front-panel programmable in

standard flow rate units.

Power 11-28 VDC

Flow Sensor Power 5 Volts DC, 50 mA maximum

Temperature 0° C to 70° C

Display Custom 8-digit LCD,

0.4" digits

Totalizer 8-digit resettable

(non-reset optional)

Rate Indication 8-digit

K Factor Range .050 - 2000.000

Pulse Output Range 0.1 - 200000.0 gallons per

pulse

Pulse Output 0.1-second open-collector

transistor, 100 mA, 40 VDC

maximum; optional FORM C

SPST relay contact closure

5A@ 24VDC

Analog Output

(Optional) 4-20 mA isolated 24 VDC, 500

Ohm maximum; may be wired

non-isolated

Analog Output

Resolution 500 counts full scale

Sensor Output 100 mA, 40 VDC maximum

Features

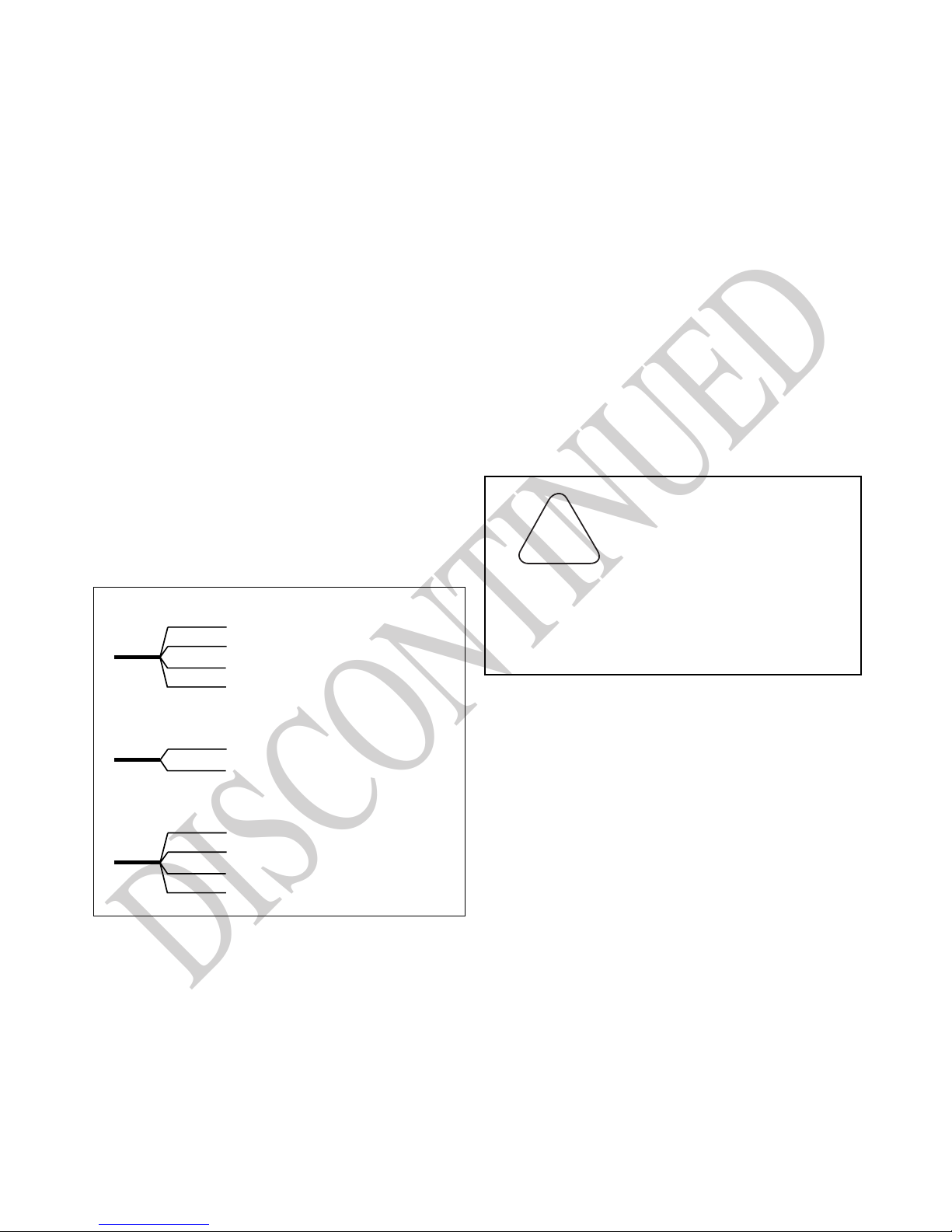

Promptsappear

whenprogram

buttonispushed.

"SETP"means

setpulseoutput

ingallonsper

pulse.

Otherprompts:

•SETK(meterfactor)

•SET20mA(optional)

•SETDP(totalizer)

ResetTotalizertoZero

(Non-resettableoptional)

FT410

RESET RATE/TOTAL

SETP

410.0

PROGRAM

-

+

Presstochange

settings:

•K-factor

•PulseOutput

•4-20mA(optional)

SwitchesbetweenRateand

TotalDisplays(Alsorespondsto

magnetoutsideenclosure)

Selectable

decimal

point

Buttonsincrease

ordecreasesetting

PUB -19740-1000

Page 1 0f 4

Page 2

Installation

!

DISCONTINUED

FT410W: Wall Mounting. Four 3/16" screw holes are

located at the bottom of the front cover screw holes.

Mark the locations through the holes, then drill. Slip

screws down the holes and tighten.

FT410P: Panel Mounting. Use the dimensions on the

back page for making the panel cutout. Locate the dovetail mounting bracket grooves on the side and the top of

the unit. After cutting out the panel, break any sharp or

rough edges, then slip the panel gasket in place behind

the FT410 bezel and slide the unit through the panel

hole. Install the mounting brackets in their dovetail

grooves, with the slots of the clamping screws facing

out. Tighten the screws to pull the unit tightly against the

panel and compress the gasket slightly.

Connections

FT410M: This unit is pre-wired with 18 ft. of four-con-

ductor cable. See diagram for color coding of the leads.

If desired, the cable supplied can be removed, and connections can be made inside the unit, following the Connections diagram.

FT410M - Standard Unit:

Red (+) 12 VDC to power supply

Black (-) 12 VDC to power supply

Green (+) pulse output

White (-) pulse output

Sensor Out terminals are provided for passing on the

signal from a flow sensor to a second electronic device.

They do no need to be connected unless using such a

device.

FT410P: This unit is ordinarily supplied without pre-wiring. T o reach the terminals, remove the four screws which

hold the back cover of the housing in place. Follow the

connections diagram

Analog Output Board. The optional 4-20 mA output

uses a third printed circuit board which plugs into the

terminal connection board. This board is pre-wired at

the factory with a jumper, so that powering the FT410

automatically provides power to the current loop. If an

isolated 4-20 mA output is required (see Connections) it

is necessary to remove the jumper and rewire as shown

in “Analog Output - Isolated”.

Programming

Caution: If pulse output is being

used to control an external device,

such as a metering pump, do not

connect the pulsed device until

programming is completed. If malfunction or incorrect programming of the pulse output could

cause personal injury or property damage, separate safeguards must be installed to prevent such

injury or damage.

FT410W - Standard Unit:

Red (+) 12 VDC to power supply

Black (-) 12 VDC to power supply

FT410M, FT410W - With Analog Option:

Red (+) 12 VDC to power supply

Black (-) 12 VDC to power supply

Blue (+) 4-20 mA

Orange (-) 4-20 mA

FT410W: This unit is pre-wired with 6 ft. of two-conductor cable for the power connections. See diagram for

color coding of the leads. T o complete the wiring needed

for the application, remove the front clear cover, then

remove the front panel to reach the terminals. Turn the

front panel over, with the circuit boards still attached.

Follow the connections diagram.

Note the polarity of the Pulse Output terminals. Be sure

to observe proper polarity when connecting to an electronic metering pump. If the pump does not respond to

the pulse output, try switching polarity.

Set K-Factor. To begin programming, press the PROGRAM key . The prompt SET K should appear . The Kfactor is the number of pulses per volume unit. This

number is provided with SeaMetrics meters, in pulses

per gallon. If the FT410 is to read in other units, the number provided with the meter must be converted. The

FT410 will then totalize in the selected units, and the

rate reading will be in those units per minute. The rate is

always in units per minute.

To enter the K-factor, press the “+” or “-” keys until the

desired number is reached.

Set Pulse Output. Pressing PROGRAM a second time

brings up the prompt SET P. This setting controls the

pulse output, if it is being used. It is set in units per pulse.

For example, if the FT410 is reading in gallons, a setting

of 2.00 means that a pulse will occur every 2 gallons.

Settings may be as small as 0.1, which means that there

is a pulse every 0.1 units. If the optional dry contact pulse

output is present, SET P sets that pulse output also.

(NOTE:

Pulse output is limited to 100 ppm

)

2 of 4

Page 3

Standard Connections

DISCONTINUED

To 2nd FT410

or control

DC Power

RED

BLACK

RED

WHITE

BLACK

IP SENSOR

Analog output - Non-Isolated

DC Power

RED

BLACK

RED

WHITE

BLACK

IP SENSOR

+

+

SIG

-

+

+

SIG

-

POWER

INPUT

SENSOR

+

POWER

SENSOR

-

INPUT

OUT

SENSOR

OUT

PULSE

+

-

+

-

NC

COMNO

OUT

SENSOR

OUT

PULSE

GREEN

WHITE

DRY CONTACT

PULSE OUTPUT

(OPTIONAL)

+

+

-

NC

DRY CONTACT

COMNO

PULSE OUTPUT

(OPTIONAL)

METERING PUMP

To 2nd FT410

or control

METERING PUMP

GREEN

WHITE

Analog output - Isolated

DC Power

IP SENSOR

Blue +

OPTIONAL 4-20mA

CURRENT LOOP

Orange -

CHART RECORDER

To 2nd FT410

or control

METERING PUMP

+

-

POWER

+

SIG

-

-

24

VDC

++-

INPUT

SENSOR

+

OUT

-

SENSOR

+

-

OUT

PULSE

NC

COMNO

DRY CONTACT

PULSE OUTPUT

(OPTIONAL)

OPTIONAL 4-20mA

CURRENT LOOP

CHART RECORDER

3 of 4

Page 4

Set 4-20 mA Span. If the optional 4-20 mA board is in-

DISCONTINUED

stalled, the prompt SET 20 mA will appear. Set this value

to the flow rate, in units per minute, at which the full 20

mA output is desired. Zero flow will automatically be

scaled to 4 mA.

Set Decimal Point. Pressing PROGRAM again brings

up SET DP. Choices are one decimal place or none.

Pressing the +/- keys alternates between the two. Typically, a decimal place is only required with low-flow

meters. Exit programming mode. Pressing rate/totalizer

button returns unit to operating state.

Repair

The only field-repairable component on the FT410 is

the fuse. The fuseholder is found on the back of the circuit board stack. Replace with a Littlefuse 3AG 1/2-Amp

or equivalent automotive-type fuse.

On units with the 4-20 mA option, it is necessary to remove the analog board at the back of the stack to reach

the fuse. Unplug the board by gently tugging on it. On

some models, it is also necessary to remove four screws

to get the analog board loose.

Operation

In normal operation the FT410 displays rate or total.

Pressing RA TE/TOTAL alternates from one to the other .

This can also be accomplished from outside the unit by

touching a magnet to the outside of the case in the general vicinity of the RA TE/TOT AL key. When rate is showing, total continues to accumulate. Unless the unit has

the NR (non-reset) option, pressing the RESET key sets

total to zero. T otal is stored in nonvolatile memory and is

kept on loss of power, although the unit will not operate

during the power outage.

Mounting Dimensions

FT410W Wall Mount

If failure is due to a cause other than a blown fuse, it is

necessary to replace the entire board stack. Contact your

distributor for information.

FT410P Panel Mount

3/16" MOUNTING HOLES

UNDER COVER SCREWS

3"

4 of 4

4.20"

RESET RATE/TOTAL

+

PROGRAM

FT410

5"

-

5"

20419 80th Ave. So., Kent WA. 98032 USA

Phone: 253-872-0284 Fax: 253-872-0285

www.seametrics.com 1-800-975-8153

3.75"

3.75"

FT410

RESET RATE/TOTAL

+

PROGRAM

3.55"

3.5"

-

2"

3.55"

PANEL CUTOUT

Loading...

Loading...