Page 1

EX90-Series

Electomagnetic Insertion

Flow Sensor

Precision Flow Measurement

An ON

I

CON Brand

PROUDLY

MADE

IN THE

USA

C

o

d

m

e

i

f

i

t

r

e

C

ISO

9001

p

a

n

y

Page 2

TABLE OF CONTENTS

EX90-SERIES INSTRUCTIONS

General Information

General Information ...................................................................................................................................................Page 3

Features ...........................................................................................................................................................................Page 3

Specications ................................................................................................................................................................Page 4

Flow Rate ........................................................................................................................................................................Page 4

Dimensions ....................................................................................................................................................................Page 5

Installation

Chemical Injection or Fertigation ..........................................................................................................................Page 6

Fitting Installation ........................................................................................................................................................Page 6

Meter Installation ........................................................................................................................................................Page 6

Saddle Installation .......................................................................................................................................................Page 7

Straight Pipe Recommendations ...........................................................................................................................Page 8

Full Pipe Recommendations ....................................................................................................................................Page 9

Connections

General Cable Information .......................................................................................................................................Page 10

Cable Gland Opening and Sealing ........................................................................................................................Page 10

Cable Installation .........................................................................................................................................................Page 10

Wiring Diagrams ..........................................................................................................................................................Page 11

Cable Wiring Table ......................................................................................................................................................Page 11

Conguration

Cable Shield ...................................................................................................................................................................Page 12

Pulse Output ..................................................................................................................................................................Page 12

Operation

Minimum Flow ..............................................................................................................................................................Page 13

Filtering ............................................................................................................................................................................Page 13

Electrode Coating ........................................................................................................................................................Page 13

Changing Flow Meter Settings - Standard Menu Options ..........................................................................Page 13

Changing Flow Meter Settings - Submenu .......................................................................................................Page 13

Changing Flow Meter Settings - Home Screen and General Navigation ..............................................Page 15

Changing Flow Meter Settings - Making Selections......................................................................................Page 15

To Change a Passcode ...............................................................................................................................................Page 16

Power Indicators ..........................................................................................................................................................Page 16

Battery Powered Units ...............................................................................................................................................Page 17

Troubleshooting & Error Messages

Problem ...........................................................................................................................................................................Page 18

Probable Cause.............................................................................................................................................................Page 18

Things to Try ..................................................................................................................................................................Page 18

Error Messages .............................................................................................................................................................Page 19

Seametrics • 253.872.0284 Page 2 seametrics.com

Page 3

GENERAL INFORMATION

EX90-SERIES INSTRUCTIONS

The EX90-series battery powered, insertion electromagnetic

ow meter is designed for use with conductive uids in 4”–

12” pipe. The EX90’s stainless steel body allows the meter

to operate in a wide range of temperatures, pressure, and

corrosive or dirty environments.

The EX90 is highly suitable for dicult applications. With

no moving parts, these meters can be used in “dirty water”

applications where debris would foul a mechanical meter. If

the EX90 meter is used with a programmable controller, the

output signal can be fed direct, with no other conditioning

required.

Features

Hinged Display Cover

User access lid

Output cable port access

Rate and total units can be set via the front panel touch key

pad by the user. Bidirectional ow is standard with totals

available in forward, reverse, net, batch forward and batch

reverse.

The EX90 is battery powered and an output cable is

available for transmitting the pulse signal to remote

devices. The EX90 includes a Seametrics saddle which has

been designed to accommodate a wide range of pipe sizes

and types while ensuring correct placement in the pipe.

In addition, an optional internal data logger allows local

storage of ow history.

Rate and total indicator with

light sensor button controls

Data logger connector (optional)

Equalization lug

O-ring, EPDM

PVDF electrode cap

Quickly and easily change Total Volume Units,

Flow Rate Units, Pulse Output Scaling, and many

other settings using the two light sensor button

controls on the display panel.

Powder-coated diecast aluminum

electronics housing

Sensor body (Stainless)

Hastelloy electrodes

Battery Power

Bidirectional Flow Reading

Pulse Scaled Output

Built-in Data Logger (Optional)

Saddle Included

Seametrics • 253.872.0284 Page 3 seametrics.com

Page 4

GENERAL INFORMATION

EX90-SERIES INSTRUCTIONS

Specications*

Pipe Size 4” to 12”

Materials Sensor Body 316 SS

Electrodes Hastelloy

Housing Powder-coated diecast aluminum

Electrode Cap PVDF (Kynar®)

O-Ring EPDM

Temperature Ambient

Temperature

Fluid Temp. 32˚ to 200˚ F (0˚ to 93˚ C)

Pressure 200 psi (14 bar)

Flow Rate 0.5 - 4.5 m/sec (1.64 - 14.8 ft/sec) (Low ow cuto .15 m/sec; .49 ft/sec)

Calibration

Accuracy

0.5 - 4.5 m/s

(1.64-14.76 ft/sec)

0.3 - 0.5 m/sec

(0.98 - 1.64 ft/sec)

Display Type 128x64 dot-matrix LCD

Digits 5 Digit Rate 8 Digit Total

Units

Please Note:

All meters are factory

set for gallons per

minute (GPM) rate and

acre foot total. If other

units are required, they

can be set in the eld.

Bidirectional Forward Total, Reverse Total, Net Total, Batch Forward, Batch Reverse

Power One lithium 7.2V ‘D’ size battery pack, replaceable.

Scaled Pulse

Output

Signal Current sinking pulse, isolated, 36 Vdc at 10 mA max

Pulse Rates User-scalable from 0.1 to 99,999.9 volume units/pulse. Pulse width varies with output frequency, 150

Cable Optional Output

Cable

Conductivity >20 microSiemens/cm

Empty Pipe Detection Hardware/software, conductivity-based

Regulatory

Environmental IP68

* Specications subject to change. Please consult our website for the most current data (seametrics.com).

1

Rate Time Unit is available in Day only.

Kynar is a registered trademark of Arkema, Inc.

Flow Rate (4” - 12”)

0˚ to 160˚ F (-17˚ to 72˚ C)

+/- 2% of reading

+/- (2% of reading + 0.25% of full scale)

Rate Volume Units Rate Time Units Total Volume Units

Gallons

Liters

Barrels (42 gallons)

Cubic Feet

Cubic Meters

Million Gallons

Mega Liters

1

1

Imperial Gallons

Million Imperial Gallons

1

Second

Minute

Hour

Day

Gallons

Gallons x 10

Gallons x 100

Gallons x 1000

Million Gallons

Liters

Kilo Liters

Mega Liters

Barrels (42 gallons)

Cubic Meters

pulses/sec max

20ft (6m) standard length polyurethane jacketed cable—for power and outputs.

(Lengths up to 200’ (60 m) available.)

(EN 61326) Pending

Cubic Meters x 1000

Cubic Feet

Cubic Feet x 1000

Million Cubic Feet

Imperial Gallons

Imperial Gallons x 1000

Million Imperial Gallons

Acre Inch

Acre Foot

Fluid Ounce

FLOW

Nominal Pipe Size

Low Flow Cuto GPM

Low Flow Cuto LPS

Min GPM

Min LPS

Max GPM

Max LPS

4” 6” 8” 10” 12”

19.3

1.22

64.3

4.1

578

36.5

43.11

2.72

144.6

9.1

1301

82.1

77.1

4.86

257

16.2

2313

145.9

120.5

7.6

401.6

25.3

3614

228

173.5

10.95

578.3

36.5

5204

328.3

10x/5x

Pipe Diameter

2x

Pipe Diameter

Upstream straight pipe is selected during initial setup. Upstream

options are 5X or 10X the diameter and are based on the

amount of straight pipe available in either new or propeller meter

replacement installation. Downstream straight pipe requirement

is 2X the diameter. See programming setup for details.

Seametrics • 253.872.0284 Page 4 seametrics.com

Page 5

GENERAL INFORMATION

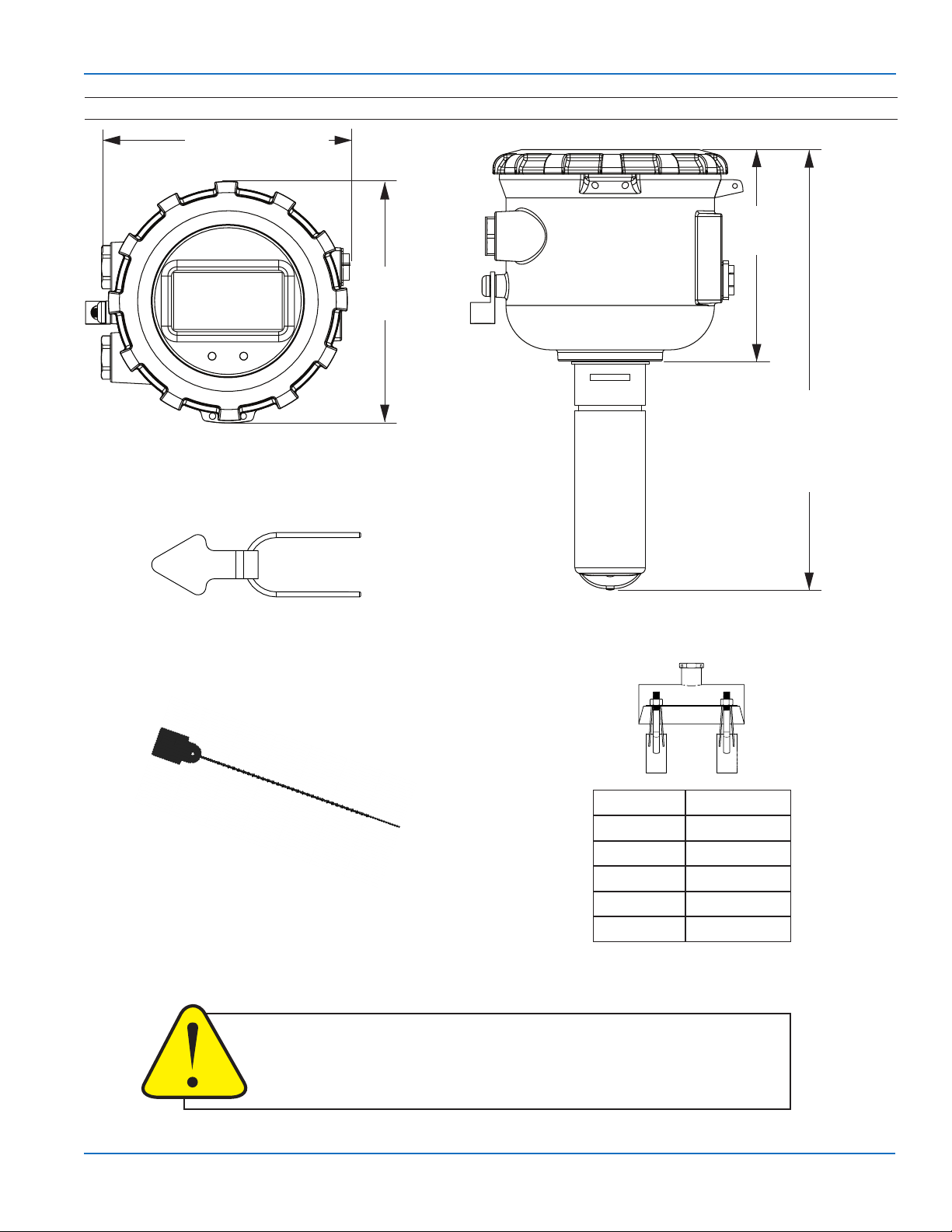

Dimensions

5.48 in (13.92 cm)

EX90-SERIES INSTRUCTIONS

4.76 in

(12.09 cm)

5.28 in

(13.41 cm)

Top of Saddle

EX90-0400 - 10.40 in (26.42 cm)

EX90-0600 - 11.14 in (28.30 cm)

EX90-0800 - 11.86 in (30.12 cm)

EX90-1000 - 12.60 in (33.73 cm)

EX90-1200 - 14.29 in (36.30 cm)

Attach U-clip retainer during installation

Attach display security seal during

installation if regulations require.

CAUTION: Ensure that the U-clip is installed and never remove the U-clip

retainer when the pipe is under pressure. Always remove pressure from

the pipe before you attempt to remove the meter. Removal under pressure

may result in damage or serious injury.

Saddle Size Range

4” 4.00”- 4.90”

6” 6.00”- 6.90”

8” 8.00” - 9.05”

10” 10.40” - 11.10”

12” 12.10” - 13.20”

Consult factory if your OD

does not match.

Seametrics • 253.872.0284 Page 5 seametrics.com

Page 6

INSTALLATION

Fitting Installation

EX90-Series meters require special saddles that ensure

that the ow sensor is installed to the correct depth. The

saddle must be installed in the pipeline before the meter

can be installed. For best results, see straight pipe and full

pipe information on pages 8 and 9.

If there is not enough straight run to smooth out the

turbulence caused by valves, ttings, and changes in

direction, some decrease in accuracy may result. This does

not mean that the ow meter’s reading is meaningless

however. In some applications (control systems, valve

operation, chemical addition) a repeatable reading may

be more important than a highly accurate one.

EX90-SERIES INSTRUCTIONS

Side (3 o’clock), top (12 o’clock) installations are acceptable.

Orienting the Meter

FLOW

10X/5X

Upstream straight pipe is selected during initial setup. Upstream

options are 5X or 10X the diameter and are based on the amount of

straight pipe available in either new or propeller meter replacement

installation. Downstream straight pipe requirement is 2X the diameter.

See programming setup for details.

.

Meter Installation

After the saddle is installed in the pipeline, the meter can

be installed in the tting. After noting the direction of the

ow arrow, press the meter into the tting as far as it will

go. Retain the meter in place by inserting the U-clip. The

pin can be installed from either side. It may be necessary

to rotate the probe back and forth slightly to start the pin

into the slots on the probe. Slide the pin in as far as it will

go.

2X

Chemical Injection

When any magmeter, by any manufacturer, is used in a

chemical injection application (including fertigation), the

chemical injection point must be placed downstream of

the magmeter OR far enough upstream for complete

mixing to occur before the uid reaches the meter. When

unmixed chemical or fertilizer alternates with water passing

through the meter, the rapid changes in conductivity may

cause sudden spikes and drops in the meter’s reading,

resulting in inaccurate measurement. The magmeter will

restabilize, however, with a steady ow of uid of uniform

conductivity.

Caution: In chemical injection

applications, install chemical injection

point downstream of magmeter, or far

enough upstream to allow complete

mixing of uids before the meter.

Seametrics • 253.872.0284 Page 6 seametrics.com

Page 7

New Installation

BEFORE INSTALLING measure & record inside diameter (ID) of pipe.

EX90-SERIES INSTRUCTIONS

1. Clean the mounting surface, remove

any roughness from the area.

4. Place saddle top over gasket. Make sure

saddle top covers entire gasket. Place the

saddle clamps under the pipe and align

with the clamp guides on the saddle top.

Propeller Replacement Installation

2. Cut a 1.75” hole into pipe. 3. Place gasket centered over pipe opening.

5. Place saddle plates over saddle

clamp threads. Attach nuts and

tighten as shown below. Torque to

6. Insert the EX90 sensor into the saddle

tting and secure with mounting clip or

attach security clip and seals if required.

75 ft-lb in cross pattern.

th

4

nd

2

st

1

rd

3

BEFORE INSTALLING measure & record inside diameter (ID) of pipe.

1. Clean the mounting surface, removing any roughness which would prevent

the gasket from sealing. Place gasket

centered over pipe opening.

4. Place the saddle clamps under the

pipe and align with the clamp guides

on the saddle top.

2. Place saddle top over gasket. 3. Make sure saddle top covers entire

gasket.

5. Place saddle plates over saddle

clamp threads. Attach nuts and

tighten as shown below. Torque to

6. Insert the EX90 sensor into the saddle

tting and secure with mounting clip or

attach security clip and seals if required.

75 ft-lb in cross pattern.

th

4

st

1

nd

2

Seametrics • 253.872.0284 Page 7 seametrics.com

rd

3

Page 8

INSTALLATION

Grounding

EX90-SERIES INSTRUCTIONS

Electronically Noisy Installations. When the EX90 is

installed in an electrically noisy system (near a VFD etc.),

grounding is recommended. Where lightning is a threat, or

in severe electrical environments, an optional connection to a

nearby equipment ground or ground rod is advisable.

Straight Pipe Recommendations (X = diameter)

Two Elbows In Plane

Equalization Lug

#6, #8, or #12 AWG Stranded

Copper Ground Wire < 5’

Ground Clamp

(Exothermically weld when

corrosion is a concern)

Earth

8’ Ground Rod

Full Pipe Recommendations

Possible Problem

Can create air pocket at sensor

10X/5X

2X

Pipe conguration selected during program setup.

Better Installation

Allows air to bleed o

Seametrics • 253.872.0284 Page 8 seametrics.com

Page 9

INSTALLATION

Full Pipe Recommendations

Allows air pockets to form at sensor Ensures full pipe

EX90-SERIES INSTRUCTIONS

Better InstallationPossible Problem

Better InstallationPossible Problem

Post-valve cavitation can create air pocket Keeps pipe full at sensor

Better InstallationPossible Problem

Air can be trapped Allows air to bleed o

Seametrics • 253.872.0284 Page 9 seametrics.com

Page 10

CONNECTIONS

EX90-SERIES INSTRUCTIONS

EX90 General Cable Information

In the EX90 meter, there are two output cable ports. Either

port can be used. The cable contains the wires for scaled

pulse output and optional external DC power. See Sample

Cable Wiring Diagrams and Wiring Table.

Power/Output Cable

The EX90 is available as a Battery powered meter

EX90 Cable Installation (Wiring)

Battery Version with external pulse output.

1. Unscrew the display lid and remove it.

2. Remove the display assembly from the

meter exposing the internal connectors.

Be sure NOT to undo any connections to

the display assembly as you remove it.

3. There is a two 2-pin connector already

installed.

4. Remove the plug and o-ring from the cable port(s)

where you want to insert the cable.

5. Install cable gland and insert cable end.

6. Strip cable jacket and conductors and install the wires

into the connectors in their respective locations. (See

Cable Wiring Table for details.)

7. Plug the battery cable into the circuit board, as shown:

Battery

connection

Battery version with two 2-pin connectors

Battery Version with no external pulse output

No wiring is needed.

Cable Gland Opening and Sealing

WARNING: Improper sealing of glands or cables will invalidate any warranty.

8. Secure the cables inside the internal strain relief clip

and tighten the cable gland sealing nut securely.

(torque nut to 22 in-lbs.). A loose nut could cause

moisture ingress and compromise the meter head’s

IP67 rating, voiding the warranty.

9. Remount the display assembly, being careful to not

pinch any wires.

10. Reinstall the display lid, being sure to avoid crossthreading. Ensure the lid is screwed down fully to

prevent water ingress.

Remove plug & o-ring. Insert

cable gland/strain relief. Feed

cable through cable gland.

Seametrics • 253.872.0284 Page 10 seametrics.com

Clamp cable with strain relief

clips. Attach drain wire lug to

bracket post.

CRITICAL!

Torque cable gland sealing

nut to 22 in-lbs.

Page 11

CONNECTIONS

Black (C1) DC-

EX90-SERIES INSTRUCTIONS

EX90 Wiring Diagrams

Unscrew the display lid and remove it from the meter. Unsnap the display assembly and remove it from the meter

exposing the internal wiring connector. Install the wires through the cable glands into the 2 pin screw connector.

C1 = Power/Output cable)

C1

White (C1) PulseGreen (C1) Pulse+

With Pulse Output Only

With No External Output

C1

White (C1) PulseGreen (C1) Pulse+

Pulse with External Power

Red (C1) DC+

NOTE:

If not using external output,

no wiring is required.

EX90 Cable Wiring Table

PIN 1 PULSE SCLD - 2 PULSE SCLD + PWR - PWR +

Battery

Powered

Meter

Externally

Powered

Meter

Seametrics • 253.872.0284 Page 11 seametrics.com

WHITE

C1

WHITE

C1

GREEN

C1

GREEN

C1

(C1 = Power/Output Cable 1)

BLACK

C1

NOT USED

RED

C1

Page 12

CONFIGURATION

EX90-SERIES INSTRUCTIONS

Cable Shield. In general, the cable shield and its bare drain

wire should be left unconnected at the user equipment end

of the cable to minimize “ground loop” problems.

Pulse Output Conguration. A pulse output is standard

on all models. Since this is an isolated output, the external

equipment must include a DC power source to regenerate

the pulse from the open-collector output (transistor

equivalent of a contact closure). A pull-up or pulldown resistor may be needed if not included in the user

equipment. Both the power source and resistor may be

supplied internally in some types of control and monitoring

devices. If not, as for most PLC discrete input modules, they

must be added externally at the module input terminals.

The pulse output rate in volume units/pulse can be set by

the user via the SETP tab on the meter’s setup menus.

Because the pulse output of an EX90 meter is set by the

user, care must be taken to assure the output pulses do not

exceed the maximum frequency of the meter while also

ensuring a reasonable resolution.

K-factor: Remember that SETP is expressed in units totaled

per output pulse (G/P if using gallons) while K-factors

are expressed in pulses per gallon (P/G.) To determine

K-factor from SETP, divide 1 by SETP (if SETP is expressed in

gallons.) Conversely, 1 divided by the K-factor equals SETP

Because all pulse outputs (SETP) are congured in (rate)

units totaled per pulse, all sizes of meters can be congured

with the same SETP values

For example, if your rate is chosen as gallons per minute

(GPM) the table below applies. If your rate is dierent,

simply use your rate label in place of (GPM.) The numerical

values will remain the same.

SETP

0.1 6 900

0.2 12 1800

0.3 18 2700

0.4 24 3600

0.5 30 4500

0.6 36 5400

0.7 42 6300

0.8 48 7200

0.9 54 8100

1.0 60 9000

Flow Rate at 1 Hz

(GPM)

Flow Rate at 150 Hz

(GPM) Battery Powered

Meters

Lower frequency output pulses (1 pulse for some particular

number of gallons) can also be set.

EX90 battery powered units have a maximum output

frequency of 150 Hz.

Pulse Units. The units of measure of SETP are independently

selectable and are not tied to rate or total. Upon change of the

SETP unit, the pulse output may take up to 10 seconds, or the

duration of one pulse (whichever is longer) to take eect.

If Pulse Output is Inconsistent. The DAMP lter may need

to be increased.

Pulse Width Timing. The unit and value of SETP must be

chosen to keep the duration between meter pulse outputs to

less than 500 seconds.

Pulse Timing in Battery Powered Units. The output pulse

width in battery powered units is short and varies with pulse

frequency. (See table)

Any output frequency can be determined by:

Rate (units/minute) ÷ SETP (units/pulse) = pulse/minute

Hz = pulse/minute ÷ 60 seconds / minutes

Output Pulse Width of Battery Powered Units

Output Pulse Width as a Percentage of

Output Pulse Frequency

Zero to 1 Hz

>1 to 20 Hz

>20 to 100 Hz

>100 to 150 Hz

Example: If frequency = 20 Hz then the pulse period = 50 milliseconds and pulse

width = (.05 x 50 milliseconds) = 2.5 ms

(Pulse period = 1000 milliseconds/fre-

Multiply the pulse

period by 0.01

Multiply the pulse

period by 0.05

Multiply the pulse

period by 0.1

Multiply the pulse

period by 0.15

the Pulse Period

quency)

= Output Pulse

Width (ms)

= Output Pulse

Width (ms)

= Output Pulse

Width (ms)

= Output Pulse

Width (ms)

Seametrics • 253.872.0284 Page 12 seametrics.com

Page 13

OPERATION

EX90-SERIES INSTRUCTIONS

Minimum Flow

As with any other ow sensor, there is a rate below which

the EX90-Series sensor cannot read. Check the table below

(also on page 4) for the minimum ow rate detectable by

the sensor for a given pipe size.

Nominal Pipe Size

Low Flow Cuto GPM

Low Flow Cuto LPS

Min GPM

Min LPS

Max GPM

Max LPS

4” 6” 8” 10” 12”

19.3

1.22

64.3

4.1

578

36.5

43.11

2.72

144.6

9.1

1301

82.1

77.1

4.86

257

16.2

2313

145.9

120.5

7.6

401.6

25.3

3614

228

173.5

10.95

578.3

36.5

5204

328.3

Standard Menu Options

T UNIT

View or change TOTAL

volume units

T UNIT R UNIT SET P DAMP

TOTAL = GALLONS

PRESS + TO SET TOTAL

UNITS FOR DISPLAY

EXIT

Filtering

The software of the EX90-Series lters out electrical noise

and averages sudden variations in the ow to smooth the

output. It takes a matter of seconds for the ow sensor to

get up to full output after ow begins.

Electrode Coating

Grease or other adhering, non-conductive materials can

stop ow detection if the electrodes become heavily

coated. To clean the electrodes, remove the sensor from

the pipe and gently wipe o the electrodes (three silver

bumps) on the reading face of the ow sensor. A mild soap

(dish washing liquid for example) can be used to aid the

cleaning process.

SET P

View or change pulse

output scaling

T UNIT R UNIT SET P DAMP

00001.0 GALLONS

PRESS + TO SET

GALLONS TOTALIZED PER

PULSE SENT OUT PULSE1

EXIT

R UNIT

View or change ow

RATE units

T UNIT R UNIT SET P DAMP

FLOW RATE = GALLONS/MIN

PRESS + TO SET RATE

UNITS FOR DISPLAY

EXIT

Special SUBMENU for Further Options

The EXIT tab in the MAIN MENU has a second function. If,

instead of using the hold and tap sequence to return to the

HOME screen, you tap ve times, you will be redirected

to a SUBMENU screen from which you can access several

more options.

Navigation in this SUBMENU is the same as for the MAIN

MENU. Whenever you wish, go to the EXIT tab in the

SUBMENU and perform the hold and tap sequence to

return to the MAIN MENU.

DAMP

View or change # of

sample periods for

rolling average.*

(0=1 sample period,

1=2 sample periods, etc.)

T UNIT R UNIT SET P DAMP

DAMPING = 1

PRESS + TO SET

DAMPING VALUE

EXIT

* See DAMP Settings for Battery Units on page 16.

INFO: Meter model number, serial number, and

rmware version.

SAMP: Sample rate.

SETUP: View or change pipe settings.

EXIT: Return to MAIN MENU.

INFO COMM MBID FL DIR

PRESS + TO VIEW INFO

ABOUT METER

SAMP

HPOLL SETUP EXITSAMP

Sub-Menu - Battery Only Version

Seametrics • 253.872.0284 Page 13 seametrics.com

Page 14

OPERATION

Initial Setup

INITIAL SETUP OF ID, HOLE, AND PIPE IS

REQUIRED FOR THE METER TO OPERATE

PROPERLY.

When you remove the meter from the box, it will prompt

you to perform initial SETUP of ID, Hole and PIPE before

you can proceed to other menu functions or return to the

HOME screen.

EX90-SERIES INSTRUCTIONS

the pipe size. These are considered “LARGE” holes. In this

type of installation, the meter has signicant room between

it and the hole cut into the pipe. When water ows by the

meter, it lls this extra cross sectional area while owing

past the measurement point. This means that unlike the

“SMALL” hole case, the cross sectional area at the point

of measurement is not equal to the I.D. of the pipe. When

this menu is selected, the EX90 will compensate for this

condition.

SETUP Menu Functionality

The SETUP menu works slightly dierently than other

menus inside the EX90. The black square highlighting the

left most text is similar to a cursor on a computer. It lets

you know where you are within the menu. Press Up 1x

and the menu category will change. The categories are as

follows:

ID (Internal Diameter in inches)

HOLE (Hole Size Cut into Pipe for Inserting Meter)

PIPE (Piping Conguration Selection)

ID

The Internal Diameter (or I.D.) of the Pipe in which the EX90

is installed is critical to the meter’s performance. The EX90

senses a local velocity around the electrodes and uses that

information to extrapolate the ow over the entire pipe

section. The ID is also used ‘under the hood’ to scale many

critical values such as Low Flow Cuto, Max Flow Rate, etc.

The installer should measure the ID in the most accurate

way possible prior to saddle installation.

HOLE

PIPE

The PIPE menu is used to compensate for altered velocity

proles in various piping congurations. When obstructions

or disturbances are introduced to straight pipe (particularly

upstream of the meter), the velocity prole changes shape.

Since the AG90 measures a relatively small cross section of

the velocity prole, large distortions of this prole can lead

directly to measurement error. The pipe menu has distinct

pipe conguration compensation built into the AG90

allowing you to select the closest condition to your actual

pipe and allows the AG90 to operate at peak performance.

STRAIGHT

Straight Pipe is a relative term. For this conguration, the

EX90 considers the pipe to be straight if there are 20+

diameters of straight pipe upstream from the meter and

at least 2 diameters downstream from the meter from any

obstruction in the pipe.

10/2 ELB

This selection represents an install condition in which there

exists a single in plane elbow 10 diameters upstream from

the meter and 2 diameters downstream from the meter.

HOLE references dierent types of installs:

SMALL

5/2 ELB

This selection represents an install condition in which there

exists a single in plane elbow 5 diameters upstream from

New Installations will cut a 1.75” hole into the pipe. This is

the meter and 2 diameters downstream from the meter.

considered a “SMALL” hole. In this type of installation, the

meter is ush to the diameter of the hole. This represents

an ideal installation condition, because the cross-sectional

area at the measurement point is equal to the I.D. of the

pipe.

LARGE

ADJ

The adjustment menu is for installers and regulating

bodies. This menu allows manual adjustment of the rate

(on a % of reading basis) in installations outside of the

scope of this document. This menu should be used when

a known reference is temporarily (or otherwise) installed

Retrot installations already have a hole cut into the pipe.

Typically they are quite large (especially when replacing

into the system and adjustment can be made with high

condence and reliability.

mechanical meters), although the exact size depends on

Seametrics • 253.872.0284 Page 14 seametrics.com

Page 15

OPERATION

1.2345678

TAP

TAP

1.2345678

100

TOTAL

CU FT

X1000

RATE

GPM

FWD TOTAL

1.2345678

100

TOTAL

CU FT

X1000

RATE

GPM

T UNIT R UNIT S ET PDAMP

SET 4

SET 20 EXIT

TOTAL = GALLONS

PRESS + TO SET TOTAL

UNITS FOR DISPLAY

FWD TOTAL

TAP

TAP

TAP

TAP

+

HOLD TAP

+

HOLD TAP

Changing Flow Meter Settings

EX90-SERIES INSTRUCTIONS

Home Screen and General Navigation

The HOME Screen displays ow volume, direction of the

ow total and ow RATE along with status conditions such

as Empty Pipe. Two buttons below the LCD display are used

to access menu screens for viewing and changing meter

setup parameters.

TOTAL

CU FT

X1000

RATE

100

FWD TOTAL

GPM

These two buttons are light sensors which can detect

when a nger is covering them and operate upon release.

Only three button touch actions are needed to control

navigation through the menus, settings changes and back

to the home screen.

HORIZONTAL SCROLLING:

Tap right button to scroll horizontally through

menu tabs or move horizontally within a tab

dialog when applicable.

Making Selections

Once in the Menu System, move from tab to

tab by tapping the right button. (See the next

page for details on the various available tabs.)

Select the parameter. In the screen for

the highlighted tab you will see the current

parameter value for that tab. Tapping the right

button, move to the tab for the parameter you

want to change.

In this example, the rst line indicates that the

current unit for the TOTAL is GALLONS. The

next two lines tell you what to do next.

T UNIT R UNIT S ET PDAMP

TOTAL = GALLONS

PRESS + TO SET TOTAL

UNITS FOR DISPLAY

SET 4

SET 20 EXIT

If you would like to change the TOTAL units,

just perform the hold and tap sequence to

bring up a screen to change the setting.

+

HOLD TAP

VERTICAL SCROLLING:

Tap left button to change a highlighted item

within a tab dialog.

SELECT/ENTER/EXIT:

Hold left button while tapping right button

once to enter or exit a tab dialog or to

navigate between the HOME and other

menu screens.

To enter the Menu System perform the hold

and tap sequence. The Passcode entry screen

will display. The default passcode is 000000. If

a dierent passcode has previouly been set,

use the and to enter that passcode.

In either case, hold and tap again to move

passcode, hold and tap again to return to the

previous screen. See page 16 for information on

how to change a passcode.)

into the menu system. (If you enter the wrong

ENTER PASSCODE

T UNIT R UNIT S ET PDAMP

TOTAL:

PRESS TO CHANGE

SET 4SET 20 S ET F EXIT

GALLONS

Scroll through setting. Select the new setting

by scrolling through a list of selections by

tapping the left button to nd a dierent

TOTAL unit.

Accept changes. To accept any changes

you have made, perform the hold and tap

sequence.

When nished making changes. When you

are nished making changes, move to the EXIT

tab using the right button.

+

HOLD TAP

Seametrics • 253.872.0284 Page 15 seametrics.com

000000

PRESS AND TO CHANGE

To return to the HOME screen, perform the

hold and tap sequence.

+

HOLD TAP

Page 16

OPERATION

1.2345678

100

TOTAL

CU FT

X1000

RATE

GPM

FWD TOTAL

LO

1.2345678

EX90-SERIES INSTRUCTIONS

To Change a Passcode and Decimal Places

The EX90 has a passcode system for restricting access to the

menus. The EX90 comes from the factory with the passcode

set to 000000. When a user attempts to enter the menu system

(see details on page 14), the passcode entry screen will be

displayed.

The default passcode is 000000. If a dierent passcode has

previously been set, then the user must enter that passcode at

this time. After entering the passcode, or leaving it at 000000

if using the default passcode, the user does the hold and tap

sequence to move into the menu system.

To change the passcode, you must use the THIRD MENU

screen. Access the THIRD MENU screen as follows:

• Enter the main menu system, as described above.

On the main menu, tab over to the EXIT tab and tap the up

arrow ve times. A SUBMENU screen will display.

• On the SUBMENU screen tab over to the EXIT tab and

• To set the code, hold and tap SETCD and then use the

• Hold and tap again to return to the THIRD MENU screen.

• Tab to EXIT, and then hold and tap to return to the

To change the number of decimal places in the total

• To set the decimal point, hold and tap on SETD and then

• Hold and tap again to return to the THIRD MENU screen.

• Tab to EXIT, and then hold and tap to return to the

ENTER PASSCODE

000000

PRESS AND TO CHANGE

T UNIT R UNIT SET PDAMP

TOTAL = GALLONS

PRESS + TO SET TOTAL

UNITS FOR DISPLAY

SET 4

SET 20 S ET F EXIT

INFO COMM MBID FL DIR

PRESS + TO VIEW INFO

ABOUT METER

SAMP

SAMP SETUP EXIT

tap the up arrow ve times. The THIRD MENU screen

will display.

SETD

PLMIN

FOUT EXIT

TEST

SETCD

000000

PRESS + TO SET

PASSCODE

SAMP

and to enter the new code.

SUBMENU.

use the to move the decimal point.

SUBMENU.

Power Indicators

A power indicator is displayed in the lower left of the main

display window.

When powered by battery a battery icon will display.

OK on the battery indicator means battery voltage is above

6.4 volts.

LO on the battery indicator means the battery is low and

should be replaced soon.

Powered by battery -

voltage is sucient

Powered by battery voltage is low

100

P

OK

FWD TOTAL

TOTAL

CU FT

X1000

RATE

GPM

OK

LO

PLMIN

PLMIN is a measure of stability within the lter. Its setting

is in terms of a percentage subtracted from 100. When

PLMIN = 0, the DAMP lter will be applied regardless of

changing ow rates. No amount of ow rate changes seen

by the meter will restart the DAMP lter.

When PLMIN is ≠ 0, PLMIN is subtracted from 100. The

resulting percentage is used as a DAMP lter restart

condition. When this condition is met, the DAMP lter will

be emptied and restarted with fresh data. For instance,

when PLMIN = 25: 100-25=75%. This means that any

reading that diers from its predecessor by 75% or more

(in either the positive or negative direction), will trigger

the DAMP lter reset condition. If PLMIN = 5, the DAMP

lter will only reset when a value is ±95% dierent than its

predecessor.

It is very important to note that PLMIN settings should vary

based upon ow conditions at the install site. If the DAMP

lter is being used to smooth out known varying ow

conditions (pulsating or highly turbulent ows), too high

of a PLMIN value can exacerbate unstable ow conditions.

When ow conditions are such, a value of PLMIN = 0 is

suggested. Note however, that upon startup and shutdown,

this will aect ow rate values responsiveness.

Seametrics • 253.872.0284 Page 16 seametrics.com

Page 17

OPERATION

TEST

TEST allows the user to initiate a fully functional, articial

ow rate for the purpose of testing other connected

equipment. When TEST is applied, all features of the meter

will function at the stated ow rate (in gallons per second).

For TEST to function, the meter must be in water (not

EMPTY PIPE), a rate must be entered and the feature must

be turned ON.

After use, the TEST feature must be turned OFF. If the

TEST feature is not turned OFF, the stated static ow rate

(in gallons per second) will be shown any time the meter is

full or in a owing condition.

Battery Powered Units

To ‘wake up’ a battery powered meter, you may need to

hold the up arrow for 2 seconds and release.

The EX90 meter comes congured with a 7.2V ‘D’ size

lithium battery pack. In this conguration, the only option/

output is the scaled pulse output which comes standard.

Be sure to set your SETP value such that the meter will

function properly over the ow range in your application

(see page 12 for details). The sample rate of the meter is

user selectable through the SAMP tab in the meter’s sub-

menu. Sample periods of 1/5, 1/3, 1, 3, 5, 15, 30, and 60

seconds can be selected. (A sample period of 5 seconds

- 4 year battery life - is the default.)

Larger sample periods will yield longer battery life but

slower response time. Care must be taken to select a

sample period that is suitable for your application. See the

table below for the expected battery life as a function of

sample period.

DAMP/Filtering

The DAMP Filter allows multiple readings to be averaged

over time, thus reducing the meters sensitivity to minor

changes in ow rate. The DAMP Filter is extremely useful for

situations where the ow is not perfectly steady (pulsating

ows, turbulent ows, etc.)

EX90-SERIES INSTRUCTIONS

seconds of data within the lter. This means that the lter

will average readings for 8 seconds prior to displaying a

reading. After the rst reading is displayed, the lter kicks

out the oldest 1 second of data, adds the newest 1 second

of data, recomputes the average ow rate, and displays it

to the screen/output. In this way, it is considered a “running

average”.

SAMP > 1 second

When the SAMP menu is set to a number greater than

1 second, the DAMP menu is dened on a “per reading”

basis. Again, the DAMP lter must always use at least 1

reading to generate a ow rate, so the lter will add 1 to

your selection. For instance, if SAMP is set to 15, and DAMP

is set to 7, the DAMP lter will utilize 7+1=8 readings worth

of data for the lter. This means that the lter will not be

full for 15x8=120 seconds. Note that in most long term

applications, these long lters may be ne, but in shorter

term applications, the DAMP and SAMP menus need to be

adjusted accordingly.

Battery Life/Sample Period

Sensor sample period(s)

Expected battery life*

(Seconds)

1/5 (0.2) 4.5 Months

1/3 (0.33) 7 Months

1 1.5 years

3 3.25 years

5 4 years

15 5.5 years

30 6 years

60 6.25 years

*Based on 85% battery capacity at room temperature.

The DAMP Filter works dierently depending on the SAMP

selection:

SAMP < 1 second

When the SAMP setting is less than 1 second, the DAMP

lter is dened on a “per second” basis. The DAMP lter

always utilizes at least 1 second of data for its lter. Then, it

adds however many seconds you’ve selected in the DAMP

menu setting to that 1 second of data. For instance, if you

set the DAMP menu to 7, your EX90 meter will utilize 7+1=8

Seametrics • 253.872.0284 Page 17 seametrics.com

Page 18

TROUBLESHOOTING & ERROR MESSAGES

Troubleshooting

Problem Probable Causes Things to try…

Blank Display Battery has not been plugged in

Dead battery

Flow rate reading uctuates

excessively when ow is

unchanging

Excessively turbulent or unsteady ow

due to partially closed valves or other

ow obstructions

Plug in the battery

Replace battery

Eliminate or minimize causes of ow disturbances

or increase meter damping

EX90-SERIES INSTRUCTIONS

Flow Rate appears correct but

pulse/ frequency output is low,

erratic or absent

Flow Rate appears correct

but pulse/frequency output is

erratic and/or too high

Flow rate steadily reads

zero when there is ow

Hole reference incorrect or not set.

Straight pipe conguration not set

Pipe not full Provide back pressure or other means to ensure

Pulsing ow due to combining multiple

upstream ow sources

Insucient mixing of upstream chemicals Move chemical injection downstream from meter

Low uid conductivity < 20 µS/cm Replace with dierent type of meter

Noisy electrical environment Improve grounding at meter and nearby

External device input impedance too low

Cable too long

Electrical noise sources interfering with

pulse frequency signal

Wrong type of cable Use only twisted pair cable and ensure both signal

Grounding problem Improve or try dierent grounding method

Pipe ID not set

Flow is below cutoff (very low)

Set correct hole reference

Program straight pipe conguration

pipe is lled

Move connection point further upstream

potentially noisy electrical equipment. Increase

distance between meter and electrical noise

sources.

Use sourcing rather than sinking interface

connection

Reduce interface pull-up resistance

Isolate, remove or reduce noise sources. Move

meter control cable away from noise sources.

wires are on same twisted pair

Program ID of pipe

Reading will resume when ow increases

Flow rate intermittently

Air in the pipe

Air in the pipe Reposition meter for full pipe

Reposition meter for full pipe

drops when there is ow

Jumpy reading Improperly grounded

Pulsing ow

Check for proper grounding

Increase DAMP value

Use external power source

(allows more ow averaging)

Seametrics • 253.872.0284 Page 18 seametrics.com

Page 19

TROUBLESHOOTING & ERROR MESSAGES

EX90-SERIES INSTRUCTIONS

Error Messages

Under certain conditions an error message may be displayed.

Message Description Notes

INIT Initialization is occurring during power up.

EMPTY PIPE Fluid is not detected between the sensing electrodes.

LO in battery icon Battery is getting low, replace soon. Meter still functions. Above 6.4V, OK appears in icon

BATT END Battery is very low (approx. 6.1V). Totalizer stops updating.

COIL FAIL Coil current too high or too low (short or open).

COMM FAIL Communication between transmitter and sensor board fails.

OVER RANGE Rate exceeds number of digits that can be displayed. Adjust units.

Seametrics • 253.872.0284 Page 19 seametrics.com

Page 20

SEAMETRICS LIMITED WARRANTY

The limited warranty set forth below is given by Seametrics, with respect to Seametrics and INW brand products purchased in the

United States of America.

Seametrics warrants that products manufactured by Seametrics, when delivered to you in new condition in their original containers

and properly installed, shall be free from defects in material and workmanship. Seametrics products are warranted against

defects for a period of two (2) years from date of installation, with proof of install date. If no proof of install date can be

provided, warranty period will be two (2) years from date of shipment from Seametrics, as dened on Seametrics’ invoice.

Seametrics’ obligation under this warranty shall be limited to replacing or repairing the part or parts, or, at Seametrics’ option, the

products, which prove defective in material or workmanship. The following are the terms of Seametrics’ limited warranty:

a. Buyer must give Seametrics prompt notice of any defect or failure and satisfactory proof thereof.

b. Any defective part or parts must be returned to Seametrics’ factory or to an authorized service center for inspection.

c. Buyer will prepay all freight charges to return any products to Seametrics’ factory, or another repair facility. as designated by

Seametrics.

d. Defective products, or parts thereof, which are returned to Seametrics and proved to be defective upon inspection, will be

repaired to factory specications.

e. Seametrics will deliver repaired products or replacements for defective products to the buyer (ground freight prepaid) to the

destination provided in the original order.

f. Products returned to Seametrics for which Seametrics provides replacement under this warranty shall become the property

of Seametrics.

g. This limited warranty covers all defects encountered in normal use of Seametrics products, and does not apply to the

following cases:

i. Loss of or damage to Seametrics product due to abuse, mishandling, or improper packaging by buyer

ii. Failure to follow operating, maintenance, or environmental instructions prescribed in Seametrics’ instruction manual

iii. Products not used for their intended purpose

iv. Alterations to the product, purposeful or accidental

v. Electrical current uctuations

vi. Corrosion due to aggressive materials not approved for your specic product

vii. Mishandling, or misapplication of Seametrics products

viii. Products or parts that are typically consumed during normal operation

ix. Use of parts or supplies (other than those sold by Seametrics) which cause damage to the products, or cause

abnormally frequent service calls or service problems

h. A new warranty period shall not be established for repaired or replaced material, products, or supplied. Such items shall

remain under warranty only for the remainder of the warranty period on the original materials, products, or supplies.

i. In the event that equipment is altered or repaired by the buyer without prior written approval by Seametrics, all warranties

are void. Damage caused by equipment or accessories not manufactured by Seametrics may void the product’s warranty.

j. SOFTWARE: The Seller grants the user a non-exclusive license to use Seametrics’ software, according to the following

limitations and conditions:

i. The user may install the software on one or more desktop or laptop computers.

ii. All title and intellectual rights to the software are owned by Seametrics.

iii. No copies may be made or distributed except as described above.

iv. The user may not modify or reverse-engineer the software.

THE FOREGOING WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, WHETHER ORAL, WRITTEN, EXPRESSED, IMPLIED OR STATUTORY. NO

IMPLIED WARRANTY, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, APPLIED TO

THE PRODUCTS AFTER THE APPLICABLE PERIOD OF THE EXPRESS LIMITED WARRANTY STATED ABOVE, AND NO OTHER EXPRESS WARRANTY

OR GUARANTY, EXCEPT AS MENTIONED ABOVE, GIVEN BY ANY PERSON OR ENTITY WITH RESPECT TO THE PRODUCTS, SHALL BIND

SEAMETRICS. SEAMETRICS SHALL NOT BE LIABLE FOR LOSS OF REVENUES, OR PROFITS, OR INCONVENIENCES, EXPENSE FOR SUBSTITUTE

EQUIPMENT OR SERVICE, STORAGE CHARGES, LOSS OF DATA, OR ANY OTHER SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGE CAUSED

BY THE USE OR MISUSE OF, OR INABILITY TO USE THE PRODUCTS, REGARDLESS OF THE LEGAL THEORY ON WHICH THE CLAIM IS BASED,

AND EVEN IF SEAMETRICS HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. IN NO EVENT SHALL RECOVERY OF ANY KIND

AGAINST SEAMETRICS BE GREATER IN AMOUNT THAN THE PURCHASE PRICE OF THE PRODUCT SOLD BY SEAMETRICS AND CAUSING THE

ALLEGED DAMAGE. WITHOUT LIMITING THE FOREGOING, YOU ASSUME ALL RISK OF LIABILITY FOR LOSS, DAMAGE, OR INJURY TO YOU AND

YOUR PROPERTY AND TO OTHERS AND THEIR PROPERTY ARISING OUT OF USE OR MISUSE OF, OR INABILITY TO USE THE PRODUCTS NOT

CAUSED DIRECTLY BY THE NEGLIGENCE OF SEAMETRICS.

SOME STATES DO NOT ALLOW LIMITATIONS ON THE DURATION OF AN IMPLIED WARRANTY, SO THE ABOVE LIMITATIONS MAY NOT

APPLY TO YOU. SIMILARLY, SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATIONS OF CONSEQUENTIAL DAMAGE, SO THE ABOVE

LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU. THIS LIMITED WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS; HOWEVER, YOU MAY

ALSO HAVE OTHER RIGHTS WHICH MAY VARY FROM STATE TO STATE.

Seametrics • 19026 72nd Avenue South • Kent, Washington 98032 • USA

(P) 253.872.0284 • (F) 253.872.0285 • 1.800.975.8153 • seametrics.com

LT-14262r2.0 20190404

4/4/2019

Loading...

Loading...