Page 1

EX800-Series

9 001:2008

ISO

ELECTROMAGNETIC FLOW SENSOR INSTRUCTIONS

EX800 SERIES ELECTROMAGNETIC FLOW SENSOR INSTRUCTIONS

CERTIFIED COMPANY

Page 2

TABLE OF CONTENTS

EX800 SERIES INSTRUCTIONS

General Information

General Information, Features .............................................................................................................................Page 3

Specications ........................................................................................................................................................Page 4

Installation

Fitting Installation, Meter Installation, Chemical Injection or Fertigation .........................................................Page 5

Straight Pipe Recommendations .........................................................................................................................

Full Pipe Recommendations .................................................................................................................................Page 7

Electrical Connections

General Electrical Guidelines, Power, Output (Forward Flow and Reverse Flow), Grounding Guidelines .......Page 8

Connections Diagrams

Counter or PLC, A055 4-20 mA Output, FT520 Controller .................................................................................Page 9

FT430/440 Display & Proportional Feed, FT440 & 4-20 mA Output, Dual FT430/440 Displays ..................Page 10

DL76 Data Logger, FT440/DL76 ..........................................................................................................................Page 11

Operation & Maintenance

Zero Adjustment, Minimum Flow, Flow Rate Table,

Filtering, Electrode Coating, Calibration (“K-Factor”), K-Factor Chart ...............................................................Page 12

Exploded Parts View, Parts List ............................................................................................................................Page 13

Page 6

roubleshooting

Problems, Probable Causes .................................................................................................................................Page 14

TABLES AND DIAGRAMS

Features .................................................................................................................................................................Page 3

Specications ........................................................................................................................................................Page 4

Distorted Flows, Orienting the Meter ...................................................................................................................Page 5

Straight Pipe Recommendations .........................................................................................................................

Full Pipe Recommendations .................................................................................................................................Page 7

Grounding Diagram ...............................................................................................................................................Page 8

Connection Diagrams: Counter or PLC, A055 4-20 mA Output, FT520 Controller ...........................................Page 9

Connection Diagrams: FT430/440 Display & Proportional Feed, FT440 & 4-20 mA Output,

Dual FT430/440 Displays .............................................................................................................................Page 10

Page 6

Connection Diagrams: DL76 Data Logger, FT440/DL76 ...................................................................................Page 11

Flow Rate Table, K-Factor Chart ...........................................................................................................................Page 12

Exploded Parts View, Parts List ............................................................................................................................Page 13

Troubleshooting .....................................................................................................................................................Page 14

Page 2

Seametrics • 253.872.0284 • www.seametrics.com

Page 3

GENERAL INFORMATION

EX800 SERIES INSTRUCTIONS

EX800-Series insertion electromagnetic ow meters are

designed for use with conductive liquids in 1 to 12” pipe. A

choice of materials (stainless steel, brass, and PVC) allows

the meter to adapt to a range of temperature, pressure, and

corrosive environments.

The EX800 is highly suitable for difcult applications with

changing viscosities and pulsating ows, such as air-driven

diaphragm pumps. With no moving parts, these meters can

be used in “dirty water” applications where debris would foul a

mechanical meter. Like all magmeters, when used in chemical

injection applications, these meters should be installed

upstream of the chemical line (or far enough downstream to

allow complete mixing of uids before the meter).

Designed for modularity and versatility, the EX800-Series has

a current-sinking pulse output that can be combined with the

appropriate transmitter or indicator for the application. For

Features

basic rate/total and pulse output, the FT430 is best. For

analog output and display of rate and total, the FT440 can be

used. Blind analog output is provided by the AO55. The PD10

can be used to divide the pulse for pacing chemical metering

pumps. Electronic modules can be wall- or meter- mounted.

If the EX800 meter is used with a programmable controller,

the output signal can be fed direct, with no other conditioning

required.

EX800-Series xed depth insertion meters require special

ttings. Factory installation in the tting ensures correct depth

placement in the pipe. The EX800-Series meter can be ordered

in a full power model when a source of electricity is available, or

in a low power model that can run on an external battery with

solar panel.

Reverse ow output and immersibility are optional.

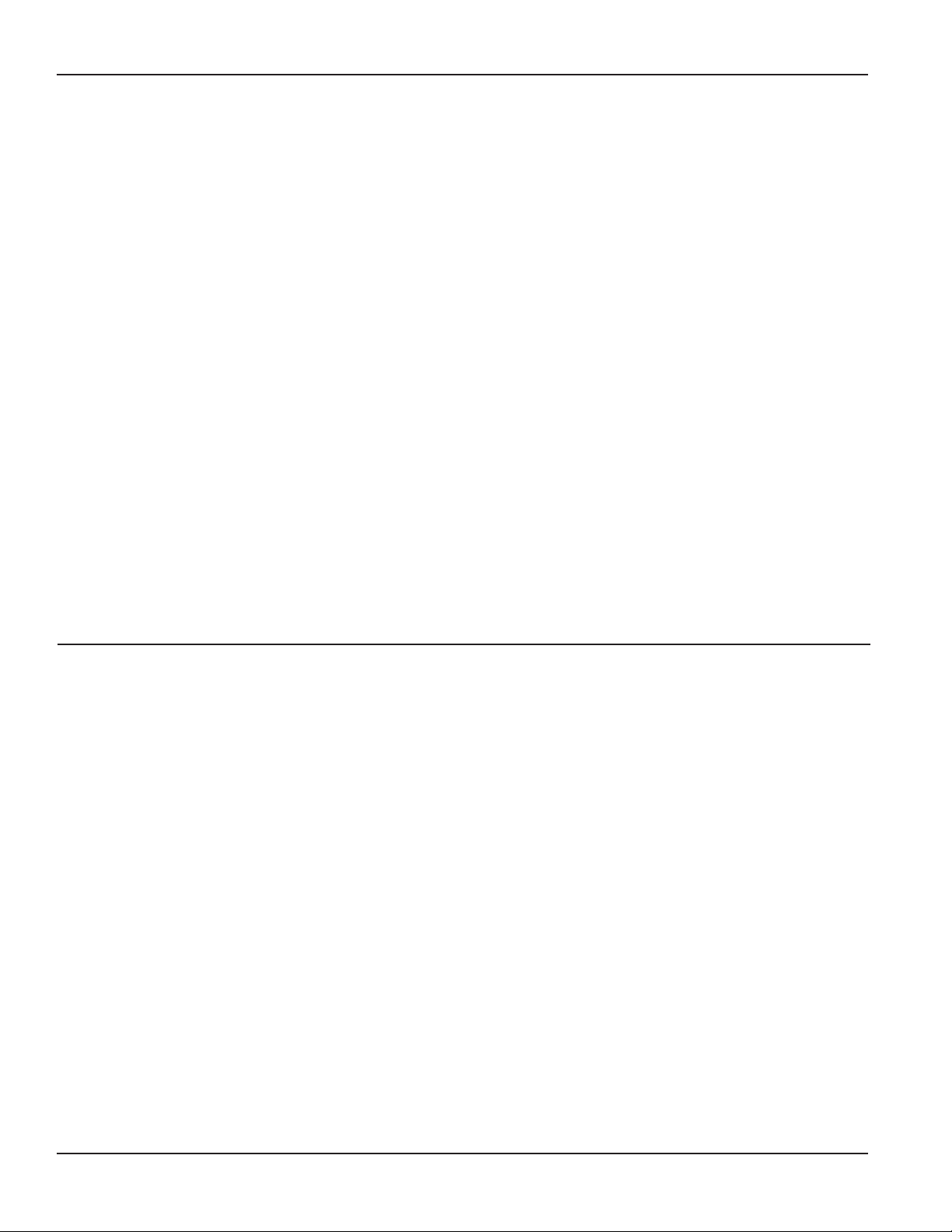

Cover, or electronics module

Powder-coated aluminum housing

Power cord strain relief

O-ring, EPDM (Viton® optional)

Sensor body (Stainless, Brass, PVC)

PVDF electrode cap

Hastelloy electrodes

Seametrics • 253.872.0284 • www.seametrics.com

Page 3

Page 4

GENERAL INFORMATION

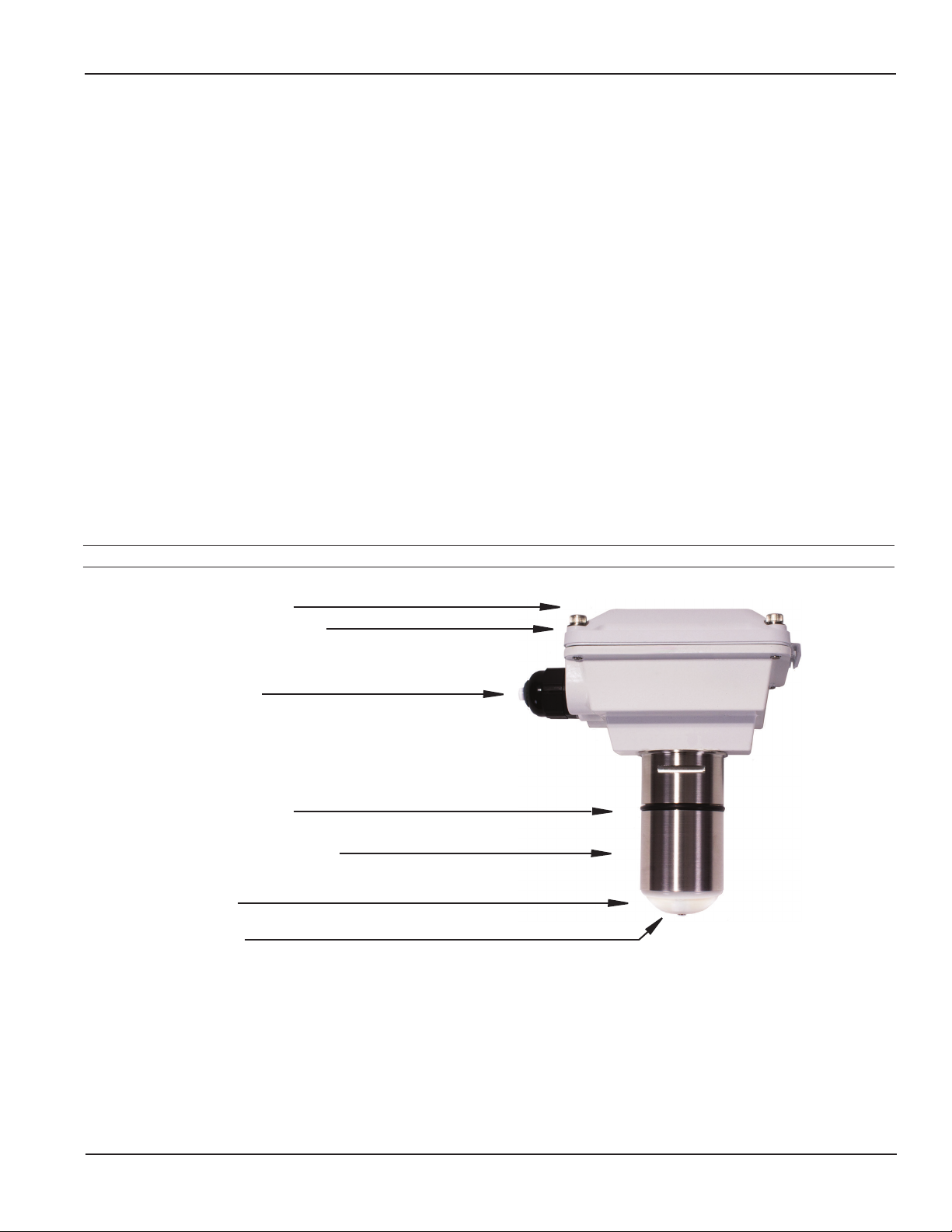

Specications*

Pipe Sizes 1” to 12”

Materials Mechanical 316 SS or Brass

Electrodes Hastelloy

Electrode Cap PVDF (Kynar®)

Housing Cast powder-coated aluminum

Valve Assembly (15x/25x only) Bronze (stainless optional) with bronze ball valve

O-Ring (15x/25x only) EPDM standard (Viton® optional)

Power Full Power 12-25 Vdc, 250 mA

Low Power 12-25 Vdc, 40 mA average with 250 mA peaks

Flow Rate 0.28 to 20 ft/sec (0.08 - 6.09 m/sec)

Temperature Ambient 0˚ to 160˚F (-17˚ to 72˚C)

Fluid (Brass/SS) 32˚ to 200˚ F (0˚ to 93˚ C)

Fluid (PVC) 32˚ to 130˚ F (0˚ to 55˚ C) @ 0 psi

EX800 SERIES INSTRUCTIONS

Pressure Brass/SS 200 psi (14 bar)

PVC 150 psi (10 bar) @ 75˚ F (24˚ C)

Minimum Conductivity 20 microSiemens/cm

Calibration Accuracy +/- 1% of full scale

Output Square wave pulse, opto isolated, 500 Hz @ 20 ft/sec

Empty Pipe Detection Software, defaults to zero ow

Regulatory

*Specications subject to change • Please consult our website for current data (www.seametrics.com).

Kynar is a registered trademark of Arkema, Inc., Viton is a registered trademark of DuPont Corporation.

(Standard power only)

Page 4

Seametrics • 253.872.0284 • www.seametrics.com

Page 5

INSTALLATION

Fitting Installation

EX800-Series meters require special ttings that ensure that

the ow sensor is installed to the correct depth. The tting

must be installed in the pipeline before the meter can be

installed. For best results, install with at least ten diameters

of straight pipe upstream of the meter and ve diameters

downstream (or more under specic adverse circumstances).

See diagrams, next page.

EX800 SERIES INSTRUCTIONS

Caution: These ow sensors are not

recommended for installation downstream of

a boiler feedwater pump where installation

fault may expose the ow sensor to boiler

pressure and temperature. Maximum recommended

temperature is 130°F (Plastic), 200°F (Metal).

If there is not enough straight run to smooth out the turbulence

caused by valves, ttings, and changes in direction, some

decrease in accuracy may result. This does not mean that

the ow meter’s reading is meaningless, however. In some

applications (control systems, valve operation, chemical

addition), a repeatable reading may be more important than

a highly accurate one.

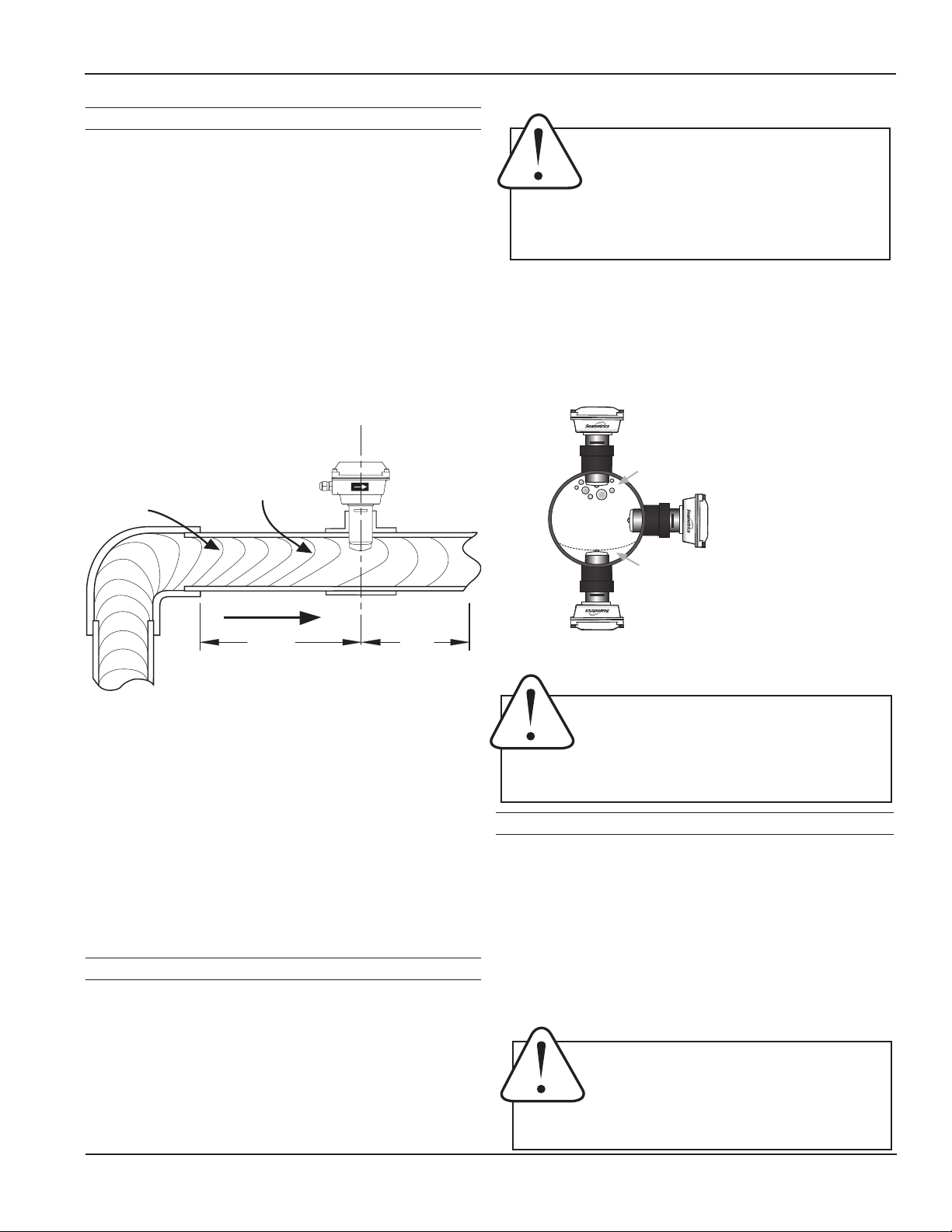

Faster Flow

Causes Meter

Distorted

To Read High

Flow Prole

10X

Distorted Flows

5X

Although EX800-Series PVC meter tees are supplied with some

straight pipe, additional straight pipe should be added to meet

straight pipe recommendations. It is not advisable to connect

a ow-disturbing device (e.g. valve or elbow) directly to the end

of these ttings.

A PVC tting is usually installed by solvent welding. The

stainless steel and brass meter ttings have female pipe

threads, requiring the appropriate male threaded ttings.

Saddle or weld ttings (3” and above) require a hole to be cut

in the pipe. Recommended hole size is 1-3/4”.

Meter Installation

After the meter tting is installed in the pipeline, the meter

can be installed in the tting. After noting the direction of the

ow arrow, press the meter into the tting as far as it will go.

Retain the meter in place by inserting the U-clip. The pin can

be installed from either side. It may be necessary to rotate the

probe back and forth slightly to start the pin into the slots on

the probe. Slide the pin in as far as it will go.

Horizontal (3 o’clock or 9 o’clock position) is the preferred

installation orientation, since it improves low-ow performance

and avoids problems with trapped air and sediment. (See

Orienting the Meter diagram below.) Bottom (6 o’clock), top

(12 o’clock), and vertical pipe installations are all acceptable if

required by the piping layout.

Fair

Unacceptable if pipe

contains air

Air bubbles

Best

Position

Sediment

Fair

Unacceptable if pipe

contains sediment

Orienting the Meter

Caution: Never remove the U-clip retainer when

the pipe is under pressure. Always remove

pressure from the pipe before you attempt to

remove the meter. Removal under pressure may result in

damage or serious injury.

Chemical Injection or Fertigation

When any magmeter, by any manufacturer, is used in a

chemical injection application (including fertigation), the

chemical injection point must be placed downstream of the

magmeter OR far enough upstream for complete mixing to

occur before the uid reaches the meter. When unmixed

chemical or fertilizer alternates with water passing through the

meter, the rapid changes in conductivity may cause sudden

spikes and drops in the meter’s reading, resulting in inaccurate

measurement. The magmeter will restabilize, however, with a

steady ow of uid of uniform conductivity.

Caution: In chemical injection or fertigation

applications, install chemical injection point

downstream of magmeter, or far enough

upstream to allow complete mixing of uids

before the meter.

Seametrics • 253.872.0284 • www.seametrics.com

Page 5

Page 6

Straight Pipe Recommendations (X = diameter)

Reduced Pipe

EX800 SERIES INSTRUCTIONSINSTALLATION

5X10X

Two Elbows In Plane

Two Elbows, Out Of Plane

Expanded Pipe

20X

20X

5X10X

5X

5X

Page 6

30X

Spiral Flow

Propeller Meter

20X

Swirling Flow

Partially Open

Buttery Valve

Seametrics • 253.872.0284 • www.seametrics.com

Page 7

INSTALLATION

Full Pipe Recommendations

Allows air pockets to form at sensor Ensures full pipe

EX800 SERIES INSTRUCTIONS

Better InstallationPossible Problem

Better InstallationPossible Problem

Post-valve cavitation can create air pocket Keeps pipe full at sensor

Better InstallationPossible Problem

Air can be trapped Allows air to bleed off

Caution: These ow sensors are not recommended for installation

downstream of a boiler feedwater pump where installation fault may

expose the ow sensor to boiler pressure and temperature. Maximum

recommended temperature is 130°F (Plastic), 200°F (Metal).

Seametrics • 253.872.0284 • www.seametrics.com

Page 7

Page 8

ELECTRICAL CONNECTIONS

EX800 SERIES INSTRUCTIONS

General Electrical Guidelines

• Whenever possible avoid running control cables in the

same conduit with or bundled with AC power.

• Using shielded cable, be sure to connect shield to ground

at power supply end of the cable.

• Avoid routing ow sensor cables in close proximity to a

variable frequency drive.

• Recommended power and output wiring is shielded

twisted pair 18-22 AWG control cable.

• Recommended voltage is 12-24 Vdc. Note that

unregulated power supplies can vary from nameplate

voltage by a considerable amount, especially with AC

line voltage uctuation. Therefore 24V power supplies

must be regulated.

See the Connections diagrams on the following pages for the

appropriate terminals.

Power

A 12 - 24 Vdc power supply capable of at least 250 mA current

output is needed.

Output

Forward Flow Output: This open-collector isolated output does

not supply power. This pulse is generated in the forward ow

direction on the standard unit. (Reverse ow output is available

as an option). Note: This output is limited to 6 mA at 30 Vdc

maximum.

Reverse Flow Output: Reverse ow output is available as

an option. This open-collector isolated output does not supply

power. It functions like a polarity-sensitive switch closure. Note:

This output is limited to 6 mA at 30 Vdc maximum. Grounding

Guidelines:

Grounding Guidelines

For best results, use a good quality earth ground, such as

metallic water piping or a driven ground, to ensure a good

connection to earth ground and good noise suppression.

If the ow sensor is installed in metallic piping, for optimum

connection clamp wire to the piping a short distance to one

side of the ow sensor using an electrical grounding clamp.

Connect the wire to the earth ground and to one of the housing

screws.

For Non-Metallic Pipe: Connect one to the housing screws by

wire to a good earth ground, such as metallic water piping or a

rod driven into the ground.

EX meters are usually unaffected by moderate levels of

electrical noise. In some applications performance may be

improved by taking the following steps:

• Use shielded twisted pair cable (Belden 8723 or

equivalent above ground or Alpha 35482 or equivalent

burial).

• Clamp a ferrite bead (Steward 28A2029-OAO or

equivalent) on meter signal/power wire within 3/4”

of the meter strain relief (tape or tie wrap in place if

necessary). See diagram below.

• IMPORTANT - Connect the cable shield ground

wire to ground, ONLY at power supply end of cable.

Place Ferrite Bead Here

Housing

Screw

Earth

Ground

Caution: The EX800 has a strong start and

run current. When using solar panels and

VRSLA batteries as a power source, use

caution to insure the EX-series sensor has

the -50 Low-power Option and that all Seametrics

products on the power circuit receive sufcient voltage and current under all conditions. Failure to do so

will lead to unreliable operation and possible damage

to the unit/s. Please reference the technical bulletin,

‘Solar and Battery-Power Guidelines’ available on our

website: www.seametrics.com

Page 8

Seametrics • 253.872.0284 • www.seametrics.com

Metallic Pipe

Grounding

Clamp

Grounding Diagram

Page 9

CONNECTIONS DIAGRAMS

+

_

+

_

00

9

8

7

6

5

4

3

2

1

00

9

8

7

6

5

4

3

2

1

00

9

8

7

6

5

4

3

2

1

00

9

8

7

6

5

4

3

2

1

+

_

S

+

_

+

_

+

_

+

+

_

_

+

_

+

+

_

_

+

_

+

_

Counter or PLC

EX800 SERIES INSTRUCTIONS

EX-SERIES

Power

12 - 24 Vdc

COUNTER OR PLC

Forward Output

(open collector)

See Dual FT430/440 Diagram for an

Reverse Output

(Option -15 only)

example of bidirectional connections.

Max. 6 mA, 30 Vdc

Max. 6 mA 30 Vdc

DIGITAL INPUT

AO55 4-20 mA Output

AO55

24 Vdc Power

Red

EX-SERIES

Black

Power

Forward Output

Reverse Output

(Option-15 only)

Green

White

+

–

Sensor

FREQUENCY

4-20 mA

24 Vdc Power

Black

Red

4-20 mA

See Dual FT430/440 Diagram for an

example of bidirectional connections.

FT520 Controller

Pulse

Out

See Dual FT430/440 Diagram for an

example of bidirectional connections.

FT520

24 Vdc Power

Black

+12V

SEN1

Green

G

SEN2

White

Seametrics • 253.872.0284 • www.seametrics.com

EX-SERIES

Red

Power

Forward Output

Reverse Output

+

(Option-15 only)

–

Page 9

Page 10

FT430/440 Display and Proportional Feed

+

+

_

_

+

_

+

_

+

_

+

_

+

_

S

+

_

+

_

+

_

Power

Pulse

Out 2

Sensor

Input

Pulse

Out 1

(Scaled)

(Scaled)

_

EX-SERIES

+

Power

_

Forward Output

Reverse Output

(Option-15 only)

See Dual FT430/440 Diagram for an

example of bidirectional connections.

FT440 DISPLAY AND 4-20 mA Output

+

_

+

_

Black

24 Vdc Power

Red

Green

White

EX800 SERIES INSTRUCTIONSCONNECTIONS DIAGRAMS

FT430/440

(430 = Pass-Thru

440 = Scaled)

+

Power

_

+

Pulse

Out 2

_

+

To

Proportional

Feed

Metering

Pump

Sensor

Input

_

S

+

_

+

Pulse

Out 1

(Scaled)

FT440

EX SERIES

Power

Forward Output

Reverse Output

(Option-15 only)

See Dual FT430/440 Diagram for an

example of bidirectional connections.

Red

Black

Black

24 Vdc

Power

4-20 mA Device

(e.g. pump, PLC)

24 Vdc

Power

Green

White

Black

Red

Dual FT430/440 Displays (Example of Bidirectional Connection)

Black

(Scaled)

Pulse

Out 1

Sensor

Input

+

+

_

+

Pulse

Page 10

Out 2

(430 = Pass-Thru

440 = Scaled)

_

S

_

+

_

Power

Seametrics • 253.872.0284 • www.seametrics.com

Red

EX-SERIES

White

Green

(Option-15 only)

Power

Forward Output

Reverse Output

24 Vdc

Power

Black

Red

Green

White

Power

Sensor

Input

_

+

_

S

+

FT430/440FT430/440

(430 = Pass-Thru

440 = Scaled)

Pulse

Out 2

_

+

_

+

Pulse

Out 1

(Scaled)

Page 11

CONNECTIONS DIAGRAMS

+

_

S

+

+

_

_

+

_

+

_

+

_

S

+

_

+

_

+

_

Power

Pulse

Out 2

Sensor

Input

Pulse

Out 1

(Scaled)

(430 = Pass-Thru

440 = Scaled)

DL76 Data Logger

EX800 SERIES INSTRUCTIONS

DL76

Power

Forward Output

Reverse Output

(Option-15 only)

See Dual FT430/440 Diagram for an

example of bidirectional connections.

FT430/440 and DL76

EX-SERIES

Power

Forward Output

EX-SERIES

24 Vdc

Power

Red

Black

Green

White

Black

Red

12-24 Vdc

Green

White

Sensor

Input

Power

DL76FT430/440*

Sensor

Input

White

Green

Reverse Output

(Option-15 only)

See Dual 430/440 Diagram for an

example of bidirectional connections.

* Note on FT440

The FT440 has Scaled Pulse Output only –

6.5 pulses/second maximum. Pulse Output 1 or

Pulse Output 2 can be used with DL76.

Seametrics • 253.872.0284 • www.seametrics.com

Page 11

Page 12

OPERATION & MAINTENANCE

10031295

EF81T-P200

K:158.42

EX800 SERIES INSTRUCTIONS

Zero Adjustment

When the EX800-Series meter is powered up and there is no

ow, there should be no output pulses (or, if connected to the

FT430/440, ow rate should read “0”). If there are pulses,

it may be necessary to adjust the ow meter under no-ow

conditions after it has been installed. This should only be

done if the indicated ow is low, near the lower cutoff.

Status

LED

Zero

Adjust

Pins

Reverse Output Option

unauthorized repair

Warranty is void if

is attempted!

Max. 6mA

30Vdc

3 4 5 6 2 1

Forward

Output

- + -

+

Power

12-24Vdc

Status

LED

Zero

Adj

Zero Adjustment

NOTICE

To perform the adjustment, after determining that there is a

full pipe with no ow, short between the two pins marked “Zero

Adjust”. A red LED light will come on for approximately 50

seconds and then go out. The zero adjustment is completed.

Electrode Coating

Grease or other adhering, non-conductive materials can stop

ow detection if the electrodes become heavily coated. To clean

the electrodes, remove the sensor from the pipe and gently

scrub the electrodes (three silver bumps) on the reading face

of the ow sensor. A mild soap (dish washing liquid for example)

can be used to aid the cleaning process.

Calibration (“K-Factor”)

The K-factor represents the actual number of pulses per gallon

the meter produces during a ow test. This number can be

entered into your electronic control to make it read properly.

If the EX800-Series meter is ordered with a tee tting, it is

factory-calibrated in the tting and the K-factor is indicated on

the side of the tting (see diagram).

Find your K-Factor Here

Minimum Flow

As with any other ow sensor, there is a rate below which the

EX800-Series sensor cannot read. Check the table below for

the minimum ow rate detectable by the sensor for a given

pipe size.

Flow Rate (GPM)

Nominal

Pipe Size

Min

@ 0.28 ft/sec

Max

@ 20 ft/sec

1” 1-1/2” 2” 3” 4” 6” 8” 10” 12”

0.7 1.5 2.7 6 11 25 44 69 99

49 110 196 440 783 1760 3130 4900 7050

Presence of Flow Indication. To assist in troubleshooting,

the “Status LED” has two blinking modes in normal operation.

When there is no ow detectable by the meter (below minimum

threshold) the LED blinks every 8.0 seconds. When there is

detectable ow, the same indicator blinks every 3.0 seconds

(Pulses are being output when indicator is blinking every 3

seconds).

Filtering

The software of the EX800-Series lters out electrical noise

and averages sudden variations in the ow to smooth the

output. It takes a matter of seconds for the ow sensor to get

up to full output when it is powered up or when ow begins.

If the EX800-Series meter is ordered with a saddle or weldolet

tting, nd your K-factor in the chart below.

K-Factors: Saddles & Weldolets

3” 4” 6” 8” 10” 12”

Schedule 40 70.397 40.985 18.120 10.474 6.674 4.709

Schedule 80 78.748 45.360 20.084 11.495 7.322 5.184

Stainless

Steel (10S)

Stainless

Steel (40S)

Copper

Tubing (L)

Copper

Tubing (K)

Brass Pipe 70.672 41 . 517 17.778 10.445 6.674 4.661

Duct. Iron

(Class 52)

NOTE: K-factors are in pulses/gallon. For pulses/liter, divide by 3.785

62.385 36.626 16.510 9.642 6.173 4.373

70.397 40.985 18.130 10.497 6.674 4.661

76.371 43.552 19.513 11.201 7.230 5.016

78.371 44.638 20.223 11.622 7.500 5.239

57. 376 37.320 16.915 9.503 6.197 4.325

Page 12

Seametrics • 253.872.0284 • www.seametrics.com

Page 13

EX800 Parts List

1

2

3

8

EX800 SERIES INSTRUCTIONSOPERATION & MAINTENANCE

EX800 Series Parts

4

7

1 Upper housing

assembly

2 Housing Gasket 100411

3 Lower housing Not eld replaceable

4 Housing screw/washer

kit (4 each)

7 Strain relief kit, large

(includes 1)

8 Sensor assembly Not eld replaceable

100662

103702

103700

Seametrics • 253.872.0284 • www.seametrics.com

Page 13

Page 14

TROUBLESHOOTING

Problem Probable Cause Try...

No pulse output Pipe not full Check plumbing

Below minimum ow cutoff Check the presence of ow LED (see page 12)

Unit not grounded Connect to earth ground (see page 8)

Excessive electrical noise Check for proper electrical wiring

No power Check for power across power input terminals

Power reversed Reverse connections

Flow reversed Note ow direction arrow,

reverse direction of meter

EX800 SERIES INSTRUCTIONS

Output connections reversed Change output connections

Fluid conductivity <20 microSiemens/cm Select another ow meter

Output pulses incorrect Missing or incorrect ground wire Check for proper ground

Excessive electrical noise Check for proper electrical wiring

Fluid conductivity <20 microSiemens/cm Select another ow meter

Empty pipe Check for full pipe or install meter in the

vertical position

Not enough straight pipe Check for ten diameters upstream AND ve

diameters downstream

Jumpy reading Rapidly changing conductivity (in chemical

injection or fertigation applications)

Install chemical injection line downstream of

magmeter (or far enough upstream to allow

complete mixing of uids before meter)

Page 14

Seametrics • 253.872.0284 • www.seametrics.com

Page 15

EX800 SERIES INSTRUCTIONSNOTES

Seametrics • 253.872.0284 • www.seametrics.com

Page 15

Page 16

Seametrics • 19026 72nd Avenue South • Kent, Washington 98032 • USA

(P) 253.872.0284 • (F) 253.872.0285 • 1.800.975.8153 • www.seametrics.com

LT-65200203r1.0-20160225

2/25/16

Loading...

Loading...