Page 1

9 0 0 1 : 2 0 0 8

ISO

ISO

9001:2008

CERTIFIED COMPANY

EX800-SERIES

Insertion Electromagnetic Flow Sensor

APPLICATIONS

FEATURES

• Conductive fl uids

• Small pipe applications (1”-12”)

• Industrial processes

• Chemical metering pumps

• Fertigation

• No moving parts

• Economical

• Durable

• Easy to install

• Easy to maintain

GENERAL INFORMATION

EX800-Series insertion electromagnetic fl owmeters are designed

for use with conductive liquids in 1 to 12” pipe. A choice of

materials (stainless steel, brass, and PVC) allows the meter

to adapt to a range of temperature, pressure, and corrosive

environments.

The EX800 is highly suitable for difficult applications with

changing viscosities and pulsating fl ows, such as air-driven

diaphragm pumps. With no moving parts, these meters can

be used in “dirty water” applications where debris would foul a

mechanical meter. Like all magmeters, when used in chemical

injection applications, these meters should be installed upstream

of the chemical line (or far enough downstream to allow complete

mixing of fl uids before the meter).

Designed for modularity and versatility, the EX800-Series has

a current-sinking pulse output that can be combined with the

appropriate transmitter or indicator for the application. For basic

rate/total and pulse output, the FT430 is best. For analog output

and display of rate and total, the FT440 can be used. Blind

analog output is provided by the AO55. The PD10 can be used to

divide the pulse for pacing chemical metering pumps. Electronic

modules can be wall- or meter- mounted. If the EX800 meter is

used with a programmable controller, the output signal can be

fed direct, with no other conditioning required.

EX800-Series fi xed depth insertion meters require special fi ttings.

Factory installation in the fi tting ensures correct depth placement

in the pipe. The EX800-Series meter can be ordered in a full

power model when a source of electricity is available, or in a low

power model that can run on an external battery with solar panel.

Reverse fl ow output and immersibility are optional.

Seametrics Incorporated • 253.872.0284 • www.seametrics.com

Page 2

FEATURES

EX800-SERIES

Insertion Electromagnetic Flow Sensor

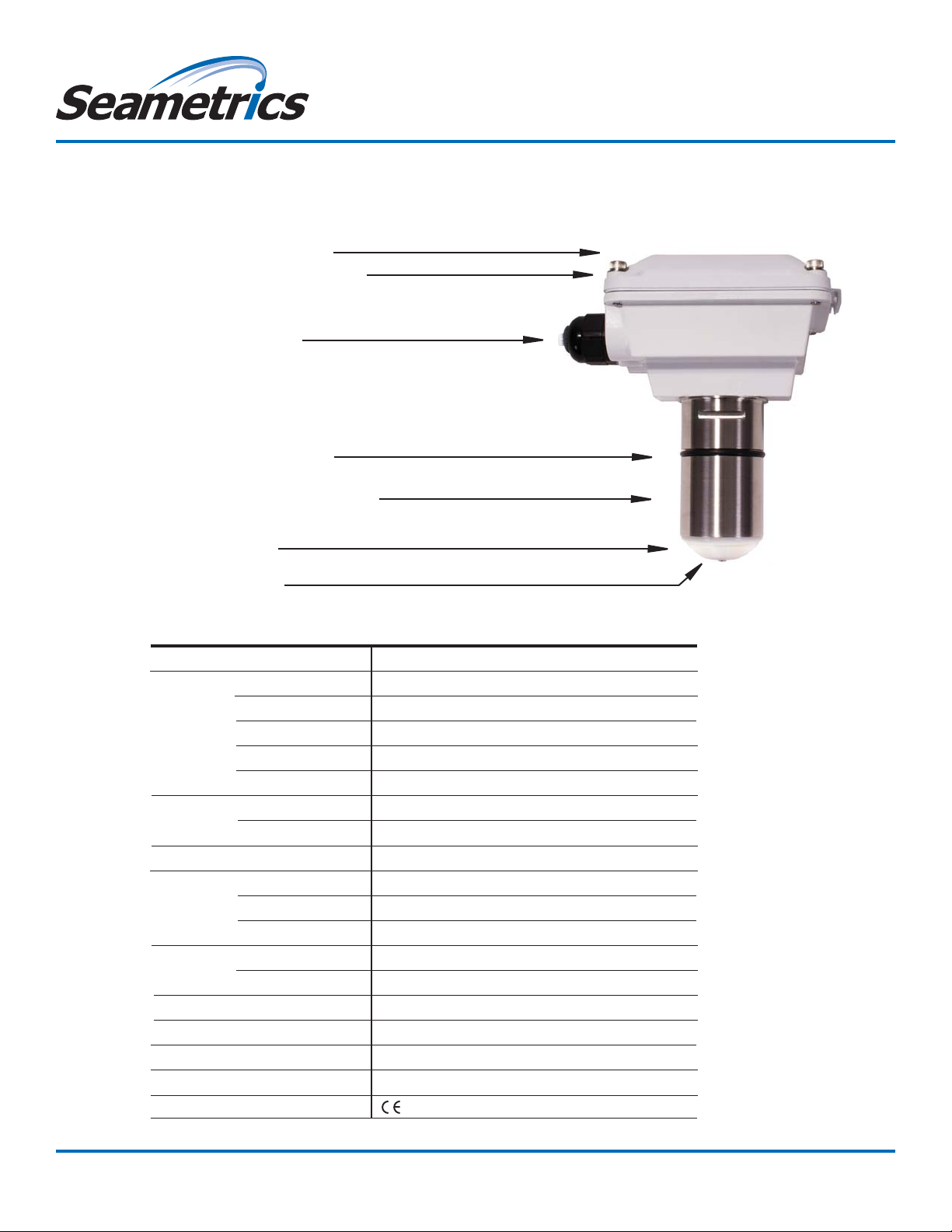

Cover, or electronics module

Powder-coated aluminum housing

Power cord strain relief

O-ring, EPDM (Viton® optional)

Sensor body (Stainless, Brass, PVC)

PVDF electrode cap

Hastelloy electrodes

SPECIFICATIONS*

Pipe Size

Materials Mechanical

Electrodes

Housing

Electrode Cap

O-Ring

Power Full Power

Low Power

Flow Rate

Temperature Ambient Temp

Fluid Temp : Brass/SS

Fluid Temp: PVC

Pressure Brass/SS

PVC

Minimum Conductivity

Calibration Accuracy

Output

Empty Pipe Detection

Regulatory

*Specifi cations subject to change • Please consult our website for current data (www.seametrics.com).

Kynar is a registered trademark of Arkema, Inc., Viton is a registered trademark of DuPont Corporation.

1” to 12”

316 SS/Brass/PVC

Hastelloy

Cast powder-coated aluminum

PVDF (Kynar

EPDM standard (Viton® optional)

12 - 25 Vdc, 250 mA

12 - 25 Vdc, 40 mA average with 250 mA peaks

0.28 - 20 ft/sec (0.08 - 6.09 m/sec)

0˚ to 160˚ F (-17˚ to 72˚ C)

32˚ to 200˚ F (0˚ to 93˚ C)

32˚ to 130˚ F (0˚ to 55˚ C) @ 0 psi

200 psi (14 bar)

150 psi (10 bar) @ 75˚ F (24˚ C)

20 microSiemens/cm

+/- 1% of full scale

Square wave pulse, opto isolated, 550 Hz @ 20 ft/sec

Software, defaults to zero fl ow

®

)

(Standard power only)

Seametrics Incorporated • 253.872.0284 • www.seametrics.com

Page 3

EX800-SERIES

Insertion Electromagnetic Flow Sensor

DIMENSIONS

FLOW RANGE

Nominal

Pipe Size

Min GPM

Min LPM

Max GPM

Max LPM

PRESSURE VS. TEMPERATURE (PVC)

Temperature ˚F

60˚ 70˚ 80˚ 90˚ 100˚ 110˚ 120˚ 130˚ 140˚

200

150

P.S. I.

100

50

4.33 in

(11.0 cm)

2.76 in

(7 cm)

TOP OF TEE

EX81X 5.76 in (14.6 cm)

EX82X 6.76 in (17.2 cm)

EX83X 7.76 in (19.7 cm)

4.09 in

(10.4 cm)

1” 1½” 2” 3” 4” 6” 8” 10” 12”

.69

2.61

49

185.49

1.5

5.68

110

416.40

2.7

10.22

196

741.94

6.2

23.47

440

1665.58

11

41.64

783

2963.98

25

94.64

1760

6662.33

43

162.77

3130

11848.34

68

257.41

4900

18548.52

374.76

26687.15

99

7050

EX800-COMPATIBLE FITTINGS

Bronze 1-4"

PVC 1-2"

Stainless Steel 1-2"

Carbon Steel 1-2"

Ductile Iron

Tee Saddle Weld/Braze Sweat Tee

3-4"

3-8"

xx

3-12"

x

x

3-12" 1-4"

xx

3-12"

3-12"

PVC TEE FITTINGS

Seametrics Incorporated • 253.872.0284 • www.seametrics.com

PVC BLOCK TEE FITTING

2.00

x

x

x

B

A

2.00

SIZE 1-1/2" 2"

Dim C 19.2 19.9

C

SIZE 1/2" 3/4" 1"

Dim A 1.50 1.90 1.88

Dim B 3.80 4.00 4.00

Page 4

HOW TO ORDER

Sensor Only. 1” - 3” = EX810

Only

Sensor

Blind 4-20 mA analog

transmitter (AO55) mounted

AO55

FT430

DL76

on the sensor.

Mounted

on Sensor

Rate & total indicator with

pulse, externally powered

(FT430) mounted on the

sensor.

Mounted

on Sensor

Data logger (DL76) mounted

on the sensor.

Mounted

on Sensor

EX800-SERIES

Insertion Electromagnetic Flow Sensor

Description Size Sensor Material Options

4” - 10” = EX820

12” = EX830

Brass = B

316 Stainless Steel = S

PVC = P

Description Size Sensor Material Options

1” - 3” = EX812

4” - 10” = EX822

12” = EX832

Brass = B

316 Stainless Steel = S

PVC = P

Description Size Sensor Material Options

1” - 3” = EX813

4” - 10” = EX823

12” = EX833

Brass = B

316 Stainless Steel = S

PVC = P

Description Size Sensor Material Options

1” - 3” = EX816

4” - 10” = EX826

12” = EX836

Brass = B

316 Stainless Steel = S

PVC = P

Reverse Flow Output = -15 Viton® O-Ring = -125

*Immersible = -40

Low Power Option = -50

Reverse Flow Output = -15

Low Power Option = -50

Viton® O-Ring = -125

Reverse Flow Output = -15 Viton® O-Ring = -125

Tamper Evident Kit = -32 Hinged Display Cover= -126

Low Power Option = -50

Non-resettable Total = -64

Reverse Flow Output = -15

Tamper Evident Kit = -32

Low Power Option = -50

Viton® O-Ring = -125

Description Size Sensor Material Options

FT450

Mounted

on Sensor

Rate & total indicator with

pulse, battery powered

(FT450) mounted on the

sensor.

1” - 3” = EX817

4” - 10” = EX827

12” = EX837

Brass = B

316 Stainless Steel = S

PVC = P

Description Size Sensor Material Options

PD10

Mounted

on Sensor

Pulse Divider (PD10)

mounted on the sensor.

1” - 3” = EX818

4” - 10” = EX828

12” = EX838

Brass = B

316 Stainless Steel = S

PVC = P

Description Size Sensor Material Options

Rate & total indicator with

pulse & 4-20 mA output,

loop powered (FT440)

FT440

* Immersible to maximum of 3 ft (1m), up to 2 weeks

Roytronic is a registered trademark of Milton Roy Company. Viton is a registered trademark of DuPont Corporation.

mounted on the sensor.

Mounted

on Sensor

1” - 3” = EX819

4” - 10” = EX829

12” = EX839

Brass = B

316 Stainless Steel = S

PVC = P

CONTACT YOUR SUPPLIER

Reverse Flow Output = -15 Viton® O-Ring = -125

Tamper Evident Kit = -32 Hinged Display Cover= -126

Low Power Option = -50

Non-resettable Total = -64

LMI Pump Connector = -06 Roytronic® Series-A Pump /

Reverse Flow Output = -15 5-pin Connector = -106

10 Ft. Cable for LMI Connector = -37 Viton® O-Ring = -125

Low Power Option = -50

Reverse Flow Output = -15 Viton® O-Ring = -125

Tamper Evident Kit = -32 Hinged Display Cover= -126

Low Power Option = -50

Non-resettable Total = -64

Seametrics Incorporated • 19026 72nd Avenue South • Kent, Washington 98032 • USA

(P) 253.872.0284 • (F) 253.872.0285 • 1.800.975.8153 • www.seametrics.com

LT-65650134r2.0-20151015

10/15/15

Loading...

Loading...