Page 1

9 0 0 1 : 2 0 0 8

ISO

CERTIFIEDCOMP

AN

Y

9001:2008

CERTIFIED COMPANY

X11x/21x

EX11x/21x

EX100/200-SERIES

Insertion Electromagnetic Flow Sensor

FEATURES

• No moving parts

• Durable

• Adjustable depth

• Hot-tap available

• Brass or stainless steel

• Immersibility available

• Reverse fl ow output available

APPLICATIONS

• 3”- 48” pipe (up to 72” optional)

• Clean or “dirty” liquids

• Conductive liquids

• Municipal

EX15x/25x

X15x/25x

• Industrial

• Irrigation

GENERAL INFORMATION

The EX100/200-Series are adjustable depth insertion magmeters that fi t 3” to 48” pipe (up to 72” optional). The complete

lack of moving parts of the EX100/200-Series is the source

of its reliability. Brass and stainless steel models withstand a

variety of temperature, pressure, and chemical conditions. The

EX-Series has no rotor to stop turning in dirty water and there

are no bearings to wear out. Like all magmeters, when used in

chemical injection applications, these meters should be installed

upstream of the chemical line (or far enough downstream to allow complete mixing of fl uids before the meter). Adapters mate

with standard 1-1/2” (11x/21x) or 2” (15x/25x) FNPT threaded

fi ttings such as saddles and weldolets which may be purchased

either locally or from Seametrics.

A rapidly reversing magnetic fi eld is produced in the lower hous-

ing. As the fl uid moves through this fi eld, a voltage is generated

that is measured and translated into a frequency signal proportional to fl ow rate. This square wave signal can be sent directly

to a PLC or other control or can be converted using any of the

Seametrics family of indicators and converters.

Seametrics Incorporated • 253.872.0284 • www.seametrics.com

A modular system of electronics can be installed directly on the

fl ow sensor or mounted remotely. The FT430 (externally powered

with pulse) and the FT440 (loop powered), both provide digital

rate and total displays, as well as a programmable pulse; the

FT440 also provides a 4-20 mA analog output. The AO55 is a

blind analog (4-20 mA) transmitter. Programmable pulse for

pump pacing is available with the PD10.

The “hot-tap” models (EX15x/25x) can be installed or serviced

without shutting down the line by means of a 2” full-port isolation valve that comes with a nipple for installation on the pipe

fi tting; a bronze ball valve is standard, with a 316 stainless steel

valve option if needed. In most circumstances, no special tool

is required.

Reverse fl ow output and immersibility are optional.

Page 2

EX100/200-SERIES

Insertion Electromagnetic Flow Sensor

FEATURES

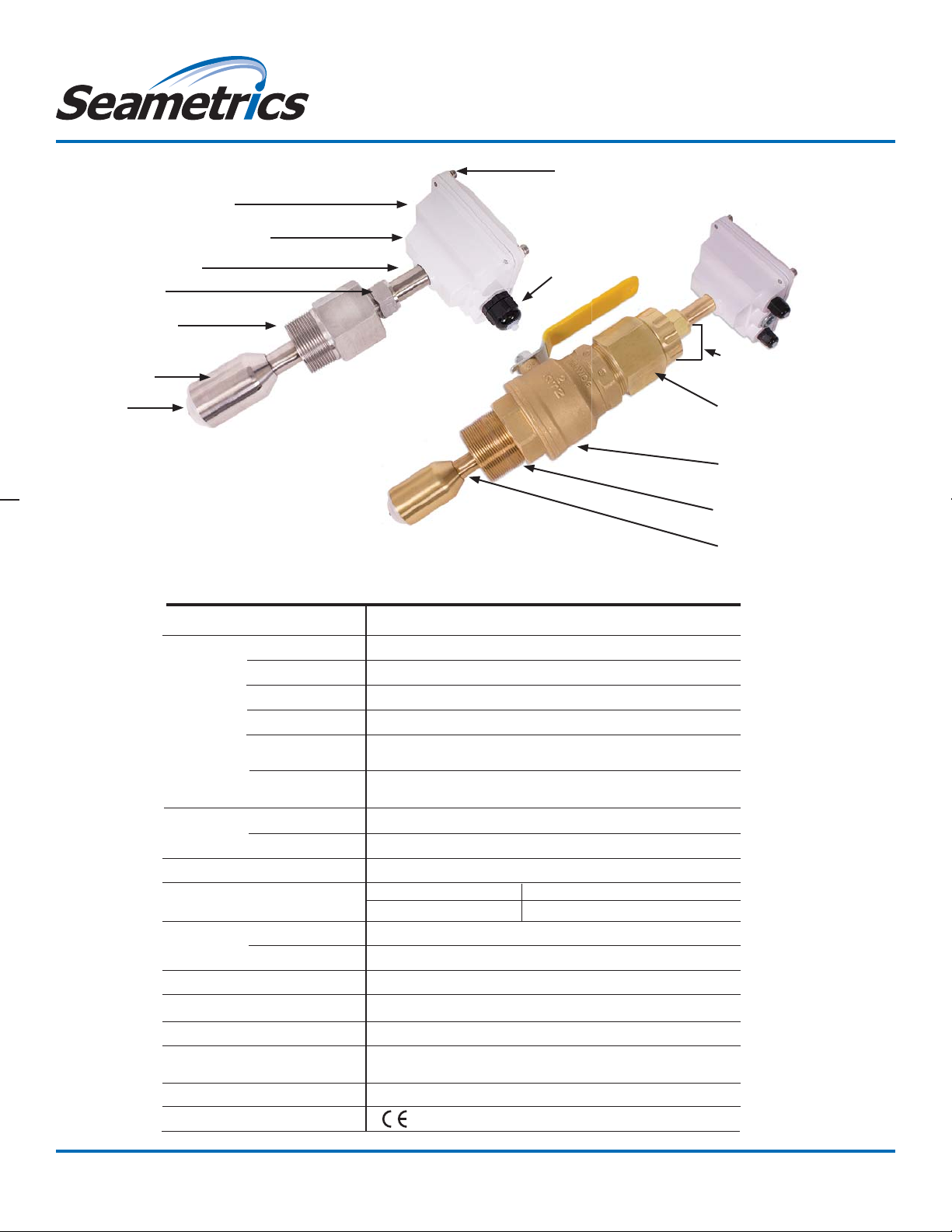

Cover or Electronics Module

Powder-Coated Aluminum Housing

Brass or 316 SS Shaft

Compression Nut

Adapter mates with

1 1/2” FNPT threaded fi tting

Sensor housing

Electrodes

and Cap

EX11x/21x

SPECIFICATIONS*

EX15x/25x

Housing Screw

(connect ground to one)

Cable Strain

Relief

Compression Nut & Locking

Collar for easy adjustment

2” Adapter (removes to

mount hot-tap machine)

Valve assembly for hot-tap

installation

Adapter mates with 2” FNPT

threaded fi tting

3/4” tubing, low insertion

force (typically no tool

required)

Pipe Sizes

Materials Shaft/Fitting

Electrodes

Electrode Cap

Housing

Valve Assembly

(15x/25x Only)

O-Ring

(15x/25x Only)

Power Full Power

Low Power

Flow Range

Fitting Size Required

Temperature Ambient

Fluid

Pressure

Minimum Conductivity

Calibration Accuracy

Output

Empty Pipe Detection

Regulatory

*Specifi cations subject to change • Please consult our website for current data (www.seametrics.com).

3” to 48” (up to 72” optional)

316 SS or Brass

Hastelloy

PVDF

Cast powder-coated aluminum

Bronze (stainless optional) with bronze ball valve

EPDM

12-25 Vdc, 250 mA

12-25 Vdc, 40 mA average with 250 mA peaks

0.28 to 20 ft/sec (0.08 - 6.09 m/sec)

EX11x/21x EX15x/25x

1-1/2” FNPT 2” FNPT

0˚ to 160˚ F (-17˚ to 72˚ C)

32˚ to 200˚ F (0˚ to 93˚ C)

200 psi (14 bar)

20 microSiemens/cm

+/- 1% of full scale

Square wave pulse, opto isolated, 550 Hz @ 20 ft/sec

6 mA max, 30 Vdc forward fl ow standard; reverse fl ow optional

Software, defaults to zero fl ow

(Standard power only)

Seametrics Incorporated • 253.872.0284 • www.seametrics.com

Page 3

DIMENSIONS

EX100/200-SERIES

Insertion Electromagnetic Flow Sensor

4.33”

(11.0cm)

4.33”

(11.0cm)

EX11x = 11.5” (29.2cm)

EX21x = 16.5” (41.9cm)

EX15x = 18.5” (47.0cm)

EX25x = 22.5” (57.2cm)

Nominal Pipe Size

3

4

6

8

10

12

14

16

18

20

24

30

36

48

Flow Range (GPM)

Min. Flow

6

11

25

44

69

99

134

175

222

274

395

617

888

1,580

Seametrics Incorporated • 253.872.0284 • www.seametrics.com

Max. Flow

440

783

1,762

3,133

4,895

7,050

9,596

12,533

15,863

19,584

28,200

44,064

63,452

112,804

(11.0cm)

4.33”

4.09”

(10.39cm)

Page 4

HOW TO ORDER

Description Size Sensor Material Options (110/210) Options (150/250)

Sensor Only. 3” – 10” pipe = EX110

Sensor Only

Description Size Sensor Material Options (112/212) Options (152/252)

Blind 4-20 mA analog

transmitter (AO55)

mounted on the sensor.

on Sensor

AO55 Mounted

Description Size Sensor Material Options (113/213) Options (153/253)

Rate & total indicator

with pulse, externally

powered (FT430) mounted

on the sensor.

on Sensor

FT430 Mounted

10” – 48” pipe = EX210

Hot Tap

3” – 10” pipe = EX150

10” – 48” pipe = EX250

3” – 10” pipe = EX112

10” – 48” pipe = EX212

Hot Tap

3” – 10” pipe = EX152

10” – 48” pipe = EX252

3” – 10” pipe = EX113

10” – 48” pipe = EX213

Hot Tap

3” – 10” pipe = EX153

10” – 48” pipe = EX253

EX100/200-SERIES

Insertion Electromagnetic Flow Sensor

Brass = B

316 Stainless = S

Brass = B

316 Stainless = S

Brass = B

316 Stainless = S

Brass Adapter Fitting 2” NPT = -02

SS Adapter Fitting 2” NPT = -02

Reverse Flow Output = -15

Brass Adapter 1 ½” BSP = -23

SS Adapter 1 ½” BSP = -24

Old Style Adapter 1 ½” NPT = -35

*Immersible = -40

Low Power = -50

12” Extension (200 Series Only) = -72

Brass Adapter Fitting 2” NPT = -02

SS Adapter Fitting 2” NPT = -02

Reverse Flow Output = -15

Brass Adapter 1 ½” BSP = -23

SS Adapter 1 ½” BSP = -24

Old Style Adapter 1 ½” NPT = -35

Low Power = -50

12” Extension (200 Series Only) = -72

Brass Adapter Fitting 2” NPT = -02

SS Adapter Fitting 2” NPT = -02

Reverse Flow Output = -15

Brass Adapter 1 ½” BSP = -23

SS Adapter 1 ½” BSP = -24

Tamper Evident Kit = -32

Old Style Adapter 1 ½” NPT = -35

Low Power = -50

Non-resettable Total = -64

12” Extension (200 Series Only) = -72

Hinged Display Cover = -126

316 SS Valve Assembly = -08

No Valve Assembly = -09

316 SS Valve Assembly = -08

Reverse Flow Output = -15

*Immersible = -40

Low Power = -50

12” Extension (200 Series Only) = -72

316 SS Valve Assembly = -08

No Valve Assembly = -09

Reverse Flow Output = -15

Low Power = -50

12” Extension (200 Series Only) = -72

316 SS Valve Assembly = -08

No Valve Assembly = -09

Reverse Flow Output = -15

Tamper Evident Kit = -32

Non-resettable Total = -64

12” Extension (200 Series Only) = -72

Hinged Display Cover = -126

Description Size Sensor Material Options (116/216) Options (156/256)

Data logger (DL76)

mounted on the sensor.

on Sensor

DL76 Mounted

Description Size Sensor Material Options (118/218) Options (158/258)

Pulse Divider (PD10)

mounted on the sensor.

on Sensor

PD10 Mounted

Description Size Sensor Material Options (119/219) Options (159/259)

Rate & total indicator

with pulse & 4-20 mA

output, loop powered

(FT440) mounted on the

sensor.

on Sensor

FT440 Mounted

3” – 10” pipe = EX116

10” – 48” pipe = EX216

Hot Tap

3” – 10” pipe = EX156

10” – 48” pipe = EX256

3” – 10” pipe = EX118

10” – 48” pipe = EX218

Hot Tap

3” – 10” pipe = EX158

10” – 48” pipe = EX258

3” – 10” pipe = EX119

10” – 48” pipe = EX219

Hot Tap

3” – 10” pipe = EX159

10” – 48” pipe = EX259

Brass = B

316 Stainless = S

Brass = B

316 Stainless = S

Brass = B

316 Stainless = S

Brass Adapter Fitting 2” NPT = -02

SS Adapter Fitting 2” NPT = -02

Reverse Flow Output = -15

Brass Adapter 1 ½” BSP = -23

SS Adapter 1 ½” BSP = -24

Tamper Evident Kit = -32

Old Style Adapter 1 ½” NPT = -35

Low Power = -50

12” Extension (200 Series Only) = -72

Brass Adapter Fitting 2” NPT = -02

SS Adapter Fitting 2” NPT = -02

LMI Pump 4-pin Connector = -06

Reverse Flow Output = -15

Brass Adapter 1 ½” BSP = -23

SS Adapter 1 ½” BSP = -24

Old Style Adapter 1 ½” NPT = -35

10 Ft. Cable for LMI Connector = -37

Low Power = -50

12” Extension (200 Series Only) = -72

Roytronic® Series-A 5-Pin Connector = -106

Brass Adapter Fitting 2” NPT = -02

SS Adapter Fitting 2” NPT = -02

Reverse Flow Output = -15

Brass Adapter 1 ½” BSP = -23

SS Adapter 1 ½” BSP = -24

Tamper Evident Kit = -32

Old Style Adapter 1 ½” NPT = -35

Low Power = -50

Non-resettable Total = -64

12” Extension (200 Series Only) = -72

Hinged Display Cover = -126

316 SS Valve Assembly = -08

No Valve Assembly = -09

Reverse Flow Output = -15

Tamper Evident Kit = -32

Low Power = -50

12” Extension (200 Series Only) = -72

LMI Pump 4-pin Connector = -06

316 SS Valve Assembly = -08

No Valve Assembly = -09

Reverse Flow Output = -15

10 Ft. Cable for LMI Connector = -37

Low Power = -50

12” Extension (200 Series Only) = -72

Roytronic® Series-A 5-Pin Connector = -106

316 SS Valve Assembly = -08

No Valve Assembly = -09

Reverse Flow Output = -15

Tamper Evident Kit = -32

Non-resettable Total = -64

12” Extension (200 Series Only) = -72

Hinged Display Cover = -126

* Immersible to maximum of 3 ft (1m), up to 2 weeks • Roytronic is a registered trademark of Milton Roy Company.

Seametrics Incorporated • 19026 72nd Avenue South • Kent, Washington 98032 • USA

(P) 253.872.0284 • (F) 253.872.0285 • 1.800.975.8153 • www.seametrics.com

LT-65650131r2.1-20151026

10/26/15

Loading...

Loading...