®

Performance Mounted Spherical Roller Bearings

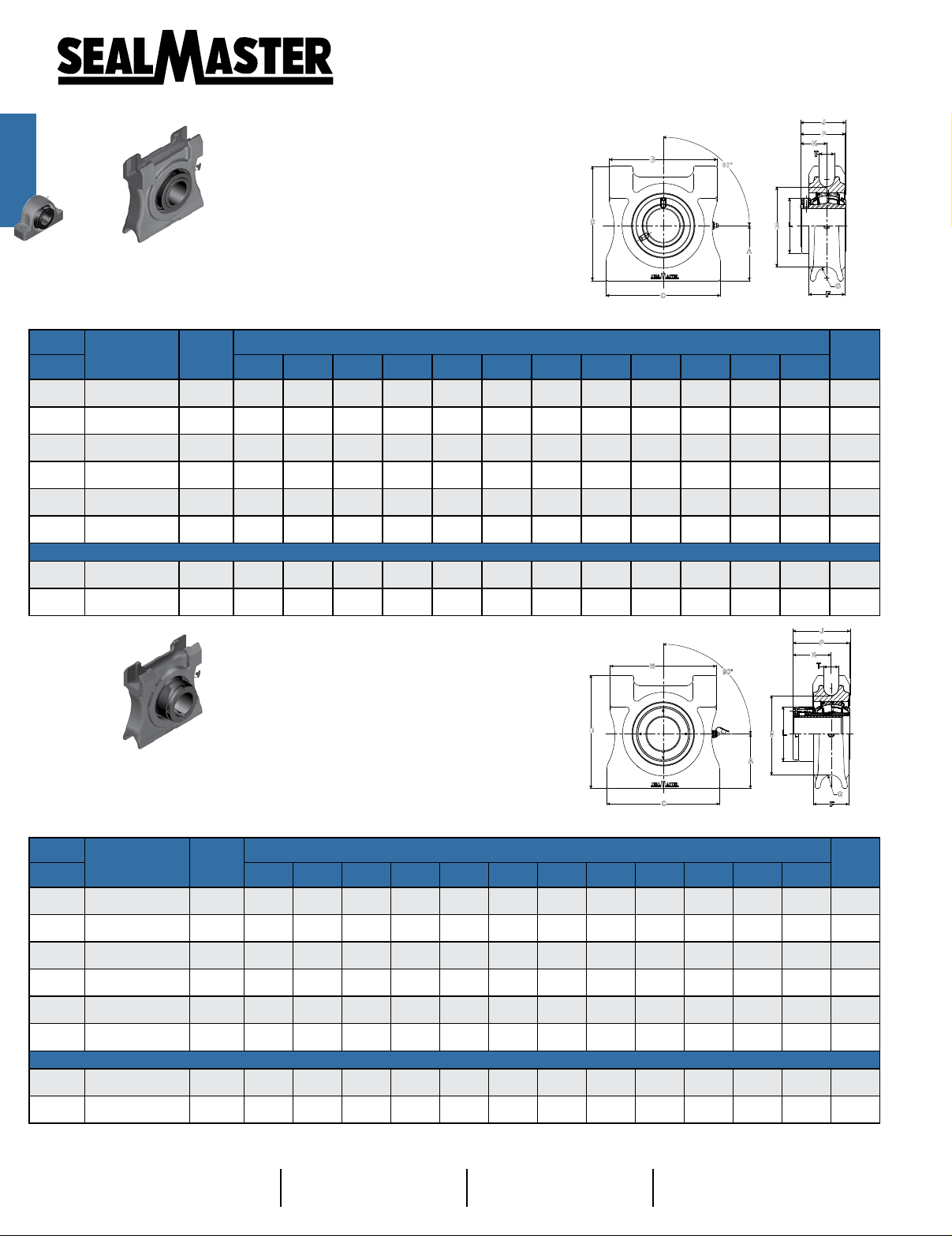

Rolling Elements: Spherical Roller

Bearings

Mtd. Spherical

Housing: Cast Iron Top Angle Take-Up

Self Alignment: +/- 2 Degrees

Lock: Setscrew

D

Seal: Felt

Optional Seal: Double Lip Contact

Temperature: -20° to 220° F

USTA5000 Series Top Angle Take-Up Units - Collar Mount

Bore

Diameter

inch A B C D F G J K L N P T

1 15/16 USTA5000-115

2 3/16 USTA5000-203

2 7/16 USTA5000-207

2 15/16 USTA5000-215

3 7/16 USTA5000-307

3 15/16 USTA5000-315

2 3/16 USTAE5000-203

2 7/16 USTAE5000-207

Part No.

Basic

Dynamic

Rating

lb/N

23520 3 1/4 6 6 1/2 6 3/8 2 7/16 51/64 2 7/8 1 11/16 3 3 33/64 2 7/8 7/8 12.1

104617 82.6 152.4 165.1 162.1 62.0 20.3 73.0 42.9 76.2 89.3 73.2 22.4 5.49

28087 3 1/2 7 7 1/2 7 7/16 2 7/16 51/64 3 1/8 1 7/8 3 1/4 4 57/64 3 1/4 1 1/8 18.0

124931 88.9 177.8 190.5 189.0 62.0 20.3 79.7 47.5 82.6 124.2 82.3 28.4 8.16

44691 4 8 8 1/2 8 5/16 2 11/16 51/64 3 3/8 1 61/64 4 5 53/64 3 21/64 1 1/8 27.9

198786 101.6 203.2 215.9 211.1 68.3 20.3 85.7 49.6 101.6 148.0 84.5 28.4 12.66

47447 4 8 8 1/2 8 5/16 2 13/16 51/64 3 7/8 2 11/32 4 17/32 5 53/64 3 47/64 1 1/8 27.4

211044 101.6 203.2 215.9 211.1 71.4 20.3 98.3 59.5 115.1 148.0 94.9 28.4 12.43

72640 4 1/2 9 9 1/2 9 5/8 3 3/16 51/64 4 15/32 2 21/32 5 5/16 6 53/64 4 1/4 1 3/8 39.3

323103 114.3 228.6 241.3 244.6 81.0 20.3 113.5 67.5 134.5 173.4 108.0 35.1 17.83

96050 5 1/2 10 1/2 11 11 3 9/16 51/64 4 15/16 2 15/16 6 7 19/32 4 1/2 1 23/64 54.5

427230 139.7 266.7 279.4 279.4 90.4 20.3 125.4 74.4 152.4 192.9 114.0 34.5 24.72

Dimensions inch / mm

Type E Mounting Dimensions

28087 3 1/16 6 3/4 7 6 7/8 2 1/2 51/64 3 1/8 1 55/64 3 1/4 4 37/64 3 3/64 7/8 11.3

124931 77.7 171.5 177.8 174.8 63.5 20.3 79.7 47.2 82.6 116.3 77.4 22.4 5.13

44691 3 1/2 7 7 1/2 7 7/16 2 3/4 49/64 3 3/8 1 61/64 4 4 15/16 3 21/64 1 1/8 19.6

198786 88.9 177.8 190.5 189.0 69.9 19.3 85.7 49.6 101.6 125.2 84.5 28.4 8.89

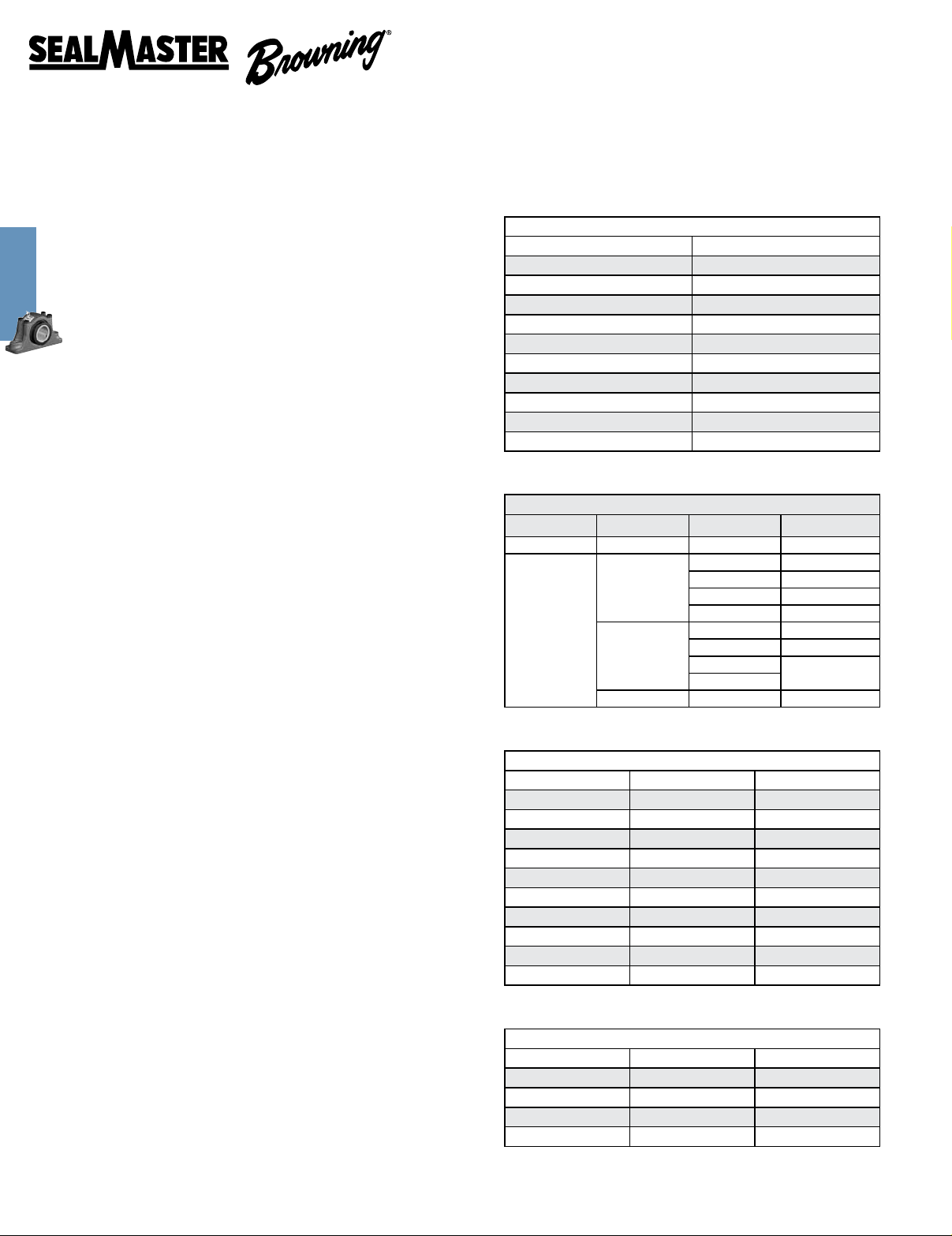

Rolling Elements: Spherical Roller

Housing: Cast Iron Top Angle Take-Up

Self Alignment: +/- 2 Degrees

Lock: Adapter

D

Seal: Felt

Optional Seal: Double Lip Contact

Temperature: -20° to 220° F

USTA5000A Series Top Angle Take-Up Units - Adapter Mount

Bore

Diameter

inch A B C D F G J K L N P T

1 15/16 USTA5000A-115

2 3/16 USTA5000A-203

2 7/16 USTA5000A-207

2 15/16 USTA5000A-215

3 7/16 USTA5000A-307

3 15/16 USTA5000A-315

2 3/16 USTAE5000A-203

2 7/16 USTAE5000A-207

Note: One expansion unit is to be used in conjunction with one non-expansion unit for applications using an adapter lock unit.Failure to utilize one expansion and one non-expansion unit is likely to result in reduced bearing performance.

Metric dimensions for reference only.

Not all parts are available from stock. Please contact customer service for availability (800) 626-2120.

For more information on bearing capabilities outside of our standard offering, please contact Application Engineering (800) 626-2093.

Part No.

Bearing Selection

H-29

Dynamic

Page H-3

Basic

Rating

lb/N

23520

104617

28087

124931

44691

198786

47447

211044

72640

323103

96050

427230

28087

124931

44691

198786

Dimensions inch / mm

3 1/4 6 6 1/2 6 3/8 2 7/16 51/64 3 1/2 2 5/16 3 3/16 3 33/64 3 1/2 7/8 12.6

82.6 152.4 165.1 162.1 62.0 20.3 88.9 58.7 80.6 89.3 88.9 22.4 5.72

3 1/2 7 7 1/2 7 7/16 2 7/16 51/64 3 7/8 2 5/8 3 7/16 4 57/64 4 1 1/8 18.7

88.9 177.8 190.5 189.0 62.0 20.3 98.4 66.5 87.4 124.2 101.6 28.4 8.48

4 8 8 1/2 8 5/16 2 11/16 51/64 4 5/16 2 7/8 3 63/64 5 53/64 4 17/64 1 1/8 28.9

101.6 203.2 215.9 211.1 68.3 20.3 109.5 73.2 101.2 148.0 108.3 28.4 13.11

4 8 8 1/2 8 5/16 2 13/16 51/64 4 31/64 2 31/32 4 25/64 5 53/64 4 11/32 1 1/8 27.6

101.6 203.2 215.9 211.1 71.4 20.3 113.9 75.4 111. 5 148.0 110.3 28.4 12.52

4 1/2 9 9 1/2 9 5/8 3 3/16 51/64 5 35/64 3 47/64 5 15/32 6 53/64 5 21/64 1 3/8 41.3

114.3 228.6 241.3 244.6 81.0 20.3 140.9 94.9 138.9 173.4 135.3 35.1 18.73

5 1/2 10 1/2 11 11 3 9/16 51/64 5 15/16 3 15/16 5 37/64 7 19/32 5 1/2 1 23/64 55.4

139.7 266.7 279.4 279.4 90.4 20.3 150.8 99.8 141.7 192.9 139.7 34.5 25.13

Type E Mounting Dimensions

3 3/8 6 3/4 7 6 7/8 2 1/2 51/64 3 7/8 2 5/8 3 7/16 4 37/64 3 13/16 7/8 15.7

85.7 171.5 177.8 174.8 63.5 20.3 98.4 66.5 87.4 116.3 96.8 22.4 7.12

3 1/2 7 7 1/2 7 7/16 2 3/4 49/64 4 5/16 2 7/8 3 63/64 4 15/16 4 17/64 1 1/8 20.6

88.9 177.8 190.5 189.0 69.9 19.3 109.5 73.2 101.2 125.2 108.3 28.4 9.34

Nomenclature Aid

Page H-6

Features & Benets

Page H-7

B

C

B

C

Technical Engineering

Page I-47

90°

L

N

A

90°

L

N

A

J

P

K

T

J

P

K

T

G

F

Unit Wt.

lb/kg

G

F

Unit Wt.

lb/kg

®

Mounted Roller Bearing Engineering Section

Installation Instructions continued

Mtd. Tapered

Alternate Lubrication Procedure:

Stop rotating equipment. Add one half the recommended amount shown in Table V. Start the bearing

and run for a few minutes. Stop the bearing and add the

Bearings

second half of the recommended amount. A temperature rise after lubrication, sometimes 30°F (17°C), is

normal. Bearing should operate at temperatures less

than 200°F (94°C) and should not exceed 250° (121°C)

for intermittent operation. For lubrication guidelines,

see Table VI.

Note: Table VI are general recommendations. Experi-

ence and testing may be required for specic applica-

Table V

Grease Charge for Relubrication

Bore Size Grease Charge (Mass - Ounces)

1 1/8 - 1 1/2 0.20

1 11/16 - 1 3/4 0.20

1 15/16 - 2 0.25

2 3/16 0.40

2 7/16 - 2 1/2 0.60

2 11/16 - 3 0.75

3 3/16 - 3 1/2 1.25

3 11/16 - 4 2.00

4 7/16 - 4 1/2 2.75

4 15/16 - 5 4.00

tions.

Table VI

Note: Grease charges in Table V are based on the use

of lithium complex thickened grease with a NLGI grade

2 consistency.

Expansion Bearing Applications:

Before installation, make certain proper expansion is

accounted for. Expansion units should be placed in a

location where relative movement between the bear-

Environment Temperature (°F)

Dirty -20 to 250 0 - 100% Daily to 1 Week

Clean

Relubrication Recommendations

-20 to 125

125 to 175

175 to 250 0 - 100% Daily to 1 Week

Speed

(% Catalog Max)

0 - 25% 4 to 10 Months

26 - 50% 1 to 4 Months

51 - 75% 1 Week to 1 Month

76 - 100% Daily to 1 Week

0 - 25% 2 to 6 Weeks

26 - 50% 1 Week to 1 Month

51 - 75%

76 - 100%

Frequency

Daily to 1 Week

ing insert and the housing can be tolerated. For most

applications using expansion type units, the xed unit

(non-expansion unit) is placed at the drive end of the

shaft. Use Table VIII to review the total available bearing

expansion. If the application requires additional expansion, consult Application Engineering.

NOTICE: One expansion unit is to be used in conjunc-

tion with one non-expansion unit for applications using

adapter lock units. Failure to utilize one expansion and

one non-expansion unit is likely to result in reduced

bearing performance.

Table VII

Maximum Operational Speed

Bore Size Felt Seal (RPM) Contact Seal (RPM)

1 1/8 - 1 1/2 4000 3000

1 11/16 - 1 3/4 4000 2750

1 15/16 - 2 4000 2500

2 3/16 3750 2200

2 7/16 - 2 1/2 3250 1750

2 11/16 - 3 3000 1600

3 3/16 - 3 1/2 2500 1350

3 11/16 - 4 2250 1200

4 7/16 - 4 1/2 2000 1100

4 15/16 - 5 1750 900

I-69

Table VIII

Total Available Housing Expansion (inch)

Bore Size Setscrew Adapter Lock

1 1/8 - 1 1/2 3/16 5/32

1 11/16 - 3 1/2 1/4 7/32

3 11/16 - 4 5/16 1/4

4 7/16 - 5 3/8 9/32

Loading...

Loading...