Sealmaster RCI Series Replacement Cartridge Inserts, RCIA Series Replacement Cartridge Inserts Catalog Page

MOUNTED ROLLER BEARINGS

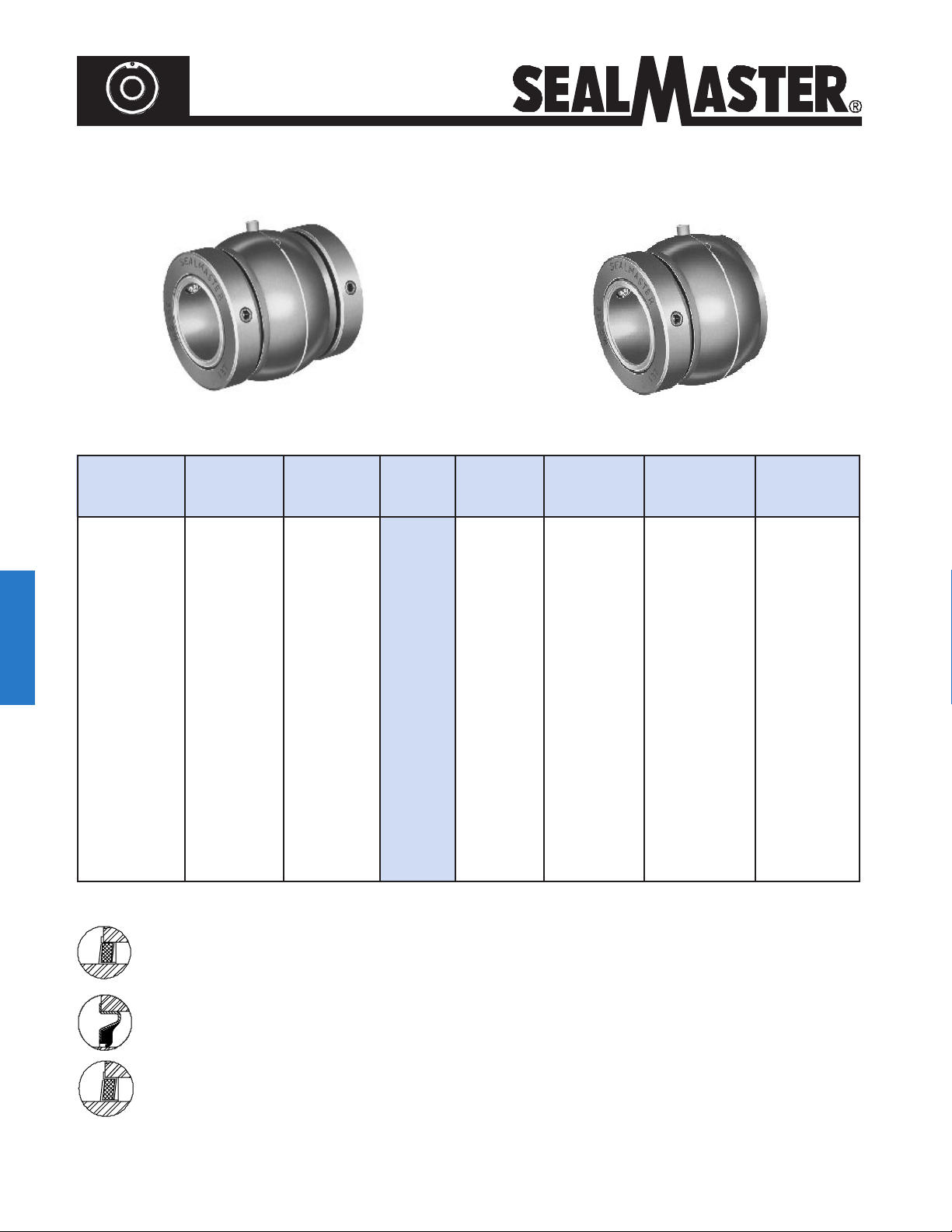

RCI Series RCIA Series

Double Extension Single Extension

Two Locking Collars One Locking Collar

RCI & RCIA Series Replacement Cartridge Inserts*

RCI FELT CONTACT HI-TEMP SHAFT APPROX. RCIA FELT CONTACT FELT

SEAL SEAL SEAL DIAM. SHIPPING SEAL SEAL SEAL

RCI-103 RCI-103-C †RCI-103-N 1 3/16 2.0 †RCIA-103 †RCIA-103-C †RCIA-103-N

RCI-104 RCI-104-C †RCI-104-N 1 1/4 1.9 †RCIA-104 †RCIA-104-C †RCIA-104-N

RCI-106 RCI-106-C †RCI-106-N 1 3/8 2.9 †RCIA-106 †RCIA-106-C †RCIA-106-N

RCI-107 RCI-107-C †RCI-107-N 1 7/16 2.7 †RCIA-107 †RCIA-107-C †RCIA-107-N

RCI-108 RCI-108-C †RCI-108-N 1 1/2 4.5 †RCIA-108 †RCIA-108-C †RCIA-108-N

RCI-110 RCI-110-C †RCI-110-N 1 5/8 4.2 †RCIA-110 †RCIA-110-C †RCIA-110-N

RCI-111 RCI-111-C †RCI-111-N 1 11/16 4.0 †RCIA-111 †RCIA-111-C †RCIA-111-N

RCI-112 RCI-112-C †RCI-112-N 1 3/4 5.3 RCIA-112 RCIA-112-C RCIA-112-N

RCI-115 RCI-115-C †RCI-115-N 1 15/16 4.8 RCIA-115 RCIA-115-C RCIA-115-N

RCI-200 RCI-200-C †RCI-200-N 2 4.6 RCIA-200 RCIA-200-C RCIA-200-N

RCI-203 RCI-203-C †RCI-203-N 2 3/16 6.2 RCIA-203 RCIA-203-C RCIA-203-N

RCI-204 RCI-204-C †RCI-204-N 2 1/4 8.4 RCIA-204 RCIA-204-C RCIA-204-N

RCI-207 RCI-207-C †RCI-207-N 2 7/16 7.4 RCIA-207 RCIA-207-C RCIA-207-N

RCI-208 RCI-208-C †RCI-208-N 2 1/2 7.2 RCIA-208 RCIA-208-C RCIA-208-N

RCI-211 RCI-211-C †RCI-211-N 2 11/16 11.5 RCIA-211 RCIA-211-C RCIA-211-N

RCI-212 RCI-212-C †RCI-212-N 2 3/4 11.3 RCIA-212 RCIA-212-C RCIA-212-N

RCI-215 RCI-215-C †RCI-215-N 2 15/16 10.3 RCIA-215 RCIA-215-C RCIA-215-N

RCI-300 RCI-300-C †RCI-300-N 3 10.0 RCIA-300 RCIA-300-C RCIA-300-N

RCI-303 RCI-303-C †RCI-303-N 3 3/16 19.6 RCIA-303 RCIA-303-C RCIA-303-N

RCI-307 RCI-307-C †RCI-307-N 3 7/16 17.8 RCIA-307 RCIA-307-C RCIA-307-N

RCI-308 RCI-308-C †RCI-308-N 3 1/2 17.3 RCIA-308 RCIA-308-C RCIA-308-N

RCI-315 RCI-315-C †RCI-315-N 3 15/16 23.1 RCIA-315 RCIA-315-C RCIA-315-N

RCI-400 RCI-400-C †RCI-400-N 4 22.6 RCIA-400 †RCIA-400-C RCIA-400-N

RCI-407 RCI-407-C †RCI-407-N 4 7/16 30.4 RCIA-407 †RCIA-407-C RCIA-407-N

RCI-408 RCI-408-C †RCI-408-N 4 1/2 29.9 RCIA-408 †RCIA-408-C RCIA-408-N

RCI-415 RCI-415-C †RCI-415-N 4 15/16 45.6 RCIA-415 †RCIA-415-C RCIA-415-N

RCI-500 RCI-500-C †RCI-500-N 5 44.4 RCIA-500 †RCIA-500-C RCIA-500-N

IN. WEIGHT

LBS.

120

Felt Seal Standard

Positive sealing for low, medium, and high

speed operation.

Single Lip Contact Seal

Available on all sizes. Recommended where

moisture conditions prevail.

Hi-Temp Seal

Available as an option where operating

temperatures are in 250-400° range.

* Insert package includes factory lubed, adjusted, and sealed cartridge complete

with single or double locking collars.

† Contact Customer Service Center for availability.

For Load Ratings, See Page 121.

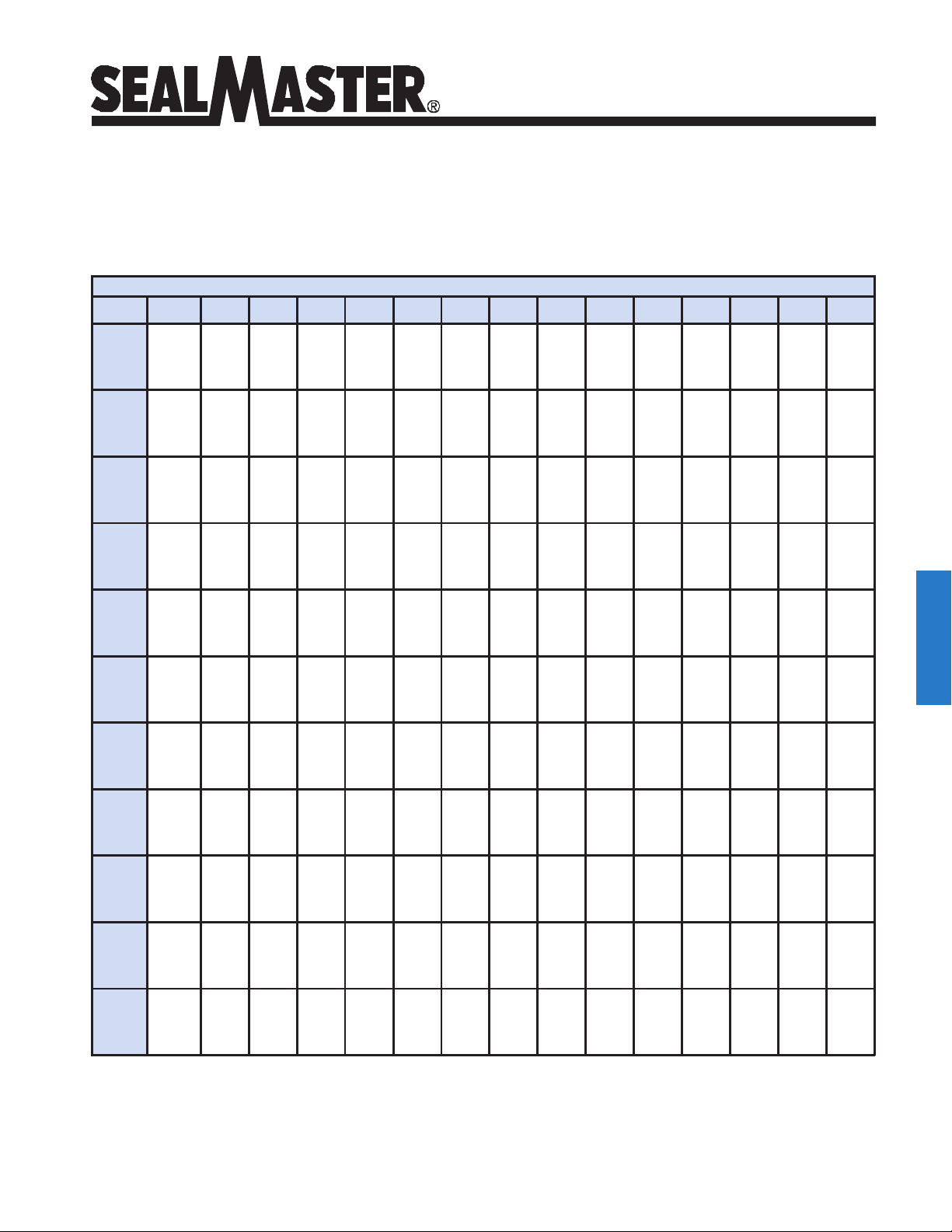

ROLLER BEARING RATING TABLES

LOAD RATING TABLES - RPB ROLLER BEARINGS

This chart displays the Sealmaster RPB Roller Bearing’s load capacity for a given L10 life, speed, and shaft size.

Areas designated by “-” exceed maximum value for standard bearings. Consult Sealmaster Application Engineering for load and speed

applications not covered in this table or for operation at high speeds or high loads.

REVOLUTI O NS PER M I NU T E

SHAFT

SIZ E

1 3/ 16

1 1/4

1 3/8

1 7/ 16

1 1/2

1 5/8

1 11/ 16

1 3/4

1 15/ 16

2

2 3/ 16

2 1/4

2 7/ 16

2 1/2

2 11/ 16

2 3/4

2 15/ 16

3

3 3/ 16

3 7/ 16

3 1/2

3 15/ 16

4

4 7/ 16

4 1/2

4 15/ 16

5

For high load-high speed applications, see page 204.

For Bearing Selection and Engineering, see page 176.

L10

HOURS

5000

1000 0

3000 0

5000 0

1000 00

5000

1000 0

3000 0

5000 0

1000 00

5000

1000 0

3000 0

5000 0

1000 00

5000

1000 0

3000 0

5000 0

1000 00

5000

1000 0

3000 0

5000 0

1000 00

5000

1000 0

3000 0

5000 0

1000 00

5000

1000 0

3000 0

5000 0

1000 00

5000

1000 0

3000 0

5000 0

1000 00

5000

1000 0

3000 0

5000 0

1000 00

5000

1000 0

3000 0

5000 0

1000 00

5000

1000 0

3000 0

5000 0

1000 00

50 100 250 500 75 0 1000 1250 1500 1750 2000 2500 3000 3500 4000

871

747

607

971

1424

1156

832

714

580

2278

1850

1331

1142

927

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

3360

3360

2975

2552

2073

5376

5376

4760

4084

3317

6934

6934

6140

5268

4279

9114

9114

8070

6923

5624

9679

9679

8570

7352

5972

10198

10198

9030

7747

6293

10876

10876

9630

8262

6711

17302

17302

15320

13143

10676

23694

23694

20980

17999

14620

29081

29081

25750

22091

17944

40114

40114

35520

30473

24752

3360

3360

2416

2073

1684

5376

5376

3866

3317

2694

6934

6934

4987

4279

3475

9114

9114

6555

5624

4568

9679

9679

6961

5972

4851

10198

10198

7335

6293

5111

10876

10876

7822

6711

5451

17302

17302

12444

10676

8671

23694

23694

17041

14620

11875

29081

29081

20915

17944

14575

40114

40114

28851

24752

20105

3142

2552

1836

1575

1279

5028

4084

2937

2520

2047

6485

5268

3789

3250

2640

8524

6923

4979

4272

3470

9052

7352

5288

4538

3685

9538

7747

5572

4780

3883

10171

8262

5942

5098

4141

16181

13143

9453

8110

6587

22159

17999

12945

11106

9021

27198

22091

15889

13631

11072

37517

30473

21917

18803

15273

2552

2073

1491

1279

1039

4084

3317

2386

2047

1662

5268

4279

3077

2640

2144

6923

5624

4045

3470

2818

7352

5972

4295

3585

2993

7747

6293

4526

3883

3154

8262

6711

4826

4141

3363

13143

10676

7678

6587

5351

17999

14620

10515

9021

7327

22091

17944

12906

11072

8993

30473

24752

17802

15273

12405

2260

1836

1320

1133

920

3616

2937

2112

1812

1472

4664

3789

2725

2338

1899

6130

4979

3581

3072

2496

6510

5288

3803

3263

2650

6860

5572

4007

3438

2793

7316

5942

4274

3666

2978

11638

9453

6799

5833

4738

15938

12945

9311

7988

6488

19561

15889

11427

9804

7963

26983

21917

15763

13524

10985

2073

1684

1211

1039

844

3317

2694

1938

1662

1350

4279

3475

2500

2144

1742

5624

4568

3285

2818

2289

5972

4851

3489

2993

2431

6293

5111

3676

3154

2562

6711

5451

3920

3363

2732

10676

8671

6237

5351

4346

14620

11875

8541

7327

5952

17944

14575

10483

8993

7305

24752

20105

14460

12405

10076

1939

1575

1279

1081

971

3104

2521

2048

1732

1555

4000

3249

2640

2231

2007

5259

4271

3470

2934

2636

5584

4587

3684

3115

2799

5940

4824

3918

3313

2977

6279

5100

4143

3502

3147

9983

8109

6587

5569

5004

13673

11106

9021

7627

6852

16783

13632

10072

9362

8412

-

-

-

-

-

1836

1491

1072

920

747

2937

2386

1716

1472

1196

3789

3077

2213

1899

1542

4979

4045

2909

2496

2027

5288

4295

3089

2650

2153

5572

4526

3255

2793

2268

5942

4826

3471

2978

2419

9453

7678

5522

4738

3848

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

1753

1424

1024

878

714

2804

2278

1638

1406

1142

3617

2938

2113

1813

1473

4754

3862

2777

2383

1935

5049

4101

2950

2530

2055

5320

4321

3108

2666

2166

5674

4608

3314

2843

2310

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

1684

1368

984

844

685

2694

2188

1574

1350

1097

3475

2823

2030

1742

1415

4568

3710

2668

2289

1859

4851

3940

2834

2431

1975

5111

4152

2986

2562

2081

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

1575

1279

920

789

641

2520

2047

1472

1263

1026

3250

2640

1899

1629

1323

4272

3470

2496

2141

1739

4537

3685

2650

2274

1847

1491

1211

2386

1938

1394

1196

3077

2500

1798

1542

1253

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

1368

1111

902

763

685

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

121

TOUGH

AS THEY COME!

Corrosion-Resistant Bearings

All RPB Series Pillow Block, Flange and Piloted Flange Units can be provided with

to resist corrosion in many difficult environments.

matrix with a fluoropolymer rich surface on a molecular binder layer that provides significant application

advantages in harsh atmospheres:

• Excellent corrosion-resistance.

• Excellent weathering resistance.

• Hard (Matrix) polymer resists abrasion.

• Molecular binder resists peeling, etc.

• Standard silver color blends well with other equipment.

• A wide variety of other colors available on special order.

• Fluropolymer means “Non-Stick”.

RPB-CR bearings feature a corrosion-resistant

“CR” housings

All The Longer Life

Features...

Plus A

Corrosion-Resistant

Polymer Coating

• Split housing, entirely

polymer coated,

• Polymer coated Locking Collars.

• Polymer coated Cap bolts.

including bore.

Other Components:

• Stainless Steel Grease Fitting.

• Stainless Steel Washers.

• Standard Contact Seal.

• Black Oxide Outer Race.

• Standard Setscrews.

For more information on wet environments, see applications section, page 136.

122

MOUNTED ROLLER BEARINGS

SEALMASTER Corrosion-Resistant

Mounted Roller Bearings

Take On The Tough Applications...

We begin with the best...

and then improve the design to the most

demanding specific services.

The RPB Series Bearings are used in applications where they may be subjected to moisture,

corrosive and abrasive atmosphere. Typical applications include:

• Food Processing Equipment.

• Chemical Processing Plants.

• Rubber and Plastic Plants.

• Pulp and Paper Mills.

• Marine and Naval Applications.

• Waste Water Treatment Facilities.

• Bulk Material Handling.

Fluoropolymer

Rich Surface

Non-stick release layer...

resistant to most

chemical attacks.

Fluoropolymer

and Binder Matrix

Hard dense materials that have

excellent wear and abrasion

resistance; resistant to most

hydrocarbon solvents...

all but the most concentrated acids...

detergents, bases up to PH 11...

high temperatures, up to 400°F (204°C)

continuous duty...as well as atmospheric

corrosion conditions.

How To Specify:

Sealmaster RPB-CR Units are

identified on the metal nametag.

To specify, add "CR" to the basic

part number: "RPB215-2CR"

Molecular Binder Layer

Provides peeling-resistant

bond...reduces burrowing/

blistering and adds to

corrosion protection.

UNIQUE...UNCHALLENGED...THE UNDISPUTED LEADER

IN QUALITY, VALUE-ADDED ADVANTAGES

AND CUSTOM DESIGNS

123

TOUGH

AS THEY COME!

SEALMASTER RPB-AH

With Enhanced Performance...

for the World-Wide HVAC Industry...

Air Handling

Roller bearing units for

HVAC applications are subjected to

a number of unique challenges that

include:

1. Running at

2. Exposure to

3. Running with

4.Mounting on fan frames that have reduced

structural

SEALMASTER RPB-AH tapered roller

bearings units are

engineering features that address each of

these challenges,

performance in air handling services. Here are

several reasons why...

HIGH LOAD CAPACITIES... RPB-AH Tapered roller

bearings offer both high radial as well as high thrust

load capacities, or any combination of the two.

Spherical roller bearings, on the other hand, are

known for their thrust capacity, and are generally not

selected/specified for vertical shaft applications which

are often encountered in HVAC.

higher

vibration

low

mass.

operating speeds.

.

noise levels.

specially-designed with

and offer overall enhanced

not

Roller Bearings...

CUSTOM FIT-UP... Sealmaster engineers have

developed a custom fit-up between the bearing

cartridge O.D. and the bearing housing specifically for

air handling applications. This fit is looser than standard

which provides lighter misalignment torque. Fan frames

are generally light weight which may deflect before the

bearing insert adjusts for misalignment in standard

units. This special feature also allows full roller contact

with the races and reduces roller edge loading in the

bearing.

PINNED OUTER RACE PREVENTS ITS ROTATION...

The RPB-AH bearing has a self-aligning

capability of

concept to the proven SEALMASTER

ball bearing units which utilize a

spherical O.D. insert mounted in a

spherical I.D. cast iron housing,

equipped with a locating pin. This

anti-rotation pin prevents outer race

rotation under load and does not limit

the RPB-AH self-aligning capability.

The extensions on the cartridge inserts limit

misalignment to ± 3°.

For more information on air handling, see applications section, page 132.

124

± 3°.

This design is similar in

± 3°

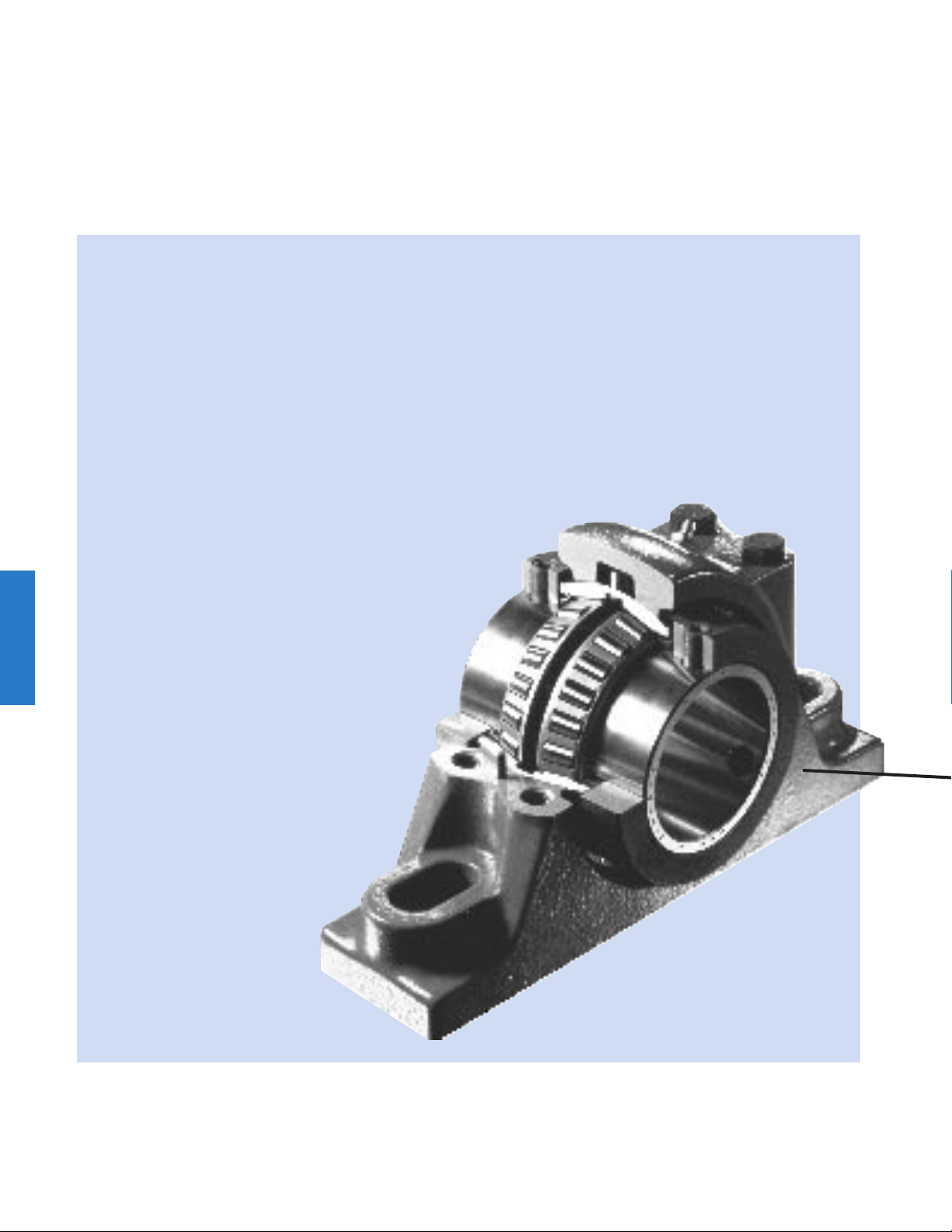

MOUNTED ROLLER BEARINGS

DURABLE CAST IRON SPLIT HOUSING - Compact split housing provides quickest replacement of bearing

inserts, reduced downtime and replacement costs.

PATENTED FELT LABYRINTH SEALS - Proven design directs contaminants away from sealing surfaces, provides

a tight fit to exclude foreign material; once grease permeates the felt there’s a lower coefficient of friction ( or reduced

drag), less heat generation, extended operating life.

EXTENDED INNER RACES - With double locking collars provides a more secure locking system, more holding

power and greater stability on the shaft.

MORE CHOICES... MORE STYLES AND SIZES

Air Handling - Self Aligning Roller Bearing Units

SHAFT SIZE

INCH

1 3/ 16 - 1 1. 4

1 3/ 8 - 1 7/ 16

1 1/2 - 1 11/16

1 3/ 4 - 2

2 3/ 16

2 1/ 4 - 2 1/ 2

2 11/16 - 3

3 3/ 16 - 3 1/ 2

3 15/16 - 4

4 7/ 16 - 4 1/ 2

4 15/16 - 5

SPECIFICATIONS

n Available as Air Handling Units.

Replacement Cartridge inserts, see page 120.

**HVAC applications are normally lightly loaded but may require higher speed capability. For these applications consult Sealmaster Engineering for assistance.

HOUSI NG

SIZE

RANGE

SIZE

103/104

106/107

108/111

112/200

203

204/208 ■■■■- ■■■■2000

211/300

303/308

315/400 - 407/408 - 415/500 - - ■ ----■-1000

SEE PAGE FOR

OTHER OPTIONS:

• EXPANSION BEARINGS - Type ERPB-AH

Expansion bearings are available on request.

• HIGH TEMPERATURE OPERATIONS - Standard

bearings can be modified for operation at higher

temperatures.

For more details on full range of features and benefits,

2 BOLT PILLOW

BLOCKS

RPB

■

■

■■

■■

■■■■

■■■■

■■■■

104 105,107,108 104,111 105 107,108 114 115 116 117

RPB-A

DRPB

DRPB-A

----

----

4 BOLT PIL LOW B L OCKS

RPB

RPBXT

---

---

■■■■

■

RPB- A

----

DRPB

DRPB- A

-

-

-

RFB RFB-A RF P RFP-A

■

■

■

■■■■

■■■■

■■■■1750

■■■■

HOW TO SPECIFY:

SEALMASTER RPB-AH Air

Handling units are clearly

identified on the special

metal nameplate

-

to specify, add the

“AH” to the basic

part number:

“RPB-207-2AH”

FLANGE BL OCKS

PILOTED FLANGES

-

-

-

-

■

■

■

■■

■

MAX

SPEEDS**

-

-3500

-3000

-1250

4000

2500

2500

1500

1250

refer to pages 98-103.

NAMEPLATE IDENTIFICATION

RPB-AH Air Handling units are identified with a special

SEALMASTER metal nameplate indicating that they

are equipped with the special housing fit and are

custom engineered for HVAC Air Handling applications.

125

TOUGH

AS THEY COME!

SEALMASTER RPB-M

Series Metric Bore Bearings

The RPB-M Series Metric bore bearing

as shown in the Table on the opposite page. These metric bearings have the full range of features and benefits of

the RPB Series self-aligning bearings described in detail on pages 98-103.

is available in the full range of sizes and various mounted bearing styles

Three basic sealing arrangements

are offered for the RPB-M Metric Bore

Bearing...

Patented Felt Labyrinth Seal...

Directs contaminants away from the sealing

surfaces... provides a tight fit to exclude foreign

material... has less drag (friction) and less heat

generation than radial lip contact seals;

provides positive sealing for low, medium, and

high speed operation.

Single Lip Contact Seal...

Available in all sizes... recommended where

moisture conditions prevail... functions well in

wet and dirty environments up to 250°F... has

good chemical resistance properties.

126

SEALMASTER

Metric bore RPB bearings

incorporates a metric bore

from 35 - 125mm and is furnished with

metric setscrews. All other components and

hardware are standard.

High Temperature Seal...

Available extra-cost option where operating

temperatures are in the 250 - 400°F range;

units with these sealing arrangements are

prelubricated at the factory with a special high

temperature synthetic lubricant which is

normally satisfactory for the temperature range

0f -40°F to +400°F.

MOUNTED ROLLER BEARINGS

METRIC BORE

SHAFT

SIZE

METRIC

35

40 1 1/2 - 1 11/16 108/111 ■ --■-----■-■--

45 1 3/4 - 2 112/200

50 1 3/4 - 2 112/200

55 2 3/16 203 ■■ ■ ■ -----■■■■ ■

60 2 1/4 - 2 1 / 2 20 4/ 2 08

65 2 1/4 - 2 1 / 2 20 4/ 2 08

70 2 11/16 - 3 211/3 00 ■■ ■ ■ ■ ■ ---■■■■ ■

75 2 11/16 - 3 211/3 00

80 3 3/ 16 - 3 1/2 303/308

85 3 3/ 16 - 3 1/2 303/308 ■■ ■ ■ ■ ■ ---■■■■ ■

90 3 3/ 16 - 3 1/2 303/308

95 3 3/ 16 - 3 1/2 303/308

100 3 15/16 - 4 315/ 4 00 - - - -

105 3 15/16 - 4 315/ 4 00 - - - - ■ ■ ■ ■ ■■■■■ ■

110 4 7/ 16 - 4 1/2 407/4 08 - - - -

115 4 7/ 16 - 4 1/2 407/4 08 - - - -

120 4 15/16 - 5 415/ 5 00 - - - - ■ - ■ - ■ --■-■

125 4 15/16 - 5 415/ 5 00 - - - -

SHAFT

SIZE

RANGE

(INCH)

1 3/8 - 1 7/16 106/107

See Pa ge For M o unting Dime ns i ons 104 105 10 6,107,108 112 104,1 11 105 106 107,108 112 114 115 116 117 118,119

HOUSING

SIZE

RANGE

(INCH)

Self-Aligning Roller Bearing Units

2 BO LT PI LL OW BLOCKS 4 BOLT PIL LO W BL OCKS

ERPB

RPB RPB- A

■

DRPB

DRPB-A

EDPB -A

--------

■■ ■ ■

■■ ■ ■

RPB

SPB

RPBXT

ERPBXT

RPB-A ERPB

-----

-----

■■ ■ ■ ■ ■

■■ ■ ■ ■ ■

■■ ■ ■ ■ ■

■■ ■ ■ ■ ■

■■ ■ ■ ■ ■

■■ ■ ■ ■ ■

■ ■ ■ ■ ■■■■■ ■

-

■

-

■

-

■

DRPB

DRPB- A

EDPB

EDPB-A

---

---

---

---

---

---

-

■

-

■

-

■

FLA NGE BLOCKS

PILOTED FLANGE

CYLI NDRICAL CART RIDG E INSERTS

SPB RFB RF B- A RF P RFP-A ERCI

-

■

--

■

■■■■ ■

■■■■ ■

■■■■ ■

■■■■ ■

■■■■ ■

■■■■ ■

■■■■ ■

■■■■ ■

■

■

■

--

--

--

■

■

■

-

-

-

■

■

■

n Available as metric bore units, including metric setscrews. To order: Add “M” to part number. Example: RPB-65M-C2

RCI-M & RCIA-M Replacement Cartridge Units

RCI-M SERIES RCIA-M SERIES

BORE SIZE FELT SEAL CO NTACT SEAL HI -TEM P SE AL BORE SI Z E FE LT SEAL CONTACT SEAL HI -TE M P S E AL

35

40 RCI - 40 M RCI40M-C RCI40M-N 40 RCIA-40M RCIA40M-C RCIA40M-N

45 RCI - 45 M RCI45M-C RCI45M-N 45 RCIA-45M RCIA45M-C RCIA45M-N

50 RCI - 50 M RCI50M-C RCI50M-N 50 RCIA-50M RCIA50M-C RCIA50M-N

55 RCI - 55 M RCI55M-C RCI55M-N 55 RCIA-55M RCIA55M-C RCIA55M-N

60 RCI - 60 M RCI60M-C RCI60M-N 60 RCIA-60M RCIA60M-C RCIA60M-N

65 RCI - 65 M RCI65M-C RCI65M-N 65 RCIA-65M RCIA65M-C RCIA65M-N

70 RCI - 70 M RCI70M-C RCI70M-N 70 RCIA-70M RCIA70M-C RCIA70M-N

75 RCI - 75 M RCI75M-C RCI75M-N 75 RCIA-75M RCIA75M-C RCIA75M-N

80 RCI - 80 M RCI80M-C RCI80M-N 80 RCIA-80M RCIA80M-C RCIA80M-N

85 RCI - 85 M RCI85M-C RCI85M-N 85 RCIA-85M RCIA85M-C RCIA85M-N

90 RCI - 90 M RCI90M-C RCI90M-N 90 RCIA-90M RCIA90M-C RCIA90M-N

95 RCI - 95 M RCI95M-C RCI95M-N 95 RCIA-95M RCIA95M-C RCIA95M-N

100 RCI-100M RCI100M-C RCI100M-N 100 R CIA-1 00 M RCIA1 00M-C R CIA 100M -N

105 RCI-105M RCI105M-C RCI105M-N 105 R CIA-1 05 M RCIA1 05M-C R CIA 105M -N

110 RCI-110M RCI110M-C RCI110M-N 110 R CIA-1 10 M RCIA1 10M-C R CIA 110M -N

115 RCI-115M RCI115M-C RCI115M-N 115 R CIA-1 15 M RCIA1 15M-C R CIA 115M -N

120 RCI-120M RCI120M-C RCI120M-N 120 R CIA-1 20 M RCIA1 20M-C R CIA 120M -N

125 RCI-125M RCI125M-C RCI125M-N 125 R CIA-1 25 M RCIA1 25M-C R CIA 125M -N

* Insert package includes factory lubed, adjusted, and sealed cartridge complete with single or double locking collars.

RCI-35 M RCI35M-C RCI35M-N 35 RCIA-35M RCIA35M-C RCIA35M-N

127

Loading...

Loading...