®

Performance Spherical Roller Bearing

Installation Instructions

Split Pillow Block Housings

F O R M

PN 787408, PS-740-0001

9567E

Revised

September 2015

• Read and follow all instructions carefully.

• Disconnect and lock-out power before installation and maintenance.

Working on or near energized equipment can result in severe injury or death.

• Do not operate equipment without guards in place. Exposed equipment can

result in severe injury or death.

Mounting Lock Collar Units:

Step 1: Inspect Shaft and Bore-

Shaft should be within tolerance range shown in Table I, clean and

free of nicks and burrs. Mount bearings on unused section of shafting

or repair/ replace shafting as required. Inspect both the shaft and the

bearing bore for debris or contaminants. Wipe clean as necessary.

Table I

Recommended Shaft Tolerances

Nominal Bore Diameter Tolerance (inch)

1 7/16 - 2 +0.0000 / -0.0005

2 7/16 - 4 +0.000 / -0.001

4 7/16 - 5 15/16 +0.0000 / -0.0015

6 7/16 - 7 +0.000 / -0.002

Step 2: Check Support Surfaces:

Make sure the base of the housing and the support surfaces are clean

and free from burrs. If the housing elevation is adjusted with shims these

must cover the entire contact area between the housing and the support

surface.

Step 3: Install Unit:

To aid installation, keep weight off bearing during mounting. Slide unit

onto the shaft by pushing on the inner ring. If it is difcult to mount

bearing on shaft, use a piece of emery cloth to reduce any high spots on

the shaft.

• Periodic inspections should be performed. Failure to perform proper maintenance

can result in premature product failure and personal injury.

Step 5: Position Insert:

Expansion units must be located in the housing to allow axial shaft

expansion and/or contraction. Position bearing insert to obtain the

required axial expansion in the desired directions. It may be necessary

to unload the bearing while moving the assembly.

Step 6: Tighten Setscrews:

Setscrews in multiple bearing applications should be aligned as seen in

Figure 1. Tighten the bearing units to the shaft as follows:

a) Torque the rst setscrew to one half of the recommended torque

in Table II.

b) Torque the second setscrew to the full torque. Go back to the

rst setscrew and tighten to the full torque.

If the bearing unit has two lock collars, one on either end, repeat the

same procedure for the second lock collar. Check shaft again for

freedom of rotation and then tighten second bearing unit in the same

fashion. When all bearings are tightened, perform a nal check to the

shaft for freedom of rotation.

Figure 1

Step 4: Fasten Unit In Place:

Install housing mounting bolts and check bearing alignment. Align

the bearing units as closely as possible. Tighten mounting bolts to

recommended fastener torques. Check the shaft for freedom of rotation

by rotating shaft with hand in both directions.

Table II

Lock Collar Setscrew Torque

Bore Size Hex Size Foot-Pounds

1 7/16 - 1 3/4 5/32 14

1 15/16 - 2 1/2 3/16 25

2 15/16 - 3 1/2 1/4 55

3 15/16 - 4 1/2 5/16 120

4 15/16 - 5 15/16 3/8 180

6 7/16 - 7 1/2 428

Mounting Adapter Lock Units:

Step 1: Inspect Shaft and Bore-

Shaft should be within tolerance range shown in Table III, clean and

free of nicks and burrs. Mount bearings on unused section of shafting

or repair/replace shafting as required. Inspect both the shaft and the

adapter bore for debris or contaminants. Wipe clean as necessary.

Notice: Do not apply any additional lubricant (ex. Grease, oil, or antiseize compound) to bearing tapered surfaces, bore or shafting. Bearing

components have a light oil, rust preventative coating that should not

be removed. Application of additional lubricant may cause reduction in

bearing performance and may lead to equipment failure and/or personal

injury.

Table III

Recommended Shaft Tolerances

Nominal Bore Diameter Tolerance (inch)

1 7/16 - 2 +0.000 / -0.003

2 7/16 - 4 +0.000 / -0.004

4 7/16 - 5 15/16 +0.000 / -0.005

6 7/16 - 8 +0.000 / -0.006

Step 2: Check Support Surfaces:

Make sure the base of the housing and the support surfaces are clean

and free from burrs. If the housing elevation is adjusted with shims these

must cover the entire contact area between the housing and the support

surface.

Step 3: Install Unit:

Notice: One expansion unit is to be used in conjunction with one

non-expansion unit for applications using an adapter lock unit. Failure to utilize one expansion and one non-expansion unit is likely to

result in reduced bearing performance.

To aid installation, keep weight off bearing during mounting. Slide

unit onto the shaft by pushing on the inner ring. If it is difcult to

mount bearing on shaft, use a piece of emery cloth to reduce any

high spots on the shaft.

Step 5: Position Insert:

Expansion inserts must be located in the housing. If the direction of shaft

growth is in the direction seen in Figure 2, align the bearing as shown. If

the direction of shaft growth is opposite to that shown in Figure 2, center

the insert in the housing.

Figure 2

Step 6: Shaft Lock:

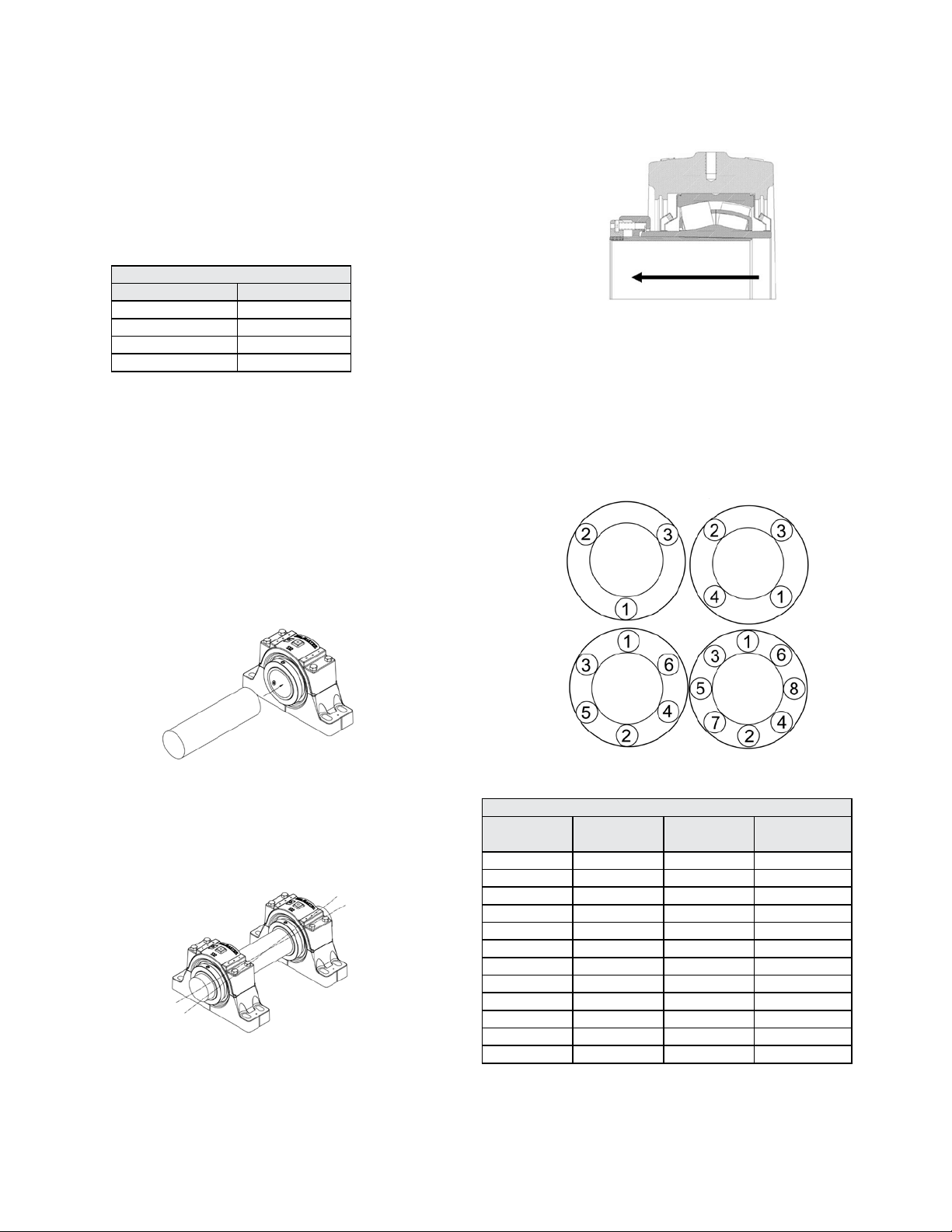

Tighten the cap screws in the specied order as seen in Figure 3.

Continue tightening until all cap screws have become snug. Using a

torque wrench, tighten each cap screw to one half of the appropriate

torque value in Table IV. In the same order, repeat the procedure

tightening each cap screw to the full appropriate value. Once complete,

follow the same pattern and verify each cap screw has met the

appropriate torque value and all cap screws have achieved equivalent

resistance. Repeat step 6 for other bearing(s). Rotate the shaft by hand

to check for freedom of rotation.

Figure 3

Step 4: Fasten Unit In Place:

Install housing mounting bolts and check bearing alignment. Align the

bearing units as closely as possible.

Tighten mounting bolts to recommended fastener torques. Check

the shaft for freedom of rotation by rotating shaft with hand in both

directions.

MCIM15048E • Form 9567E • Printed in USA

2

Table IV

Adapter Lock Cap Screw Information

Bore Size

1 7/16 - 1 1/2 45 1/8 3

1 15/16 - 2 30 1/8 3

2 7/16 - 2 1/2 60 1/8 4

2 15/16 - 3 55 1/8 4

3 7/16 - 3 1/2 80 3/16 4

3 15/16 - 4 80 3/16 4

4 7/16 - 4 1/2 11 5 3/16 4

4 15/16 - 5 130 3/16 6

5 7/16 - 5 1/2 11 5 3/16 6

5 15/16 175 3/16 8

6 7/16 - 7 225 1/4 8

7 1/2 - 8 275 1/4 8

Torque

(inch - Pounds)

Hex Size # Cap Screws

Replacing Existing Sealmaster Inserts:

Pre-Mounting Checklist:

Step 1: Remove Housing Cap Bolts

Step 2: Remove Top Half of Housing

Step 3: Remove Bearing from Shaft

For setscrew units, loosen the setscrews and slide the bearing off the

shaft. For adapter lock units, loosen cap screws in the specied order as

seen in Figure 3 and slide the bearing off the shaft.

Step 4: Inspect Shaft and Bore:

Shaft should be within tolerance range, clean and free of nicks and

burrs. Mount bearings on unused section of shafting or repair/replace

shafting as required. Inspect both the shaft and the bearing bore for

debris or contaminants. Also be sure to inspect the housing bore and

stabilizing ring. Wipe clean as necessary.

Step 5: Load New Insert:

Slide the bearing onto the shaft and seat the bearing in the housing

base.

Step 6: Install Top Half of Housing:

Be sure to check the bearing inserts for proper alignment. Align the

bearing. Install the top half of the housing. Tighten down the cap bolts to

the recommended torque in Table V. Rotate the shaft by hand to check

for freedom of rotati

Lubrication:

All Sealmaster Spherical Roller Bearings are delivered with a high

quality lithium complex base grease with an EP additive. The bearing is

ready for use with no initial lubrication required. The grease is a lithium

complex base, mineral oil, NLGI grade 2 consistency, with a base oil

viscosity of ISO VG 220.

Compatibility of grease is critical; therefore consult with Sealmaster

Application Engineering and your grease supplier to insure greases are

compatible. For best performance it is recommended to relubricate with

lithium complex thickened grease with a comparable NLGI consistency

and base oil viscosity.

Relubricatable Sealmaster bearings are supplied with grease ttings or

zerks for ease of lubrication with hand or automatic grease guns. Always

wipe the tting and grease nozzle clean.

Notice: If possible, it is recommended to lubricate the bearing while

rotating, until grease purge is seen from the seals. If this is not an option

due to safety reasons, follow the alternate lubrication procedure below.

Alternate Lubrication Procedure:

Stop rotating equipment. Add one half the recommended amount shown

in Table VI. Start the bearing and run for a few minutes. Stop bearing

and add the second half of the recommended amount. A temperature

rise after lubrication, sometimes 30°F (17°C), is normal. Bearing should

operate at temperatures less than 200°F (94°C) and should not exceed

250°F (121°C) for intermittent operation. For lubrication guides, see

Tables VII and VIII.

Note: Tables VI & VII are general recommendations. Experience and

testing may be required for specic applications.

Table V

Cap Bolt Tightening Torque

Casting Bore Size Foot-Pounds

509 1 7/16 - 1 1/2 31

511 1 15/16 - 2 31

515 2 7/16 - 2 1/2 75

517 2 15/16 - 3 75

520 3 7/16 - 3 1/2 109

522 3 15/16 - 4 150

526 4 7/16 - 4 1/2 150

528 4 15/16 - 5 266

532 5 7/16 - 5 1/2 266

534 5 15/16 266

536 6 7/16 - 6 1/2 266

538 6 15/16 - 7 600

544 7 1/2 - 8 600

Step 7: Refer to Steps 5 and 6 from the Previous Installation Sections for

the Respective Shaft Locking Mechanism

Table VI

Grease Charge for Relubrication

Bore Size Grease Charge (Mass - Ounces)

1 7/16 - 1 1/2 0.20

1 15/16 - 2 0.30

2 7/16 - 2 1/2 0.60

2 15/16 - 3 0.80

3 7/16 - 3 1/2 1.20

3 15/16 - 4 2.00

4 7/16 - 4 1/2 2.75

4 15/16 - 5 4.00

5 7/16 - 5 1/2 6.10

5 15/16 10.60

6 7/16 - 7 13.90

7 1/2 - 8 17.60

Table VII

Relubrication Recommendations

Environment Temperature (°F)

Dirty -20 to 250 0 - 100% Daily to 1 Week

-20 to 125

Clean

125 to 175

175 to 250 0 - 100% Daily to 1 Week

Speed

(% Catalog Max)

0 - 25% 4 to 10 Months

26 - 50% 1 to 4 Months

51 - 75% 1 Week to 1 Month

76 - 100% Daily to 1 Week

0 - 25% 2 to 6 Weeks

26 - 50% 1 Week to 1 Month

51 - 75%

76 - 100%

HI Sufx

Daily to 1 Week

MCIM15048E • Form 9567E • Printed in USA

3

Table VIII

Maximum Operational Speed

Bore Size Felt Seal (RPM) Contact Seal (RPM)

1 7/16 - 1 1/2 4000 3000

1 15/16 - 2 4000 2500

2 7/16 - 2 1/2 3250 1750

2 15/16 - 3 3000 1600

3 7/16 - 3 1/2 2500 1350

3 15/16 - 4 2250 1200

4 7/16 - 4 1/2 2000 1100

4 15/16 - 5 1750 900

5 7/16 - 5 1/2 1500 900

5 15/16 1300 800

6 7/16 - 7 1200 750

7 1/2 - 8 1100 750

Expansion Bearing Applications:

Before installation, make certain proper expansion is accounted for.

Expansion units should be placed in a location where relative movement

between the bearing insert and the housing can be tolerated. For most

applications using expansion type units, the xed unit (non-expansion

unit) is placed at the drive end of the shaft. Use Table IX to review the

total available bearing expansion. If the application requires additional

expansion, consult engineering.

Notice: One expansion unit must be used in conjunction with one

non-expansion unit for applications using an adapter lock unit. Failure

to utilize one expansion and one non-expansion unit is likely to result in

reduced bearing performance.

Table IX

Total Available Housing Expansion (inch)

Casting Bore Size Setscrew Adapter Lock

509 1 7/16 - 1 1/2 7/32 3/16

511 1 15/16 - 2 1/4 7/32

515 2 7/16 - 2 1/2 5/16 9/32

517 2 15/16 - 3 3/8 11/32

520 3 7/16 - 3 1/2 3/8 11/32

522 3 15/16 - 4 3/8 5/16

526 4 7/16 - 4 1/2 3/8 9/32

528 4 15/16 - 5 3/8 9/32

532 5 7/16 - 5 1/2 3/8 9/32

534 5 15/16 3/8 9/32

536 6 7/16 - 6 1/2 3/8 9/32

538 6 15/16 - 7 3/8 9/32

544 7 1/2 - 8 3/8 9/32

Sealmaster is a trademark of Regal Beloit Corporation or one of its afliated companies.

©2015 Regal Beloit Corporation, All Rights Reserved. MCIM15048E • Form 9567E • Printed in USA

Loading...

Loading...