Sealey YAJ15-30.V2,YAJ15-30DC.V2,YAJ20-40.V2,YAJ20-40DC.V2,YAJ20-40LR Instruction Manual

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these

instructions, and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY

Disconnect jack from air supply before changing parts, servicing or performing any maintenance.

R WARNING! Ensure correct air pressure is maintained and not exceeded. Recommended pressure 116-145psi or 174psi for

YAJ20-40LR. Required air ow 10.5cfm or 11.5cfm for YAJ20-40LR.

Keep air hose away from heat, oil and sharp edges. Check air hose for wear before each use, and ensure that all connections

are secure.

Ensure Jack is kept clean and in good working order. Immediately repair or replace damaged parts.

Use recommended parts only. Incorrect parts may be dangerous and will invalidate the warranty.

Use a qualied person to lubricate and maintain the jack.

Locate jack in a suitable, well lit work area. Keep area clean and tidy and free from unrelated materials.

Use jack on level & solid ground, preferably concrete. Avoid tarmacadam since jack may sink in.

Place wedges under wheels of vehicle (but ensure wheels of jack can freely move).

Ensure the vehicle handbrake is engaged (or in “PARKED” mode), and switch the engine off.

Ensure minimum distance of 0.5m between vehicle tilt & static objects such as doors, walls, etc.

Ensure all non essential persons keep a safe distance and that there are no passengers in the vehicle to be jacked up.

Place jack under vehicle manufacturer’s recommended jacking points (see vehicle handbook).

Check that the jacking point is stable and centred on the jack saddle and is free from grease or oil.

Ensure jack wheels are free to move and that there are no obstructions.

V DANGER: Use jack for lifting only, NOT for supporting the raised load. Use correctly rated axle stands under vehicle before

proceeding with task.

DO NOT use brake uid to top up system. Use Sealey hydraulic oil only.

DO NOT apply your body weight to the handle during jacking. The handle is only for moving the jack to and from the lifting location.

DO NOT operate the jack if parts are missing or damaged.

DO NOT exceed the rated capacity of the jack.

DO NOT allow the vehicle to move during lifting and do not use the jack to move the vehicle.

DO NOT jack a vehicle which may result in the spillage of fuel, battery acid, or dangerous substances.

DO NOT work under the vehicle until Axle Stands have been correctly positioned.

DO NOT use the jack for purposes other that than which it is designed for.

DO NOT adjust the safety overload valve.

DO NOT pull the hose from the air supply, and DO NOT direct air from the air hose at yourself or others.

Ensure there are no persons or obstructions beneath the vehicle before lowering.

When not in use disconnect jack from the air supply, and store in the lowered position in a safe, dry, childproof area.

R WARNING! Turn off air supply and de-pressurise the control nozzle before removing the pump unit from any installation or mobile

system.

Failure to comply with this instruction may damage the unit and will invalidate your warranty.

2. INTRODUCTION

Ideal for workshop or roadside use, these jacks take the effort out of lifting heavy plant, tractors and commercial vehicles. Models feature dead

man’s control for extra safety (detachable on Model No’s YAJ15-30DC.V2 and YAJ20-40DC.V2 making these models extremely portable)

and multi-position locking handles. Each jack is supplied with a 45mm and 75mm extension to help close the gap between the saddle of the

jack and the jacking point. Model No. YAJ20-40LR also offers a long reach chassis, ideal for accessing deep set jacking points.

Refer to

Instruction

Manual

YAJ15-30.V2, YAJ15-30DC.V2,YAJ20-40.V2,

YAJ20-40DC.V2, YAJ20-40LR| Issue 2 (I) 28/04/15

Original Language Version

© Jack Sealey Limited

INSTRUCTIONS FOR :

AIR OPERATED JACKS TELESCOPIC

MODEL No's YAJ15-30.V2 YAJ15-30DC.V2 YAJ20-40.V2 YAJ20-40DC.V2 YAJ20-40LR

3. SPECIFICATION

Note: The maximum heights shown may be extended by use of the extension pins.

4. ASSEMBLY

4.1. Attaching the Handle - YAJ15-30.V2, YAJ20-40.V2, YAJ20-40LR

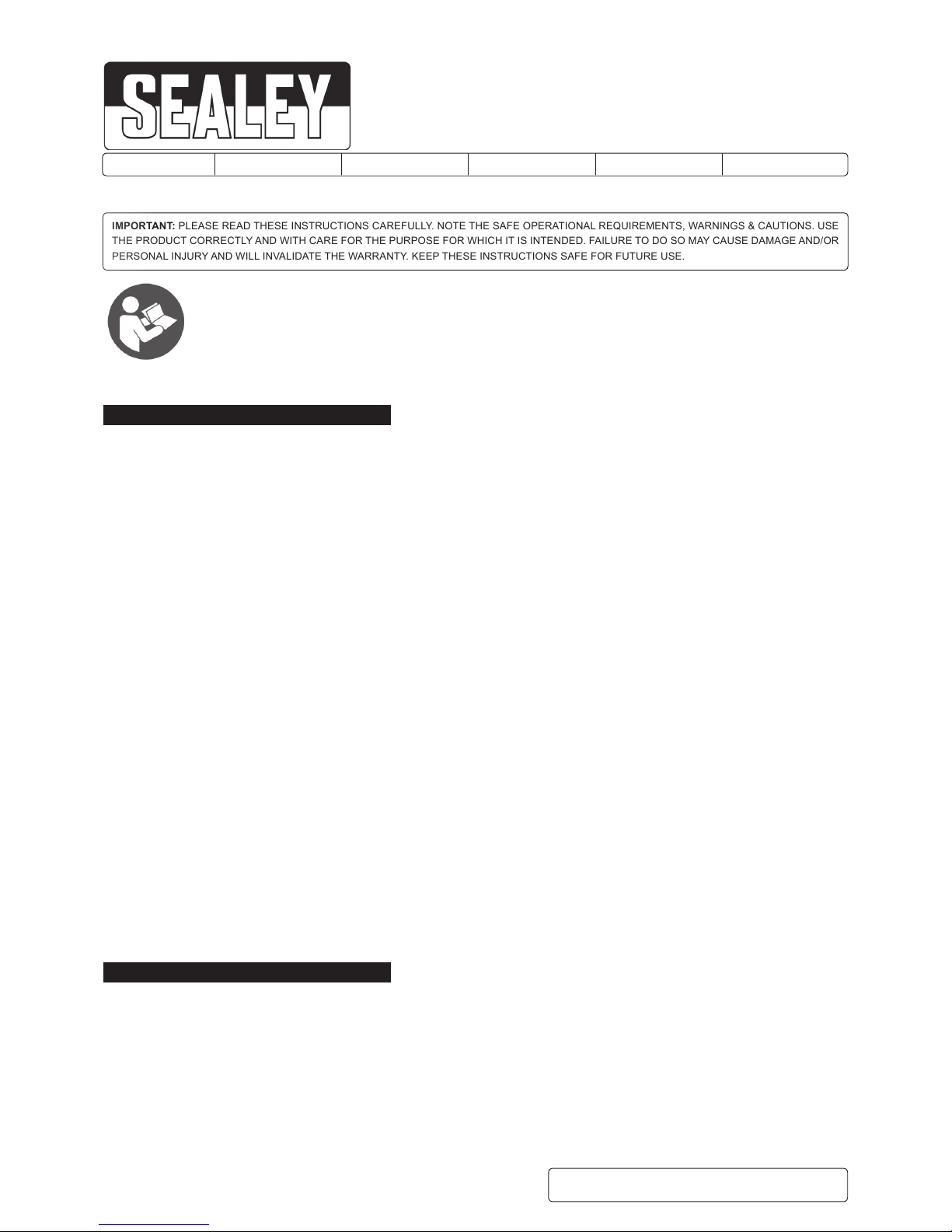

4.1.1. Remove a circlip from either side of the large pin (g.1A).

4.1.2. Slide out the pin and place the handle into the opening. Slide the pin back through the jack, lining up the handle and through the

other side. Secure with circlips.

4.2. Air Hoses - YAJ15-30.V2, YAJ20-40.V2, YAJ20-40LR

4.2.1. Screw in the two air hoses from the handle into the jack.

4.2.2. The hose marked orange must be screwed into the left-hand side. The hose marked black or clear into the right-hand side, (g.1).

4.2.3. Ensure the hoses are tight and do not obstruct the movement of the handle.

5. AIR SUPPLY

5.1. Ensure that the jack pneumatic switch is in the “off” position before connecting to the air supply.

5.2. You will require an air pressure of at least 116psi (max 145psi or 174psi for YAJ20-40LR) and an air ow of 10.5cfm (or 11.5cfm for

YAJ20-40LR) to get the best performance from this jack.

R WARNING! Ensure the air supply does not exceed 145psi (or 174psi for YAJ20-40LR) while operating the jack.

Too high an air pressure and unclean air will shorten the products life due to excessive wear, and may be dangerous causing

possible damage and personal injury.

5.3. Drain the air tank daily. Water in the air line will damage the jack.

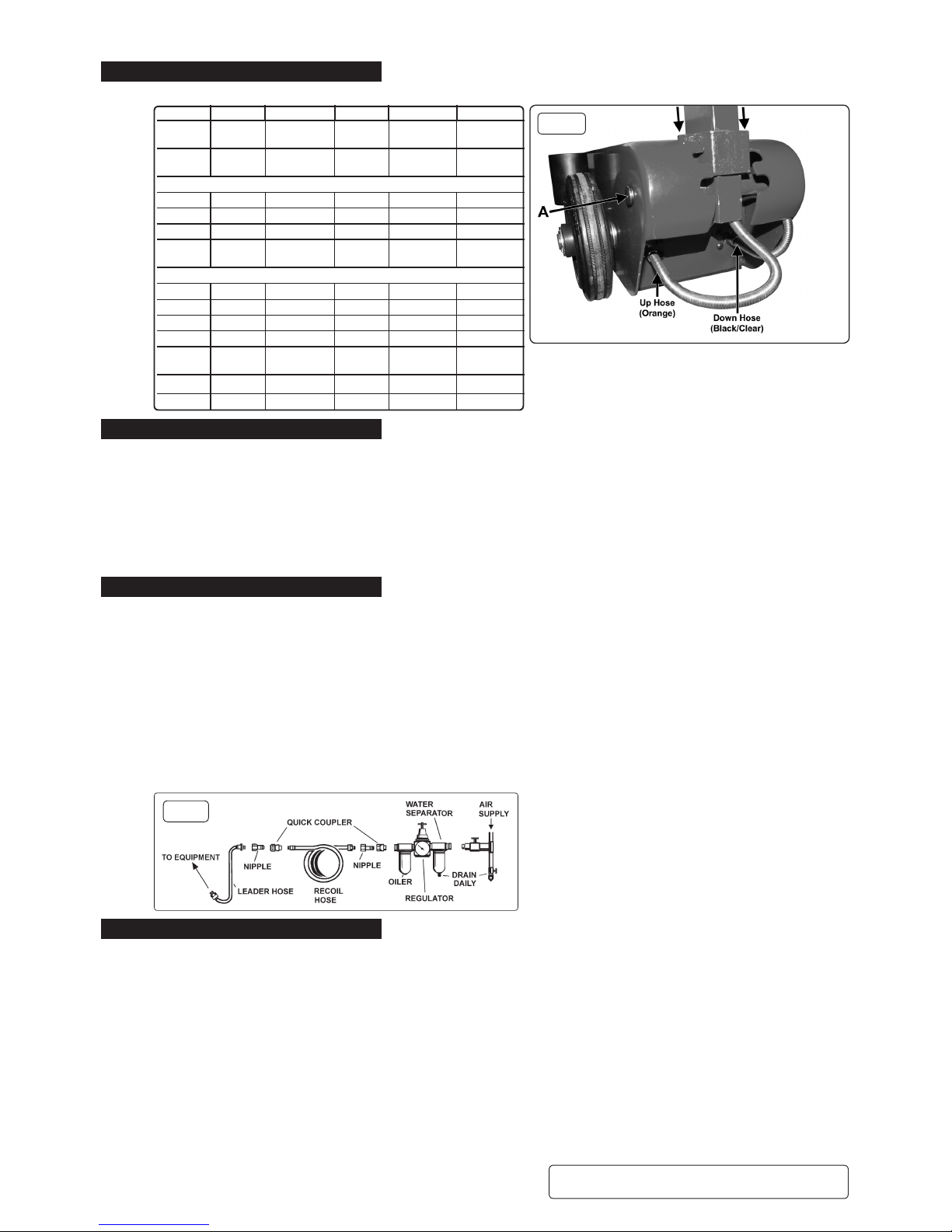

5.4. Clean the air inlet lter screen weekly.

5.5. Keep the air hose between the compressor and the air jack as short as possible, and install an air lter and oiler (g.2).

5.6. Line pressure should be increased to compensate for unusually long air hoses (over 8 metres). The minimum hose diameter should

be 3/8” I.D. and ttings must have the same inside dimensions.

5.7. Keep hose away from heat, oil and sharp edges. Check hoses for wear, and make certain that all connections are secure.

6. OPERATION

6.1. PREPARATION - YAJ15-30.V2, YAJ20-40.V2, YAJ20-40LR

6.1.1. You will require an air pressure of at least 116psi (max 145psi or 174psi for YAJ20-40LR) and an air ow of 10.5cfm or 11.5cfm for

YAJ20-40LR to get the best performance from the jack.

6.1.2. Connect the air supply to the connector (g.3B).

6.1.3. Set the handle to the required angle using the handle release lever shown in g.3A. Pull the lever upwards towards the main

handle. Move the handle to the required position and release the lever to lock it into position.

6.2. PREPARATION - YAJ15-30DC.V2, YAJ20-40DC.V2

6.2.1. Connect the air supply to the connector (g.4A).

6.2.2. To change the handle position on the “DC” models turn the handle (g.4D) anti-clockwise then pull out of socket, insert into the

other handle socket and turn clockwise to secure.

6.3. PURGE THE SYSTEM - YAJ15-30.V2, YAJ20-40.V2 AND YAJ20-40LR

6.3.1. Before using the jack, purge the hydraulic circuit in order to eliminate any possible air that may have entered the system during

transit.

6.3.2. Push the control lever (g.5A) to the ‘down’ position and hold it there for several seconds.

Model No

YAJ15-30.V2 YAJ15-30DC.V2 YAJ20-40.V2 YAJ20-40DC.V2 YAJ20-40LR

Maximum

Capacity

30Tonne 30Tonne 40Tonne 40Tonne 40Tonne

Minimum

Height

175mm 150mm 175mm 150mm 190mm

Maximum Height/Capacity (mm/Tonne)

Stage 1 393/30 343/30 393/40 343/40 416/40

Stage 2 472/15 409/15 472/20 409/20 504/20

Extension 45/75mm 45/75mm 45/75mm 45/75mm 45/75mm

Chassis

Length

480mm 430mm 480mm 430mm 770mm

Length inc. Handle

Position 1 460mm 1280mm 460mm 1280mm 820mm

Position 2 1380mm 1600mm 1380mm 1600mm 1770mm

Position 3 1700mm - 1700mm - 2100mm

Width 290mm 290mm 290mm 290mm 282mm

Working

Pressure

116-

145psi

116-

145psi

116-

145psi

116-

145psi

116-

174psi

Air Flow 10.5cfm 10.5cfm 10.5cfm 10.5cfm 11.5cfm

Weight 39kg 31kg 41kg 33kg 62kg

fig.1

fig.2

YAJ15-30.V2, YAJ15-30DC.V2,YAJ20-40.V2,

YAJ20-40DC.V2, YAJ20-40LR| Issue 2 (I) 28/04/15

Original Language Version

© Jack Sealey Limited

Loading...

Loading...