Page 1

INSTRUCTIONS FOR:

FUEL INJECTION

PRESSURE TEST KIT

MODEL: VSE210

Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions and properly

maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS, AND

CAUTIONS. USE THIS PRODUCT CORRECTLY, AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO

MAY CAUSE DAMAGE AND/OR PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY.

1. SAFETY INSTRUCTIONS

1.1 FUEL SAFETY

p WARNING! Ensure Health and Safety, local authority, and general workshop practice regulations are adhered to when working with

fuel injection systems and petrol in general.

p WARNING! Petrol fumes and battery gases are explosive, DO NOT smoke or allow an open flame or sparks in the work area.

1.1.1 FUEL LEAKS

3 Keep a dry chemical (class B) fire extinguisher near to the work area.

3 Avoid fire hazard by using caution when disconnecting fuel lines and installing adaptors, as some spillage is inevitable.

3 When connecting, or disconnecting from a fuel system, relieve pressure from system and wrap a cloth around the fuel line fitting to absorb any

fuel leakage. Constantly check gauge and adaptor connections for leaks. If you see leakage turn off the ignition or disable the fuel pump,

relieve fuel pressure if necessary and correct leaks before continuing.

3 When using tee adaptors, secure hose with hose clamps to ensure leak-free connections.

3 Check all adaptor sealing washers and 'O' rings are in good condition before use.

3 When connecting hose coupler to Test Port, Tee and In-Line Banjo Bolt Adaptors ensure coupler is correctly seated onto adaptor.

7 DO NOT let fuel spill onto a hot engine.

7 DO NOT allow fuel to remain in the adaptors or hoses after use. To clear any fuel trapped in the gauge/hose assembly after use, hold gauge

vertical with hose coupler end in suitable fuel container. Depress coupler valve stem and at the same time, depress pressure relief button

situated under the gauge.

p WARNING! Wipe up fuel spills immediately.

1.2 GENERAL

p WARNING! Exhaust gas contains deadly poisonous gases. Test area must well ventilated - route exhaust gas outdoors.

3 Maintain tools in good and clean condition for best and safest performance.

3 If required, ensure the vehicle to be worked on is adequately supported with axle stands, ramps and chocks.

3 Before performing a test with the engine running (unless the manufacturer's manual states otherwise), set the parking brake and place the gear

selector in neutral or park, and block the drive wheels.

3 Before repairing the fuel system, turn off the ignition switch and disconnect the battery per manufacturer's procedure. Never disconnect the

battery while the engine is running.

3 Wear approved safety goggles. A full range of personal safety equipment is available from your Sealey dealer.

3 Wear suitable clothing to avoid snagging. Do not wear jewellery and tie back long hair.

3 Keep yourself, clothing and test equipment away from all moving or hot engine parts.

7 DO NOT use tools if damaged.

7 DO NOT use the components from this kit on diesel fuel systems.

3 Account for all tools being used and do not leave them in or near the engine.

3 IMPORTANT: Always refer to the vehicle manufacturers service instructions, or proprietary manual to establish the current procedure and data.

These instructions for use are provided as a guide only.

2. INTRODUCTION

Comprehensive kit of adaptors and fittings for modern fuel injection systems.

Components fitted with quick coupling system and safety valve to prevent

inadvertent discharge of fuel under pressure. Kit supplied with large high pressure

gauge reading 0-145psi and 0-1000kpa and a small low pressure gauge for

accurate low pressure readings. Pressure release valve fitted with long drain hose

allows safe recovery of fuel. Supplied in carry-case.

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without

prior notice. IMPORTANT: No liability is accepted for incorrect use of this equipment. WARRANTY: Guarantee is 12 months from purchase date,

proof of which will be required for any claim. INFORMATION: For a copy of our latest catalogue and promotions call us on 01284 757525 and

leave your full name and address, including postcode.

Sole UK Distributor, Sealey Group, Bury St. Edmunds, Suffolk.

01284 757500

01284 703534

www.sealey.co.uk

Web

sales@sealey.co.uk

email

VSE210 - 1 - 211204

Page 2

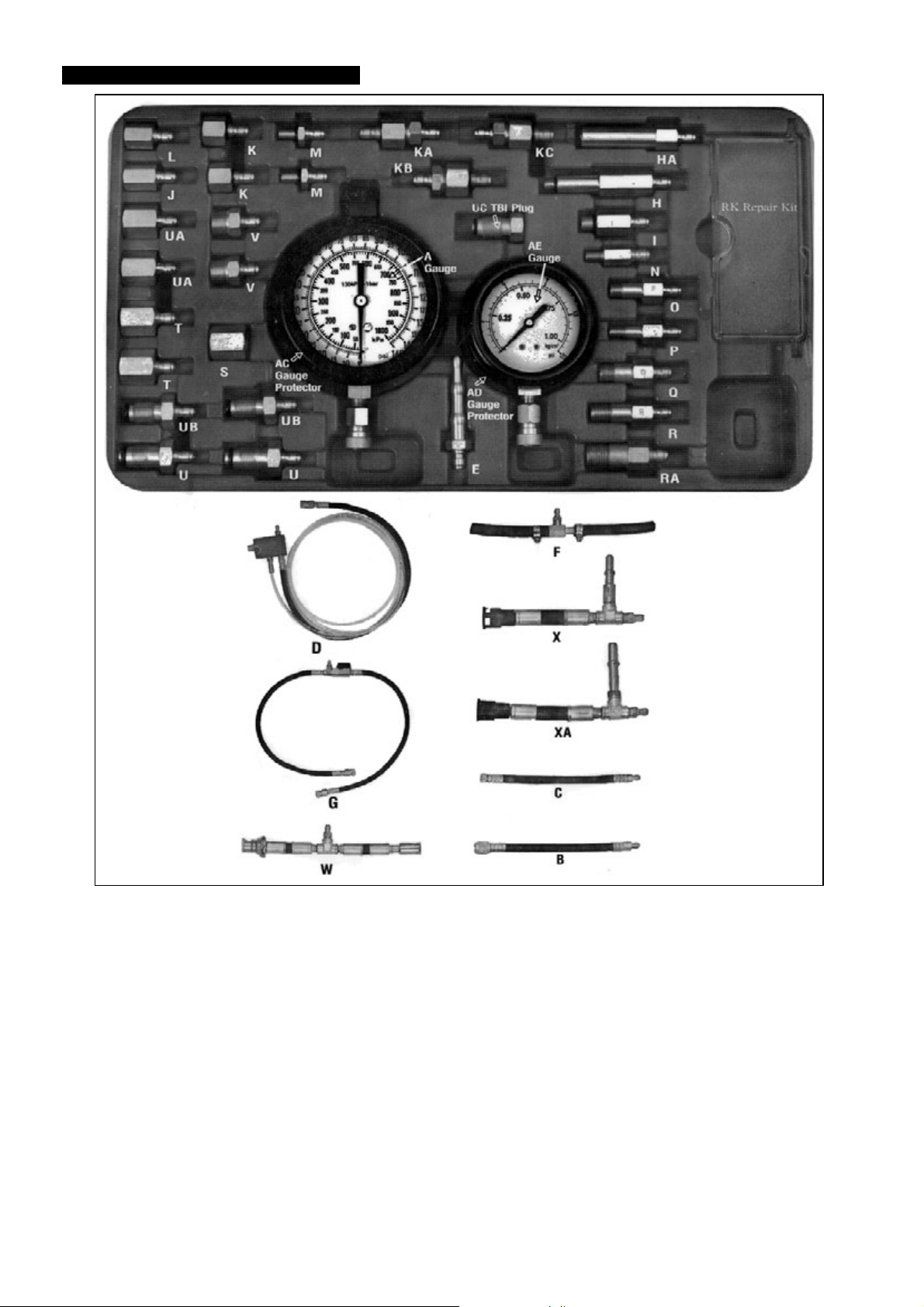

3. TOOL PARTS & CONTENT LIST

Issue: 1

Issue Date: 030205

ITEM PART NO. DESCRIPTION

A VSE210.A GAUGE 3-1/2

AC VSE210.AC GAUGE PROTECTOR 3-1/2

AD VSE210.AD GAUGE PROTECTOR 2-1/2

AE VSE210.AE GAUGE 2-1/2

B VSE210.B ADAPTOR HOSE 7/16 X 20 (GM/CHRYS)

BC VSE210.BC BLOW CASE

C VSE210.C ADAPTOR HOSE 308 X 32 (FORD/EFI)

D VSE210.D GAUGE HOSE C/W RELIEF VALVE

E VSE210.E SINGLE END HOSE ADAPTOR 1/4-3/8

F VSE210.F DOUBLE END HOSE ADAPTOR 5/16-3/8

G VSE210.G HOSE ASSEMBLY C/W VALVE (CIS/TBI)

H VSE210.H MALE CIS FITTING (LONG) 8MM X 1.0

HA VSE210.HA FEMALE CIS FITTING (LONG) 8MM X 1.0

I VSE210.I MALE CIS FITTING 10MM X 1.0

J VSE210.J FEMALE CIS FITTING 10MM X 1.0

K VSE210.K FEMALE CIS FITTING 12MM X 1.5

KA VSE210.KA SWIVEL FITTING M&F 14MM X 1.5

KB VSE210.KB SWIVEL FITTING M&F 16MM

KC VSE210.KC SWIVEL FITTING M&FBSPT 1/4

ITEM PART NO. DESCRIPTION

L VSE210.L FEMALE CIS FITTING 8MM X 1.0

M VSE210.M MALE CIS FITTING 8MM X 1.0

N VSE210.N BANJO FITTING 6MM X 1.0

O VSE210.O BANJO FITTING 8MM X 1.0

P VSE210.P BANJO FITTING 10MM X 1.0

Q VSE210.Q BANJO FITTING 12MM X 1.25

R VSE210.R BANJO FITTING 12MM X 1.5

RA VSE210.RA BANJO FITTING 14MM X 1.5

RK VSE210.RK REPAIR KIT

S VSE210.S UNION 5/8 X 18

T VSE210.T FEMALE TUBE ADAPTOR 16MM X 1.5

U VSE210.U MALE TUBE ADAPTOR 16MM X 1.5

UA VSE210.UA FEMALE TUBE ADAPTOR 14MM X 1.5

UB VSE210.UB MALE TUBE ADAPTOR 14MM X 1.5

UC VSE210.UC MALE PLUG 14MM X 1.5

V VSE210.V MALE FITTING 5/8 X 18

W VSE210.W SPRING LOCK HOSE (FORD)

X VSE210.X HAIR PIN HOSE 5/16 (FORD)

XA VSE210.XA HAIR PIN HOSE 3/8 (GM/CHRYS)

VSE210 - 1 - 211204

Page 3

4. GENERAL INFORMATION

Because fuel systems and access points are so varied, it is impractical to list all of the applications. Always refer to a reliable shop manual, or the

car manufacturer for the recommended test procedure and access points.

There are two basic types of fuel injection systems. Port Fuel Injection (PFI) uses separate injectors to supply the fuel to each cylinder.

Throttle Body Injection (TBI) injects fuel from a position above the throttle plate on the intake manifold. On both systems there is a supply side,

which brings fuel to the injectors, and a return side which brings unused fuel back to the tank.

Basically, there are three ways to check fuel pressure. First, many domestic cars with PFI are equipped with a special test port. Simply connect the

proper adaptor to the gauge assembly, thread the adaptor to the test port, and run the test (section 15). Second is an end of hose connection.

Some older PFI systems have a flexible hose connection at the cold start injector. Connect our single barb fitting (section 18) with a hose clamp to

run the test. Also, some systems have fuel bolt or banjo type fittings as an access point (section 18).

Third is in-line connecting. This means installing the proper adaptor(s) in series with the fuel line (sections 16, 17 & 19).

Unless a schrader-type test port is available, most manufacturers require that you relieve the fuel pressure before entering or leaving the system.

To relieve the pressure, it may be necessary to remove the fuel pump connector, relay, or fuse. Some models may have two fuel pumps - make

sure both are disabled. After the pump(s) are disabled, run the engine until it stalls, then try to restart it for five to ten seconds. The system is now

ready for testing. Once the proper adaptors and gauge are in place, reactivate the fuel pump and run tests.

When finished testing, repeat above procedure before removing tester.

5. BASIC DIAGNOSIS

Fuel injected engines require precise fuel pressure as well as adequate volume. Without the correct pressure and volume, performance and fuel

economy can suffer. Always consult the correct repair manual for accurate specifications.

When running tests, it may help to picture the fuel system as a circle. Fuel is pumped from the tank to the fuel regulator and injectors, and the

unused fuel is then returned to the tank. The fuel regulator serves as a divider between the supply side and the return side.

Lower than recommended pressure usually indicates a problem on the supply side of the circle. Likely causes would include a damaged or

restricted fuel line, clogged fuel filter, defective fuel pump or regulator, or improper tank ventilation. Higher than normal pressure usually indicates a

problem on the return side of the circle. Likely causes are a damaged or restricted fuel line, poor venting of the tank, or a defective fuel regulator.

You may be able to pinpoint problem areas on the return side by resetting. For example - by removing the return line near the fuel regulator and

putting the fuel line into a proper container, a retest that still shows a high reading would indicate a faulty regulator. If the reading would drop into

the normal range, you know that problem is further down the return line or the tank. Again, always consult the manufacturer of the vehicle, or a

good repair manual for specific trouble-shooting procedures. When testing is completed, make sure the fuel line is reassembled correctly. Replace

any o-rings or washers, and follow the manufacturer's recommendations for proper torque on any bolts or connections. Check the entire system

thoroughly for any leaks.

Following are some typical test procedures for different models.

6. FUEL PRESSURE TESTS FOR GENERAL MOTORS (TYPICAL)

CAUTION: Fuel system test begins with checking fuel injection system pressure. High fuel pressure may be present in fuel lines and

components. Relieve fuel pressure before disconnecting any fuel system components.

6.1 FUEL PRESSURE CHECK FOR TBI

6.1.1 Disconnect negative battery cable. Remove fuel filler cap. Since these TBI units contain an internal bleed-down feature, after a short time,

system fuel pressure should dissipate.

6.1.2 Remove air cleaner and plug thermal vacuum port on throttle body. When removing fuel line, always use 2 wrenches. Install Fuel Pressure

Gauge and Adaptor in fuel system between steel line and flexible hose.

CAUTION: DO NOT pinch off fuel return line completely. DO NOT exceed pressure build-up of more than 13 psi. as regulator may be

damaged.

6.1.3 Start engine and observe fuel pressure reading. Fuel pressure should read 9-13 psi. (if fuel pressure is okay, proceed to step 4). If fuel

pressure is low, gradually pinch off fuel return line to fuel tank. If pressure remains low, check and/or replace fuel filter or fuel pump. If

pressure increases to greater than 13 psi, replace fuel pressure regulator.

6.1.4 Allow fuel pressure to dissipate. Remove pressure gauge and reconnect fuel line. Start engine and watch for fuel system leaks.

6.2 FUEL PRESSURE CHECK OF PFI

6.2.1 Disconnect fuel pump at rear body connector (electrical). Start engine and run engine until it stalls. Crank starter for 3 seconds to remove

remaining fuel from fuel lines. Reconnect rear body connector.

6.2.2 Connect Fuel Pressure Gauge to fuel pressure fitting on fuel rail.

6.2.3 Reconnect fuel pump.

6.2.4 With gauge installed at fuel rail connector, turn ignition on. With ignition on and engine off, pressure should read within specifications.

6.2.5 Start engine. Pressure should drop 3-10 psi.

7. FUEL PRESSURE TESTS FOR FORD (TYPICAL)

CAUTION: High fuel pressure may be present in fuel lines and component parts. Relieve pressure before attempting to open system for

testing or component replacement. DO NOT allow fuel to run onto engine or electrical parts or allow an open flame in area while testing

fuel system components.

7.1 FUEL PRESSURE CHECK FOR PFI

7.1.1 On 2.2L & 2.2L Turbo models, relieve fuel line pressure by disconnecting fuel pump relay and starting engine. After engine stalls, turn

ignition off. Reconnect fuel pump relay.

7.1.2 On all other models, remove fuel tank cap. Using Fuel Pressure Gauge, release pressure from system at pressure relief valve (Schrader

valve) on fuel injection manifold rail.

7.1.3 The fuel pump may be activated by grounding the fuel pump lead at the SELF-TEST connector. Use a jumper lead and ground the "FP"

terminal with ignition on. This activates the fuel pump.

CAUTION: Inspect fuel system for leaks or damage before testing fuel pump.

7.2 FUEL PRESSURE TEST FOR TBI

7.2.1 Disconnect wiring at inertia switch. Inertia switch is located behind trim panel in right rear side of cargo area on Sable and Taurus station

wagons and behind trim panel on left side of trunk on all other models. Crank engine for at least 15 seconds to reduce system fuel

pressure.

7.2.2 Disconnect fuel supply line at throttle body. Install in-Line Adaptor and fuel Pressure gauge at fuel filter. Reconnect intertia switch and start

engine. Check fuel pressure at idle and when accelerating engine. Pressure should remain stable through entire period of acceleration.

7.2.3 If gauge readings are correct, disconnect inertia switch. Crank engine for 15 seconds to reduce fuel pressure. Remove gauge and in-line

adaptor. Install original fuel line and connect intertia switch. Start engine and check for fuel leaks.

VSE210 - 1 - 211204

Page 4

8. FUEL PRESSURE TESTS FOR CHRYSLER (TYPICAL)

CAUTION: High fuel pressure may be present in fuel lines and component parts. Relieve pressure before attempting to open system for

testing or component replacement. DO NOT allow fuel to run onto engine or electrical parts while testing fuel system components.

8.1 FUEL PRESSURE RELEASE

8.1.1 Fuel Pressure must be fully released before opening fuel system or removing any fuel carrying components. To release pressure in tank,

open fuel tank cap slowly.

8.1.2 To release remaining pressure in system, disconnect fuel pump connector (electrical) in boot and crank engine.

8.2 TBI FUEL PUMP TEST

8.2.1 Release fuel pressure. Disconnect 5/16" fuel supply hose. Connect fuel system pressure Gauge between fuel supply hose and engine fuel

line.

8.2.2 Turn ignition on. Activate fuel pump. If fuel pump pressure is at specification, fuel system is functioning properly.

8.2.3 If fuel pressure is not to specification, record pressure. Install fuel pressure gauge in fuel supply line at rear of vehicle between fuel tank

and fuel filter.

8.2.4 Activate fuel pump. Record pressure reading. If fuel pressure is 5 psi higher than the first pressure reading, replace fuel filter.

8.2.5 If no change in pressure reading is observed, gently squeeze fuel return hose. If fuel pressure increases, replace fuel pressure regulator. If

no change in fuel pressure is observed, problem is plugged fuel pump filter sock or defective fuel pump.

8.2.6 If fuel pressure is more than specification, remove fuel return hose at rear of vehicle. Connect an extension hose to return hose. Place

hose in an approved container with at least a 2 gallon capacity.

8.2.7 Activate fuel pump. If fuel pressure is now within specification, check in-tank return fuel hose for kinking. Replace fuel tank assembly if

in-tank reservoir check valve or aspirator jet is plugged.

8.2.8 If fuel pressure is still more than specification, remove fuel return hose from throttle body. Connect a substitute hose to throttle body return

nipple. Place other end of hose in an approved container.

8.2.9 Activate fuel pump. If fuel pressure is at specification, check for a restricted fuel return line between throttle body and fuel tank. If no change

was observed, replace fuel pressure regulator.

NOTE: Perform fuel pump test with fuel tank at least half full. Before disconnecting a fuel line during testing, repeat fuel pressure release procedure.

8.3 PFI FUEL PUMP TEST

8.3.1 Release fuel pressure. Remove cap from service valve on fuel rail. Connect fuel system pressure Gauge to service valve.

8.3.2 Turn ignition on. Activate fuel pump. If fuel pump pressure is at specification, fuel system is functioning properly.

8.3.3 If fuel pressure is not to specification, record pressure and remove gauge. Activate pump. Ensure no fuel leaks from service valve. Install

cap on service valve.

8.3.4 If fuel pressure is not to specification, install pressure gauge in fuel supply line between fuel tank and fuel filter at rear of vehicle. Activate

fuel pump.

8.3.5 Record pressure reading. If fuel pressure is 5 psi higher than the first pressure reading, replace fuel filter. If no change in pressure reading

is observed, gently squeeze fuel return hose.

8.3.6 If fuel pressure increases, replace fuel pressure regulator. If no change in fuel pressure is observed, problem is plugged fuel pump filter

sock or defective fuel pump.

8.3.7 If fuel pressure is more than specification, remove fuel return hose at rear of vehicle. Connect an extension hose to return hose. Place hose

in an approved container with at least a 2 gallon capacity.

8.3.8 Activate fuel pump. If fuel pressure is now within specification, check in-tank return fuel hose for kinking. Replace fuel tank assembly if

in-tank reservoir check valve or aspirator jet is plugged.

8.3.9 If fuel pressure is still more than specification, remove fuel return hose from pressure regulator. Connect a substitute hose to fuel pressure

regulator. Place other end of hose in an approved container.

8.3.10 Activate fuel pump. If fuel pressure is at specification, check for a restricted fuel line. If no change was observed, replace fuel pressure

regulator.

NOTE: Perform fuel pump test with fuel tank at least half full. Before disconnecting a fuel line during testing, repeat fuel pressure release procedure.

9. FUEL PRESSURE TESTS FOR HONDA/ACURA (TYPICAL)

CAUTION: High fuel pressure may be present in fuel lines and component parts. Relieve pressure before attempting to open system for

testing or component replacement. DO NOT allow fuel to run onto engine or electrical parts, or allow an open flame in area while testing

fuel system components.

Basic diagnosis of fuel system should begin with determining fuel system pressure. If fuel pump fails to run, inspect power supply to main

relay. If all power supplies are present (i.e. battery, ignition and starter switch during cranking), perform functional test of main relay.

9.1 RELIEVING FUEL PRESSURE

9.1.1 Remove negative battery cable.

9.1.2 Loosen fuel tank filler cap.

9.1.3 Place clean shop rag around fuel filter.

9.1.4 Slowly loosen 6mm service bolt on top of fuel filter (one complete turn) to relieve system pressure.

9.1.5 Always replace washer under 6mm bolt after loosening.

9.2 PRESSURE TESTING

9.2.1 After relieving fuel pressure connect Fuel Pressure Gauge at 6mm service bolt location. Reconnect negative battery cable. Start engine

and note pressure. If vehicle will not start, has spark, and no fuel pressure is evident, inspect fuel pump main relay.

9.2.2 Disconnect vacuum hose from pressure regulator and inspect for manifold vacuum. If vacuum is not present, check for restriction in

vacuum port or hose. Plug vacuum hose and note fuel gauge reading. Gauge reading should be 36-41 psi. Pressure should have risen

slightly when vacuum hose was disconnected from pressure regulator.

9.2.3 If pressure is higher than specified, inspect for pinched or clogged fuel return line between fuel rail and fuel tank. If no problem is found

in fuel line, replace pressure regulator.

9.2.4 If pressure is lower than specified, inspect for plugged fuel filter. If filter is not plugged, lightly pinch off fuel return line. If fuel pressure

does not rise, replace fuel pump. If fuel pressure does rise, replace pressure regulator.

VSE210 - 1 - 211204

Page 5

10. FUEL PRESSURE TESTS FOR TOYOTA (TYPICAL)

CAUTION: High fuel pressure may be present in fuel lines and component parts. Relieve pressure before attempting to open system for

testing or component replacement. DO NOT allow fuel to run onto engine or electrical parts, or allow an open flame in area while testing.

10.1 FUEL PUMP QUICK TEST

10.1.1 Turn ignition on, with engine off. On all except Van, place jumper wire across"+B" and "FP" terminals of engine check connector in engine

compartment. On Van, place jumper wire across 2-wire fuel pump check connector (White/Black and Green wires) located under drivers

seat.

10.1.2 On all models, listen for fuel pump running sound. Feel for pressure in fuel line between filter and fuel rail. Turn ignition off. Remove

jumper wire. If fuel pump sound was present and fuel hose showed pressure, go to FUEL SYSTEM PRESSURE TEST.

10.1.3 If no pressure or fuel pump sound was present, on all except Van, connect a jumper wire from battery sources to "FP" terminal of engine

check connector.

10.1.4 On all except Van, if fuel pump does not run or no pressure is felt in line, check for defective fuel pump. Check for open circuit between

engine check connect and fuel pump or poor fuel pump ground.

NOTE: All models use in-tank fuel pump. Fuel pump contains internal relief valve and check valve.

10.1.5 If fuel pump ran after battery source as connected to "FP" terminal in step 3, check EFI main relay and relating wiring. Also check "EFI"and

"IGN"fuses.

10.2 FUEL SYSTEM PRESSURE TEST

NOTE: Before testing fuel pressure, check all fuel delivery and return lines for leaks.

10.2.1 Ensure battery is fully charged. Turn ignition off. On all except Pickup and 4Runner with 3VZ-E, place container or shop towel under cold

start injector. Slowly loosen cold start injector union bolt to relieve fuel pressure. Remove union bolt and 2 gaskets.

10.2.2 Install fuel pressure gauge to the cold start injector delivery pipe. Wipe off excess fuel.

10.2.3 On all except Van, install jumper wire between engine check connector "FP"and"B" pins. On Van, place jumper wire across 2-wire fuel

pump check connector (White/Black and Green wires).

10.2.4 On all models, turn ignition on, with engine off. Measure fuel pressure. Fuel pressure should be same as regulated pressure.

10.2.5 If fuel pressure is high, replace the fuel pressure regulator. If fuel pressure is low, check the following:

Fuel hoses and connections, Fuel filter, Fuel pump, Fuel pressure regulator.

10.2.6 Remove jumper wire installed in step 3. Start engine and run for 2 minutes. Disconnect vacuum sensing hose from fuel pressure regulator

and plug hose end. Fuel pressure regulator is mounted on fuel rail.

NOTE: On Celica (3S-GTE), Corolla (4A-GE), MR2, PickupMRunner, and Van it is necessary to allow engine to idle for 2 minutes to

stabilize fuel pressure. These models are equipped with a fuel pressure-up system which temporarily increases fuel pressure after a hot

start.

10.2.7 Measure regulated fuel pressure at idle speed.

10.2.8 With engine still idling, reconnect fuel pressure regulator sensing hose. Measure regulated pressure at idle.

10.2.9 If regulated pressure was not specified, check vacuum sensing hose fuel pressure regulator. On models so equipped, check fuel

pressure-up system.

10.2.10 Stop engine. Note fuel pressure. Leave fuel pressure gauge attached to engine for at least 5 minutes.

10.2.11 Residual fuel pressure after 5 minutes should be at least 21 psi (1.5 kg/cm²). If pressure is not as specified check for leaking injectors,

fuel pressure regulator or bad check valve in fuel pump.

10.2.12 Relieve fuel system pressure. Remove fuel pressure gauge. Reconnect cold start injector. Run engine and check for fuel leaks.

11. FUEL PRESSURE TESTS FOR BOSCH (TYPICAL)

CAUTION: High fuel pressure may be present in fuel lines and component parts. Relieve pressure before attempting to open system for

testing or component replacement. DO NOT allow fuel to run onto engine or electrical parts, or allow an open flame in area while testing

fuel system components.

11.1 FUEL PUMP CIRCUIT

11.1.1 Remove fuel tank cap.

11.1.2 Turn ignition on and listen for fuel pump operating sound for approximately 2 seconds. If there is not sound, check fuse, fuel pump relay,

fuel pump and all electrical connections.

11.2 VISUAL CHECK

11.2.1 Remove air cleaner and check for any visible fuel leaks.

11.2.2 Push airflow sensor plate down manually.

11.2.3 Uniform resistance should be felt throughout travel after slight amount of free travel. No binding should be felt when sensor plate is

released.

11.2.4 Upward movement of sensor plate should be slow with slight resistance from control piston adjusting lever. No binding should be felt.

Push airflow sensor plate down and hold briefly. Slight fuel seepage past control is acceptable.

12. FUEL PRESSURE TESTS FOR CIS (TYPICAL)

NOTE: Control pressure is measured with the valve open and system pressure is measured with valve closed.

12.1.1 Install Fuel Pressure Gauge and Adaptor between the fuel distributor test port and cold start valve. Ensure control lever is in the closed

position. Bleed excess air from system by cycling control valve with gauge upside down.

12.1.2 Using a jumper wire, connect terminals No. 30 and 87 on fuel pump relay. Open fuel pressure gauge control lever. Fuel pressure should

be within specification If fuel pressure is low, perform fuel volume check. If fuel volume is okay, replace fuel pressure regulator.

12.1.3 If fuel pressure is above specification, remove return hose from pressure regulator and repeat test. Fuel pressure should be within

specification. If okay, check for restricted fuel return line. If pressure is incorrect, replace fuel pressure regulator.

13. FUEL PRESSURE TESTS FOR L-JETRONIC (TYPICAL)

13.1.1 Install Fuel Pressure Gauge at fuel supply hose 3-way "T" connector.

13.1.2 Turn ignition on.

13.1.3 With fuel pump operating,minimum pressure should be within specification. if fuel pressure is incorrect, inspect for restricted fuel lines,

defective fuel pump or weak pressure regulator.

VSE210 - 1 - 211204

Page 6

14. BASIC TESTER

A. 3-1/2" Gauge Head with dual readings - 0-145 psi & 0-1000

KPA (10 Bar). Can be used for all tests.

D. Gauge Hose assembly with blow-down valve. Can be used

on all tests between the gauge and adaptors. Provides a

clean and convenient method of relieving pressure after

testing, or for a retest. Can also be used for observing

steadiness and volume of fuel.

Simply put end of clear tubing into proper container and

push the side button. Always make sure that the quick

couplers on all gauge and fitting snap firmly into place with

the locking sleeve in proper position.

AE. Low pressure 2-1/2" gauge with dual readings - 0-15psi &

0-1 kg/cm2 (1 Bar). Use for tests where an accurate

reading below 15 psi is required.

G. CIS/TBI Test Hose - use when testing CIS or TBI Systems

where in-line connections are needed. Includes shut-off

valve for both control & primary system pressure checks.

We recommend that the D Gauge Hose is used with CIS

testing, as most manufacturers require that all air be purged

from the tester when running tests.

Always make sure that the quick couplers on all gauge, hoses, and fitting snap firmly into place with the locking sleeve in proper position.

15. TEST PORT ADAPTOR

C. Small Schrader type test hose with .308 x 32 thread.

Common applications - Ford EFI.

B. Large Schrader type test hose with 7/16 x 20 thread.

Common applications include Chrysler, Jeep, and GM Test

Ports.

Always make sure that the quick couplers on all gauge, hoses, and fitting snap firmly into place with the locking sleeve in proper position.

16. IN-LINE TESTING TBI

V. . . . . . . . . . . . . . . . . . . . . . . . . . . . .5/8 x 18 Male Fitting

U. . . . . . . . . . . . . . . . . . . . . . . . .16mm x 1.5 Male Tube Nut

T. . . . . . . . . . . . . . . . . . . . . . .16mm x 1.5 Female Tube Nut

UB. . . . . . . . . . . . . . . . . . . . . . . .14mm x 1.5 Male Tube Nut

Always make sure that the quick couplers on all gauge, hoses, and fitting snap firmly into place with the locking sleeve in proper position.

UA. . . . . . . . . . . . . . . . . . . . . .14mm x 1.5 Female Tube Nut

UC. . . . . . . . . . . . . . . . . . . . .14mm x 1.5 Female Tube Nut

S. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5/8 x 18 Union

VSE210 - 1 - 211204

Page 7

17. IN-LINE TESTING - SPECIAL CONNECTIONS

X. Hair Pin Hose 5/16" - Common

Application - Ford EFI

W. Spring Lock Hose - Common

Application - Ford EFI

XA. Hair Pin Hose 3/8" - Common

Application - GM, Chrysler

F. Double Ended Barb Fitting -

Common Application - Where 5/163/8 fuel line hose can be entered for

testing - AMC, Chrysler, w/TBI, Fiat, GM

w/Bosch L-Jetronic, Jaguar, Mazda,

Nissan, Puegot & Porsche w/Bosch LJetronic, Renault, Subaru, Triumph, and

VW & Volvo w/Bosch L-jetronic.

Always make sure that the quick couplers on all gauge, hoses, and fitting snap firmly into place with the locking sleeve in proper position.

18. END OF LINE, BANJO-FUEL BOLT ADAPTORS

E. 1/4 x 3/8 - Single End Hose Connection

Common Applications - Older Port Systems with hose connection, and where

rubber hose fuel lines from 1/4"-3/8" can be accessed.

Fuel Bolt Common Applications - Accura, Honda, Hyundai, Mazda, Suzuki,

Toyota.

N. 6mm x 1.0 Thread

O. 8mm x 1.0 Thread

P. 10mm x 1.0 Thread

Q. 12mm x 1.25 Thread

R. 12mm x 1.5 Thread

RA. 14mm x 1.5 Thread

Always make sure that the quick couplers on all gauge, hoses, and fitting snap firmly into place with the locking sleeve in proper position.

19. IN-LINE TESTING CIS, CISE & K-JETRONIC

H. 8mm x 1.0 Male

HA. 8mm x 1.0 Female Long

I. 10mm x 1.0 Male

J. 10mm x 1.0 Female

K. 12mm x 1.5 Swivel Female

KA. 14mm x 1.5 Swivel Male & Female

KB. 16mm x 1.5 Swivel Male & Female

KC. 1/4 BSPT Swivel Male & Female

L. 8mm x 1.0 Female

M. 8mm x 1.0 Male

Common Applications - Audi, BMW, Mercedes, Puegot, Porshe,

Saab, VW, Volvo w/CIS, CISE, or K-Jetronic systems.

Always make sure that the quick couplers on all gauge, hoses, and fitting snap firmly into place with the locking sleeve in proper position.

VSE210 - 1 - 211204

Loading...

Loading...