Page 1

Instructions For:

VAG Code Reader

and Reset Tool

Model No: VS862

SOFTWARE VERSIONS > V2.6 (V1.9 SERIAL)

Table of Contents

1. Safety Precautions and Warnings........................................2

2. Product Information .............................................................2

2.1 Tool Description..........................................................3

2.2 Specifications...............................................................4

2.3 Accessories Included...................................................4

2.4 Navigation Characters................................................4

2.5 Keyboard .....................................................................5

2.6 Power............................................................................5

2.7 Product Setup ..............................................................5

2.8 Vehicle Coverage.......................................................10

3. Operating Instructions........................................................10

3.1 VW/AUDI Diagnostics..............................................10

3.2 OBDII/EOBD Diagnostics........................................16

3.3 Oil Service..................................................................20

4. Warranty and Service .........................................................34

4.1 Limited One Year Warranty ...................................34

4.2 Service Procedures....................................................34

< V2.6 USB-V1.9 SERIAL SOFTWARE

1

Page 2

1. Safety Precautions and Warnings

• WARNING! Ensure that Health and Safety, local authority and

general workshop practice regulations are strictly adhered to.

• DO NOT use the unit if it, or any attachment, is damaged.

• Maintain the unit in good and clean condition for best and safest

performance.

• If required, ensure that the vehicle to be worked on is adequately

supported with axle stands or ramps and is chocked.

• Put transmission in PARK (for automatic transmission) or

NEUTRAL (for manual transmission) and make sure the parking

brake is engaged.

• Wear approved eye protection. A full range of personal safety

equipment is available from your Sealey dealer.

• 3Wear suitable clothing to avoid snagging. Do not wear jewellery

and tie back long hair.

• WARNING! Use extreme caution when working around the

ignition coil, distributor cap, ignition wires and spark plugs. These

components create hazardous voltages when the engine is running.

• DO NOT connect or disconnect any test equipment with ignition

on or engine running.

• Keep a fire extinguisher suitable for gasoline/chemical/ electrical

fires nearby.

• Account for all tools and parts being used and do not leave them

on or near the engine.

• Keep code reader dry, clean and free from oil, water and grease.

Use a mild detergent on a clean cloth to clean the outside of the

tool.

• Operate the vehicle in a well-ventilated work area; exhaust gases

are poisonous.

IMPORTANT: Always refer to the vehicle manufacturer’s service

instructions to establish the current procedure and data. These instructions are

provided as a guide

only.

< V2.6 USB-V1.9 SERIAL SOFTWARE

2

Page 3

2. Product Information

2.1 Tool Description

① LCD DISPLAY -- Indicates test results. Backlit, 128 x 64 pixel

display with contrast adjustment.

② Y BUTTON -- Confirms a selection (or action) from a menu.

When a DTC’s definition covers more than one screen, it is used

to move down to the next screen for additional data.

③ N BUTTON -- Cancels a selection (or action) from a menu or

returns to the menu. It is also used to set up the unit when being

pressed and held for at least 3 seconds.

< V2.6 USB-V1.9 SERIAL SOFTWARE

3

Page 4

④ UP SCROLL BUTTON -- Moves up through menu and

submenu items in menu mode. When more than one DTC is

retrieved, moves up through the current screen to the previous

screens for additional DTCs and definitions.

⑤ DOWN SCROLL BUTTON -- Moves down through menu

and submenu items in menu mode. When more than one DTC is

retrieved, moves down through the current screen to the next

screens for additional DTCs and definitions.

⑥ OBD II CONNECTOR -- Connects the scan tool to the vehicle’s

Data Link Connector (DLC).

2.2 Specifications

1) Display: Backlit, 128 x 64 pixel display with contrast adjustment

2) Operating Temperature: 0 to 50°C (32 to 122 F°)

3) Storage Temperature: -20 to 70°C (-4 to 158 F°)

4) External Power: 8.0 to 15.0 Volts provided via vehicle battery

5) Dimensions:

Length Width Height

178 mm (7.00”) 95 mm (3.75”) 34 mm (1.35”)

6) NW: 0.70kg (1.54lb), GW: 1.0kg(2.20lb)

2.3 Accessories Included

1) User’s Manual -- Instructions on tool operations

2) OBD2 cable -- Provides power to tool and communicates

between tool and vehicle

3) USB Cable -- Used to upgrade the scan tool

4) Carry Case -- A nylon case to store the scan tool when not in use.

2.4 Navigation Characters

Characters used to help navigate the scan tool are:

1) “►” -- Indicates current selection.

2) “↓” -- A flashing down arrow indicates additional information is

available on the next screen.

3) “↑” -- A flashing up arrow indicates additional information is

available on the previous screen.

< V2.6 USB-V1.9 SERIAL SOFTWARE

4

Page 5

4) “pd” -- Identifies a pending DTC when viewing DTCs.

2.5 Keyboard

No solvents such as alcohol are allowed to clean the keypad or

display. Use a mild nonabrasive detergent and a soft cotton cloth. Do

not soak the keypad as the keypad is not waterproof.

2.6 Power

The external power of the scan tool is provided via the vehicle Data

Link Connector (DLC). Just follow the steps below to turn on the scan

tool:

1) Connect the OBD II Cable to scan tool.

2) Find DLC on vehicle.

A plastic DLC cover may be found for some vehicles and you

need to remove it before plugging the OBD2 cable.

3) Plug OBD II Cable to the vehicle’s DLC.

2.7 Product Setup

The scan tool allows you to make the following adjustments and

settings:

1) Contrast Adjustment: Adjusts the contrast of the LCD display.

2) Display Test: Tests the LCD display.

3) Keyboard Test: Tests the keyboard.

To enter the setup menu mode

1) From the keyboard: Press and hold the N button for at least 3

seconds until the System Setup menu shows up. Follow the

instructions to make adjustments and settings as described in the

following setup options.

< V2.6 USB-V1.9 SERIAL SOFTWARE

5

Page 6

2) From the Main Menu: Use the UP/DOWN Scroll Buttons to

select System Setup and then press the Y button. Follow the

instructions to make adjustments and settings as described in the

following setup options.

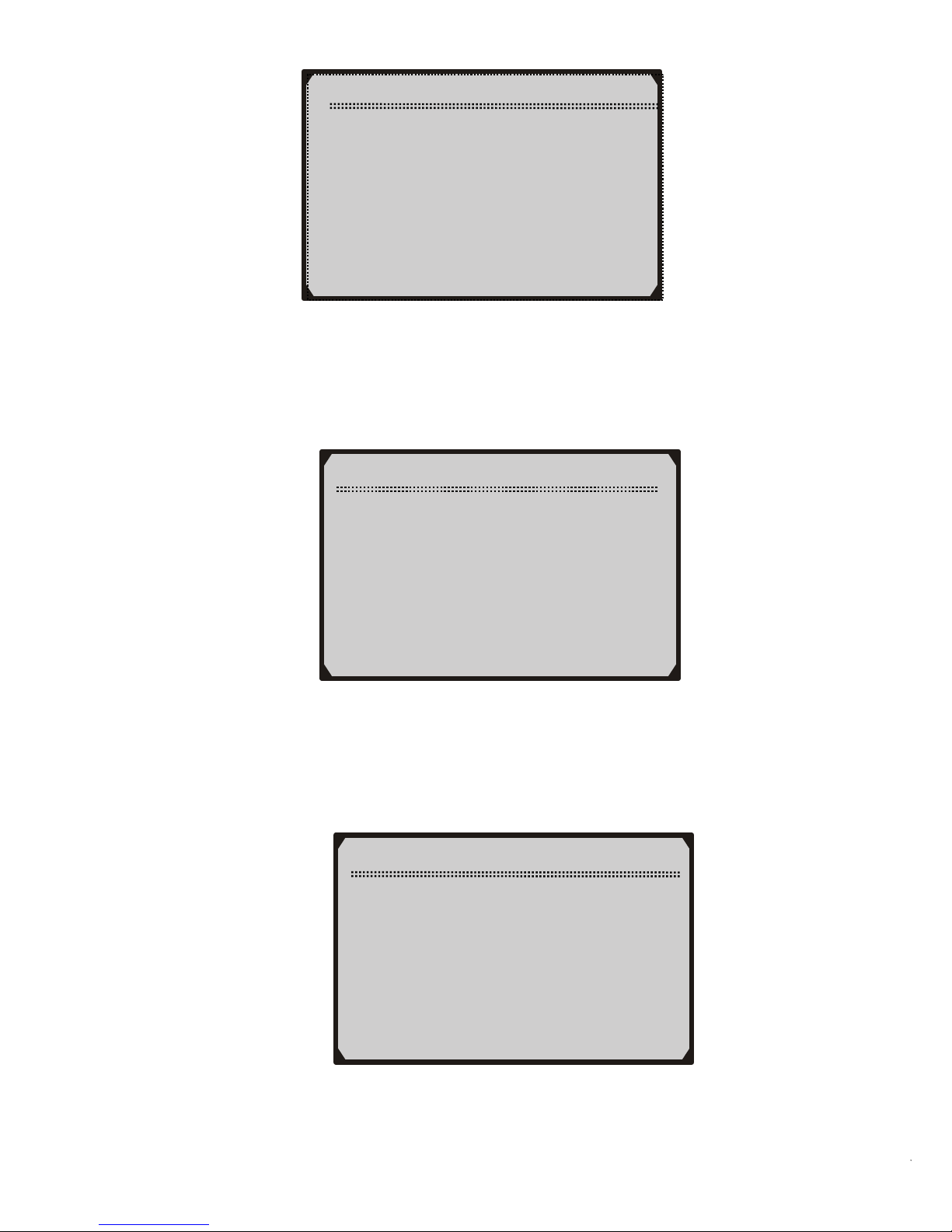

Contrast Adjustment

1) From the System Setup menu, use the UP/DOWN scroll buttons

to select Contrast, and press the Y button.

System Setup

►1) Contrast

2) Display Test

3) Keyboard Test

Main Menu

1) VW/AUDI

2) OBDII/EOBD

3) Oil Service

►4) System Setup

System Setup

►1) Contrast

2) Display Test

3) Keyboard Test

4) Unit of Measure

< V2.6 USB-V1.9 SERIAL SOFTWARE

6

Page 7

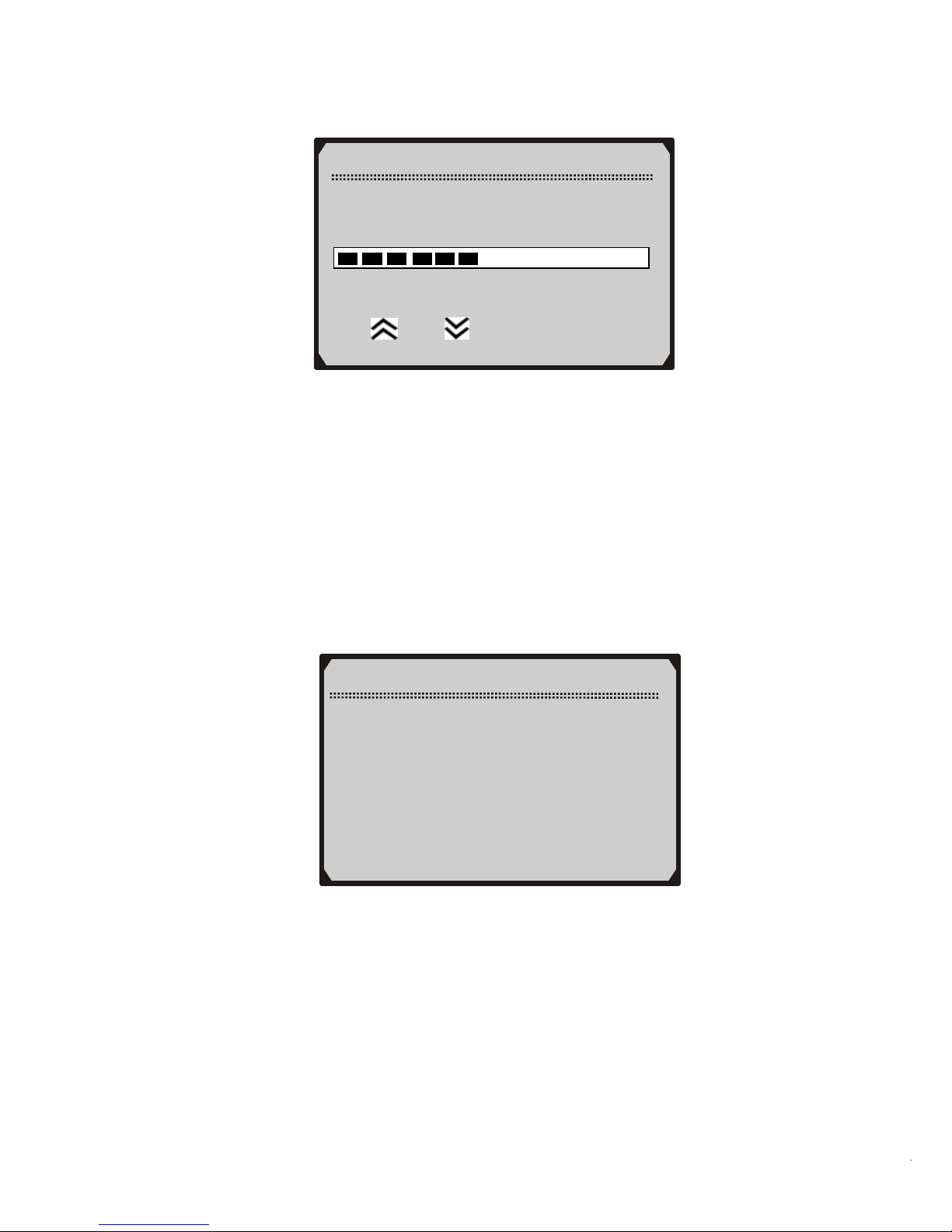

From the Contrast menu, use the UP/DOWN scroll buttons to increase or

decrease the contrast.

2) Press the Y button to save your selection and return to previous

menu.

3) Press the N button to return to previous menus.

Display Test

The Display Test is used to check the LCD display.

1) From the System Setup menu, use the UP/DOWN scroll buttons

to select

Display Test and press the Y button.

Contrast

Contrast (45%)

Use

or to change

System Setup

1) Contras

t

►2) Display Test

3) Keyboard Test

4) Unit of Measure

2) Press the Y button again to start test. Look for missing spots in

the solid black characters.

< V2.6 USB-V1.9 SERIAL SOFTWARE

7

Page 8

3) When completed, press the N button to return.

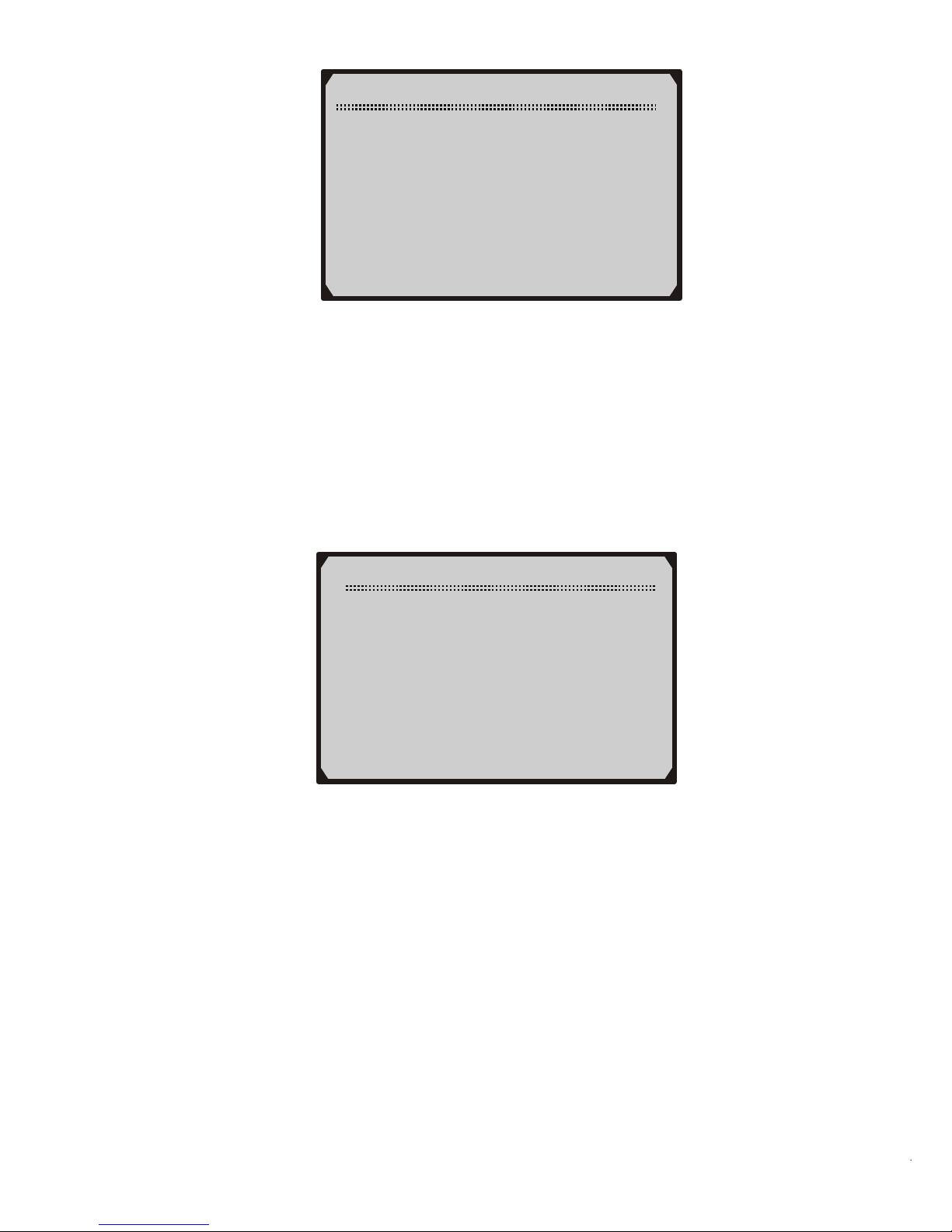

Keyboard Test

The Keyboard Test is used to verify that the keys are functioning

properly.

1) Use the UP/DOWN scroll buttons to select Keyboard Test from

System Setup menu, and then press Y button.

Display Test

Press [Y] to test.

Look for missing

spots in characters.

Press <N> to return.

System Setup

1) Contras

t

2) Display Test

►3) Keyboard Test

4) Unit of Measure

2) Press any key to start test. When you press a key, the key name

should be observed on the display. If the name does not show up,

then the key is not functioning properly.

< V2.6 USB-V1.9 SERIAL SOFTWARE

8

Page 9

Keyboard Test

Press any key to

Start test to

display name.

Key:

Double [N] to Return

3) Double press N to return to the previous menu.

Unit of Measure

The Unit of Measure function is used to change between metric

and English unit of measurement.

1) Use the UP/DOWN scroll buttons to select Unit of Measure

from System Setup menu, and then press Y button.

2) From Unit of Measure menu, use UP/DOWN scroll button to

select the desired unit of measurement.

System Setup

1) Contras

t

2) Display Test

3) Keyboard Test

►4) Unit of Measure

Unit of Measure

01) English

►02) Metric

< V2.6 USB-V1.9 SERIAL SOFTWARE

9

Page 10

2.8 Vehicle Coverage

The V862 VW/AUDI Code Scanner is specially designed to work

with most Volkswagen and

Audis sold worldwide of 1990 or newer

models. If a VW/AUDI has a 16-pin "OBD-II style" Data Link

Connector (DTC), the code reader will certainly work. If it has an oldstyle 2x2 Data Link Connector (DTC), then it depends on whether

there are 4 or 3 wires connecting to the pins. If there are 4 wires, each

connecting a pin, then it will work. If there are only 3 wires, leaving

one pin disconnected, then it will not work.

For VW/AUDI with old-style 2x2 Data Link Connector (DTC), you

need to have a 2x2 cabling adapter which is not included in this

product package.

3. Operating Instructions ons

3.1 VW/AUDI Diagnostics

Reading Codes

CAUTION: Don’t connect or disconnect any test equipment with

ignition on or engine running.

1) Turn the ignition off.

2) Locate the vehicle’s 16-pin Data Link Connector (DLC).

3) Plug the OBDII connector to the vehicle’s DLC.

4) Turn the ignition on. But do not start the engine.

5) Press the Y button. The Main Menu will be observed on the

display.

6) Use the UP/DOWN scroll buttons to select VW/AUDI from the

menu and press the Y button.

< V2.6 USB-V1.9 SERIAL SOFTWARE

10

Page 11

7) Use the UP/DOWN scroll buttons to select the system from the

Select System menu and press the Y button.

Main Menu

►1) VW/AUDI

2) OBDII/EOBD

3) Oil Service

4) System Setup

Select System

►01) Engine

02) Auto Trans

15) Airbags

03) ABS Brakes

08) Auto HVAC

09) Cent. Elect.

If the scan tool fails to communicate with the selected

vehicle’s ECU (Electronic Control Unit), a “LINK

ERROR!” message shows up on the display.

Verify that the ignition is ON;

Check if the scan tool’s OBD II connector is securely

connected to the vehicle’s DLC;

Verify that the module is supported;

Turn the ignition off and wait for about 10 seconds. Turn the

ignition back to on and repeat the procedure from step 5.

If the “LINK ERROR” message does not go away, then

there might be problems for the scan tool to communicate

with the module being tested. The most common cause is

that the scanned module is not supported on the vehicle.

The numbers (01, 02, 15, 03, 08, etc) in front of the system

names refer to the physical addresses assigned to the systems,

not the sequence of the systems to be arranged.

< V2.6 USB-V1.9 SERIAL SOFTWARE

11

Page 12

8) Select Read Codes from the Select Function menu and press the

Y button.

Select Function

►1) Read Codes

2) Erase Codes

3) ECU Information

4) Readiness Test

If there are no Diagnostic Trouble Codes present, the display

will indicate “NO CODES ARE STORED IN THE

MODULE!”

● If there are any Diagnostic Trouble Codes present, the DTC

number and its definition will show on the LCD display.

● The sub-code, the communication protocol, the sequence of

the DTC currently being observed and the total number of

codes detected will be observed on the upper right hand

corner of the display.

● When a DTC’s definition covers more than one display

screen, use the Y button, as necessary, to view any additional

information.

If the DTC definition is not available, an advisory message

prompting you to refer to the vehicle service manual will be

observed on the display.

If more than one DTC is found, use the UP/DOWN scroll

buttons, as necessary, until all the codes have been shown up.

< V2.6 USB-V1.9 SERIAL SOFTWARE

12

Page 13

Erasing Codes

CAUTION: Erasing the Diagnostic Trouble Codes may allow the

scan tool to delete not only the codes from the vehicle’s on-board

computer, but also “Freeze Frame” data and manufacturer specific

enhanced data. Further, the I/M Readiness Monitor Status for all

vehicle monitors is rese t to Fail status. Do not erase the codes before

the system has been checked completely by a technician.

16627 --100 01/10

CAN BUS

↓

Solenoid Valve (A)

For Boost Pressure

Control (N75):

Malfunction: P0243

1) If you decide to erase the DTCs, use the UP/DOWN scroll

buttons to select Erase Codes from Select Function menu and

press the Y button.

Select Function

1) Read Codes

►2) Erase Codes

3) ECU Information

4) Readiness Test

If the scan tool is not connected or no communication is

established with the vehicle yet, then refer to Reading Codes

from 1 to 7 at Paragraph 3.1.

2) A warning message comes up asking for your confirmation.

< V2.6 USB-V1.9 SERIAL SOFTWARE

13

Page 14

3) If you do not want to proceed with erasing the codes, press the N

button to exit. A message of “command cancelled” will show up.

4) If you do wish to proceed to erase the codes, then press the Y

button.

5) If the codes are cleared successfully, an “ERASE DONE!”

confirmation message will show on the display. Press any button

to return to the previous menus.

6) If the codes are not cleared, then an “ERASE FAILURE!”

message will appear. Press the N button to return to previous

menus.

Viewing ECU Information

1) To view ECU Information, use the UP/DOWN scroll buttons

to select ECU

Information from Select Function menu and

press the Y button.

Erase Codes

Erase Trouble Codes!

Are you sure?

<YES> NO

Select Function

1) Read Code

2) Erase Code

►3) ECU Information

4) Readiness Test

● If the scan tool is not connected or no communication is

established with the vehicle yet, then refer to Reading Codes

from 1 to 7 at Paragraph 3.1.

< V2.6 USB-V1.9 SERIAL SOFTWARE

14

Page 15

ECU Information

VAG No.: 06A906032TF

Component:

Bosch 1.815VT

0020

Coding: 0008570

Imp: 0000 WSC: 000078

If there is no ECU Information available, a warning message

shows on the display.

2) Press the N button to return to previous menus.

Readiness Test

Important: The Readiness Test function is used to check the

operations of the Emission System on OBD2/EOBD compliant

vehicles. It is an excellent function to use prior to having a vehicle

inspected for compliance to an emissions program.

“Pass” -- Indicates that a particular monitor being checked has

completed its diagnostic testing.

“Fail” -- Indicates that a particular monitor being checked has

not completed its diagnostic testing or the monitor is not

supported on that vehicle.

1) Use the UP/DOWN scroll buttons to select Readiness Test from

Select Function menu and press the Y button.

Select Function

1) Read Code

2) Erase Code

3) ECU Information

►4) Readiness Test

If the scan tool is not connected yet, then refer to Reading

Codes from 1 to 7 at Paragraph 3.1.

< V2.6 USB-V1.9 SERIAL SOFTWARE

15

Page 16

2) Use the UP/DOWN scroll buttons, as necessary, to view the status

of the following monitors:

EGR Sys.-- EGR System Monitor

O2 Sensor(s) -- O2 Sensors Monitor

Catalyst -- Catalyst Monitor

EVAP Sys. -- Evaporative System Monitor

Heated O2 --O2 Sensor Heater Monitor

Sec Air Inject -- Secondary Air Monitor

A/C -- A/C system Monitor

Catalytic Conv. -- Catalytic Convertor Monitor

Readiness Test

↓

EGR Sys. Pass

Heated O2 Pass

O2 Sensor(s) Pass

A/C Pass

Sec. Air Inject Pass

EVAP Sys. Fail

3) Press the N button to return to previous menus.

3.2 OBDII/EOBD Diagnostics

Reading Codes

CAUTION: Don’t connect or disconnect any test equipment with

ignition on or engine running.

1) Turn the ignition off.

2) Locate the vehicle’s 16-pin Data Link Connector (DLC).

3) Plug the OBDII connector to the vehicle’s DLC.

4) Turn the ignition on. But do not start the engine.

5) Press the Y button. The Main Menu will be observed on the

display.

6) Use the UP/DOWN scroll buttons to select OBDII/EOBD from

the menu.

< V2.6 USB-V1.9 SERIAL SOFTWARE

16

Page 17

Main Menu

1) VW/AUDI

►2) OBDII/EOBD

3) Oil Service

4) System Setup

7) Press the Y button. A sequence of messages showing the

OBDII/EOBD protocols will be observed on the display until the

vehicle protocol is detected.

If the scan tool fails to communicate with the vehicle’s ECU

(Engine Control Unit), a “LINK ERROR!” message shows

up on the display.

Verify that the ignition is ON;

Check if the scan tool’s OBD II connector is securely

connected to the vehicle’s DLC;

Verify that the vehicle is OBDII/EOBD compliant;

Turn the ignition off and wait for about 10 seconds. Turn the

ignition back to on and repeat the procedure from step 5.

If the “LINK ERROR” message does not go away, then there

might be problems for the scan tool to communicate with the

vehicle. Contact your local distributor or the Sealey’s

customer service department for assistance.

8) After the vehicle protocol is displayed on the screen, press any key or

wait about 2 seconds for the OBDII/EOBD DIAG. menu to come up.

9) Use the UP/DOWN scroll buttons to select Read Codes from the

menu and press the Y button.

< V2.6 USB-V1.9 SERIAL SOFTWARE

17

Page 18

OBDII/EOBD DIAG.

►1) Read Codes

2) Erase Codes

If there are no Diagnostic Trouble Codes present, the display

will indicate “NO CODES ARE STORED IN THE

MODULE!”

If there are any Diagnostic Trouble Codes present, the Fault

Codes and Pending Codes will be reported on the display.

P0118 Pd 06/06

ISO9141 $09

↓

Pressure Control

Solenoid A Control

Circuit Low

● The DTC number will appear on the upper left hand corner

and its definition will show on the body of screen.

● The type of code (Generic or Manufacturer specific), the

vehicle protocol, the sequence of the DTC currently being

observed, the total number of codes detected and the module

ID will be observed on the upper right hand corner of the

display.

● If the code being displayed is a pending code, the Pd icon will

be observed next to the DTC number on the upper right hand

corner of the display.

● When a DTC’s definition covers more than one display screen,

use the Y button, as necessary, to view any additional

information.

< V2.6 USB-V1.9 SERIAL SOFTWARE

18

Page 19

If the retrieved DTCs contain any manufacturer specific or

enhanced codes, you will be prompted to refer to the CD DTC

library or the vehicle service manual to view the DTC

definitions.

10) If more than one DTC is found, use the UP/DOWN scroll buttons,

as necessary, until all the codes have been shown up.

Erasing Codes

1) If you decide to erase the DTCs, use the UP/DOWN scroll

buttons to select Erase Codes from the

OBDII/EOBD DIAG.

menu and press the Y button.

If the scan tool is not connected or no communication is

established with the vehicle yet, then refer to Reading Codes

from 1 to 8 at Paragraph 3.2.

2) A warning message comes up asking for your confirmation.

OBDII/EOBD DIAG.

►1) Read Codes

2) Erase Codes

Erase Codes

Erase Trouble Codes!

Are you sure?

<YES> NO

3) If you do not want to proceed with erasing the codes, press the N

button to exit. A message of “command cancelled” will show up.

< V2.6 USB-V1.9 SERIAL SOFTWARE

19

Page 20

4) If you do wish to proceed to erase the codes, then press the Y

button.

5) If the codes are cleared successfully, an “ERASE DONE!”

confirmation will show on the display. Press any button to return

to previous menus.

6) If the codes are not cleared, then an “ERASE FAILURE!”

message will appear. Press the N button to return to previous

menus.

3.3 Oil Service

1) Turn the ignition off.

2) Locate the vehicle’s 16-pin Data Link Connector (DLC).

3) Plug the OBDII connector to the vehicle’s DLC.

4) Turn the ignition on. But do not start the engine.

5) Press the Y button. The Main Menu will be observed on the

display.

6) Use UP/DOWN scroll button to select Oil Service from the menu,

and press the Y button.

Main Menu

1) VW/AUDI

2) OBDII/EOBD

►3) Oil Service

4) System Setup

If the scan tool fails to communicate with the vehicle, a

“LINK ERROR!” message shows up on the display.

Verify that the ignition is ON;

Check if the scan tool’s OBD II connector is securely

connected to the vehicle’s DLC;

Turn the ignition off and wait for about 10 seconds. Turn the

ignition back on.

< V2.6 USB-V1.9 SERIAL SOFTWARE

20

Page 21

If the “LINK ERROR” message does not go away, then

there might be problems for the scan tool to communicate

with the vehicle. Contact your local distributor or the

manufacturer’s customer service department for assistance.

A. Automatic Vehicle Detect

1) Use UP/DOWN scroll button to select All, and press Y button.

Oil Service

►1) All

2) Audi(up to 2000)

3) VW(up to 2000)

4) Seat(up to 2000)

5) Skoda(up to 2000)

All option can be used to detect all VAG vehicles before and

after 2000 automatically.

Automatic Services Detect

The Auto Detect function is used to detect services automatically.

2) Use UP/DOWN scroll button to select Auto Detect and press Y

button to confirm.

Oil Service

►1) Auto Detect

2) Longlife Oil

3) Non Longlife Oil

4) Set Insp. Interval

3) Wait a few seconds till the following screen shows.

< V2.6 USB-V1.9 SERIAL SOFTWARE

21

Page 22

4) Use UP/DOWN button to select oil type that your vehicle uses

and press Y button.

Oil Type

►01) Fixed Service

02) Flexible-Gasoline

03) Flexible-Diesel

Select Function

►01) Oil Insp. Light

02) Set Insp. 1

03) Set Insp. 2

Different vehicle supports different oil service functions, so

the displayed functions vary from one vehicle to another.

5) Select the oil service function that your vehicle supports and

press Y button. Wait a few seconds while the scan tool is

performing service resetting.

Oil Insp. Light

Service setting…

-Please Wait-

6) A message “RESET OK” comes up, indicating oil service reset is

completed.

< V2.6 USB-V1.9 SERIAL SOFTWARE

22

Page 23

Oil Service

RESET OK!

Press any key to cont.

7) If the vehicle can not be detected automatically, following screen

shows. You need to perform oil service setup manually.

Oil Service

Can’t Auto Detect!

Please try others!

8) Wait a few seconds or press any key to start reading channel data.

Press any key to con.

Manual

Reading Channel Data…

-Please Wait-

9) Use UP/DOWN button to change set value.

< V2.6 USB-V1.9 SERIAL SOFTWARE

23

Page 24

x/x to the upper right part of the screen indicates total number

of supported service channels and the sequence of current

channel.

10) Use N button to move to next setup screen.

Min Mil. to Service

1/3

Channel No 42 (Mil)

Current Value 9000

Set Value 9000

[N] = Next, [Y] = Save/Exit

[

︽]/[︾] = Change Setup

Mil. Since Service

2/3

Channel No 40 (Mil)

Current Value 700

Set Value 700

[N] = Next, [Y] = Save/Exit

[

︽]/[︾] = Change Setup

Different vehicle supports different oil service channels, so

retrieved channel numbers vary from one vehicle to another.

Normally, a vehicle supports 1-5 channels.

“Current Value” is the value of the most recent setup

retrieved by the scan tool. If you change your mind after

making new setups, it can be used to reset all changed values

to the original ones. Write down this value before making any

changes.

11) Use UP/DOWN scroll button to select Save and press Y button

to save your settings.

< V2.6 USB-V1.9 SERIAL SOFTWARE

24

Page 25

If you want to continue to set values, use UP/DOWN scroll

button to select Back and press Y button to return to continue

setup. If you want to cancel all setups, use UP/DOWN scroll

button to select Exit and press Y button, or simply press N

button to exit.

12) Wait a few seconds till the “RESET OK!” message comes up.

Press any key to return to Main Menu.

Manual Setup

RESET OK!

Press any key to con.

Oil Service

Back Save Exit

[Back] = Cont. to Set

[Save] = Save Setup

[Exit] = Cancel Setup

Resetting Long Life Oil Service

The Long Life Oil function is used to reset Long Life oil service.

1) Use UP/DOWN scroll button to select Long Life Oil from the

menu, and press Y button.

< V2.6 USB-V1.9 SERIAL SOFTWARE

25

Page 26

Oil Service

1) Auto Detect

►2) Longlife Oil

3) Non Longlife Oil

4) Set Insp. Interval

2) Use UP/DOWN scroll button to select Service Reset from Long

Life Oil menu, and press Y button.

Longlife Oil

►1) Service Reset

2) Set Oil Type

3) View Oil Type

3) Press any key to return to Long Life Oil menu.

Service Reset

RESET OK!

Press any key to con.

4) To set oil type, use UP/DOWN scroll button to select Set Oil

Type from Long Life Oil menu, and press Y button.

< V2.6 USB-V1.9 SERIAL SOFTWARE

26

Page 27

Set Oil Type

►1) Diesel

2) V6Tdi

3) Petrol

4) Non Longlife Oil

5) Use UP/DOWN scroll button to select the oil type your vehicle

uses.

6) Press any key to return to Long Life Oil menu.

7) To view oil type, use UP/DOWN scroll button to select View Oil

Type from Long Life Oil menu, and press Y button.

Longlife Oil

1) Service Reset

2) Set Oil Type

►3) View Oil Type

Oil Type Reset

RESET OK!

Press any key to con.

8) View oil type on screen and press any key to return to Long Life

Oil menu.

< V2.6 USB-V1.9 SERIAL SOFTWARE

27

Page 28

View Oil Type

Non longlife Oil

Press any key to con.

Resetting Non Long Life Oil Service

The Non Long Life Oil function is used to reset non Long Life oil

service.

1) To reset non Long Life oil service, use UP/DOWN scroll button

to select Non Long Life Oil from the Oil Service menu, and

press Y button.

Oil Service

1) Auto Detect

►2) Longlife Oil

3) Non Longlife Oil

4) Set Insp. Interval

2) Use UP/DOWN scroll button to select Service Reset from

Non Long Life Oil menu, and press Y button.

N

on Longlife Oil

►1) Service Reset

3) Press any key to return to previous menu.

< V2.6 USB-V1.9 SERIAL SOFTWARE

28

Page 29

Service Reset

RESET OK!

Press any key to con.

Setting Inspection Interval

The Set Insp. Interval function is used to set oil service interval of

different channels.

1) Use UP/DOWN scroll button to select Set Insp. Interval, and

press Y button.

2) Wait a few seconds till the following screen shows.

3) If the oil service reset is not automatically performed by the scan

tool, the following screen appears. You need to perform manual

setup.

Oil Service

RESET OK!

Oil Service

1) Auto Detect

►2) Longlife Oil

3) Non Longlife Oil

4) Set Insp. Interval

Press any key to con.

< V2.6 USB-V1.9 SERIAL SOFTWARE

29

Page 30

Manual

Reading Channel Data…

-Please Wait-

4) Use UP/DOWN scroll button to change set value.

5) Use N button to move to next setup screen.

Min Mil. to Service

1/3

Channel No 42 (Mil)

Current Value 9000

Set Value 9000

[N] = Next, [Y] = Save/Exit

[

︽]/[︾] = Change Setup

Mil. Since Service

2/3

Channel No 40 (Mil)

Current Value 700

Set Value 700

[N] = Next, [Y] = Save/Exit

[

︽]/[︾] = Change Setup

6) Use UP/DOWN scroll button to select Save and press Y button

to save your settings.

< V2.6 USB-V1.9 SERIAL SOFTWARE

30

Page 31

7) Press any key to return to Main Menu.

Manual Setup

RESET OK!

Press any key to con.

Oil Service

Back Save Exit

[Back] = Cont. to Set

[Save] = Save Setup

[Exit] = Cancel Setup

If you want to continue to set values, use UP/DOWN scroll

button to select Back and press Y button to continue to change

set values. If you want to cancel all setups, use UP/DOWN

scroll button to select Exit and press Y button, or simply press

N button to exit.

B. Manual Vehicle Selection

1) If you want to select vehicle manually, use UP/DOWN scroll

button to select Oil Service from Main Menu, and press the Y

button.

< V2.6 USB-V1.9 SERIAL SOFTWARE

31

Page 32

Main Menu

1) VW/AUDI

2) OBDII/EOBD

►3) Oil Service

4) System Setup

2) Use UP/DOWN scroll button to select vehicle make, and press Y

button to confirm.

Oil Service

1) All

2) Audi(up to 2000)

►3) VW(up to 2000)

4) Seat(up to 2000)

5) Skoda(up to 2000)

3) Use UP/DOWN scroll button to select vehicle model year, and

press Y button to confirm.

Select Vehicle

↓

01) Golf 3

02) Golf 4

►03) New Beetle

04) Passat

05) Passat B5

06) Passat 97

4) Use UP/DOWN scroll button to select the oil service function

that your vehicle supports.

< V2.6 USB-V1.9 SERIAL SOFTWARE

32

Page 33

Select Function

►01) Oil Insp. Light

02) Set Insp. 1

03) Set Insp. 2

5) Wait a few seconds till the following screen appears.

Oil Service

RESET OK!

Press any key to con.

If a message “Service reset failed!” comes up, repeat the

procedure from Step 3 or use Auto Detect to detect service

automatically.

If the message “Service reset failed!” does not go away,

Verify that the ignition is ON;

Check if the scan tool’s OBD II connector is securely

connected to the vehicle’s DLC;

Turn the ignition off and wait for about 10 seconds. Turn the

ignition back on.

If the scan tool still fails to perform oil service reset, contact

your local distributor or the manufacturer’s customer service

department for assistance.

< V2.6 USB-V1.9 SERIAL SOFTWARE

33

Page 34

4. Warranty and Service

4.1 Limited One Year Warranty

Sealey warrants to its customers that this product will be free from all

defects in materials and workmanship for a period of one (1) year from

the date of the original purchase, subject to the following terms and

conditions:

1) The sole responsibility of Sealey under the Warranty is limited to

either the repair or, at the option of Sealey, replacement of the code

reader at no charge with Proof of Purchase. The sales receipt may

be used for this purpose.

2) This warranty does not apply to damages caused by improper use,

accident, flood, lightning, or if the product was altered or repaired

by anyone other than the Manufacturer’s Service Center.

3) Sealey shall not be liable for any incidental or consequential

damages arising from the use, misuse, or mounting of the code

reader.

4) All information in this manual is based on the latest information

available at the time of publication and no warranty can be made

for its accuracy or completeness. Sealey reserves the right to make

changes at any time without notice.

4.2 Service Procedures

If you have any questions, please contact your local store, distributor

or visit our website at www.sealey.co.uk

If it becomes necessary to return the scan tool for repair, contact your

local distributor for more information.

NOTE: It is our policy to continually improve products and as such we reserve the right to

alter data, specifications and component parts without prior notice. IMPORTANT: No

liability is accepted for incorrect use of product. WARRANTY: Guarantee is 12 months

from purchase date, proof of which will be required for any claim.

INFORMATION: For a copy of our latest catalogue and promotions call us on

01284 757525 and leave your full name and address, including postcode.

< V2.6 USB-V1.9 SERIAL SOFTWARE

34

Loading...

Loading...