Sealey VS7023a Instructions For

Thank you for purchasing a Sealey Product. Manufactured to a high standard this product will, if used according to these instructions

and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL

REQUIREMENTS, WARNINGS AND CAUTIONS. USE THIS PRODUCT CORRECTLY AND WITH CARE FOR THE

PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR PERSONAL INJURY

AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

INSTRUCTIONS FOR:

BEARING & BUSH REMOVAL/

INSTALLATION KIT 26pcs

MODEL No: VS7023A

1.1 GENERAL SAFETY

WARNING! Ensure Health & Safety, local authority, and general

workshop practice regulations are adhered to when using this

tool.

WARNING! Familiarise yourself with the specific applications

and limitations of the kit, as well as any potential hazards.

This kit should be used in conjunction with inspection

maintenance procedures recommended in the vehicle

manufacturer’s manual.

Ensure that the kit is correct for the task.

Wear the appropriate personal protective equipment for the

task. A full range is available from your Sealey dealer.

DO NOT use the kit for any purpose other than that for which it

is designed.

Ensure that the vehicle is properly supported with axle stands

before working under the vehicle.

Ensure there is adequate lighting prior to using the kit. A range

of inspection lamps are available from your Sealey dealer.

Keep children and unauthorised persons away from the working

area.

DO NOT use the kit if any parts are damaged or missing, as this

may cause failure and/or personal injury.

DO NOT use the kit when you are tired, or under the influence of

alcohol, drugs or intoxicating medication.

After use, store in a safe, dry childproof area.

ALWAYS KEEP FORCE SCREW

WELL LUBRICATED. MOLYBDENUM/

COPPER BASED RECOMMENDED.

DO NOT USE AIR TOOLS

1. SAFETY INSTRUCTIONS

2. INTRODUCTION

The force screw maximum recommended torque is 155Nm (M16X1.5), 99Nm (M14X1.5), 60Nm (M12X1.5), 33Nm (M10X1.5). Exceeding these

torque values may shorten the life of the force screws. The force screws are considered to be consumable items and are NOT covered

under warranty.

Comprehensive kit for fast and effective in-situ removal/installation of wheel bearings/suspension bushes and seals.

Reduces the possibility of damaging the bearing/suspension housings. Supplied with 4 stepped end plates and 4 force

screws in carry case. Plates and sleeves can also be used in a standard workshop press when in-situ access isn't

possible.

3. CONTENTS

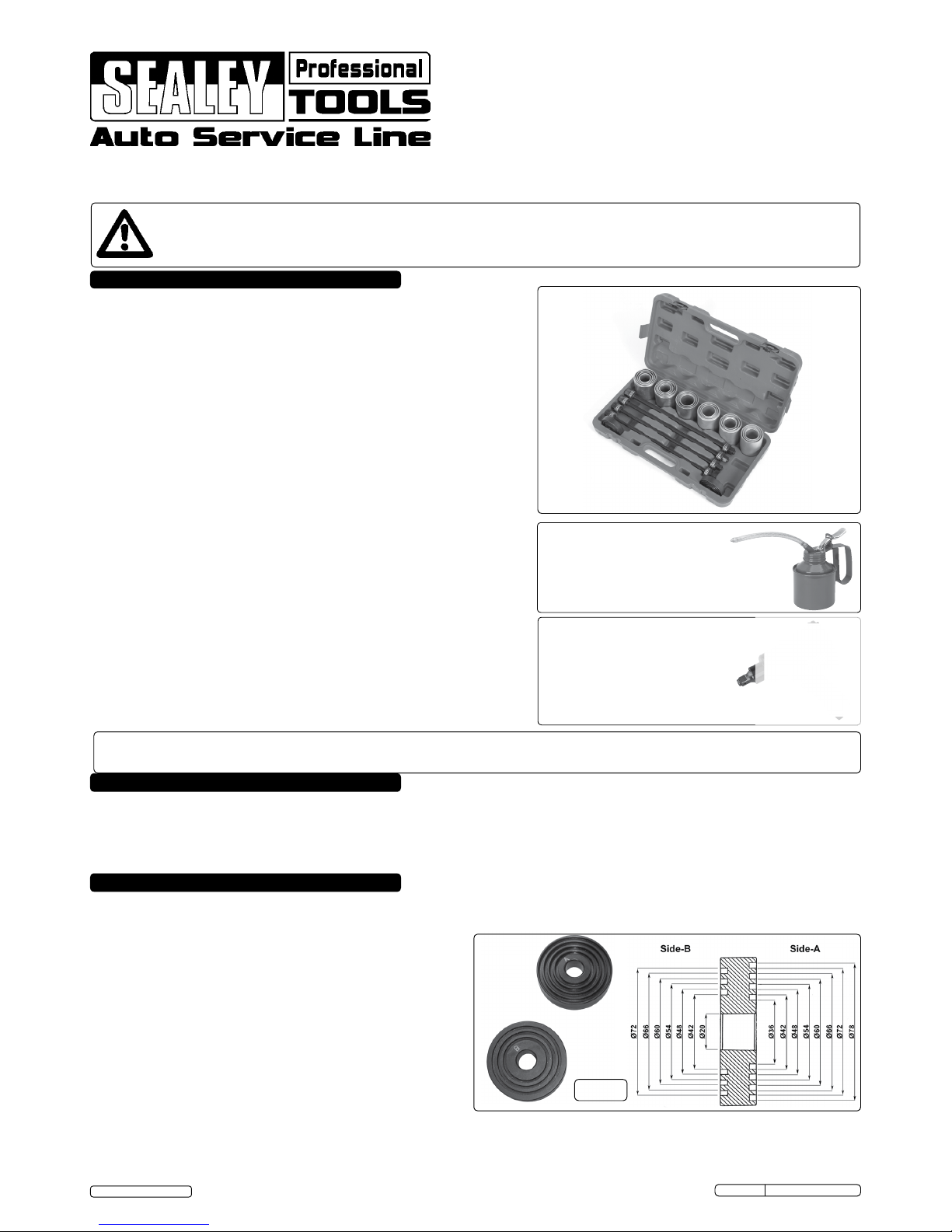

3.1 End Plates (Fig.1)

Two plates with each one having a stepped side

marked 'A' and a stepped side marked 'B'

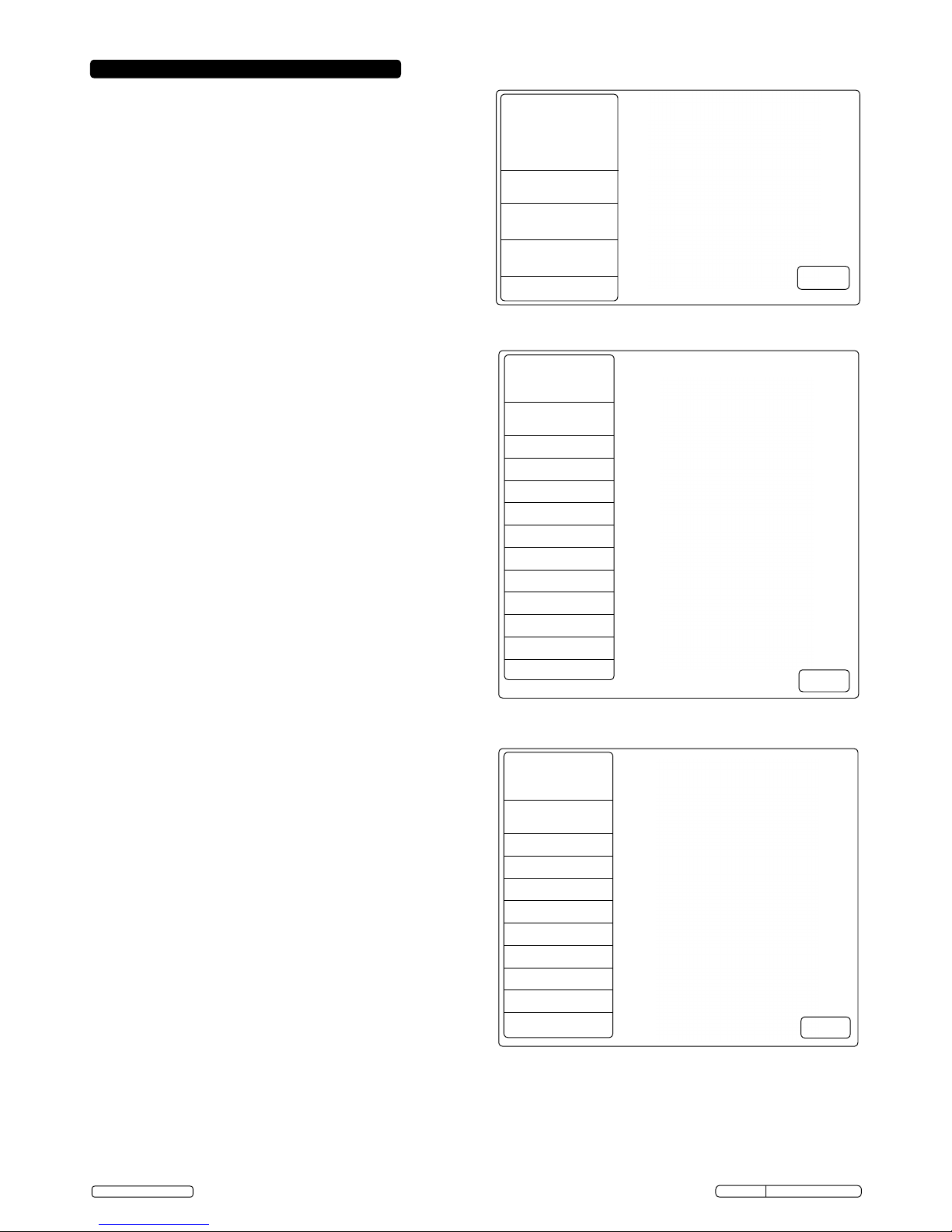

3.2 Force Screws (Fig.2)

Four different diameter force screws, each 450mm

in length. Each force screw is supplied with two nuts

and two thrust washers.

3.3 'A' Sleeves (Fig.3)

Eleven different diameter gold coloured sleeves, with

a stepped end for use with side-A of the end plates

and a force end with U-shaped inspection slot.

3.4 'B' Sleeves (Fig.4)

Nine different diameter silver coloured sleeves, with

a stepped end for use with side-B of the end plates

and a force end with U-shaped inspection slot.

Fig.1

VS7023A Issue No.1 - 14/11/12

Original Language Version

© Jack Sealey Limited

Fig.2

Sleeve 'A'

(11 pieces)

Sizes

D44 x d34

D46 x d36

D54 x d44

D56 x d46

D58 x d48

D66 x d56

D68 x d58

D70 x d60

D78 x d68

D80 x d70

D82 x d72

Sleeve 'B'

(9 pieces)

Sizes

D48 x d38

D50 x d40

D52 x d42

D60 x d50

D62 x d52

D64 x d54

D72 x d62

D74 x d64

D76 x d66

Fig.3

Fig.4

4.1 Bush/Bearing Removal (Fig.5)

4.1.1 Select a sleeve that will sit square on the bearing/bush

housing and will allow the bush/bearing to be

extracted without interference. Ensure that only the

force end of the sleeve with the U-shape inspection

slot is used to sit on the bush/bearing housing. The

stepped end of the sleeve should be used to locate in

the end plate.

4.1.2 Select a second sleeve that will sit square on the outer

ring of the bearing/bush and will pass through the

bearing/bush housing without interference. Ensure

that only the force end of the sleeve with the U-shape

inspection slot is used to sit on the outer ring of the

bush/bearing. The stepped end of the sleeve should

be used to locate in the end plate.

4.1.3 Remove the nuts and thrust washers and pass the

force screw half way through the bush/bearing centre

hole. Lubricate the force screw before use.

Note! Always use the largest diameter force screw available

thatwilltthroughthecentreofthebush/bearing.

4.1.4 Fit the end plates to the stepped ends of the selected

sleeves. Ensure that side-A is only used for 'A' sleeves

and side-B is only used for 'B' sleeves.

4.1.5 Slide the assembled end plates and sleeves over the

forcescrewandtthethrustwashersandnuts.

Progressively tighten the nuts whilst locating the

sleeves squarely on the bush/bearing housing and the

bush/bearing outer ring. Once the sleeves are square

on the housing and outer ring, tighten the nuts and

check that the thrust washers are centralised in the

end plates.

4.1.6 Using the appropriate size ring spanners for the force

screw nuts, gradually tighten the force screw nuts to

drive the bush/bearing from the housing. DO NOT use

air tools to operate the force screw nuts. DO NOT

apply more than 150Nm torque to the force screw

nuts.

4.1.7 Once the bush/bearing has been successfully

removed, clean the components used and return

them to the carry case.

4.2 Bush/Bearing Installation (Fig.5)

4.2.1 Select the appropriate sized sleeves for the housing

and bush/bearing as described in Section 4.1.

4.2.2 Prior to installing the bush/bearing clean the inside of

the housing with abrasive cloth to ensure that it is free

from debris and corrosion.

4.2.3 Lightly oil the outer ring of the bush/bearing to be

installed and using a hammer, gently tap around the

outer ring of the bush/bearing to locate it into the

housing. Care should be taken to ensure that the

bush/bearing is square to the housing when installing.

Note! Always use the largest diameter force screw available

thatwilltthroughthecentreofthebush/bearing.

4.2.4 Lubricate the force screw and assemble the kit as

described in Section 4.1 and as shown in Fig.5. Once

the sleeves are square on the housing and outer ring,

tighten the nuts and check that the thrust washers are

centralised in the end plates.

4. OPERATION

VS7023A Issue No.1 - 14/11/12

Original Language Version

450mm long

Force Screw

(4-pieces)

Sizes/Torque*

M10X1.5/ 33Nm

M12X1.5/ 60Nm

M14X1.5/ 99Nm

M16X1.5/155Nm

© Jack Sealey Limited

* Max recommended

torque (lubricated).

Loading...

Loading...