Page 1

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

INSTRUCTIONS FOR:

VACUUM TESTER AND BRAKE BLEEDING KIT

MODEL No

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these instructions,

and properly maintained, give you years of trouble free performance.

.

VS402.V3

Refer to

instructions

Wear protective

gloves

Wear eye

protection

1. SAFETY

9 Keep this product in good working order and condition, take immediate action to repair or replace damaged parts.

9 Use approved parts only. Unapproved parts will invalidate the warranty.

9 Keep children and unauthorised persons away from the work area.

9 Keep work area clean and tidy and free from unrelated materials.

9 Ensure the work area has adequate lighting.

8 DO NOT use the kit to perform a task for which it is not designed.

8 DO NOT hold pump inlet against the skin whilst using the pump.

8 DO NOT allow untrained persons to use the kit.

8 DO NOT use whilst under the inuence of drugs, alcohol or intoxicating medication.

9 After use, clean equipment and store in a cool, dry, childproof area.

WARNING! Brake uid will damage paintwork. Any spillage should be ushed with water immediately.

WARNING! Brake uid is ammable - keep away from sources of ignition, including hot surfaces e.g. exhaust manifold.

9 Dispose of waste liquids in accordance with local authority regulations.

WARNING! DO NOT pollute the environment by allowing uncontrolled discharge of uids.

9 Always read and comply with the warnings on the brake fluid container.

9 Wear eye protection and keep skin contact to a minimum. If brake fluid enters eyes rinse with plenty of water and seek medical advice. If

swallowed seek medical advice immediately.

2. INTRODUCTION

The VS402 vacuum tester and brake bleeding kit is a multi-function diagnostic tool used to test a variety of essential engine and associated

functions including fuel, ignition, transmission and emissions. Set also includes reservoir, hoses and adaptors for bleeding brake and clutch systems

on cars, commercials and motorcycles. Brass-bodied vacuum pump features large, easy-to-read vacuum gauge calibrated in both inches and

millimetres of mercury.

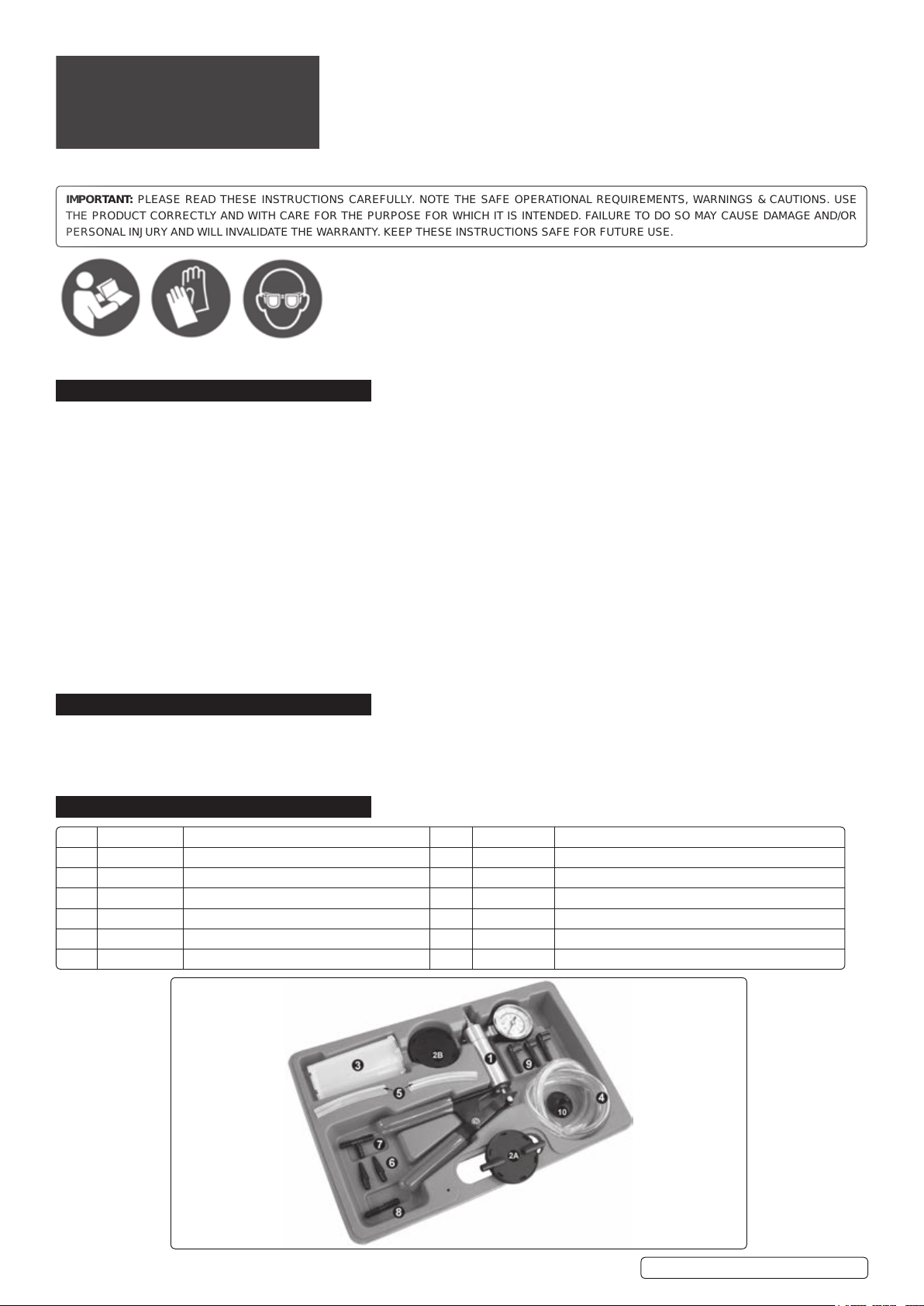

3. CONTENTS

ITEM PART No. DESCRIPTION ITEM PART No. DESCRIPTION

1 VS402.V3-01 VACUUM PUMP WITH GAUGE 6 VS402.V3-06 HOSE ADAPTOR

2A VS402.V3-02A RESERVOIR LID (FOR OPERATION) 7 VS402.V3-07 HOSE ADAPTOR 'T-PIECE'

2B VS402.V3-02B RESERVOIR LID (FOR TRANSPORT) 8 VS402.V3-08 HOSE ADAPTOR 'STRAIGHT'

3 VS402.V3-03 RESERVOIR JAR 9 VS402.V3-09 BRAKE BLEED NIPPLE ADAPTOR

4 VS402.V3-04 560mm VACUUM HOSE 10 VS402.V3-10 UNIVERSAL CUP ADAPTOR

5 VS402.V3-05 80mm VACUUM HOSE

© Jack Sealey Limited

Original Language Version

VS402.V3 | Issue - 1 14/09/16

Page 2

4. OPERATION

The use of a vacuum gauge is often overlooked when determining mechanical condition and carrying out fault diagnosis on internal combustion

engines. Monitoring actual manifold vacuum is invaluable when troubleshooting engine faults. This can only be carried out by using a good quality

vacuum gauge and this, coupled with a hand-operated vacuum pump, also allows static testing of all types of vacuum operated systems. Set out on

the following pages are applications that the VS402 vacuum tester kit can be used for, but it must always be remembered that these are examples

only and reference to manufacturer’s service manuals should always be made for correct testing procedures and specifications. In addition to this,

it is always recommended that additional tests, i.e. compression tests, cylinder leakage tests, ignition timing checks etc. be carried out to confirm

indications of vacuum gauge readings.

5. INLET MANIFOLD SYSTEMS

5.1. Analysing Engine Mechanical Condition via Manifold Vacuum Readings

5.1.1. The readings shown below are only examples of what may be observed.

It is important to remember that it is the action of the needle

rather than the actual reading that is more important. Varying engine

types will run different manifold vacuum pressures, depending on

camshaft profile, valve overlap, timing etc. so an exact vacuum reading

cannot be specified. The main criteria is that the needle reading is

between 16 to 21inHg and steady.

5.1.2. Manifold vacuum is also affected by altitude and it will drop approximately

1inHg for every 1000 feet above sea level so this must also be

considered when assessing manifold vacuum actual readings.

5.2. Basic Diagnostic Tests

5.2.1. Carry out the following procedures:

Step 1. Run engine until normal operating temperature is reached.

Switch engine off.

Step 2. Connect the vacuum gauge to a port directly on the manifold (fig.1)

or on the carburettor/throttle body below the throttle butterfly.

Step 3. Start and run the engine at idle, observing the gauge reading.

Refer to the following table to indicate any problems and their possible causes.

fig.1

READING: 16-21 in Hg with needle

steady.

CAUSE: Normal

READING: Reading low but steady.

CAUSE: Retarded ignition timing.

Conrm using timing light and reset to

manufacturer’s specication.

READING: When the throttle is

suddenly opened then released the

needle should drop to below 5inHg

then bounce up to approx. 25in Hg

settling back to original reading.

CAUSE: Normal

READING: Reading slightly low and

uctuating slowly.

CAUSE: Over lean or rich mixture.

Check and reset in accordance with

manufacturer’s specications.

READING: Reading extremely low but

steady.

CAUSE: Leaking manifold intake

system, faulty manifold gasket,

carburettor base gasket, split vacuum

hose, EGR valve seized.

READING: Regular uctuation between

normal and low readings.

CAUSE: Blown cylinder head gasket

between two adjacent cylinders. Carry

out cylinder leakage test.

© Jack Sealey Limited

Original Language Version

VS402.V3 | Issue - 1 14/09/16

Page 3

READING: Readings slightly lower

than for lower for normal engine

including when throttle is suddenly

opened then released.

CAUSE: Worn piston rings. Carry out

compression test.

5.3. Ignition system vacuum advance

5.3.1. On standard points systems and some electronic ignition systems there are two types of advance methods used, both of which must

function correctly to obtain maximum performance and fuel economy.

5.3.2. The first method Is Mechanical or Centrifugal, which operates by the use of weights located in the base of the distributor. The weights

move outwards advancing ignition timing as engine RPM increases. This is tested by firstly removing the vacuum advance line to disable

the system, then with a timing light connected, run the engine RPM up checking that the timing advances in accordance with the

manufacturer’s specification.

5.3.3. The second method is Vacuum Advance, which senses engine load via manifold vacuum. A vacuum diaphragm is mounted onto the

distributor and connected to a rotating internal base plate which advances or retards timing as required to suit varying engine

loads. To test this system for correct operation, again with the timing light connected, raise the engine RPM and check timing advance

against manufacturer specifications. In the event that the vacuum advance is not operating, remove the vacuum line from the distributor

advance mechanism. Connect the VS402 (fig.2) and create a 5-10inHg vacuum, monitoring the timing at the same time. If a timing

advance is noted this confirms that the vacuum diaphragm and mechanical links are in order and that the fault is a vacuum supply. To

confirm this, connect the VS402 to the vacuum supply line and check the gauge reading. No vacuum should be noted at idle but when

the engine RPM is increased a vacuum increase should be observed. If this does not occur, trace the vacuum line back checking for

restrictions and breaks.

READING: Regular drop between

normal and low reading.

CAUSE: Burnt valve.

READING: Normal when rst started

but drops rapidly when revs held at

3000rpm.

CAUSE: Restriction in exhaust system.

fig.4

fig.2

fig.3

6. FUEL SYSTEMS

6.1. Testing Mechanical Fuel Pumps

6.1.1. The VS402 vacuum tester can be used to evaluate the condition of a mechanical fuel pump by testing the vacuum that it is able to

create. Locate and remove the suction line from the pump. Connect the VS402 vacuum tester to the suction port of the pump, start

and run the engine at idle. The vacuum reading that should be observed will vary slightly on different makes and models but as a general

rule approximately 15inHg of vacuum should be created. This should also be held for approximately 1 minute after engine shut down.

If this vacuum reading is not achieved or the vacuum drops off immediately with the engine shut down, the fuel pump requires either

overhaul or replacement.

6.2. Carburettors

6.2.1. There are many different types of vacuum control systems used on carburettors. Using the VS402 vacuum tester kit allows quick and

accurate testing of these systems. Listed below are just two examples of tests that can be carried out:

6.2.2. Testing a Choke Break Diaphragm. With the engine at normal operating temperature but not running, disconnect the vacuum line to the

diaphragm module. Connect the VS402 vacuum tester (fig.3) and apply approximately 15inHg of vacuum and wait for 30 seconds.

No drop in gauge reading should be observed. With the vacuum still applied ensure that the choke butterfly is pulled to the fully open

position.

6.2.3. Testing Vacuum Operated Carburettor Secondary Barrel. With the engine at normal operating temperature but not running, remove

the vacuum line from the secondary diaphragm module. Connect the VS402 vacuum tester (fig.4), hold the throttle and secondary air

valve flaps open. Operate the hand pump whilst observing free and easy opening of the secondary throttle butterfly.

6.3. Testing Fuel Injection Pressure Regulator

6.3.1. Multi-point fuel injection rail pressure must vary to suit changing engine loads and fuel delivery requirements. This is done using a

vacuum operated regulator which is connected to the engine manifold vacuum to sense the varying loads.

6.3.2. To test the fuel rail pressure, a gauge is attached to the rail, then engine loads must be created to vary engine manifold vacuum. Simply

© Jack Sealey Limited

Original Language Version

VS402.V3 | Issue - 1 14/09/16

Page 4

remove and block off the vacuum supply line to the pressure regulator, connect and operate the VS402 vacuum pump (fig.5) to

simulate vacuum pressures in accordance with the manufacturer’s specifications and note variation in fuel pressure reading.

6.4. Testing Emission Control Exhaust Gas Reclrculation Valves (EGR)

6.4.1. Start engine and run at idle until normal operating temperature is reached. Remove the vacuum line from the EGR valve and attach the

VS402 vacuum tester kit (fig.6). Operate the hand pump to apply approximately 15inHg of vacuum. If the EGR Valve is working

correctly the engine idle will become rough. If the idle remains unchanged the valve is possibly seized in the closed position. If

the vacuum is not held, the diaphragm in the valve has failed.

fig.5

fig.6

7. ADDITIONAL VACUUM SYSTEMS

7.1. Testing One-Way Valves

7.1.1. Many vacuum operated circuits use in-line one-way valves to apply vacuum in one direction only.

7.1.2. To test the function of the valve remove it from the circuit. Attach the VS402 vacuum tester (fig.7) and operate pump to apply vacuum.

In one direction the valve should hold vacuum and in the opposite direction it should not.

7.2. Testing Electrically Operated Vacuum Solenoids

7.2.1. Electrically operated vacuum solenoids are commonly used in control circuits for air conditioning/ventilation systems, emission control

systems, idle step up systems etc. and testing the function of these when using the VS402 is extremely simple.

7.2.2. Locate the solenoid to be tested and remove the line that goes to the component being tested. Connect the VS402 to the solenoid

port (fig.8) and start the engine. With the system turned off there should be a zero gauge reading. Now turn the system to the ‘on’ position

and a gauge reading equal to the manifold vacuum should be observed, if no reading exists remove the vacuum supply line and test for

manifold vacuum at this point. If the vacuum does exist this indicates that the solenoid is faulty or it is not receiving a ‘switch on’ voltage

(use a multimeter to test this). If no vacuum exists trace the supply line back to the vacuum source checking for kinks and breaks.

7.3. Testing Thermal Vacuum Switches

7.3.1. There are many vacuum controlled circuits that must only operate when the engine reaches normal operating temperature. This is done

using thermal switches that remain in an ‘off’ position until a given temperature is reached.

7.3.2. To test this type of switch, remove the vacuum supply line coming from the manifold to the switch and test for manifold vacuum. If this

vacuum is correct refit the supply line to the thermal switch and remove the opposing line from the switch. Attach the VS402 vacuum

tester to the port (fig.9) and start the engine. With a cold engine no reading should be noted. When the engine reaches normal operating

temperature a manifold vacuum reading should be noted.

7.4. Testing Vacuum Operated Heater Taps

7.4.1. Climate control ventilation systems are becoming very common on newer vehicles and most of the systems use vacuum operated taps to

control the heating modes. On the majority of makes and models, the system uses vacuum to turn the heater tap ‘on’.

7.4.2. To test these remove the supply line from the tap vacuum module and connect the VS402 vacuum tester (fig.10). With the engine at

normal operating temperature locate and feel the heater return hose. With the heater tap in the ‘off’ position, this hose should be cold.

Now operate the vacuum pump to open the tap. The gauge reading must hold. If the tap is in working order, the return hose will begin to

heat. If the hose does not begin to heat, this indicates that the tap is faulty.

7.5. Testing Vacuum Operated Remote Central Locking Systems

7.5.1. Some makes and models use vacuum operated bellows mounted in each door to centrally lock and unlock the vehicles doors. These

systems use either manifold vacuum stored in a reservoir for use when the engine is not running or an electrically driven vacuum pump

which operates when the doors are locked or unlocked.

7.5.2. In either system, the VS402 vacuum tester is ideal for testing each individual door bellows. To do this, remove the door trims as

required. Remove the vacuum supply lines from the bellows and attach the VS402 vacuum tester (fig.11) and operate to apply vacuum

to the bellows. Wait for 30 seconds, no drop on the gauge should be noted. If the bellows are found to be in order attach the vacuum

supply line to the VS402 vacuum tester and operate system to test for vacuum supply. If the vacuum supply does not exist or is low

trace back down the lines to the vacuum supply looking for kinks, restrictions or cracked lines. Repair as required and retest.

7.6. Testing Automatic Transmission Vacuum Operated Modulator Valves

7.6.1. Automatic transmissions are normally equipped with a vacuum operated modulator valve in order for the automatic transmission to detect

engine loads and adjust shift points to suit.

7.6.2. The VS402 vacuum tester can be used to test both that the modulation valve diaphragm is serviceable and also to simulate varying

engine loads so modulator pressure readings can be recorded. To test the modulator valve diaphragm remove the vacuum supply line

from the valve and attach the VS402 vacuum tester. Operate the vacuum pump until approximately 15inHg is achieved and monitor

the gauge reading for approximately 30 seconds. No vacuum drop should be noted.

7.6.3. To check modulator pressure readings attach a pressure gauge to the appropriate port on the transmission. Remove the vacuum supply

line from the modulator and attach the VS402 vacuum tester (fig.12). Start and run the engine and apply vacuum pressures. Monitor

readings and confirm that these are in conformance with manufacturer specifications.

© Jack Sealey Limited

Original Language Version

VS402.V3 | Issue - 1 14/09/16

Page 5

fig.7

fig.9

fig.10

fig.8

fig.11

fig.12

fig.13

8. BRAKING SYSTEMS

8.1. Testing Brake Servo Diaphragm

8.1.1. Remove vacuum supply line from brake servo fitting. Attach VS402 vacuum tester to vacuum supply port on servo (fig.13). Operate

pump to create approximately 15inHg of vacuum and wait for 30 seconds. No vacuum drop should be observed on the gauge reading. If

the vacuum drops this indicates that the brake servo diaphragm is faulty. In this case the servo should be removed for overhaul by an

authorised repairer or replaced.

8.2. Brake Bleeding - Assembly of Brake Bleeder Kit

8.2.1. Ensure that the vacuum pump is connected to the brake bleeder reservoir in accordance with the assembly diagram (fig.14). Failure to

do so will result in brake fluid being drawn into the vacuum pump.

8.3. Brake Bleeding Procedure.

WARNING! Familiarise yourself with the hazards of brake uid - read manufacturer’s instructions on the container. DO NOT

touch the vehicle’s brake pedal whilst bleeding the brakes.

8.3.1. Refer to the specific vehicle manufacturer’s instructions for brake bleeding and wheel sequence procedure before proceeding. If no

specific instructions from the vehicle manufacturer exist, follow the instructions detailed below.

8.3.2. Remove the cap of the vehicle’s master brake fluid reservoir. If the fluid level is not at maximum, top it up.

8.3.3. Attach the appropriate size bleeding attachment to the bleed nipple on the brake calliper of the first wheel, normally nearest to master

brake fluid reservoir.

© Jack Sealey Limited

Original Language Version

VS402.V3 | Issue - 1 14/09/16

Page 6

8.3.4. Operate vacuum pump until approximately 21inHg vacuum is created.

8.3.5. Apply copper grease to the brake bleeding nipples before and after the brake bleeding procedure to reduce the possibility of seized or

broken nipples when the brakes are next bled.

8.3.6. Open the bleed nipple about a quarter of a turn. Allow brake fluid to be drawn until no air bubbles are visible in the brake fluid in the

clear hose.

8.3.7. Tighten the bleed nipple.

8.3.8. Remove the attachment from the brake nipple.

8.3.9. Repeat the process as necessary.

NOTE! Check the master brake fluid reservoir regularly to ensure that the level does not drop too far, and top up as necessary.

NOTE! Empty bleeder container regularly and DO NOT allow container to overfill as brake fluid will be drawn into vacuum pump.

WARNING! When brake bleeding and/or fluid changing is complete, test the action of the brake pedal to ensure that the brakes

are working before attempting to drive the vehicle on the road and test the vehicle for satisfactory performance of the braking

system.

8.4. Clutch Bleeding Procedure.

8.4.1. Refer to the relevant vehicle manufacturer’s instructions for clutch bleeding procedure. If no specific instructions from the vehicle

manufacturer exist, follow the same basic procedure as the brake bleeding instructions above.

fig.14

Recycle unwanted materials instead of disposing of them as waste. All tools, accessories and packaging should be

Environmental Protection

fig.15

fig.15

sorted, taken to a recycling centre and disposed of in a manner which is compatible with the environment.

When the product becomes completely unserviceable and requires disposal, drain off any fluids (if applicable)

into approved containers and dispose of the product and the fluids according to local regulations.

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of this product.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

© Jack Sealey Limited

Sole UK Distributor, Sealey Group.

Kempson Way, Suffolk Business Park,

Bury St. Edmunds, Suffolk.

IP32 7AR

Original Language Version

01284 757500

01284 703534

www.sealey.co.uk

Web

sales@sealey.co.uk

VS402.V3 | Issue - 1 14/09/16

Loading...

Loading...