Page 1

diesel injector puller set - 14 piece

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

model no: Vs2059.V3

thank you for purchasing a sealey product. Manufactured to a high standard, this product will, if used according to these

instructions, and properly maintained, give you years of trouble free performance.

Refer to

instructions

Wear eye

protection

Wear protective

gloves

1. safety

WarninG! ensure Health and Safety, local authority and general workshop

practice regulations are adhered to when using tools.

WarninG! Always use caution when working around fuel systems.

The fuel in the fuel rail may be pressurised even if the engine is not running.

These instructions are provided as a guide only. Always refer to the vehicle

manufacturer’s service instructions, or a proprietarymanual, to establish the

current procedure and data, also any warnings or cautions particular to the

vehicle.

8 do not use the set if any parts are missing or damaged.

8 do not use this tool for any purpose other than that for which it is designed.

9 Switch off vehicle’s ignition and disconnect the battery before commencing

work under the bonnet.

9 You must follow the vehicle’s service manual cautions when working around the air bag system. If the cautions are not followed the air

bag may deploy unexpectedly even after the ignition is turned ‘oFF’, resulting

in personal injury.

8 do not lay tools on the vehicle’s battery. This may short the terminals

together, causing harm to yourself, the tools, or the battery.

9 operate in a well ventilated area. do not inhale fuel vapours.

9 Wear approved eye protection.

9 Wear suitable clothing to avoid snagging. do not wear jewellery and tie

back long hair.

9 Keep children and other unauthorised persons away from the working area.

9 Keep yourself, tools, and test equipment away from hot engine parts.

9 Always keep a fire extinguisher that is suitable for fuel/electrical/chemical

fires close by,

8 do not smoke or have open ames near vehicle.

9 Always relieve fuel pressure before disconnecting fuel lines from injectors.

9 Use a cloth to cover fuel line fittings when connecting or disconnecting fuel

lines. Avoid contact with fuel.

9 Clean up all fuel spills immediately and dispose of all used cloths properly.

9 maintain the tool components in good and clean condition for best and safest

performance.

9 When work on the vehicle is finished, ensure all connections on vehicle are

restored, and that there are no tools left in the engine bay.

9 Replace tools in the carrying case and store in a safe, dry, childproof location.

g.1

g.2

2. introduction

Suitable for the fast and safe removal of Bosch, delphi, denso and Siemens

diesel injectors. Set includes keys and deep open profile sockets, used to

dismantle injectors, plus adaptors for attaching the slide hammer securely to

the body of the injector. Ball joint allows hammer to be used in confined areas.

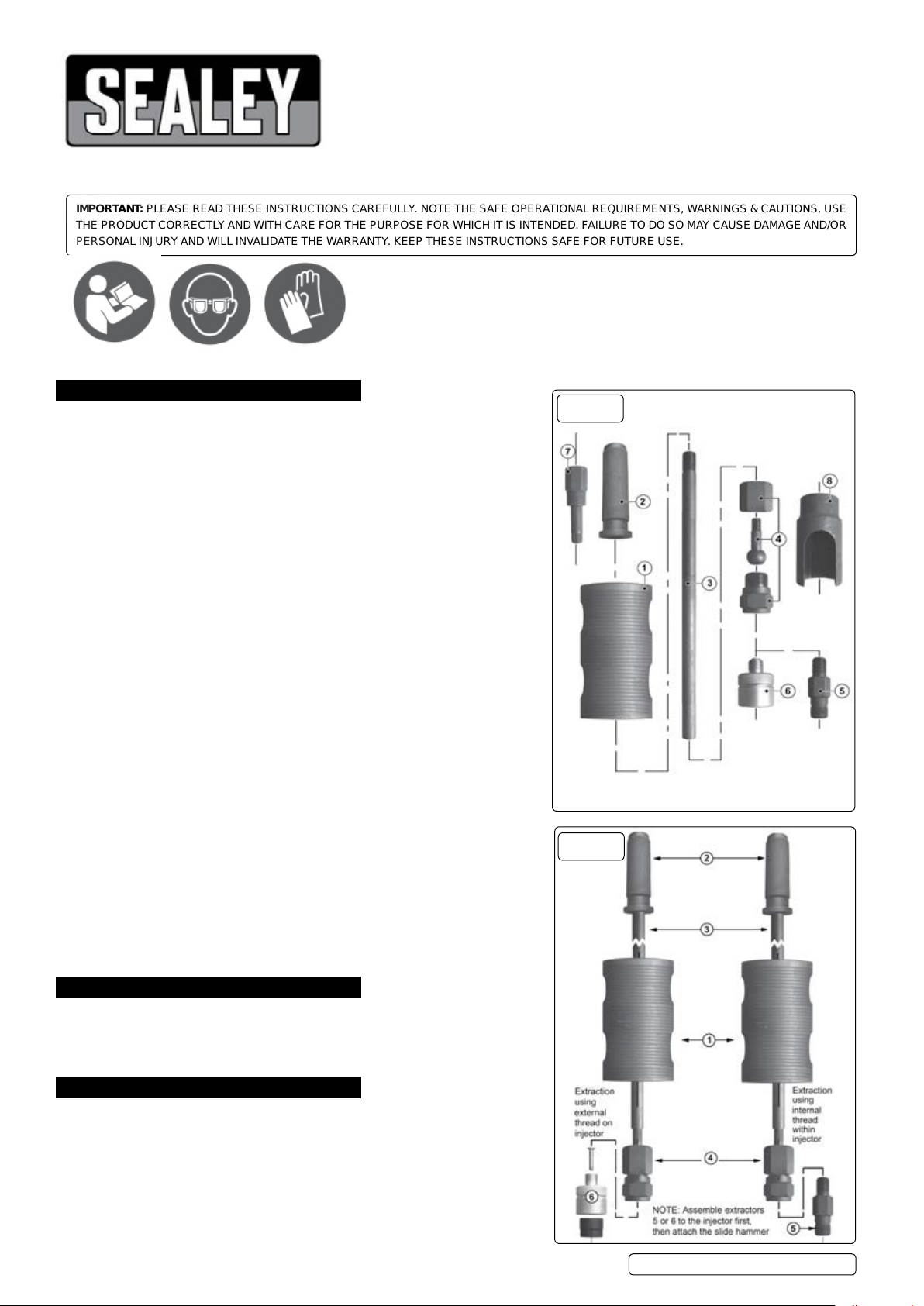

3. contents g.1.

item description

1 Sliding Hammer

2 Handle

3 Shaft

4 Ball Joint Adaptor (3 piece)

5 Adaptors - (5 Pieces - 4 internal thread, 1 external thread)

6 external Adaptor - (3 piece)

7 Security Hex Key - ½”sq. drive

8 Sockets - (4 pieces - m25, m27, m29, m30 - ½”sq. drive)

© Jack Sealey limited

Original Language Version

VS2059.V3 | Issue 2 (F) 21/03/18

Page 2

4. asseMbly

4.1. Referring to the individual components in g.1. assemble the Injector Puller as shown in g.2.

4.2. Use adaptor 6 when the injector is being extracted using the external thread revealed when the injector cap has been removed.

4.3. Use one of the adaptors (5) when the injector is being extracted using the internal thread revealed when the inner sleeve has been

removed from the injector.

5. operation

noTe: The technique required for removal of the injector will depend on which system is fitted to the vehicle.

Always use an external adaptor rst if possible. If by using reasonable force the injector cannot be removed, use an internal

adaptor.

5.1. Before working on the fuel system, make sure that the fuel system is noT pressurised. Refer to the manufacturer’s instruction

manual on how to de-pressurise the system.

5.1.1. disconnect the injector wires and connections as per the manufacturer’s instructions.

5.1.2. Remove any carbon build up from around the injector.

5.1.3. Remove the cap from the injector using the appropriate size socket (8). Refer to fig.3.A.

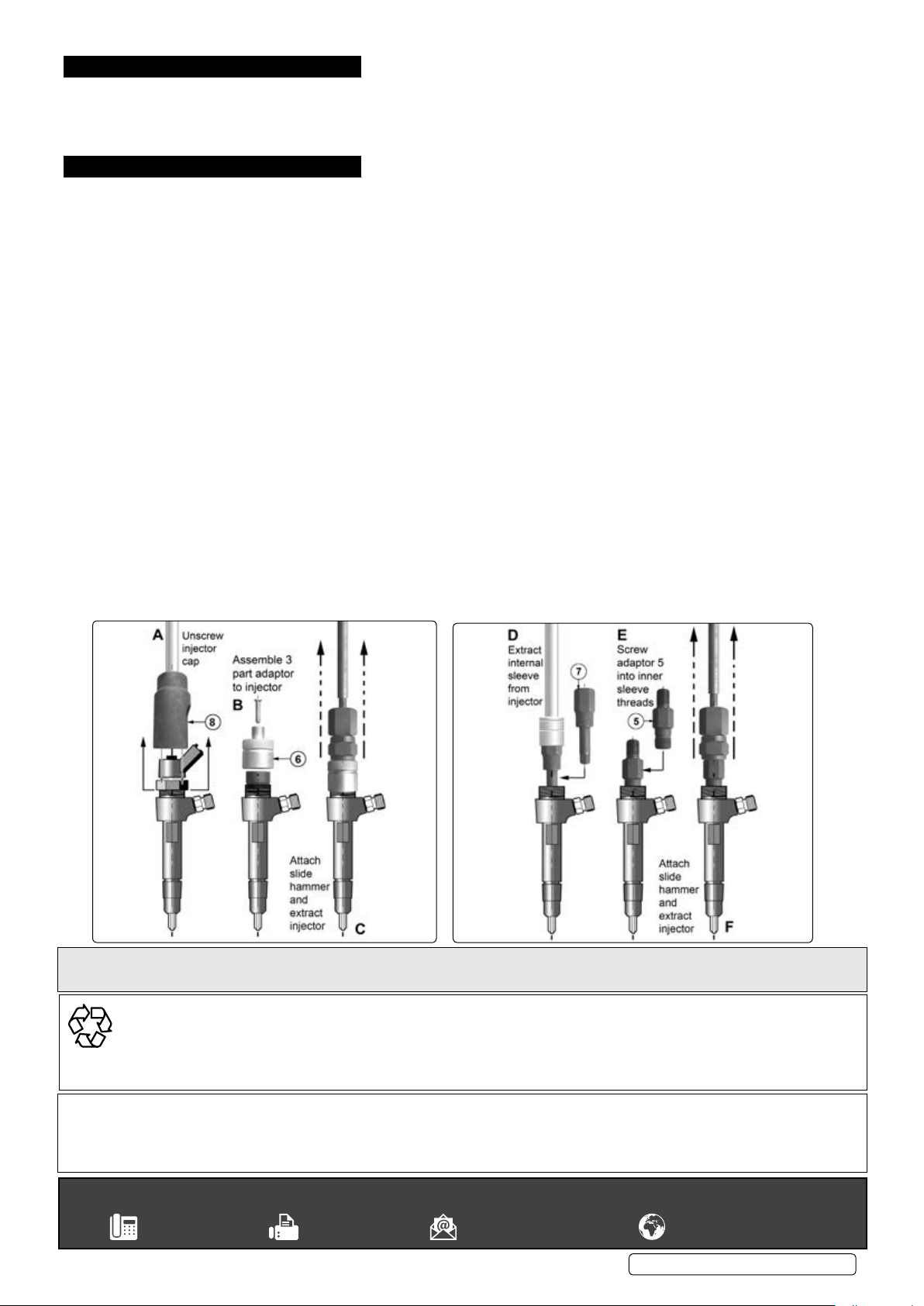

5.2. Use of external adaptor (g.3).

5.2.1. Identify the external thread adaptor (6) and separate the inner black part from the outer silver part by removing the screw from the

top of the adaptor.

5.2.2. Position the black part inside the top of the injector (see B) then place the silver part over it, and screw it down firmly onto the external

threads revealed when the cap was removed.

5.2.3. Install the screw securely thus locking the adaptor parts tightly together with the injector thread and wall in between. This ensures a

more secure fastening and reduces damage to the injector threads.

5.3. Use of internal adaptor (g.4).

5.3.1. Remove the internal parts from the injector to gain access to use the security hex key (7). It may be necessary to remove the

injector veins byforce. Insert the security hex into the inner sleeve (see d). Turn the security hex anti-clockwise using a 21mm

socket to remove the inner sleeve.

5.3.2. Screw the appropriate internal adaptor (5) into the threads of the injector and tighten with a suitable spanner (see e).

5.4. Removing the injector.

5.4.1. Screw the slide hammer assembly (handle, shaft and sliding hammer) securely onto the adaptor.

5.4.2. The injector can now be removed using reasonable force on the slide hammer. Be prepared for the sudden release of the injector from

the cylinder head.

5.4.3. If the injector cannot be removed, it may be necessary to consult a main dealer or a diesel specialist, to avoid damage to the engine.

5.4.4. When an injector has been removed, it is recommended that only a new or refurbished injector is fitted. Follow manufacturers fitting

and safety instructions.

Parts support is available for this product. To obtain a parts listing , please contact

www.sealey.co.uk, email sales@sealey.co.uk or telephone 01284 757500

enVironMent protection

Recycle unwanted materials instead of disposing of them as waste. All tools, accessories and packaging should be sorted, taken to

a recycling centre and disposed of in a manner which is compatible with the environment. When the product becomes completely

unserviceable and requires disposal, drain any fluids (if applicable) into approved containers and dispose of the product and fluids

according to local regulations.

note: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior

notice.

important: no liability is accepted for incorrect use of this product.

Warranty: Guarantee is 12 months from purchase date, proof of which is required for any claim.

sealey Group, Kempson Way, suffolk business park, bury st edmunds, suffolk. ip32 7ar

01284 757500 01284 703534 sales@sealey.co.uk www.sealey.co.uk

© Jack Sealey limited

Original Language Version

VS2059.V3 | Issue 2 (F) 21/03/18

Loading...

Loading...