Page 1

INSTRUCTIONS FOR:

TABLE SAW

Model No:

TS10CZ

Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions

and properly maintained, give you years of trouble free performance.

1. SAFETY INSTRUCTIONS

IMPOR

TANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS AND

CAUTIONS. USE THIS PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY

CAUSE DAMAGE AND/OR PERSONAL INJUR

Y AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

TS10CZ - 0016 - (1) - 040501

1.1. ELECTRICAL SAFETY

pp

WARNING! It is the users responsibility to read, understand and comply with the following:

You must check all electrical equipment and appliances, before using, to ensure that they are safe. You must inspect power supply leads, plugs

and all electrical connections for wear and damage. You must ensure the risk of electric shock is minimised by the installation of appropriate

safety devices. An RCCB (Residual Current Circuit Breaker) should be incorporated in the main distribution board. We also recommend that an

RCD (Residual Current Device) is used with all electrical products. It is particularly important to use an RCD with portable products that are

plugged into an electrical supply not protected by an RCCB. If in doubt consult a qualified electrician. You may obtain a Residual Current Device

by contacting your Sealey dealer. You must also read and understand the following instructions concerning electrical safety.

1.1.1. The Electricity At Work Act 1989 requires all portable electrical appliances, if used on business premises, to be tested by

a qualified electrician, using a Portable Appliance Tester (PAT), at least once a year.

1.1.2. The Health & Safety at Work Act 1974 makes owners of electrical appliances responsible for the safe condition of the appliance

and the safety of the appliance operator. If in any doubt about electrical safety, contact a qualified electrician.

1.1.3. Ensure the insulation on all cables and the product itself is safe before connecting to the mains power

supply. See 1.1.1. & 1.1.2. above and use a Portable Appliance Tester (PAT).

1.1.4. Ensure that cables are always protected against short circuit and overload.

1.1.5. Regularly inspect power supply leads, plugs for wear and damage and power connections, to

ensure that none is loose.

1.1.6. Important: Ensure the voltage marked on the product is the same as the electrical power supply

to be used, and check that plugs are fitted with the correct capacity fuse. A 13 amp plug may require

a fuse smaller than 13 amps for certain products, see fuse rating at right.

1.1.7. DO NOT pull or carry the appliance by its power supply lead.

1.1.8. DO NOT pull the plug from the socket by the power cable.

1.1.9. DO NOT use worn or damage leads, plugs or connections. Immediately replace or have repaired by

a qualified electrician. A U.K. 3 pin plug with ASTA/BS approval is fitted. In case of damage, cut it off

and fit a new plug according to the following instructions (discard old plug safely).

(UK only - see diagram at right). Ensure the unit is correctly wired via a three-pin plug.

a) Note that this saw is double insulated and therefore there is no GREEN/YELLOW earth wire.

b) Connect the BROWN live wire to live terminal L.

c) Connect the BLUE neutral wire to the neutral terminal N.

d) After wiring, check that there are no bare wires, that all wires have been correctly connected, that the cable outer insulation

extends beyond the cable restraint and that the restraint is tight.

Double insulated products are fitted with live (BROWN) and neutral (BLUE) wires only. Double insulated products are always marked with

this symbol . To re-wire, connect the brown & blue wires as indicated above. DO NOT connect the brown or blue to the earth terminal.

1.1.10. Some products require more than a 13 amp electrical supply. In such a case, NO plug will be fitted. You must contact a qualified electrician

to

ensure a 30 amp fused supply is available. We recommend you discuss the installation of a industrial round pin plug and socket with your electrician.

1.1.11. Cable extension reels. When a cable extension reel is used it should be fully unwound before connection. A cable reel with an RCD

fitted is recommended since any product which is plugged into the cable reel will be protected. The section of the cores of the cable

is important and should be at least 1.5mm

2

, but to be absolutely sure that the capacity of the cable reel is suitable for this product and

for others that may be used in the other output sockets, we recommend the use of 2.5mm2section cable.

Blue

Neutral

Wire

Cable

Restraint

FUSE RATING

THIS PRODUCT MUST BE FITTED

WITH A

13 AMP FUSE

Brown

Live

Wire

1.2

GENERAL SAFETY

3 Familiarise yourself with the applications, limitations and potential hazards of the saw

.

p WARNING! Disconnect the saw from the mains power before changing accessories, servicing or performing any maintenance.

3 The machine must only be serviced by a qualified person or service agent. Contact your Sealey dealer for information.

3 Select a work area suitable for the saw and keep the area clean, tidy and free from unrelated materials. Ensure that there is adequate lighting.

3 Permanently mount the saw on a supporting surface strong enough to take the weight of the machine and workpiece.

3 Ensure there is an adequate dust extraction area under the saw. Follow mounting instructions in Section 3 carefully.

3 Wood dust can be harmful to health by inhalation and skin contact and concentrations of small dust particles in the air can form an

explosive mixture. Ensure that there is adequate ventilation and that the saw is attached to a dust-extraction unit.

3 Maintain the saw in good condition, check moving parts alignment regularly. Keep saw blades clean and sharp. ,

3 Replace or repair damaged parts. Use recommended parts only. Unauthorised parts may be dangerous and will invalidate the warranty.

p WARNING! Keep all guards and holding screws in place, tight and in good working order. Check regularly for damaged parts.

A guard, or any other part, that is damaged should be repaired or replaced before the saw is next used. The safety guard is a mandatory

fitting where saw is used in premises covered by the Health & Safety at Work Act.

3 Before commencing work, ensure the saw blade is set to cut in the correct direction, securely fastened, sharp and is compatible with the

machine, spindle speed and the material to be cut. Never use a saw blade if damaged, bent or warped. Use only recommended saw blades.

3 Remove adjusting keys and wrenches from the machine and the vicinity before switching on.

3 Machine operators must have received sufficient training and instructions relating to the dangers associated with the machine, the

precautions to be observed and those requirements of the Wood Working Machines Regulations which apply. Operators must be under

the adequate supervision of a person who has a thorough knowledge and experience of the machine and the required guards.

Page 2

TS10CZ - 0016 - (1) - 040501

2. INTRODUCTION & DESCRIPTION

7 DO NOT operate the saw if any parts are damaged or missing as this may cause failure and/or injury.

7 DO NOT operate the saw when you are tired or under the influence of alcohol, drugs or intoxicating medication.

3 When not in use switch off the saw and unplug from the power supply. ,

p WARNING! Wear approved safety eye protection, ear defenders and, if dust is generated, respiratory protection.

3 Remove ill fitting clothing. Remove ties, watches, rings and other loose jewellery and contain long hair.

3 Keep hands and body clear of the blade when operating the saw.

3 Maintain correct balance and footing. Ensure the floor is not slippery and wear non-slip shoes.

3 Keep children and unauthorised persons away from the work area.

3 Avoid unintentional starting and never leave the saw operating unattended.

7 DO NOT use the saw for a task it is not designed to perform and ensure operators are trained to use the saw.

7 DO NOT get the saw wet or use in damp or wet locations or areas where there is condensation.

7 DO NOT use the saw where there are flammable liquids, solids or gases such as paint solvents and including waste cleaning rags etc.

1.3. SPECIFIC SAW SAFETY RULES

3 Connect to a suitable extraction system. failure to do so will result in the build-up of sawdust which will become a fire hazard.

3 Keep splitter and blade guard in place and operational, and replace table insert when worn.

3 Ensure you select the appropriate saw blade for the material to be cut.

p WARNING! Before each use, check that the saw blade is secure and not worn or damaged.

3 Use the blade guard for all through-sawing operations. Through-sawing operations are those where the blade cuts completely through the

workpiece as in ripping or cross-cutting.

3 Check workpiece to ensure that there are no nails or other items which may foul the saw blade.

3 Hold the work firmly against the fence of cross stop.

3 Only feed the workpiece into the blade against the rotation of the blade.

3 Avoid subjecting the saw blade to excessive strain - never force the workpiece. Maintain a controlled, steady progression.

3 Should the saw blade jam, switch the power off immediately to prevent damage to the motor.

3 To avoid kickback (when a workpiece is violently thrown back towards the operator) implement the following:

a) Keep the blade sharp. b) Keep the fence parallel to the saw blade. c) DO NOT release the workpiece before it is pushed all the way

past the saw blade. d) DO NOT rip work that is twisted or warped or does not have a straight edge to guide along the fence.

3 Use a push stick for ripping narrow stock.

3 Provide adequate support to the rear and sides of the saw table for long or wide workpieces.

7 DO NOT use your hands alone (free-hand) to guide the workpiece. Hold work firmly against the fence or cross stop to guide work through the saw.

7 DO NOT place yourself in an awkward operating position where a slip could cause your hand to move into the cutting blade.

7 DO NOT stand, or have any part of your body, in line with the path of the saw blade.

7 DO NOT use the fence as a cut-off gauge when cross-cutting.

7 DO NOT hold what will become the off-cut (the waste part of the workpiece).

p WARNING! DO NOT reach behind or over the saw blade with hands or arms.

p WARNING! DO NOT attempt to free a jammed saw blade without first switching off or removing the plug from the mains power supply.

7 DO NOT cut metals or substances that may produce toxic dust. Saw must only be used to cut wood or wood derived substances.

7 DO NOT attempt to cut round section wood.

7 DO NOT use solvents to clean plastic parts which may damage them. Use a soft damp cloth only.

3 Store blades in a safe, dry childproof location.

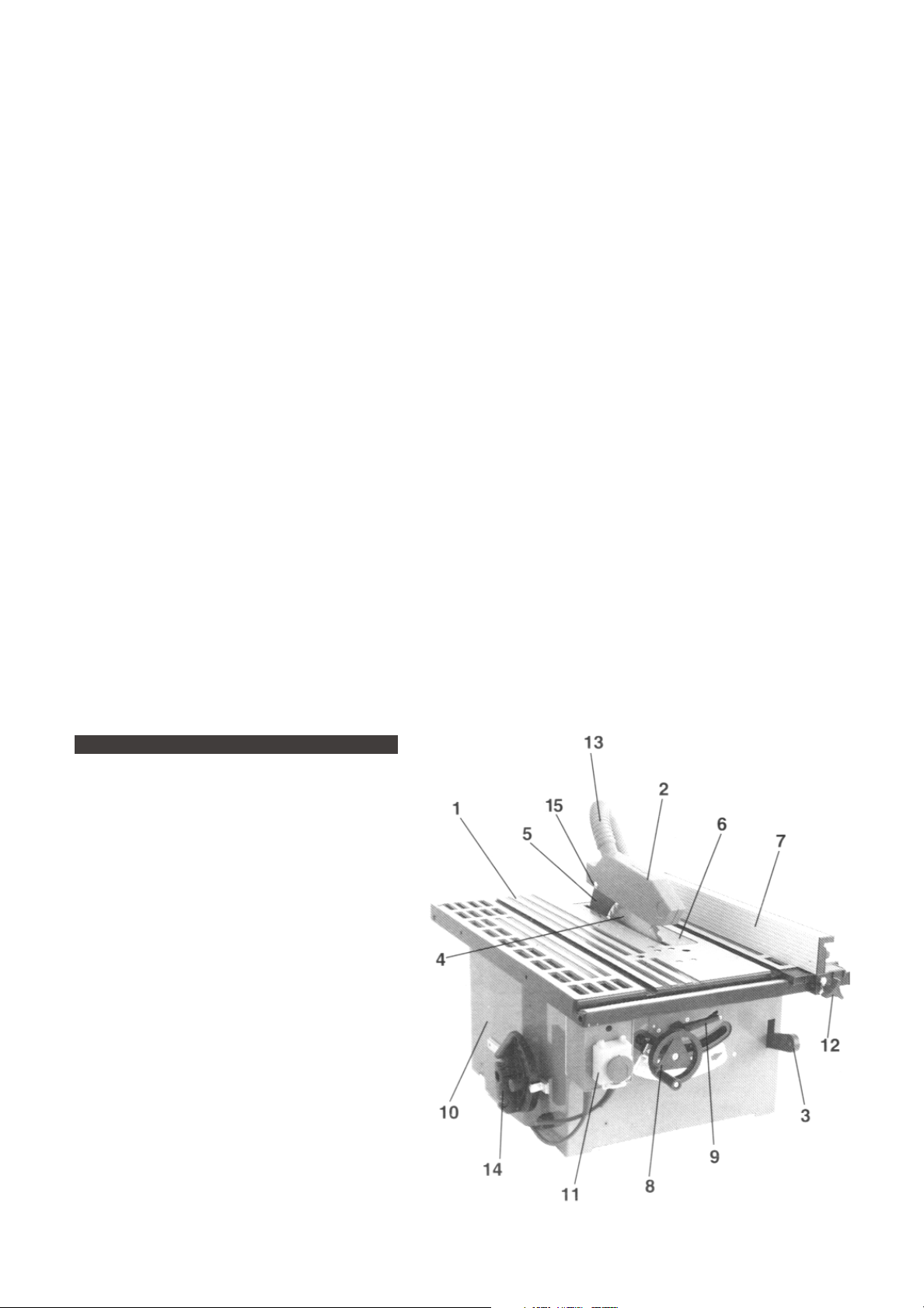

fig. 1

The TS10CZ professional quality table saw is fully approved to

CE regulations. Compound angle cutting permitted by full tilt

adjustment of up to 45

0

. The

unit is fitted with a No-Volt safety

switch and approved splitter for added user safety

.

1. Saw table 9. Power Cable

2. Blade guard 10. Casing

3. Push stick 11. On/Off switch

4.

Blade 12. Star-grip knob

5. Splitter 13. Dust extraction pipe

6. Table insert 14. Cross stop

7. Fence 15. Screw

8. Handwheel - Not shown - 2 x wrench

Page 3

Motor . . . . . . . . . . . . . . . . . . . . . . . . .230V - 1500W

Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . .4500rpm

Saw blade . . . . . . . . . . . . . . .Ø250 x Ø30 x 3.2mm

Max depth of 90

O

cut . . . . . . . . . . . . . . . . . . .70mm

Max depth of 45

O

cut . . . . . . . . . . . . . . . . . . .55mm

Table . . . . . . . . . . . . . . . . . . . . . . . . . . .625 x 463mm

Dust extraction port Ø (taper) . . . . . . . . . . .30 - 34mm

Sound power . . . . . . . . . . . . . . . . . . . . . . .114.6dB(A)

Sound pressure . . . . . . . . . . . . . . . . . . . . . 105.0dB(A)

3.

SPECIFICATION

4. ASSEMBLY

5.

ADJUSTMENTS

p WARNING! ENSURE THAT THE SAW IS NOT CONNECTED TO THE MAINS POWER BEFORE COMMENCING ASSEMBLY.

4.1. Saw stand or bench

The saw must be mounted either on the Sealey purpose designed stand, model number TS10CZ/ST, or a sturdy workbench.

Ensure that the supporting surface is strong enough to take the weight of the saw and any workpiece. Position the saw in a suitable work area

with enough clearance to allow room when working with large workpieces. Table extensions are available, Sealey model number TS10CZ/EWS,

to cater for large workpieces. Ensure that there is adequate lighting and that the saw blade can be clearly seen.

4.2. Blade guard

4.2.1. Loosen

the

wing nut on the blade guard (fig. 2.1).

4.2.2. Place the blade guard on the splitter (fig. 1.5) so that the screw fits into the slot in the splitter.

4.2.3. Slide the blade guard forward and tighten the wing nut.

4.3. Extraction

4.3.1. Fit extraction T piece (fig. 2.3) into extraction port and connect pipe (fig. 2.4) to blade guard.

4.3.2. Connect the T piece outlet (fig. 2.2) to a suitable extraction system

.

p WARNING! Wood dust can be harmful to health by inhalation and skin contact and concentrations of small dust particles in the air can

form an explosive mixture. Therefore, ensure that there is adequate ventilation and that the saw is attached to a dust-extraction unit.

fig. 2

p WARNING! ENSURE THAT THE SAW IS NOT CONNECTED TO THE MAINS POWER BEFORE MAKING ANY ADJUSTMENTS.

5.1. Cutting depth

5.1.1.

Adjust cutting depth by turning the handwheel (fig. 1.8) - anticlockwise to increase depth, clockwise to decrease.

5.2. Angle of cut

5.2.1. Set the blade for maximum depth - see 5.1.

5.2.2. Loosen the locking handle (fig. 1.9) and move the handwheel (fig. 1.8) until the pointer aligns with the required angle on the scale.

5.2.3. Firmly tighten locking handle.

Initial set-up - before first use set blade angle to 0

O

on scale and confirm, using a square, that the blade is at 90Oto the table. If it is not, loosen

locking handle and adjust stop screw (fig. 3.A) to give 90O. Similarly, set the blade at 45O on the scale and check that the blade

to table angle is 45O. Any required adjustment is provided by stop screw (fig. 3.B).

5.3. Splitter

5.3.1. Set blade to maximum cutting depth at 90

O

to the table (see paras. 5.1. & 5.2.).

5.3.2. Remove the blade guard (para.4.2.) and the table insert (para. 5.7.).

5.3.3. Loosen the two socket head screws clamping the splitter.

5.3.4. Adjust the splitter so that the top of it is 80mm above the table and the splitter-to-blade gap is 3 - 5mm.

5.3.5. Retighten the two clamping screws.

Note: If the saw is to be use for covered cuts (cutting a groove in the wood) then the splitter must be set so that the top of it is 2mm below the

tip of the topmost blade tooth. Remember to reset splitter and replace blade guard when reverting to through cutting.

5.4. Cross stop (Mitre gauge)

For straight cross-cutting set the blade at 90

0

to the table. The mitre gauge is used to cut a workpiece at an angle to the blade. To do so

position the cross stop in either the right or left hand channel and set the mitre to the required angle for cutting.

s CAUTION! If you are bevel cross cutting (i.e.blade is tilted) ensure you place cross stop in the right-hand table slot only. This will ensure

that the blade is tilted away from the cross stop and your hands.

TS10CZ - 0016 - (1) - 040501

3.1. Specification

fig. 3

Page 4

5.5. Changing the blade

5.5.1. Remove the blade guard and the table insert (paras. 4.2. & 5.7.) and raise the blade to its maximum height.

5.5.2. Remove the splitter (para. 5.3.).

5.5.3. Use the pin spanner to hold the blade flange while removing the blade retaining bolt, by turning it anti-clockwise, with the second spanner.

Remove the outer blade flange and then the saw blade with care. Wear gloves.

5.5.4. When fitting the new blade it is very important to ensure that the blade teeth are facing to the front of the saw table. Clean shaft and

flanges and then fit blade, outer blade flange, washer and bolt. Tighten bolt.

5.5.5. Refit the splitter, table insert and the blade guard.

5.6. Fence

5.6.1. To move the fence (fig. 1.7) across the table, loosen the clamp screw (fig. 1.12) and slide the fence to the required position. Retighten

the clamp screw.

5.6.2. To set the distance between the saw blade and the fence use the graduated guide at the front of the table. Align the pointer on the

fence slide with the required dimension.

Note: The fence can be mounted in the slider in two positions, with the long side vertical for normal use (fig. 4) and with the short side

vertical for cutting thin workpieces (fig. 5). Move the mounting screws from one slot in the fence to the other to change positions.

5.6.3. Loosen the wing nuts clamping the fence to the slider and adjust the fence longitudinally so that the far end coincides with an imaginary

line running from the centre of the blade rearwards at 45

O

. Retighten wing nuts.

5.7. Table insert

p WARNING! To reduce the risk of an accident the table insert (fig. 1.6) must be replaced if it becomes worn or damaged.

5.7.1. Remove the blade guard.

5.7.2. Remove the six countersunk screws and remove insert.

5.7.3. Fit new insert and retain with the six countersunk screws.

WARNING! As with all power tools, there are potential hazards

involved in the use of this saw. It is, therefore, vital to ensure you

have read and understood all the safety instructions in Section 1.

Familiarise yourself again with the specific saw safety rules for

each step of the following operation. Failure to do so could cause

serious damage and/or personal injury and may invalidate your warranty. Disconnect the saw from the mains power before making any

adjustments or removing/fitting the blade. Ensure that all screws and nuts are secure and that the blade is in good condition and correctly

fitted. ALWAYS position the blade guard as close as possible to the workpiece before turning on the saw. Wear approved safety eye protection.

Note: Figs. 6, 7 & 8 are for illustration purposes and may not reflect exactly the detail of your saw.

6.1. Cross cutting

Cross cutting requires the use of the cross stop to position and guide the work. Place the workpiece against the cross stop and

ad vanc e b o th towards the saw blade (fig. 6). The cross stop may be

used in either the left or right table slots.

s CAUTION! If you are bevel cross cutting ( i.e. blade is tilted) use the

right-hand slot only. This will ensure that the blade is tilted away

from the cross stop and your hands.

6.1.1. When you have completed the cross cut, the waste off-cut will be

unsupported and will either remain on the saw table or fall off. Before

starting, therefore, consider how you will handle the off-cut.

6.1.2. Remove the fence if the workpiece extends beyond the side of the table.

6.1.3. Check that everything is ready and that the blade guard is down.

Plug the saw into the mains power supply and switch the saw on.

6.1.4. Hold workpiece firmly against the cross stop and table (hold the main

item and not the piece that will become the of

f-cut).

6.1.5. Slowly move the workpiece forward into the rotating blade. Continue holding

the workpiece firmly whilst passing it completely past the blade so

that it is cut into two.

6.1.6. Before drawing the workpiece back towards yourself, move it slightly to the side so that it is clear of the saw blade.

p WARNING! DO NOT attempt to pick up an off-cut before the saw blade has completely stopped.

p W

ARNING!

DO NOT use the fence as a cut-off gauge when cross-cutting.

Note: For added safety you can screw an auxiliary wood-facing to the cross stop using the screw holes provided.

6.2. Rip sawing

p WARNING! The safety precautions stated at the beginning of this section must be adhered to.

Ripping is when a board or similar workpiece is held against the fence and cut along the

length (fig. 7). The fence is used to position and guide the workpiece during cutting.

The workpiece is laid flat on the saw table with one edge held tightly against the fence.

The splitter will prevent the saw cut from closing and binding the blade. Proceed as follows:

6.2.1. Move the fence to the required position and lock it to the saw table.

6.2.2. Adjust the blade height to just exceed the thickness of the workpiece.

6.2.3. Position the blade guard to just clear the workpiece.

6.2.4. Before starting consider how you will handle the workpiece and the off-cut when

ripping is complete. Depending on the size and type o

f workpiece, off-cuts and

workpiece may remain on the table or fall to the floor. Provide a support at the

rear of the saw table to prevent long workpieces and off-cuts from falling. Off-cuts

that remain on the table must not be touched until the blade has completely stopped.

6.2.5. Ripping a workpiece more than 120mm wide

a) Hold the workpiece firmly against the fence and the table, and turn the saw on.

b) Ensure you are NOT standing in line with the blade. Hold workpiece firmly with both hands, pushing it along fence and into blade (fig. 7).

c) Continue to gradually feed the workpiece past the saw blade keeping your hands away from the blade guard.

d) Move the workpiece completely past the saw blade.

e) Once the cut is complete handle the workpiece and off-cut according to 6.2.4.

6. OPERATING INSTRUCTIONS

fig.6

fig. 7

TS10CZ - 0016 - (1) - 040501

fig. 4

fig. 5

Page 5

6.2.6. Workpiece less than 120mm but more than 30mm wide

Use the push stick provided to feed workpiece forward (fig. 8).

6.2.7. Workpiece 30mm wide or less

When ripping stock 30mm or less, position the fence as for thin workpieces (para. 5.6.) and use a push block.

6.3. On/Off switch

The saw has an No-volt switch (fig. 1.11) which automatically moves to the Off condition in the case of a power interruption. The saw

will not then restart automatically when the supply is reinstated.

1) Slide up the red emergency stop button to unlatch cover. 2) Raise the cover to reveal the two switch buttons.

3) Push the

l button for On and the 0 for Off. 4) Do not latch cover when the saw is running as this will switch saw off.

5) In an emergency firmly press the red emergency stop button on the cover - this will stop the saw and latch the cover.

Sole UK Distributor,

Sealey Group,

Bury St. Edmunds, Suffolk.

01284 757500 01284 703534 E-mail: sales@sealey.co.uk

Declaration of Conformity We, the sole importer into the UK, declare that the product listed below is in conformity with the following

standards and directives.

The construction file for this product is held by the Manufacturer and may

be inspected, by a national authority, upon request to Jack Sealey Ltd.

For Jack Sealey Ltd. Sole importer into the UK of Sealey Quality Machinery.

TABLE SAW MODEL TS10CZ

73/23/EEC Low Voltage Directive

89/336/EEC EMC Directive

98/37/EC Machinery Directive

93/68/EEC EC Marking Directive

Signed by Mark Sweetman

21st May 2001

NOTE:

It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT: No responsibility is accepted for incorrect use of this equipment.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

INFORMATION: For a copy of our latest catalogue and promotions call us on 01284 757525 and leave your name and address, including postcode.

fig. 8

TS10CZ - 0016 - (1) - 040501

8. DECLARATION OF CONFORMITY

7. MAINTENANCE

7.1. Regularly clean the saw to remove dirt, dust and chippings using a brush and cloths.

7.2. Clean plastic components with water and detergent, never use caustic or abrasive cleaners.

Loading...

Loading...