Page 1

TA320

Digital Automotive

Analyser/Insulation

Tester - Hybrid Vehicles

© Jack Sealey Limited

Original Language Version

TA320 Issue No.3(L) 14/11/16

Page 2

INTRODUCTION:

Specially designed for hybrid vehicles and conforms to EN61010 CAT III (1000 Volts)

and CAT IV (600 Volts). Unlike other multimeters this unit has an insulation test function

that allows testing of the insulation of the high voltage wires found on hybrid vehicles.

Can be used as a stand-alone device or linked wirelessly with a USB interface to a PC

or laptop enabling results to be graphed, saved or printed. Supplied with high voltage

probes, thermocouple and wireless USB cable. The unit also has the usual functions

expectedonahighqualitymultimeterincludingtrueRMS(Root-Mean-Square)andIP67

waterproof rating.

TECHNICAL SPECIFICATION:

AC Voltage: 400mV, 4V, 40V, 400V, 1000V

DC Voltage: 400mV, 4V, 40V, 400V, 1000V

AC Current: 400µA, 4000µA, 40mA, 400mA, 10A

DC Current: 400µA, 4000µA, 40mA, 400mA, 10A

Capacitance: 40nF, 400nF, 4µF, 40µF, 400µF, 4000µF, 40mF

Frequency: 40Hz - 10KHz

Duty Cycle: 0.1 - 99.9%

Pulse Width: 100µs-100ms

Resistance: 400Ω,4kΩ,40kΩ,400kΩ,4MΩ,40mΩ

Continuity: <35Ω

Temperature Range: -50°C to 1000°C, -58°F to 1832°F

Diode Check: Yes

Back Light: Yes

Bar Graph Display: Yes

Display Hold: Yes

Auto-Ranging: Yes

Insulation Test: 125V, 250V, 500V, 1000V

PC Interface: Yes

Digit Height: 20mm

Auto Power Off: Yes

Low Battery Indicator: Yes

Batteries (supplied): 6 x 1.5V AA

Hi-Impact Case: Yes

Size (L x W x D): 220 x 95 x 56mm

Weight: 700g

PC Compatibility: Windows 2000, XP, Win7, Vista, Win8, Win10.

© Jack Sealey Limited

Original Language Version

TA320 Issue No.3(L) 14/11/16

Page 3

Environmental Protection

Recycle unwanted materials instead of disposing of them as waste.

All tools, accessories and packaging should be sorted, taken to a

recycling centre and disposed of in a manner which is compatible

with the environment.

When the product becomes completely unserviceable and disposal,

drain off any fluids (if applicable) into approved containers and

dispose of the product and the fluids according to local regulations.

WEEE Regulations

Dispose of this product at the end of its working life in compliance

with the EU Directive on Waste Electrical and Electronic Equipment

(WEEE). When the product is no longer required, it must be disposed

of in an environmentally protective way. Contact your local solid waste

authority for recycling information.

Battery Removal

This analyser contains 6 AA batteries which must be disposed of in an

environntally appropriate way.

TO REMOVE THE BATTERIES:

1) Lift the rear support bracket.

2) Remove the four cross-head screws from the battery cover.

3) Remove the battery cover.

4) Remove the batteries.

Under the Waste Batteries and Accumulators Regulations 2009,

Jack Sealey Ltd are required to inform potential purchasers of products

containingbatteries(asdenedwithintheseregulations),thattheyare

registered with Valpak’s registered compliance scheme.

Jack Sealey Ltd’s Batteries Producer Registration Number (BPRN) is

BPRN00705.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS,

WARNINGS AND CAUTIONS. USE THIS PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT

IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR PERSONAL INJURY AND WILL INVALIDATE THE

WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

© Jack Sealey Limited

Original Language Version

TA320 Issue No.3(L) 14/11/16

Page 4

GENERAL SAFETY PRECAUTIONS.

Wear safety eye protection that meets ANSI standards.

Operate the vehicle to be tested in a well ventilated area. Exhaust gases are

poisonous. If necessary connect the vehicle exhaust to a fume extraction system.

Place chocks in front of the drive wheels and never leave the vehicle unattended

whilst testing is in progress.

Be extra cautious when working in close proximity to the ignition coil, distributor

cap, ignition wires and spark plugs. These components create hazardous voltages

when the engine is running.

Ensure that the handbrake is on and the gearbox is in neutral or ‘Park’ for

automatic transmissions.

Keepreextinguishersnearbythataresuitableforpetrol/chemical/electricalres.

Keep the analyser clean and in good condition.

Remain vigilant when using the code reader on, or near, machinery where there are

rotational parts such as belts, pulleys and fans.

Removeillttingclothing.Removeties,watches,rings,andotherloosejewellery,

and contain and/or tie back long hair.

Maintaincorrectbalanceandfooting.Ensuretheoorisnotslipperyandwear

non-slip shoes.

Keep product surfaces clean and dry.

The user shall ensure that test probes are correctly selected in order to prevent

danger. Probes shall be selected to ensure that adequate barriers guard against

inadvertent hand contact with live conductors under test and that probes have

minimal exposed probe tips. Where there is a risk of the probe tip short circuiting

with other live conductors under test, it is recommended that the exposed tip length

shall not exceed 4mm.

DO NOT attempt to connect or disconnect any test equipment whilst the ignition

is on or the engine is running.

DO NOT use the analyser if damage is suspected. If suspected damage occurs

withthedevice,haveitinspectedbyqualiedservicepersonnelbeforeusingit

again.

DO NOT get the analyser wet or use in damp or wet locations or areas where

there is condensation.

DO NOT use the analyser for any purpose other than for which it is designed.

DO NOT allow untrained persons to use analyser.

DO NOTusetheanalyserwhenyouaretiredorundertheinuenceofalcohol,

drugs or intoxicating medication.

DO NOT operate in a potentially explosive environment/atmosphere.

WARNING: The warnings, cautions and instructions discussed in this instruction

manual cannot cover all possible conditions and situations that may occur. It must

be understood that common sense and caution are factors which cannot be built

into this product, but must be applied by the operator.

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will give you years of

trouble free performance, if these instructions are carefully followed and the product is correctly maintained.

© Jack Sealey Limited

Sole UK Distributor, Sealey Group,

Kempson Way, Suffolk Business Park,

Bury St. Edmunds, Suffolk,

IP32 7AR

Original Language Version

01284 757500

01284 703534

www.sealey.co.uk

Web

sales@sealey.co.uk

TA320 Issue No.3(L) 14/11/16

Page 5

WARNING

CAUTION

MAX

1000V

Safety Symbols

This symbol adjacent to another symbol, t erm inal

or operating device indicates that the operator

must refer to an explanation in the Operating

Instructions to avoid personal injury or damage to

the meter.

This WARNING symbol indicates a potentially

hazardous situation, which if not avoided, could

result in death or serious injury.

This CAUTION symbol indicates a potentially

hazardous situation, which if not avoided, may

result in damage to the product.

This symbol advises the user that the terminal(s)

so marked must not be connected to a circuit point

at which the voltage with respect to earth ground

exceeds (in this case) 1000 VAC or VDC.

This symbol adjacent to one or more terminals

identifies them as being associated with ranges

that may, in normal use, be subjected to

particularly hazardous voltages. For maximum

safety, the meter and its test leads should not be

handled when these terminals are energized.

This symbol indicates that a device is protected

throughout by double insulation or reinforced

insulation.

Page 6

PER IEC1010 OVERVOLTAGE INSTALLATION CATEGORY

OVERVOLTAGE CATEGORY I

Equipment of OVERVOLTAGE CATEGORY I is equipment for

connection to circuits in which measures are taken to limit the

transient overvoltages to an appropriate low level.

Note – Examples include protected electronic circuits.

OVERVOLTAGE CATEGORY II

Equipment of OVERVOLTAGE CATEGORY II is energy-consuming

equipment to be supplied from the fixed installation.

Note – Examples include household, office, and laboratory appliances.

OVERVOLTAGE CATEGORY III

Equipment of OVERVOLTAGE CATEGORY III is equipment in fixed

installations.

Note – Exam ples include switches in the fixed installation and some

equipment for industrial use with perm anent connection t o the fixed

installation.

OVERVOLTAGE CATEGORY IV

Equipment of OVERVOLTAGE CATEGORY IV is for use at the

origin of the installation.

Note – Examples include electricity meters and primary

over-current protection equipment

Page 7

ELECTRICAL SAFE TY PRECAUTIONS

10A 1000V fast acting fuse (20A

minutes)

Frequency, Resistance,

Diode Test, Continuity

This meter has been designed for safe use, but must be operated with

caution. The rules listed below must be carefully followed for safe

operation.

1. NEVER apply voltage or current to the meter that exceeds the

specified maximum:

Input Protection Limits

Function Maximum Input

V DC or V AC 1000VDC/AC rms

mA AC/DC 500mA 1000V fast acting fuse

A AC/DC

Capacitance, Duty Cycle,

Temperature 1000VDC/AC rms

Surge Protection: 8kV peak per IEC 61010

2. USE EXTREME CAUTION when working with high voltages.

3. DO NOT meas ure voltage if t he voltage on the "COM" input jack

exceeds 1000V above earth ground.

4. NEVER connect the meter leads across a voltage source while

the function switch is in the current, resistance, or diode mode.

Doing so can damage the meter.

5. ALWAYS discharge filter capacitors in power supplies and

disconnect the power when making resistance or diode tests.

6. ALWAYS turn of f the power and disconnec t t he test leads before

opening the covers to replace the fuse or batteries.

for 30 seconds max every 15

1000VDC/AC rms

Page 8

7. NEVER operate the meter unless the back cover and the battery

and fuse covers are in place and fastened securely.

If the equipment is used in a manner not specified by the

manufacturer, the protection provided by the equipment may be

impaired.

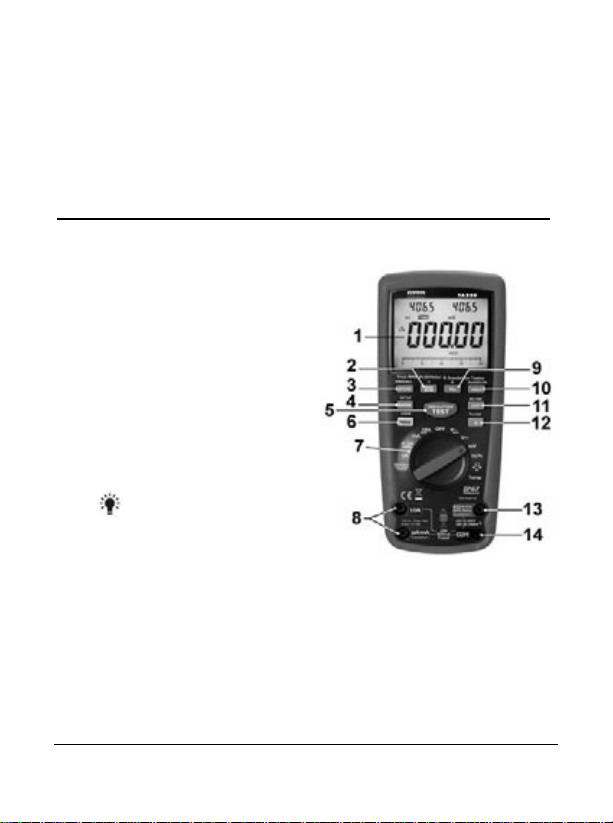

Controls and Jacks

1. 40,000 count LCD display

2. MAX/MIN (-)button

3. STORE(<RECALL) button

4. RANGE(SETUP) button

5. INSULATION TEST button

6. MODE button

7. Function switch

8. mA, µA and 10A input jacks

9. REL(+) button

10. HOLD(PEAKHOLD>) button

11. EXIT(AC+DC) button

12. Backlight and RF button

13. Positive input jack

14. COM input jack

Note: Tilt stand and battery compartment are on rear of unit.

Page 9

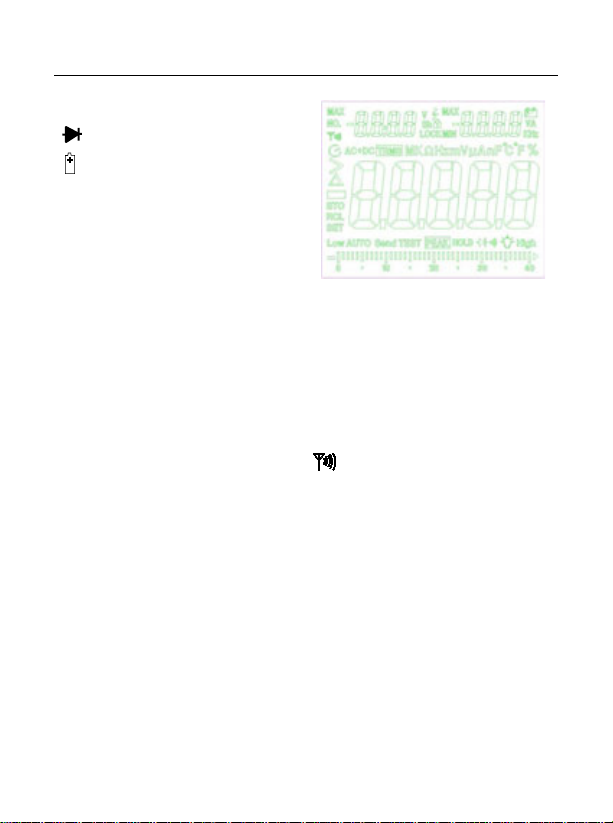

Symbols and Annunciators

•))) Continuity

Diode test

Battery status

n nano (10

µ micro (10

m milli (10

A Amps

k kilo (10

F Farads (capacitance)

M mega (10

-9

) (capacitance)

-6

) (amps, cap)

-3

) (volts, amps)

3

) (ohms)

6

) (ohms)

Ω Ohms PEAK Peak Hold

Hz Hertz (frequency) V Volts

% Percent (duty ratio) REL Relative

AC Alternating current AUTO Autoranging

DC Direct current HOLD Display hold

ºF Degrees Fahrenheit ºC Degrees Centigrade

MAX Maximum MIN Minimum

No. Serial number RF transmitter active

S Second

left auxiliary display

right auxiliary display

SET Set up parameter

AC+DC Alternating current + Direct current

TRMS True RMS

STO Store

RCL Recall

AUTO Auto Range

Timing symbol

Backlight

Bar graph

Page 10

Operating Instructions

WARNING: Risk of electrocution. High-voltage circuits, both AC and

DC, are very dangerous and should be measured with great care.

1. ALWAYS turn the function switch to the OFF position when the

meter is not in use.

2. If “OL” appears in the display during a measurement, the value

exceeds the range you have selected. Change to a higher range.

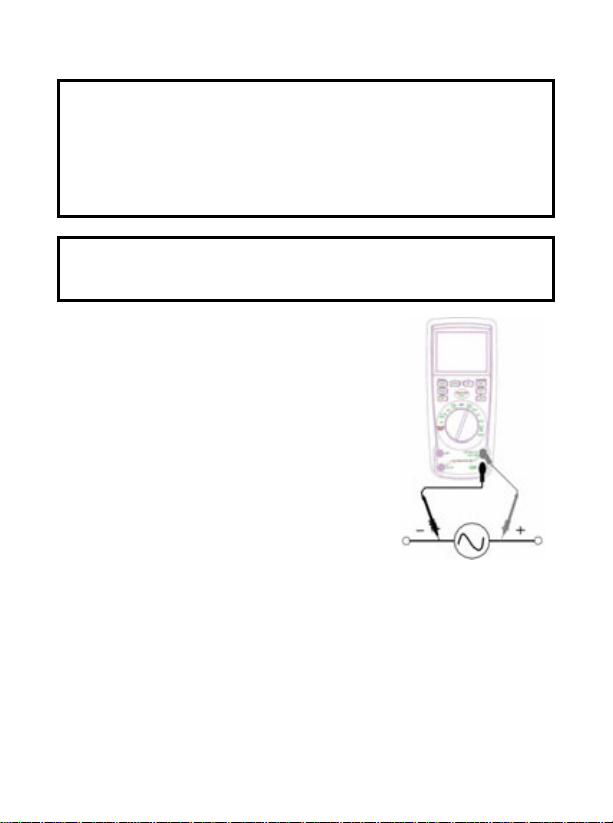

DC VOLTAGE MEASUREMENTS

CAUTION: Do not measure DC voltages if a motor on the circuit

is being switched ON or OFF. Large voltage surges may occur

that can damage the meter.

1. Set the function switch to the green VDC

position.

2. Insert the black test lead banana plug into the

negative COM jack.

Insert the red test lead banana plug into the

positive V jack.

3. Touch the black test probe tip to the negative

side of the circuit.

Touch the red test probe tip to the positive

side of the circuit.

4. Read the voltage in the display.

Page 11

AC VOLTAGE (FREQUENCY, DUTY CYCLE) MEASUREMENTS

WARNING: Risk of Electrocution. The probe tips may not be long

enough to contact the live parts inside some 240V outlets for

appliances because the contacts are recessed deep in the outlets.

As a result, the reading may show 0 volts when the outlet actually

has voltage on it. Make sure the probe tips are touching the metal

contacts inside the outlet before assuming that no voltage is

present.

CAUTION: Do not measure AC voltages if a motor on the circuit

is being switched ON or OFF. Large voltage surges may occur

that can damage the meter.

1. Set the function switch to the green

VAC/Hz/% position.

2. Insert the black test lead banana plug

into the negative COM jack.

Insert red test lead banana plug into the

positive V jack.

3. Touch the black test probe tip to the

neutral side of the circuit.

Touch the red test probe tip to the “hot”

side of the circuit.

4. Read the voltage in the main display and

the frequency in the right auxiliary

display

5. Press and hold the MODE button 2 second to indicate “Hz”.

6. Read the frequency in the main display.

7. Press the MODE button to indicate “%”.

8. Read the % of duty cycle in the main display.

9. Press EXIT for 2 seconds into the function of AC+DC. Test DC

and AC True Rms.

Page 12

MV VOLTAGE MEASUREMENTS

CAUTION: Do not measure mV voltages if a motor on the circuit

is being switched ON or OFF. Large voltage surges may occur

that can damage the meter.

1. Set the function switch to the green mV position.

2. Press the MODE button to indicate “DC”.or

““AC ”, or in AC range press EXIT for t wo

seconds and chose ”AC+DC”

Insert the black test lead banana plug into

the negative COM jack.

Insert the red test lead banana plug into

the positive V jack.

3. Touch the black test probe tip to the

negative side of the circuit.

Touch the red test probe tip to the positive

side of the circuit.

4. Read the mV voltage in the display.

Page 13

DC CURRENT MEASUREMENTS

CAUTION: Do not make 20A current measurements for longer

than 30 seconds. Exceeding 30 seconds may cause damage to

the meter and/or the test leads.

1. Insert the black test lead banana plug into the negative COM jack.

2. For current measurements up to 4000µA

DC, set the function switch to the yellow µA

position and insert the red test lead banana

plug into the µ A/mA jack.

3. For current measurements up to 400mA DC,

set the function switch to the yellow mA

position and insert the red test lead banana

plug into the µ A/mA jack.

4. For current measurements up to 20A DC,

set the function switch to the yellow 10A/HZ/%

position and insert the red test lead banana

plug into the 10A jack.

5. Press the MODE button to indicate “DC” on

the display.

6. Remove power from the circuit under test,

then open up the circuit at the point where

you wish to measure current.

7. Touch the black test probe tip to the negative side of the circuit.

Touch the red test probe tip to the positive side of the circuit.

8. Apply power to the circuit.

9. Read the current in the display.

Page 14

AC CURRENT (FREQUENCY, DUTY CYCLE) MEASUREMENTS

CAUTION: Do not make 20A current measurements for longer

than 30 seconds. Exceeding 30 seconds may cause damage to

the meter and/or the test leads.

1. Insert the black test lead banana plug

into the negative COM jack.

2. For current measurements up to

4000µA AC, set the function switch to

the yellow µA position and insert the

red test lead banana plug into the

µA/ mA jack.

3. For current measurements up to

400mA AC, set the function switch to

the yellow mA position and insert the

red test lead banana plug into the

µA/ mA jack.

4. For current measurements up to 20A

AC, set the function switch to the

yellow 10A/HZ/% position and insert

the red test lead banana plug into the

10A jack.

5. Press the MODE button to indicate “AC”

on the display.

6. Remove power from the circuit under test, then open up the

circuit at the point where you wish to measure current.

7. Touch the black test probe tip to the neutral side of the circuit.

Touch the red test probe tip to the “hot” side of the circuit.

8. Apply power to the circuit.

9. Read the current in the display. In the 10AAC range, right

auxiliary display frequency.

10. Press and hold the MODE button to indicate “Hz”.

11. Read the frequency in the display.

12. Momentarily press the MODE button again to indicate “%”.

Page 15

13. Read the % duty cycle in the display.

14. Press and hold the MODE button to return to current

measurement.

15. Press EXIT for 2 seconds into the function of AC+DC. Test DC

and AC True Rms.

RESISTANCE MEASUREMENTS

WARNING: To avoid electric shock, disconnect power to the unit

under test and discharge all capacitors before taking any

resistance measurements. Remove the batteries and unplug the

line cords.

1. Set the function switch to the green

Ω CAP position.

2. Insert the black test lead banana plug

into the negative COM jack.

Insert the red test lead banana plug into

the positive

3. Press the MODE button to indicate

Ω” on the display.

“

4. Touch the test probe tips across the

circuit or part under test. It is best to

disconnect one side of the part under

test so the rest of the circuit will not

interfere with the resistance reading.

5. Read the resistance in the display.

Ω jack.

Page 16

CONTINUITY CHECK

WARNING: To avoid electric shock, never measure continuity on

circuits or wires that have voltage on them.

1. Set the function switch to the green

Ω CAP position.

2. Insert the black lead banana plug into the

negative COM jack.

Insert the red test lead banana plug into the

positive

Ω jack.

3. Press the MODE button to indicate“ "and

“Ω” on the display

4. Touch the test probe tips to the circuit or wire

you wish to check.

5. If the resistance is less than approximately

35Ω, the audible signal will sound. If the

circuit is open, the display will indicate “OL”.

DIODE TEST

1. Set the function switch to the green Ω CAP

position.

2. Insert the black test lead banana plug into the

negative COM jack and the red test lead

banana plug into the positive V jack.

3. Press the MODE button to indicate“ “ and

“V” on the display.

4. Touch the test probes to the diode under test.

Forward voltage will typically indicate 0.400 to

0.700V. Reverse voltage will indicate “OL”.

Shorted devices will indicate near 0V and an

open device will indicate “OL” in both

polarities.

Page 17

CAPACITANCE MEASUREMENTS

WARNING: To avoid electric shock, disconnect power to the unit

under test and discharge all capacitors before taking any

capacitance measurements. Remove the batteries and unplug the

line cords.

1. Set the rotary function switch to the green

Ω C AP position.

2. Insert the black test lead banana plug into

the negative COM jack.

3. Insert the red test lead banana plug into

the positive V jack.

4. Press the MODE button to indicate “F”

5. Touch the test leads to the capacitor to be

tested.

Read the capacitance value in the

Display

TEMPERATURE MEASUREMENTS

1. Set the function switch to the green

Temp position.

2. Insert the Temperature Probe into the

input jacks, making sure to observe the

correct polarity.

3. Press the MODE button to indicate “ºF”

or “ºC”

4. Touch the T emperature Probe head to

the part whose temperature you wish to

measure. Keep the probe touching the

part under test until the reading

stabilizes (about 30 seconds).

5. Read the temperature in the display.

Note: The temperature probe is fitted with a type K mini connector.

A mini connector to banana connector adaptor is supplied for

connection to the input banana jacks.

Page 18

FREQUENCY (DUTY CYCLE) MEASUREMENTS (ELECTRONIC)

1. Set the rotary function switch to the green Hz/% position.

2. Insert the black lead banana plug into the

negative COM jack and the red test lead

banana plug into the positive Hz jack.

3. Touch t he test probe tips t o the circuit under

test.

4. Read the frequency on the display.

5. Press the MODE button to indicate “%”.

6. Read the % duty cycle in the display.

% 4 – 20mA MEASUREMENTS

1. Set up and connect as described for DC mA measurements.

2. Set the rotary function switch to the 4-20mA% position.

3. The meter will display loop current as a % with 0mA=-25%,

4mA=0%, 20mA=100%, and 24mA=125%.

INSULATION RESISTANCE MEASUREMENTS

a)Set the rotary function switch to the INSULATION position

and Press the RANGE button to chose one of the voltages

displayed in the top left corner.

b)Connect two testing lines to the item to be tested.

c)Push down and hold the “TEST” button or press the “LOCK” key first

and then the “TEST” button, if there is any static electricity present

in the item being tested and its voltage is over 30V, it will fail and no

high-voltage testing will occur, “>30V” will dis play on the LCD, the

symbol “ ” f lashes, and the buzzer will sound. Otherwise it will

enter into the formal testing process and the hi gh-voltage will show

on the primary display, the insulation resistance i n MΩ is indicated

in-phase with the analog bar; on the top right corner display, the

Page 19

tested insulation voltage in V (DC) is indicated, the symbol “ ”

flashes and the buzzer will sound.

d)Releasing the “TEST” button or pushi ng down the “TEST” button in

the “LOCK “ status will exit from the “LOCK” status and shut-off the

testing voltage, simultaneously t he resistance value indicated in the

primary display will be held, and the top right corner display will still

show the status of the insulation voltage for the item tested.

Turning the function switch to off or pressing the EXIT button

will exit fro m the testing procedure during the process.

POWER TOOLS AND SMAL L AP PLI ANCES

This test would also apply to other similar equipment that has a line

cord. For double insulated power tools, the megohmmeter lead shown

connected to the housing would be connected to some metal part lf

the tool(e.g. chuck, blade).

Note: The switch of the device must be in the “ON” position and the

main power should be disconnected.

MOTORS

AC-Disconnect the motor from the line by disconnecting the wires at

the motor terminals or by opening the main switch. If the main switch

is used and the motor also has a starter then the starter must be held,

by some means, in the “ON” position. In the latter case, the measured

resistance will include the resistance of the motor, wire and all other

components between the motor and the main switch. If a weakness is

indicated, the motor and other components should be checked

individually. If the motor is disconnected at the motor terminals,

connect one megohmmeter lead to the grounded motor housing and

the other lead to one of the motor leads. DC - Disconnect the m otor

from the line. To test the brush rigging, field coils and armature

Page 20

connect one megohmmeter lead to the grounded m otor housing and

the other lead to the brush on the commutator. If the resistance

measurement indicates a weakness, raise the brushes off the

commutator and separately test the armature, field coils and brush

rigging by connecting one megohmmeter lead to each of them

individually, leaving the other connected to the grounded motor

housing. The above also applies to DC Generators.

Page 21

CABLES

Disconnect the cable from the line. Also disconnect opposite end to

avoid errors due to leakage from other equipment. Check each

conductor to ground and /or lead sheath by connecting one

megohmmeter lead to a ground and /or lead sheather and the other

megohmmeter lead to each of the conductors in turn. Check insulation

resistance between conductors by connecting megohmmeter leads to

conductors in pairs.

Page 22

AUTORANGING/MANUAL RANGE SELECTION

When the meter is first turned on, it automatically goes into

AutoRanging. This automatically selects the best range for the

measurements being made and is generally the best mode for most

measurements. For measurement situations requiring that a range

be manually selected, perform the following:

1. Press the R ANG E key. The “AUTO” display indicator will turn off.

2. Press the RANGE key to step through the available ranges until

you select the range you want.

3. To exit the Manual Ranging mode and return to Autoranging,

press EXIT

Note: Manual ranging does not apply for the Temperature functions.

MAX/MI N

1. Press the M AX/MIN key to a ctivate the MAX/MIN recording mode.

The display icon "MAX" will appear. The meter left auxiliary

display will display and hold the maximum reading and will update

only when a new “max” occurs. The display icon "MIN" will appear.

The right auxiliary display meter will display and hold the

minimum reading and will update only when a new “min” occurs.

2.To exit MAX/MIN mode press EXIT

RELATIVE MODE

The relative measurement feature allows you to make

measurements relative to a stored reference value. A reference

voltage, current, etc. can be stored and measurements made in

comparison to that value. The displayed value is the difference

between the reference value and the measured value. Note:

Relative mode does not operate in the 4-20mA function.

1. Perform the measurement as described in the operating

instructions.

2. Press the REL button to store the reading in the display and the

"REL" indicator will appear on the display.

Page 23

3. Left auxiliary display shows the margin of initial value and t he

current value.

Right auxiliary display shows the initial reading. Main displays

the reading after REL TEST.

4. Press the EXIT button to exit the relative mode.

Display Backlight

Press the key to turn the backlight on. The backlight will

automatically turn off after SET time. Press t he EXIT button to

exit the backlight on mode.

HOLD

The hold function freezes the reading in the display. Press the

HOLD

key momentarily to activate or to exit the

PEAK HOLD

The Peak Hold function captures the peak AC or DC voltage or

current. The meter can capture negative or positive peaks as fast

as 1 millisecond in duration. Momentarily press the PE AK button,

“PE AK” and “MAX ” will display in left auxiliary display. MIN” will

display in right auxiliary display. The meter will update the display

each time a lower negative peak occurs. Press the EXIT button to

exit the PEAK HOLD mode. Auto Power Off feature will be

disabled automatically in this mode.

DATA STORAGE

1. Set the function switch to the measurement f unct i on desired.

2. Press the STORE button to access the recording interval time

set up function.

3. The auxiliary displ ay on the left i ndicates 0000 S, which is the

recording sample rate; use the + & - buttons to select t he

desired sample rate (0 to 255 seconds)

4. Set the sample rate to 0000 S for manual recording. In this

mode, each press of the STORE button will save one

measurement reading.

HOLD

function.

Page 24

5. Set the sample rate (from 1 to 255 S) for automatic recording.

In this mode, pressing the STORE button will start data

recording at the programmed sample rate.

6. The auxiliary display on the left indicates the current storage

location (0000 to 9999). New measurements will begin storing

into the next available location.

7. Press and hold the STORE button for 2 seconds to enter the

RECALL mode or press EXIT to return to the normal operating

mode.

DATA STORAGE RECALL

1. Press and hold the STORE button for two seconds (if not

already done as instructed in step 7 in the above procedure) to

enter the RECALL function.

2. The auxiliary displ ay on t he left will s how XXXX (current

storage location). The auxiliary display on the right will show

XXXX (number of storage locations used).

3. Use the + and - buttons to navigate the storage locations. The

value for the selected location is indicated in the main display.

4. Press the EXIT button to end the recall session.

CLE AR ALL D ATA

1. From the OFF position, press and hold the RANGE button

while turning the function switch to any on position

2. Release t he RANGE button. The memory has been cleared

Page 25

PC WIRELESS COMMUNICATION

1. Install and launc h the PC software (refer to the HELP utility

contained in the software for more details)

2. Press and Hold the backlight/ USB butt on for two seconds to

enter RF wireless transmit mode

3. The RF icon will appear on the display

4. When communication is established, the RF icon on the

display will blink and the LED indicator on the receiver will

blink

5. Once per second, the data will be displayed on the PC screen

(plotted on the graph and inserted to the data list)

6. Hold the backlight butt on for two seconds to exit the RF

wireless transmit mode

SENDING STORED DATA TO THE PC

1. Launch the PC software

2. Press the STORE button for two seconds to enter into data

RECALL function.

3. Press the HOLD button for two seconds. The RF transmit icon

will flash while the stored data is sent to the PC

NOTE: Refer to the HELP utility included in the supplied

software program for in-depth software instructions.

SETUP

1. Press and Hold the RANGE/SETUP button for two seconds to

enter the SET function. The first of five settable functions will

appear.

2. Press the RANGE button to step through the functi ons

a: Alarm High limit buzzer alarm OFF or Value

b: Alarm Low limit buzzer alarm OFF or Value

c: Auto power off time OFF, 10 to 30 sec

d: Button beeper ON/OFF

e: Back light time OFF, 10 to 30 sec

3. Use the +, - ,◄ and ► buttons to select and change conditions

and digits.

Page 26

4. Press the RANGE/SETUP button until the meter returns to the

normal display to exit this mode.

ALARM LIMITS

1. Press and Hold the SETUP button for two seconds to enter the

High Limit function.

2. Press the ► button to select a digit for adjustment

3. Press the + or – button to adjust the value of the digit

4. Press the

5. Press the SETUP button and repeat the procedure to set the

low limit

6. Press the SETUP button to step through the other functions

and return to the normal operating mode.

7. The meter will “beep” if the measured value is greater t han the

high limit or lower than the low limit.

.

AC+DC

In all the measuring mode VAC,mV(AC),10A(AC),mA(AC),uA(AC),

press button EXIT for 2 seconds to enter into AC+DC testing. The

precision is the same as AC measure. LCD shows AC+DC s i gnal.

Press button EXIT to exit.

LOW BATTERY INDICATION

When the icon appears alone in the display, t he batter ies

should be replaced.

◄ button to turn the alarm OFF.

Page 27

Maintenance

WARNING: To avoid electric shock, disconnect the test leads from

any source of voltage before removing the back cover or the battery

or fuse covers.

WARNING: To avoid electric shock, do not operate your meter until

the battery and fuse covers are in place and fastened securely.

This Meter is designed to provide years of dependable service, if the

following care instructions are performed:

1. KEEP THE METER DRY. If it gets wet, wipe it dry immediately.

2. USE AND STORE THE METER IN NORMAL TEMPERATURES.

Temperature extremes can shorten the life of the electronic parts

and distort or melt plastic parts.

3. HANDLE THE METER GENTLY AND CAREFULLY. Dropping it

can damage the electronic parts or the case.

4. KEEP THE METER CLEAN. Wipe the case occasionally with a

damp cloth. DO NOT use chemicals, cleaning solvents, or

detergents.

5. USE ONLY NEW BATTERIES OF THE RECOMMENDED SIZE

AND TYPE. Remove old batteries so they do not leak and

damage the unit.

6. IF THE METER IS TO BE STORED FOR A LONG PERIOD OF

TIME, the batteries should be removed to prevent damage to the

unit.

BATTERY INSTALLATION

WARNING: To avoid electric shock, disconnect the test leads from

any source of voltage before removing the battery cover.

1. Turn power off and disconnect the test leads from the meter.

2. Open the rear battery cover by removing 4 screws using a cross

head screwdriver.

Page 28

3. Insert the batteries into battery holder, observing the correct

polarity.

4. Put the battery cover back in place. Secure with the screws.

WARNING: To avoid electric shock, do not operate the meter until

the battery cover is in place and fastened securely.

NOTE: If your meter does not work properly, check the fuses and

batteries to make sure that they are still good and that they are

properly inserted.

Page 29

REPLACING THE FUSES

WARNING: To avoid electric shock, disconnect the test leads from

any source of voltage before removing the meter cover.

1. Disconnect the test leads from the meter.

2. Remove the protective rubber holster.

3. Remove the battery cover (4 screws) and the batteries.

4. Remove the six screws securing the rear cover.

5. Gently remove the old fuse and install the new fuse into the

holder.

6. Always use a fuse of the proper size and value (0.5A/1000V fast

blow for the 400mA range, 10A/1000V fast blow for the 20A range.

7. Replace and secure the rear cover, battery and battery cover.

WARNING: To avoid electric shock, do not operate your meter until

the fuse cover is in place and fastened securely.

Page 30

Specifications

Function

Range

Resolution

Accuracy

DC Voltage

400mV

0.01mV

4V

0.0001V

40V

0.001V

400V

0.01V

1000V

0.1V

AC Voltage

50 to 1000Hz

400mV

0.1mV

4V

0.001V

40V

0.01V

400V

0.1V

1000V

1V

400mV

0.1mV

4V

0.001V

40V

0.01V

400V

0.1V

1000V

1V

All AC voltage ranges are specified from 5% of range to

100% of range

DC Current

40mA

0.001mA

400mA

0.01mA

10A

0.001A

± (0.06% reading + 4digits)

± (0.1% reading + 5digits)

± (1.0% reading + 7digits)

± (1.0% reading + 5 digits)

AC+DCVoltage

± (1.0% reading + 7digits)

(50/60HZ)

400µA 0.01µA

4000µA 0.1µA

± (1.0% reading + 3 digits)

Page 31

(20A: 30 sec max with reduced accuracy)

AC Current

400µA

0.1µA

4000µA

1µA

40mA

0.01mA

AC+DCCurrent

400µA

0.1µA

± (1.5% reading + 7digits)

40mA

0.01mA

400mA

0.1mA

10A

0.01A

(20A: 30 sec max with reduced accuracy)

All AC current ranges are specified from 5% of range to

100% of range

Function

Range

Resolution

Accuracy

400Ω

0.01Ω ± (0.3% reading + 9 digits)

4kΩ

0.0001kΩ

400kΩ

0.01kΩ

4MΩ

0.001MΩ

± (1.5% reading + 7digits)

(50 to 1000Hz)

400mA 0.1mA

10A 0.01A

4000µA 1µA

(50/60HZ)

NOTE: Accuracy is stated at 65oF to 83oF (18oC to 28oC) and less

than 75% RH.

AC switch according to the calibration of sine wave. It generally

increase ±(2% reading + 2% full scale) if non sine wave in the

wave crest less than 3.0.

Resistance

40kΩ 0.001kΩ

± (0.3% reading + 4 digits)

40MΩ 0.001MΩ ± (2.0% reading + 10 digits)

Page 32

Capacitance

40nF

0.001nF

400nF

0.01nF

4µF

0.0001µF

40µF

0.001µF

400µF

0.01µF

4000µF

0.1µF

40mF

0.001mF

Frequency

(electronic)

40Hz

0.001Hz

400Hz

0.01Hz

40kHz

0.001kHz

400kHz

0.01kHz

40MHz

0.001MHz

100MHz

0.01MHz

Not specified

Sensitivity: 0.8V rms min. @ 20% to 80% duty cycle and

100kHz.

Frequency

40.00Hz-10KHz

0.01Hz - 0.001KHz

(0.5% reading)

Sensitivity:2Vrms

Duty Cycle

0.1 to 99.90%

0.01%

(1.2% reading + 2 digits)

Pulse width: 100µs - 100ms, Frequency: 5Hz to 150kHz

Temp

-50 to 1200°C

0.1°C

(probe accuracy not included)

4-20mA%

-25 to 125%

0.01%

±50 digits

0mA=-25%, 4mA=0%, 20mA=100%, 24mA=125%

± (3.5% reading + 40 digits)

± (3.5% reading + 10 digits)

± (5% reading + 10 digits)

4kHz 0.0001kHz

± (0.1% reading + 1 digits)

4MHz 0.0001MHz

<100kHz; 5Vrms min @ 20% to 80% duty cycle and >

(electrical)

±

(type-K)

-58 to 2192°F 0.1°F

±(1.0% reading + 2.5°C)

±(1.0% reading +4.5°F)

±

Page 33

Meg OHMS

Terminal

current

0.125~4.000 MΩ

0.001MΩ

+(2%+10)

4.001~40.00 MΩ

0.01MΩ

+(2%+10)

40.01~400.0 MΩ

0.1MΩ

+(4%+5)

400.1~4000 MΩ

1MΩ

+(5%+5)

0.250~4.000 MΩ

0.001MΩ

+(2%+10)

4.001~40.00 MΩ

0.01MΩ

+(2%+10)

40.01~400.0 MΩ

0.1MΩ

+(3%+5)

400.1~4000 MΩ

1MΩ

+(4%+5)

0.500~4.000 MΩ

0.001MΩ

+(2%+10)

4.001~40.00 MΩ

0.01MΩ

+(2%+10)

40.01~400.0 MΩ

0.1MΩ

+(2%+5)

400.1~4000 MΩ

1MΩ

+(4%+5)

1.000~4.000 MΩ

0.001MΩ

+(3%+10)

4.001~40.00 MΩ

0.01MΩ

+(2%+10)

40.01~400.0 MΩ

0.1MΩ

+(2%+5)

400.1~4000 MΩ

1MΩ

+(4%+5)

Range Resolution Accuracy Test

Voltage

Current

Short

circuit

125V(0

%~+10

%)

250V

(0%~+1

0%)

500V(0

%~+10

%)

1000V

(0%~+1

0%)

Note: Accuracy specifications consist of two elements:

• (% reading) – This is the accuracy of the measurement circuit.

• (+ digits) – This is the accuracy of the analog to digital converter.

1mA

@load1

25kΩ

1mA

@load2

50kΩ

1mA

@load5

00kΩ

1mA

@load1

MΩ

≤

1mA

≤

1mA

≤

1mA

≤

1mA

Page 34

Store capacitance 2000

Enclosure Double molded, waterproof

Shock (Drop Test) 6.5 feet (2 meters)

Diode Test Test current of 0.9mA maximum, open

Continuity Check Audible signal will sound if the resistance is

Peak Captures peaks >1ms

Temperature Sensor Requires type K thermocouple

Input Impedance >10MΩ VDC & >9MΩ VAC

AC Response True rms

AC True RMS: The t erm stands f or “Root-Mean-Square,”

ACV Bandwidth 50Hz to 1000Hz

Crest Factor ≤3 at full scale up to 500V, decreasing

Display 40,000 count backlit liquid crystal with

Overrange indication “OL” is displayed

Auto Power Off 15 minutes (approximatel y) with disable

Polarity Automatic (no indication for positive); Minus

Measurement Rate 2 times per second, nominal

Low Battery Indication “ ” is displayed if battery voltage drops

circuit voltage 2.8V DC typical

less than 35Ω (approx.), test current

<0.35mA

which represents the method of calculation

of the voltage or current value. Average

responding multimeters are calibrated to

read correctly only on sine waves and they

will read inaccurately on non-sine wave or

distorted signals. True rms meters read

accurately on either type of signal.

linearly to ≤1.5 at 1000V

bargraph

feature

(-) sign for negative

below operating voltage

Page 35

Battery 6 x AA batteries

Fuses mA, µA ranges; 0.5A/1000V ceramic fast

blow A range; 10A/1000V ceramic fast blow

Operating Temperature 41ºF to 104ºF (5ºC to 40ºC)

Storage Temperature -4

o

F to 140oF (-20oC to 60oC)

Operating Humidity Max 80% up to 87ºF (31ºC) decreasing

linearly to 50% at 104ºF (40ºC)

Storage Humidity <80%

Operating Altitude 7000ft. (2000metres) maximum.

Safety This meter is intended for origin of

installation use and protected, against the

user, by double insulation per EN61010-1

and IEC61010-1 2

nd

Edition (2001) to

Category IV 600V and Category III 1000V;

Pollution Degree 2. The meter also meets

UL 61010-1, 2

C22.2 No. 61010-1 2

UL 61010B-2-031, 1

nd

Edition (2004), CAN/CSA

nd

Edition (2004), and

st

Edition (2003)

Page 36

EC DECLARATION

OF CONFORMITY

Description and Function: ������������������������������������������������������������������������������������������������������������������������������������������������������������������������

Model/Type: ���������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������

Manufacturing Date/Serial Number (optional): ����������������������������������������������������������������������������������������������������������������������������������������

2006/42/EC Machinery Directive

: 2014/35/EU Low Voltage Directive

: 2014/30/EU EMC Directive

2009/125/EC Ecodesign Requirements

2009/142/EC Gas Appliance Directive

2014/29/EU Simple Pressure Vessels Directive

Manufacturer’s authorised representative within the EC: Jack Sealey Ltd, Kempson Way, Suffolk Business Park, Bury St

Edmunds, Suffolk. IP32 7AR

Conforms to the requirements of the Directives, as indicated�

And the following harmonised standard(s)

EN 61010-1:2010 �������������������������������������������������������������������������

TA320 v1

Digital Automotive Analyser/Insulation Tester - Hybrid Vehicles

2000/14/EC Noise Emission in the Environment Directive

: 2012/19/EU WEEE Directive

: 2011/65/EU RoHS Directive

2014/68/EU Pressure Equipment Directive

89/686/EEC PPE Directive

2014/53/EU RTTE Directive

������������������������������������������������������������������������������������������������������

EN 61010-2-033:2012 ������������������������������������������������������������������

EN 61326-1:2013 �������������������������������������������������������������������������

EN 61326-2-1:2013 ����������������������������������������������������������������������

������������������������������������������������������������������������������������������������������

������������������������������������������������������������������������������������������������������

������������������������������������������������������������������������������������������������������

Technical le compiled by: Jack Sealey Ltd

Being the responsible person appointed by the manufacturer.

Signed �������������������������������������������������������������������������������������������

Date �����������������������������������������������������������������������������������������������

Name ���������������������������������������������������������������������������������������������

Position �����������������������������������������������������������������������������������������

22 December 2016

Steve Buckle�

Marketing Director�

������������������������������������������������������������������������������������������������������

������������������������������������������������������������������������������������������������������

������������������������������������������������������������������������������������������������������

������������������������������������������������������������������������������������������������������

������������������������������������������������������������������������������������������������������

Place: Bury St Edmunds

Sealey Power Products Kempson Way, 01284 757500 01284 703534 sales@sealey�co�uk www�sealey�co�uk

Suolk Business Park, Bury St Edmunds,

Suolk. IP32 7AR

Loading...

Loading...