Sealey TA320 User Manual

User's Guide

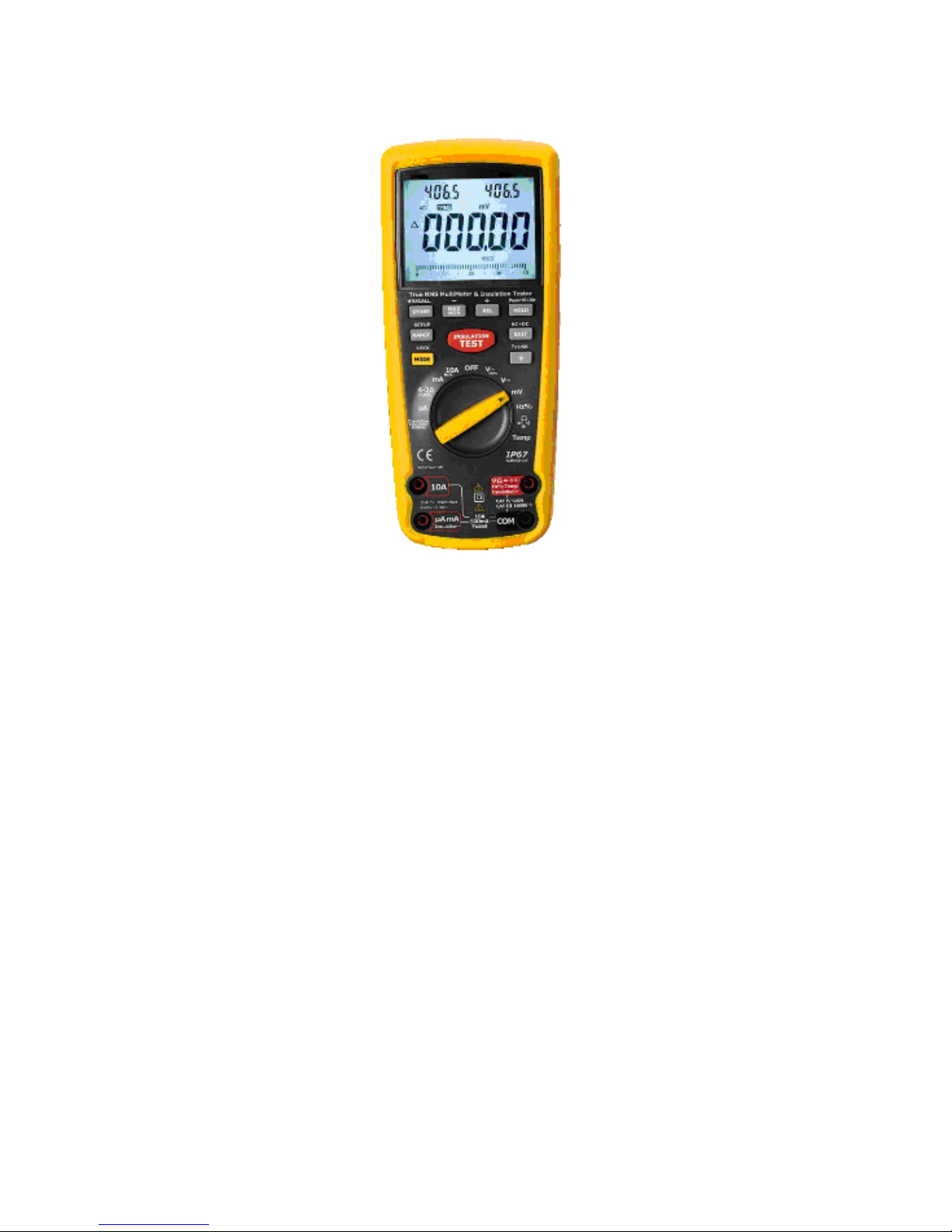

True RMS Industrial Multimeter

1

2

Introduction

This meter measures AC/DC Voltage, AC/DC Current, Resistance,

Capacitance, Frequency (electrical & electronic), Duty Cycle, Diode

Test,Insulation Test, and Continuity plus Thermocouple Temperature.

It can store and recall data. It features a waterproof, rugged design for

heavy duty use. Proper use and care of this meter will provide many

years of reliable service.

Safety

This symbol adjacent to another symbol, terminal

or operating device indicates that the operator

must refer to an explanation in the Operating

Instructions to avoid personal injury or damage to

the meter.

This WARNING symbol indicates a potentially

hazardous situation, which if not avoided, could

result in death or serious injury.

This CAUTION symbol indicates a potentially haza

rdous situation, which if not avoided, may result da

mage to the product.

This symbol advises the user that the terminal(s)

so marked must not be connected to a circuit point

at which the voltage with respect to earth ground

exceeds (in this case) 1000 VAC or VDC.

This symbol adjacent to one or more terminals

identifies them as being associated with ranges

that may, in normal use, be subjected to

particularly hazardous voltages. For maximum

safety, the meter and its test leads should not be

handled when these terminals are energized.

This symbol indicates that a device is protected

throughout by double insulation or reinforced

insulation.

WARNING

CAUTION

MAX

1000V

3

PER IEC1010 OVERVOLTAGE INSTALLATION CATEGORY

OVERVOLTAGE CATEGORY I

Equipment of OVERVOLTAGE CATEGORY I is equipment for

connection to circuits in which measures are taken to limit the

transient overvoltages to an appropriate low level.

Note – Examples include protected electronic circuits.

OVERVOLTAGE CATEGORY II

Equipment of OVERVOLTAGE CATEGORY II is energy-consuming

equipment to be supplied from the fixed installation.

Note – Examples include household, office, and laboratory appliances.

OVERVOLTAGE CATEGORY III

Equipment of OVERVOLTAGE CATEGORY III is equipment in

fixed installations.

Note – Examples include switches in the fixed installation and some

equipment for industrial use with permanent connection to the fixed

installation.

OVERVOLTAGE CATEGORY IV

Equipment of OVERVOLTAGE CATEGORY IV is for use at the

origin of the installation.

Note – Examples include electricity meters and primary overcurrent protection equipment

4

SAFETY INSTRUCTIONS

This meter has been designed for safe use, but must be operated with

caution. The rules listed below must be carefully followed for safe

operation.

1. NEVER apply voltage or current to the meter that exceeds the

specified maximum:

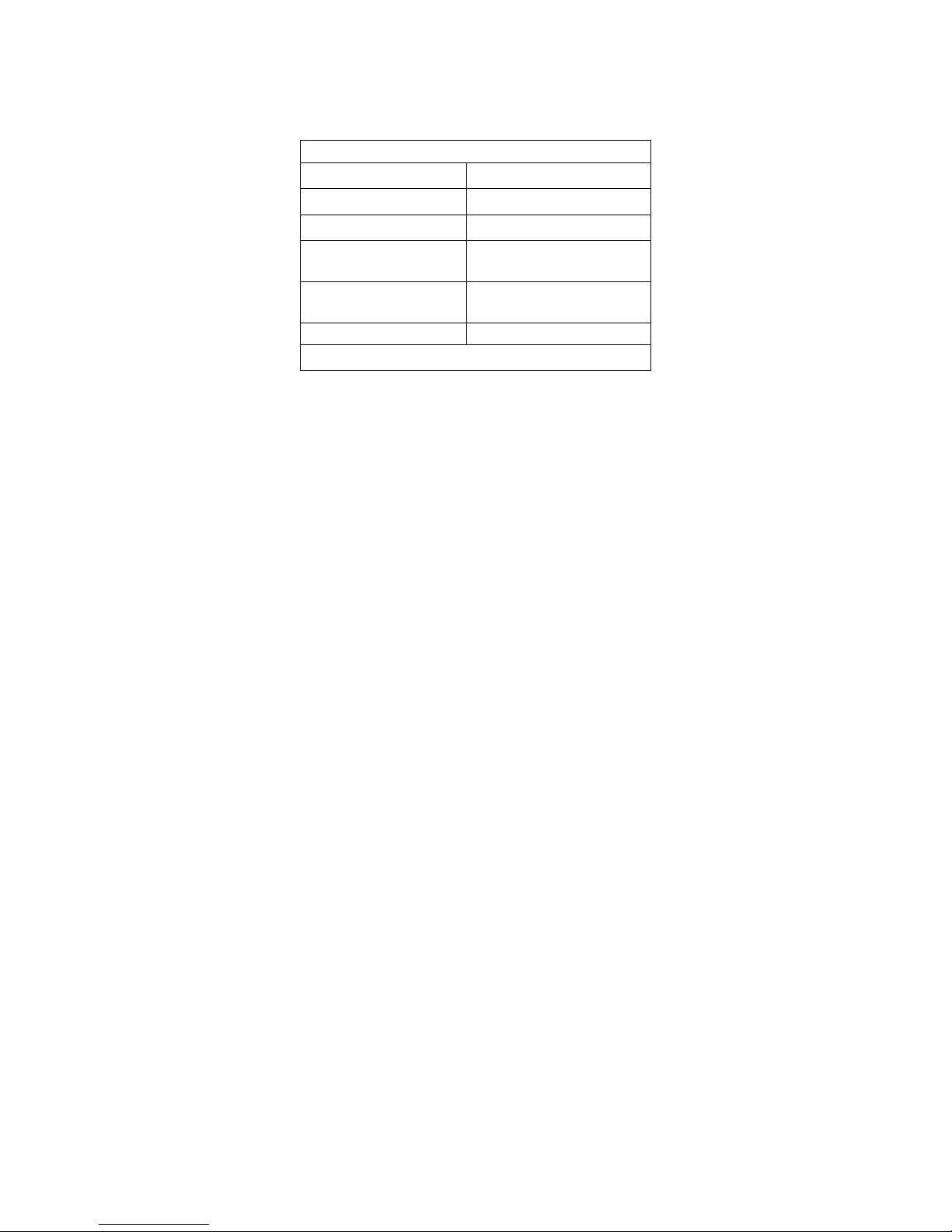

Input Protection Limits

Function

Maximum Input

V DC or V AC

1000VDC/AC rms

mA AC/DC

500mA 1000V fast acting fuse

A AC/DC

10A 1000V fast acting fuse (20A

for 30 seconds max every 15

minutes)

Frequency, Resistance,

Capacitance, Duty Cycle,

Diode Test, Continuity

1000VDC/AC rms

Temperature

1000VDC/AC rms

Surge Protection: 8kV peak per IEC 61010

2. USE EXTREME CAUTION when working with high voltages.

3. DO NOT measure voltage if the voltage on the "COM" input jack

exceeds 1000V above earth ground.

4. NEVER connect the meter leads across a voltage source while

the function switch is in the current, resistance, or diode mode.

Doing so can damage the meter.

5. ALWAYS discharge filter capacitors in power supplies and

disconnect the power when making resistance or diode tests.

5

6. ALWAYS turn off the power and disconnect the test leads before

opening the covers to replace the fuse or batteries.

7. NEVER operate the meter unless the back cover and the battery

and fuse covers are in place and fastened securely.

If the equipment is used in a manner not specified by the

manufacturer, the protection provided by the equipment may be

impaired.

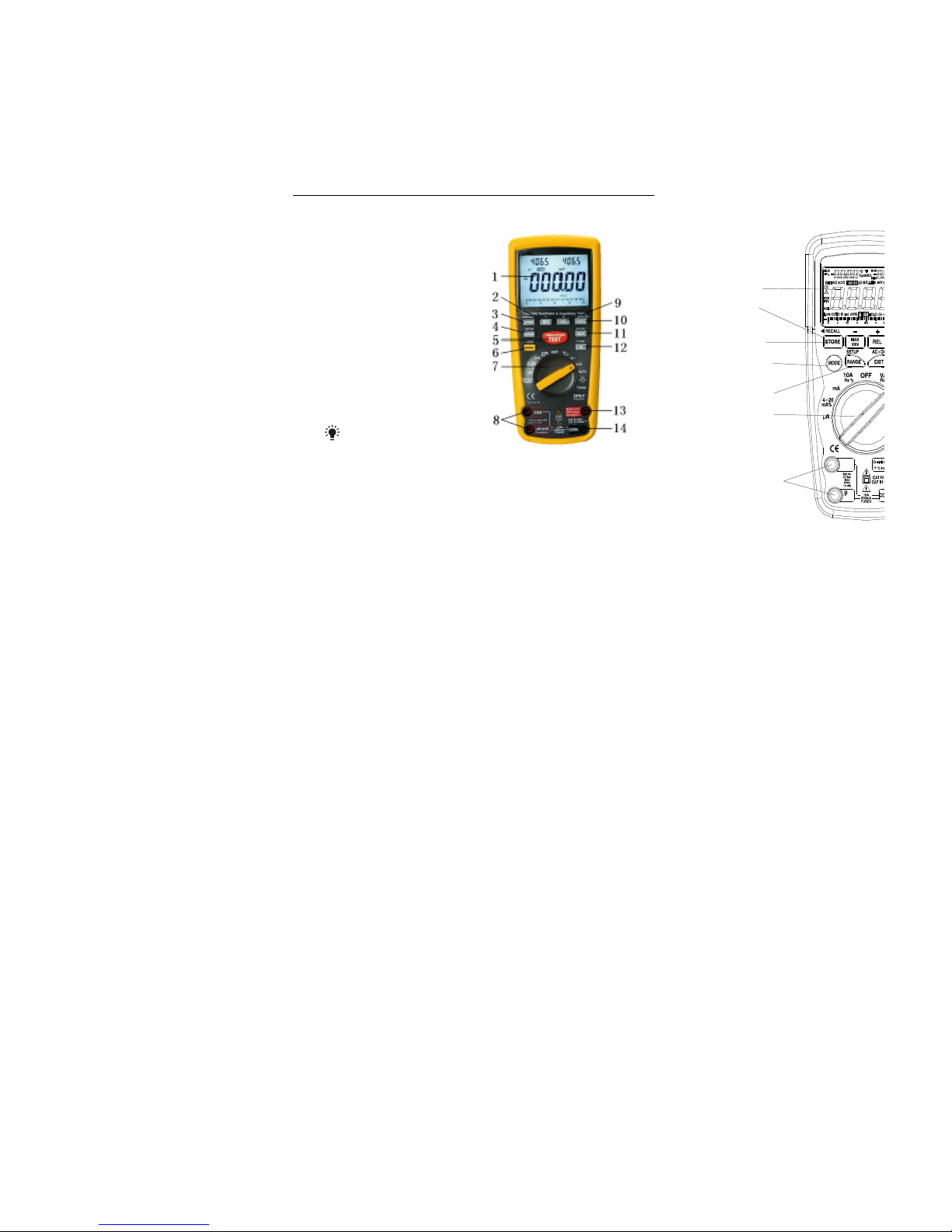

Controls and Jacks

1. 40,000 count LCD display

2. MAX/MIN (-)button

3. STORE(<RECALL) button

4. RANGE(SETUP) button

5. INSULATION TEST button

6. MODE button

7. Function switch

8. mA, µA and 10A input jacks

9. REL(+) button

10. HOLD(PEAKHOLD>) button

11. EXIT(AC+DC) button

12. Backlight button

13. Positive input jack

14. COM input jack

Note: Tilt stand and battery compartment are on rear of unit.

Ω

10A

mA

A

1

2

3

4

5

6

7

8

9

10

11

12

13

6

Symbols and Annunciators

•))) Continuity

Diode test

Battery status

n nano (10-9) (capacitance)

µ micro (10-6) (amps, cap)

m milli (10-3) (volts, amps)

A Amps

k kilo (103) (ohms)

F Farads (capacitance)

M mega (106) (ohms)

Ω Ohms PEAK Peak Hold

Hz Hertz (frequency) V Volts

% Percent (duty ratio) REL Relative

AC Alternating current AUTO Autoranging

DC Direct current HOLD Display hold

ºF Degrees Fahrenheit ºC Degrees Centigrade

MAX Maximum MIN Minimum

N0. Serial number

S second

left auxiliary display

right auxiliary display

SET Set up parameter

AC +DC Alternating current + Direct current

TRMS Ture RMS

STO Store

RCL Recall

AUTO Auto Range

Timing symbol

Backlight

bargraph

7

Operating Instructions

WARNING: Risk of electrocution. High-voltage circuits, both AC and

DC, are very dangerous and should be measured with great care.

1. ALWAYS turn the function switch to the OFF position when the

meter is not in use.

2. If “OL” appears in the display during a measurement, the value

exceeds the range you have selected. Change to a higher range.

DC VOLTAGE MEASUREMENTS

CAUTION: Do not measure DC voltages if a motor on the circuit

is being switched ON or OFF. Large voltage surges may occur

that can damage the meter.

1. Set the function switch to the green VDC

position.

2. Insert the black test lead banana plug into the

negative COM jack.

Insert the red test lead banana plug into the

positive V jack.

3. Touch the black test probe tip to the negative

side of the circuit.

Touch the red test probe tip to the positive

side of the circuit.

4. Read the voltage in the display.

8

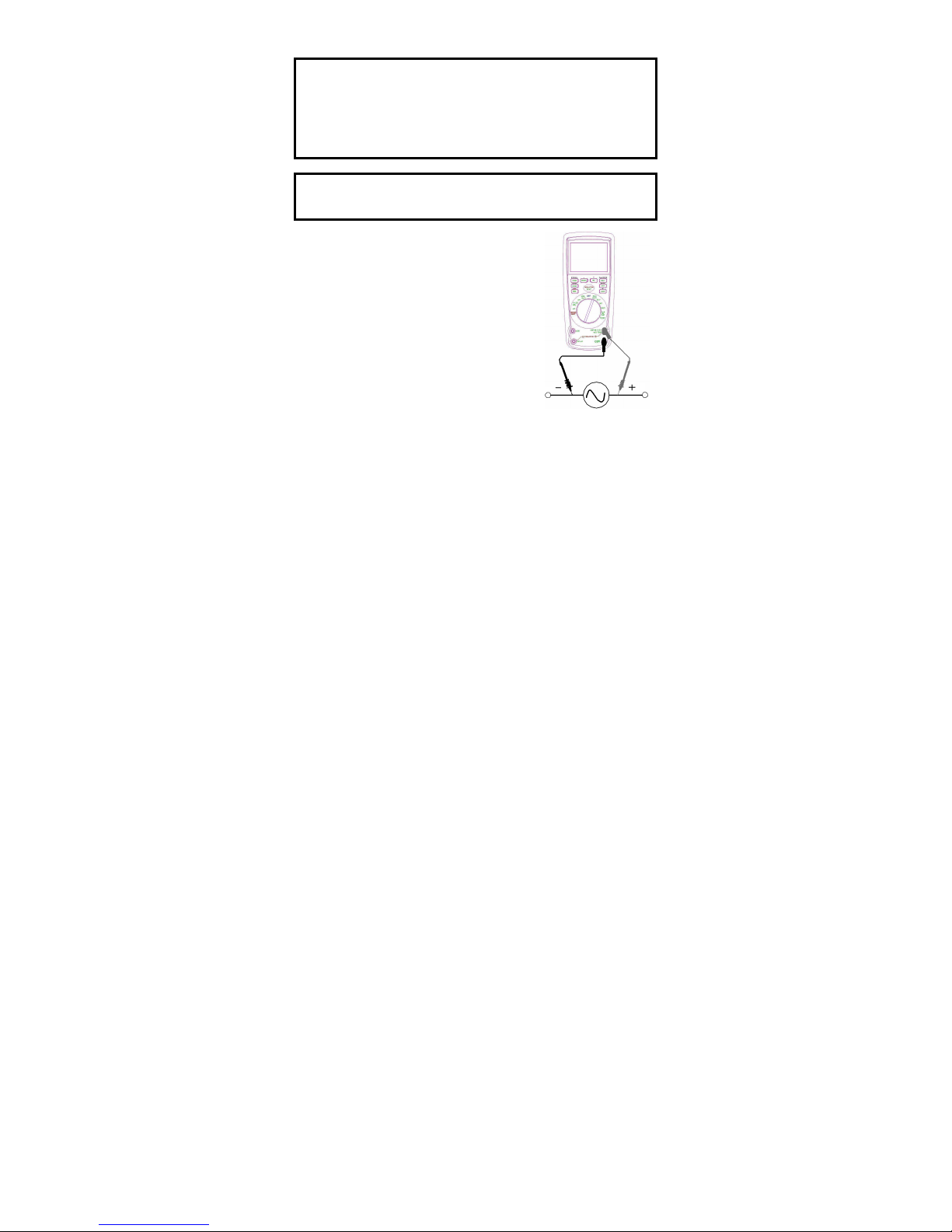

AC VOLTAGE (FREQUENCY, DUTY CYCLE) MEASUREMENTS

WARNING: Risk of Electrocution. The probe tips may not be long

enough to contact the live parts inside some 240V outlets for

appliances because the contacts are recessed deep in the outlets.

As a result, the reading may show 0 volts when the outlet actually

has voltage on it. Make sure the probe tips are touching the metal

contacts inside the outlet before assuming that no voltage is

present.

CAUTION: Do not measure AC voltages if a motor on the circuit

is being switched ON or OFF. Large voltage surges may occur

that can damage the meter.

1. Set the function switch to the green

VAC/Hz/% position.

2. Insert the black test lead banana plug

into the negative COM jack.

Insert red test lead banana plug into the

positive V jack.

3. Touch the black test probe tip to the

neutral side of the circuit.

Touch the red test probe tip to the “hot”

side of the circuit.

4. Read the voltage in the main display and

the frequency in the right auxiliary display

5. Press and hold the MODE button 2

second to indicate “Hz”.

6. Read the frequency in the main display.

7. Press the MODE button to indicate “%”.

8. Read the % of duty cycle in the main display.

9. Press EXIT for 2 seconds into the function of AC+DC. Test DC

and AC TURE Rms.

9

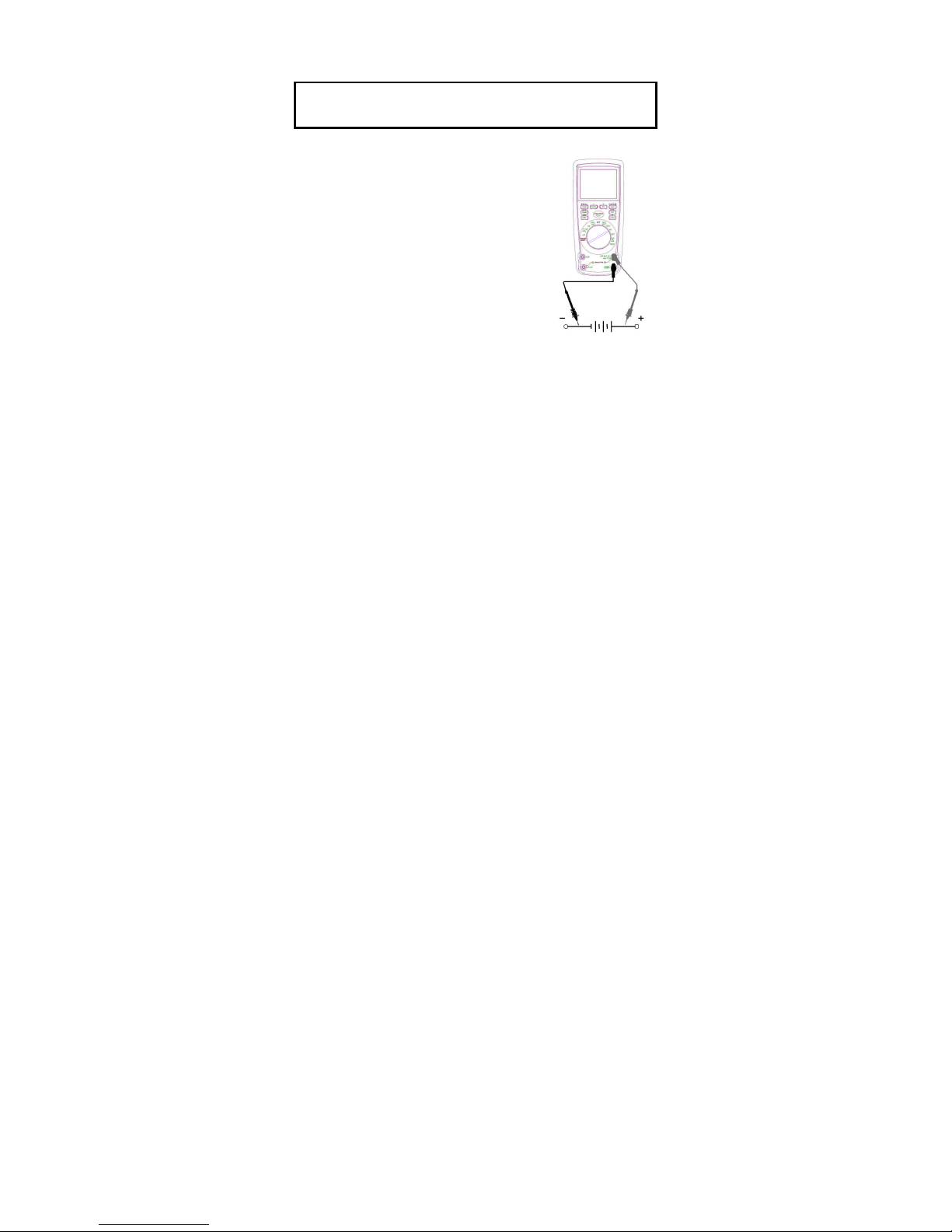

MV VOLTAGE MEASUREMENTS

CAUTION: Do not measure mV voltages if a motor on the circuit

is being switched ON or OFF. Large voltage surges may occur

that can damage the meter.

1. Set the function switch to the green mV position.

2. Press the MODE button to indicate “DC”.or

““AC ”, or in AC range press EXIT for two

seconds and chose ”AC+DC”

3. Insert the black test lead banana plug into

the

negative COM jack.

Insert the red test lead banana plug into the

positive V jack.

4. Touch the black test probe tip to the

negative side of the circuit.

Touch the red test probe tip to the positive

side of the circuit.

5. Read the mV voltage in the display.

Loading...

Loading...