Page 1

INSTRUCTIONS FOR:

DIGIT AL AUTOMOTIVE ANAL YSER 8 FUNCTION

MODEL No: TA200.V2

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these instructions,

and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE THE PRODUCT

CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/ OR PERSONAL INJURY AND WILL

INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY

Refer

to instruction

manual

WARNING! It is the user’s responsibility to read, understand and abide by the following safety instructions.

1.1. PERSONAL PRECAUTIONS

When using this meter, please observe all normal safety rules concerning:

Protection against the dangers of electric current.

Protection of the meter against misuse.

Full compliance with safety standards can only be guaranteed if used with the test leads supplied. If necessary, they must be replaced with

genuine Sealey leads with the same electronic ratings. Failure to do so will invalidate the warranty.

DO NOT use leads if damaged or if the wire is bared in any way.

1.2. GENERAL SAFETY INSTRUCTIONS

Familiarise yourself with the applications, limitations and hazards of the meter.

Before using the meter inspect the case. If you suspect any part of the case to be damaged or missing DO NOT USE THE METER.

Remove it from service immediately and contact your local Sealey dealer for advice/repairs.

When the meter is linked to a measurement circuit, do not touch unused meter terminals.

When the scale of the value to be measured is unknown set the selector to the highest range available.

Before rotating the rotary switch to change functions, disconnect test leads from the circuit under test.

WARNING! Never perform resistance measurements on live circuits.

Always be careful when working with voltages above 60Vdc or 30Vac rms. Keep your fingers behind the probe guards while measuring.

When not in use, store the meter carefully in a safe, dry, childproof location. Storage temperature range -10ºC to 50ºC.

Never apply voltage or current to the meter that exceeds the specified maximum.

Should the low battery indicator appear on the LCD display, replace the battery immediately (PP3). A low battery level could cause the meter to

produce inaccurate readings.

When not in use, store the meter in a safe, dry, cool and childproof location. DO NOT place in the proximity of a powerful source of

electromagnetic radiation.

The user shall ensure that test probes are correctly selected in order to prevent danger. Probes shall be selected to ensure that adequate

barriers guard against inadvertent hand contact with live conductors under test and that probes have minimal exposed probe tips. Where there

is a risk of the probe tip short circuiting with other live conductors under test, it is recommended that the exposed tip length shall not exceed 4mm.

2. INTRODUCTION

Durable bi-composite case and integral stand suitable for the toughest workshop conditions. Large, hi-contrast LCD display with 21mm high digital

read-out. Unique Test Lead Connection feature indicates correct hook-up. Includes data hold feature and low battery display. Supplied with test

probes and comprehensive manual.

3. FEATURES

1. LCD display

2. Data hold button

3. Rotary switch

4. Input terminals

5. Power ON/OFF

6. Probes

I

F IN ANY DOUBT CONSULT A QUALIFIED ELECTRICIAN

6

.

3.1. Rotary Switch

fig.1.3

© Jack Sealey Limited

Function

DC voltage measurement

AC voltage measurement

DC Current measurement

Diode test

Continuity test

Resistance measurement

Automotive ignition dwell testing (degrees)

Automotive engine tach (rotation speed) testing (x10 rpm)

Original Language Version

Fig.1

TA200.V2 Issue No: 1 - 15/08/16

Page 2

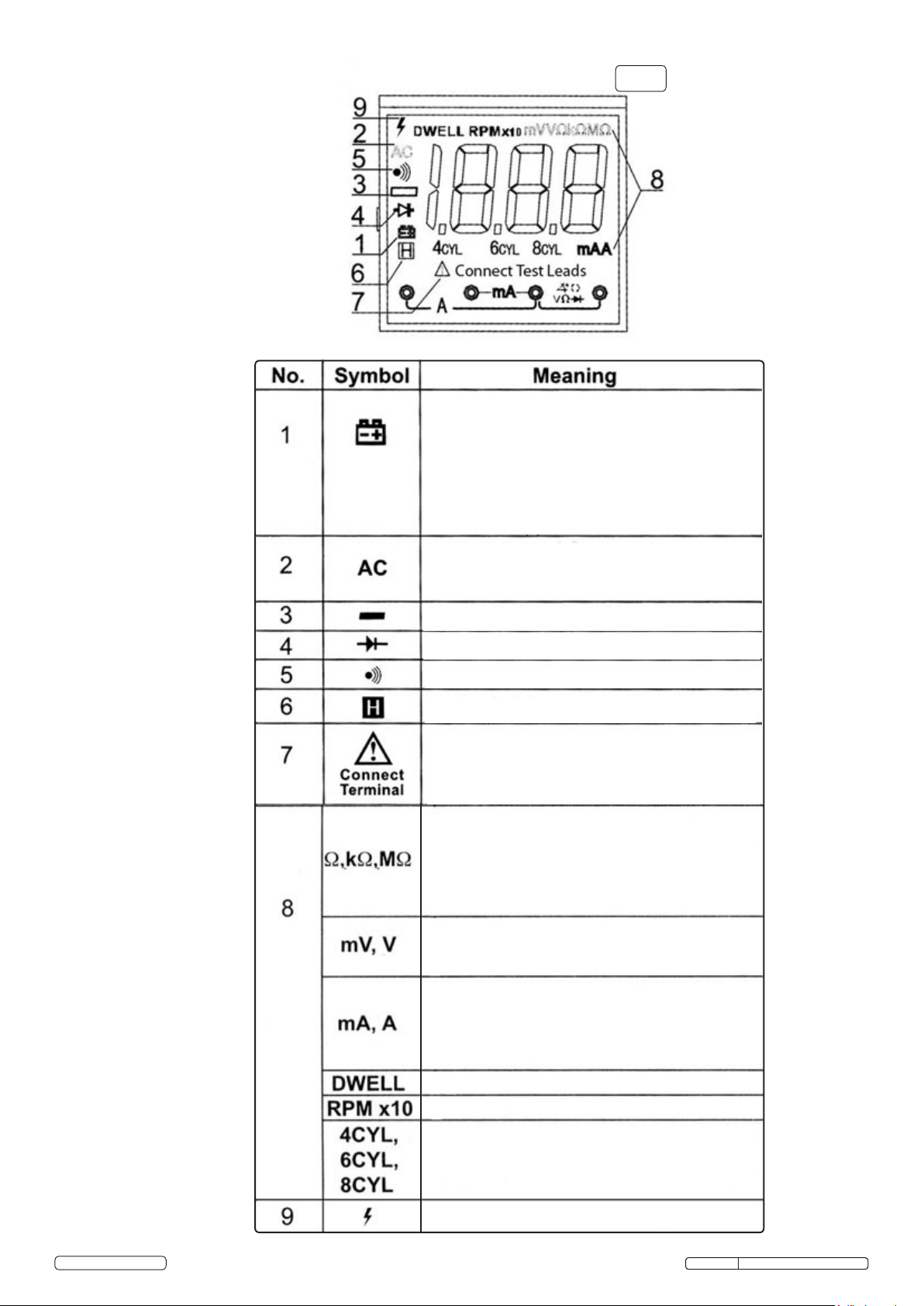

3.2. Display (Fig.2)

The LCD displays the

measured values obtained in

tests and various other

information regarding the

state/operation of the meter.

The following is an illustration

and descriptive list to enable

the user to understand the

information presented.

Fig.2

Battery is low.

Replace immediately using a PP3 9V

battery. Failure to do so could lead to

inaccurate readings.

Indicates an AC voltage or current.

The displayed value is the mean value

Indicates a negative reading

Diode test

Continuity buzzer is on

Data hold function is active

Indicates the requirement for test leads

to be connected.

Ω: Ohm. The unit of resistance.

kΩ: kilohm. 1x103 or 1000 ohms.

MΩ:Megaohm. 1x106 or

1,000,000 ohms.

V: Volts. The unit of voltage.

mV: Millivolt. 1x10

-3

or 0.001 volts

A: Amperes (amps). The unit of

current.

mA: Milliamp. 1x10

-3

or 0.001 amperes

© Jack Sealey Limited

Test of Dwell.

Tach x 10

Number of cylinders

Caution - high voltage testing

Original Language Version

TA200.V2 Issue No: 1 - 15/08/16

Page 3

6. OPERATION

Note: During any of the following testing procedures, the data hold function can be employed.

When the “HOLD” button (see fig 1.2) is pressed, data hold is activated and the value

displayed at that instant on the LCD is held until the HOLD button is pressed again, at which

point the LCD once more displays the current measured value.

4.1. AC or DC voltage testing (fig 3)

WARNING! To reduce risk of electric shock, DO NOT attempt to measure voltages

higher than 1000V.

The measurement ranges DC voltage are 200mV, 2V, 20V, 200V and 1000V.

The measurement ranges AC voltage are 2V, 20V, 200V and 750V.

Select the range appropriate to the expected reading.

If the voltage to be measured is unknown, use the maximum measurement position

(1000V DC, 750V AC) and reduce the range, step by step until a satisfactory reading is

obtained. Should the meter become overloaded, the LCD will display “1”. This indicates that

a higher range must be selected.

In each range, the meter has an input impedance of approx 10M

measurement errors when dealing with high impedance circuits.

If the circuit impedance is <= 10kΩ,the error is negligible (0.1% or less).

4.1.1. To measure DC or AC voltage, connect the meter as follows:

4.1.2. Insert the red test lead into the “V” terminal and the black test lead into the “COM” terminal.

4.1.3. Set the rotary switch to an appropriate measurement position in or

4.1.4. Connect the test leads across the source being measured. The measured value will be

displayed. When the measurement has been completed, disconnect the test leads from the

circuit being tested.

4.2. DC Current testing (fig.4)

WARNING! Never attempt an in-circuit current measurement where the open circuit

voltage between terminals and ground is greater than 250V. If the fuse burns out

during measurement, the meter may be damaged and the user may be injured. Always

use correct terminals, function and range for the measurement.

When the test leads are connected to the current terminals, DO NOT parallel them

across any circuit.

The measurement ranges for DC current are 200.0mA and 10.00A.

4.2.1. To measure DC current, use the following procedure:

4.2.2. Turn off/disconnect power to the circuit, discharge all high voltage capacitors.

4.2.3. Insert the red test lead into the mA or 10A terminal and the black test lead into the COM

terminal.

4.2.4. Set the rotary switch to an appropriate measurement position in . If the current to be

measured is unknown, use the maximum measurement position (10A) and the 10A terminal,

then reduce the range step by step until a satisfactory reading is obtained.

4.2.5. Break the current path to be tested, connect the red test lead to the positive side of the

break and the black test lead to the negative side of the break (i.e. connect the meter in

series).

4.2.6. Turn on/reconnect power to the circuit. The measured value is shown on the display.

When the measurement has been completed, disconnect the test leads from the circuit being

tested.

Note: Within the 10A range, the meter must not be used for a period of greater than 10 seconds

more than once in any 15mins.

4.3. Resistance testing (fig 5)

WARNING! To avoid damage to the meter and/or the devices being tested, disconnect

circuit power and discharge all the high-voltage capacitors before measuring

resistance.

Never attempt an in-circuit current measurement where the open circuit voltage

between terminals and ground is greater than 60V DC or 30V AC rms.

The measurement ranges for resistance are: 200

and 20MΩ.

4.3.1. To measure resistance, connect the meter as follows:

4.3.2. Insert the red test lead into the Ωterminal and the black test lead into the COM terminal.

4.3.3. Set the rotary switch to an appropriate measurement position in Ω.

4.3.4. Connect the test leads across the object being measured. The measured value will be

displayed.

Note: The test leads themselves can add 0.1-0.2

a precision reading in the low-resistance range (i.e. 200Ω,short-circuit the input terminals

using the test leads beforehand and record the measured resistance as x. Then measure the

resistance of the object under test and record this value as y.

Ω, 2kΩ, 20kΩ, 200kΩ, 2MΩ,

Ωto the resistance measurement. To obtain

Ω.This may give rise to

Fig.3

Fig.4

Fig.5

y – x = Correct value of resistance

If the resistance reading ≥0.5

damaged. If damaged, replace immediately with suitable leads from your authorised Sealey

dealer.

For high resistance (>1M

it is recommended that you use short test leads.

Where there is no input, the meter displays “1”.

When resistance measurement has been completed, disconnect the test leads from the

circuit being tested.

© Jack Sealey Limited

Ωin the short circuit condition, the test leads may be loose or

Ω) several seconds may be required to obtain a stable reading and

Original Language Version

TA200.V2 Issue No:1 - 15/08/16

Page 4

4.4. Diode testing (fig.6)

WARNING! To avoid damage to the meter and/or devices being tested, disconnect

circuit power and discharge all high-voltage capacitors before testing diodes.

Never attempt an in-circuit current measurement where the open circuit voltage

between terminals and ground is greater than 60V DC or 30V AC rms.

Use the diode test to check diodes, transistors, and other semiconductor devices. The diode

test sends current through the semiconductor junction, then measures the voltage drop

across the junction. A good silicon junction drops between 0.5V and 0.8V

4.4.1. To test a diode out of circuit, connect the meter as follows:

4.4.2. Insert the red test lead into the terminal and the black test lead into the COM terminal.

4.4.3. Set the rotary switch to .

4.4.4. For forward voltage drop readings on any semiconductor component, place the red test lead

on the components anode (+) and place the black test lead on the components cathode (-).

The measured value will be displayed.

Note: In a circuit, a good diode should still produce a forward voltage drop reading of 0.5-

0.8V but the reverse voltage drop reading can vary depending on the resistance of other

pathways between the probe tips.

Connect the test leads to the appropriate terminals as described in section 4.4.2 to avoid

error display.

The open circuit voltage is around 2.7V when testing a diode.

The LCD will display “1” indicating open-circuit if the meter test leads are incorrectly

connected.

When diode test has been completed, disconnect the test leads from the circuit being tested.

4.5. Continuity testing

WARNING! To avoid damage to the meter and to the device being tested, disconnect

circuit power and discharge all high-voltage capacitors before testing continuity.

Never attempt an in-circuit current measurement where the open circuit voltage

between terminals and ground is greater than 60V DC or 30V AC rms.

4.5.1. To test for continuity, connect the meter as you would for diode testing (see section 4.4).

4.5.2. Connect the test leads across the object/circuit being tested.

4.5.3. If the resistance value is >50

sound.

4.5.4. The buzzer sounds continuously when the resistance is ≤30

Note: The LCD displays “1” indicating the circuit being tested is open.

Open circuit voltage is approx 2.7V.

When continuity testing has been completed, disconnect the connection between the testing

leads and the circuit under test.

4.6. Dwell testing (fig.7)

4.6.1. This function can be used to test the dwell of the cut-off switch (points or electronic) of an

ignition system.

4.6.1.1. Turn the rotary switch to the appropriate setting within the “DWELL” function area. There

is a choice between 4, 6 & 8 cylinders. Choose the setting appropriate to the engine in

question.

4.6.1.2. Insert the red test lead into the terminal and the black test lead into the COM

terminal. Connect the ends to be tested as shown in fig 7.

4.6.1.3. When testing the cut-off switch of an ignition system, connect the red test lead probe to

the primary negative end of the ignition coil (refer to the vehicle service manual for the

specific position).

4.6.2. If the dwell of arbitrary ON/OFF equipment is to be tested, connect the red probe to the

end of the equipment in question fitted with an ON/OFF switch.

4.6.3. Connect the black test lead probe to the good ground terminal of the automobile.

4.6.4. The measured dwell will be displayed on the LCD.

4.7. Engine tach (rotation speed) RPM x 10 (fig.8)

Engine tach RPM is the number of rotations completed by the main shaft of the engine per

minute.

4.7.1. Turn the rotary switch to the appropriate setting within the “RPM x 10” function area. There is

a choice between 4, 6 & 8 cylinders. Choose the setting appropriate to the engine in

question.

4.7.2. Insert the red test lead into the terminal and the black lead into the COM terminal.

Connect the ends to be tested as shown in fig 8.

4.7.2.1. If the vehicle uses a DIS ignition system with no distributor board, connect the red test

lead probe to the TACH (tachometer) signal line (which is connected to the computer DIS

module of the engine). Refer to the vehicle service manual for the specific location.

4.7.2.2. If the vehicle uses an ignition system with a distributor board, connect the red test lead

probe to the primary negative end of the ignition coil. Refer to the vehicle service manual

for the specific location.

4.7.3. Connect the black test lead probe to the good ground terminal of the automobile.

4.7.4. On starting the engine or whilst it is running, test the rotation speed of the engine and read

the value displayed. The display is RPM ÷ 10 i.e. the actual rotation speed is obtained by

multiplying the displayed value by 10.

Ω(i.e. the circuit is damaged/disconnected) the buzzer will not

Ω.The circuit is operational.

Fig.6

Fig.7

Fig.8

© Jack Sealey Limited

Original Language Version

TA200.V2 Issue No: 1 - 15/08/16

Page 5

4.8. Mass Air Flow (MAF) Sensor (fig.9)

4.8.1. A mass air flow sensor converts air flow readings into one of the following, depending on the

sensor:

a) a DC voltage

b) a low frequency signal

c) a high frequency signal

The TA200 is suitable for testing those sensors with a DC voltage or low frequency signal

output.

4.8.2. Connect the DC voltage type MAF sensor in the DC voltage testing fashion (see section 4.1)

and set the rotary switch on the meter to 20V DC. For a low frequency signal type MAF

sensor, connect the meter in the RMPx10 testing fashion (see section 4.7) and choose the

appropriate setting for number of cylinders.

4.8.3. Connect the black test lead probe to the ground terminal of the sensor and connect the red

one as illustrated in fig 9.

4.8.4. Switch on the meter and the vehicles ignition but DO NOT start the engine.

4.8.5. DC Voltage type sensor: The displayed value should usually be less than or equal to 1V

(consult the vehicle manufacturer’s specifications).

4.8.6. Frequency type sensor: Refer to the vehicle manufacturer’s specifications to compare

against your readings.

4.9. Other functions

4.9.1. The TA200 can also be used to test the following automotive components:

Oxygen sensors, fuel injectors, temperature sensors, position sensors, MAP and baro

sensors.

4.9.2. Please refer to the vehicle manufacturer’s manual for specific test procedures.

Fig.9

5. MAINTENANCE

WARNING! DO NOT attempt to repair or service your meter unless you are qualified to do so and have the relevant calibration,

performance test and service information.

5.1. General maintenance:

5.1.1. Periodically wipe the case with a damp cloth and mild detergent. DO NOT use abrasives or solvents.

5.1.2. Clean the terminals with a cotton bud and mild detergent to prevent the build up of dirt/moisture in the terminals which may affect readings.

5.1.3. Turn the meter off when not in use and remove the battery if the meter is not to be used for some time.

5.2. To replace the fuses:

5.2.1. Turn the meter off and disconnect any leads/equipment from the terminals.

5.2.2. Remove the protective rubber jacket from the meter.

5.2.3. Remove the 3 larger screws from the rear of the case and open the meter.

5.2.4. Remove the fuse in question and replace with a fuse of identical type and specification:

Fuse 1: CE 315mA, 250V, fast type, 5x20mm

Fuse 2: CE 10A, 250V, fast type, 5x20mm

5.2.5. Close the meter case and replace the three screws and rubber jacket.

5.3. To replace the battery:

5.3.1. Turn the meter off and disconnect and leads/equipment from the terminals.

5.3.2. Remove the small screw holding the battery compartment lid, then remove the lid and the old battery.

5.3.3. Place a new 9V (PP3) battery into the meter taking care to observe the correct polarity.

5.3.4. Replace the battery compartment lid and the holding screw.

6. TECHNICAL SPECIFICATIONS

DC Voltage

Range Resolution Accuracy Overload protection

200mV 0.1mV

2V 1mV

20V 10mV

200V 100mV

1000V 1V ±(0.8%+5)

Input impedance: 10MΩ

AC Voltage

Range

200V 100mV

750V 1V

Input impedance: 10M

Frequency response: 40Hz ~ 400Hz

© Jack Sealey Limited

Resolution

2V 1mV

20V 10mV

±(0.5%+5)

Accuracy

±(0.8%+5)

±(1.0%+4)

230V AC

1000V DC or

750V AC continuous

Overload protection

1000V DC or

750V AC continuous

Original Language Version

Resistance

Range Resolution Accuracy Overload protection

200Ω 0.1Ω

2kΩ 1Ω

20kΩ 10Ω

200kΩ 100Ω

2MΩ 1kΩ

2MΩ 10kΩ ±(1.5%+5)

Continuity testing

Range

Resolution

1mV

±(0.8%+5)

Overload protection

600Vp

TA200.V2 Issue No:1 - 15/08/16

600Vp

Page 6

DC Current

Range Resolution

Accuracy

200mA 0.1mA ±(0.8%+5)

10A 10mA

±(1.2%+5)

Overload protection

CE: Fuse 315mA,

250V, fast type,

5x20mm

CE: Fuse 10A, 250V,

fast type, 5x20mm

Dwell testing

Range Resolution Accuracy Overload protection

4CYL

6CYL

0.1º

±(3%+5)

600Vp

8CYL

Input amplitude: ≥10V in direct impulse; ≥ 0.5mS in width.

Diode

Range

Resolution

1mV

Overload protection

600Vp

Tach (rotation speed) testing

Range Resolution Accuracy Overload protection

4CYL

6CYL

10RPM

±(3%+5)

600Vp

8CYL

Input amplitude: ≥10V in direct impulse; ≥ 0.5mS in width.

Maximum tach: 10000 RPM, displayed as RPM x10.

Environmental Protection

Recycle unwanted materials instead of disposing of them as waste. All tools, accessories and packaging should be

sorted, taken to a recycling centre and disposed of in a manner which is compatible with the environment.

When the product becomes completely unserviceable and requires disposal, drain off any fluids (if applicable)

into approved containers and dispose of the product and the fluids according to local regulations.

WEEE Regulations

Dispose of this product at the end of its working life in compliance with the EU Directive on

Waste Electrical and Electronic Equipment (WEEE). When the product is no longer required, it must be disposed

of in an environmentally protective way. Contact your local solid waste authority for recycling information.

Battery Removal: See Section 5.3.

ONLY dispose of or recycle according to local authority regulations. Under the Waste Batteries and Accumulators Regulations

2009, Jack Sealey Ltd are required to inform potential purchasers of products containing batteries (as defined within these

regulations), that they are registered with Valpak’s registered compliance scheme. Jack Sealey Ltd’s Batteries Producer

Registration Number (BPRN) is BPRN00705.

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of this product.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

© Jack Sealey Limited

Sole UK Distributor, Sealey Group,

Kempson Way, Suffolk Business Park,

Bury St. Edmunds, Suffolk,

IP32 7AR

Original Language Version

01284 757500

01284 703534

www.sealey.co.uk

sales@sealey.co.uk

TA200.V2 Issue No: 1 - 15/08/16

Loading...

Loading...