Sealey STW291 Instructions For

INSTRUCTIONS FOR:

DIGITAL TORQUE ADAPTOR

WITH ANGLE FUNCTION 1/2”Sq.Dr. 20 - 200Nm

MODEL No: STW291

Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these

instructions and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS

AND CAUTIONS. USE THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE

TO DO SO MAY CAUSE DAMAGE AND/OR PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP

INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY INSTRUCTIONS

WARNING! DO NOT use the digital torque adaptor if

damaged or thought to be faulty.

DO NOT apply force to the adaptor when the power is

off. Always turn the adaptor on before using it otherwise

the adaptor will be damaged.

DO NOT turn off the torque adaptor while torque force is

being applied.

DO NOT exceed the permitted maximum torque value

for this torque adaptor. To do so will cause it to break.

DO NOT subject the 1/2” connectors on the top and

bottom of the adaptor to any force other than a rotational

one.

Ensure that all components including all adaptors,

extensions, drivers and sockets are rated to match or

exceed the torque being applied.

Observe all equipment, system and manufacturer ’s

warnings, cautions and procedures when using this

torque adaptor.

Use the correct size socket for the fastener.

DO NOT use sockets showing wear or cracks.

Check that the torque adaptor capacity matches or

exceeds each application before proceeding.

Ensure all workshop safety rules, regulations, and

conditions are complied with when using this digital

torque adaptor.

Maintain correct balance and footing. Ensure the floor is

not slippery and wear non-slip shoes.

Keep children and unauthorised persons away from the

working area.

DO NOT press, pressure, or damage the LCD display.

DO NOT use the torque adaptor near strong magnetic

elds .

DO NOT subject the digital torque adaptor to excessive

force or shocks.

DO NOT drop or throw the digital torque adaptor.

DO NOT leave the digital torque adaptor in any place

exposed to excessive heat, humidity or direct sunlight.

DO NOT use organic solvents such as alcohol or

thinners to clean the digital torque adaptor.

DO NOT submerge the digital torque adapter in water or

any other liquid.

DO NOT disassemble the digital torque adaptor.

To ensure accurate measurement periodic re-calibration

is necessary.

After use clean with a soft dry cloth and store in a safe,

dry, childproof location.

2. INTRODUCTION

Designed for use with a standard ratchet or breaker bar. Ideal

for work around the engine bay and the tightening of wheel

nuts to factory specications. Large LCD display with LED/

audible alarm indicating achieved and target torque levels.

Selectable readings in Nm, lb.ft, lb.in or kg.m. Accurate to

±2% of stated capacity and operates in either direction.

Features angle mode, eliminating the need for

angle gauges and protractors providing the most accurate

and fastest way to measure torque plus angle tightening

sequences. Will also accumulate angle measurement when

multiple turns are required, ideal for use where access is

restricted. Includes auto shut off. Supplied with test certicate

and storage case.

3. SPECIFICATION

Model No: STW291

Drive: “1/2””Sq”

Length: 100mm

Range: 20-200Nm(15-147.5lb.ft, 354-1770lb.in)

Battery: 2 x CR2032 (Supplied)

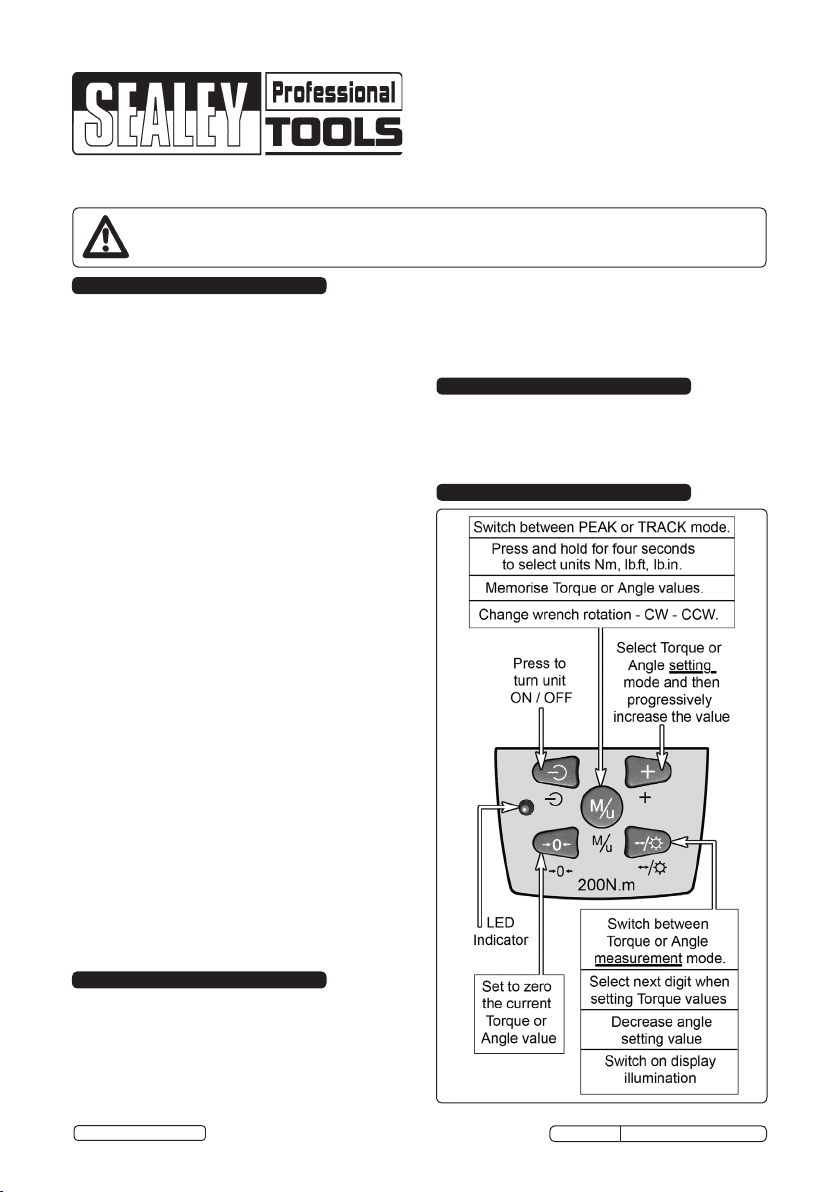

4. KEYPAD CONTROL FUNCTIONS

© Jack Sealey Limited

Original Language Version

STW291 Issue No.1 28/06/12

5. OPERATION

NOTE: ENERGY SAVINGS FUNCTION:

If left on and unused, the torque adaptor will turn off

automatically after a period of 4 minutes.

5.1 PREPARATION:

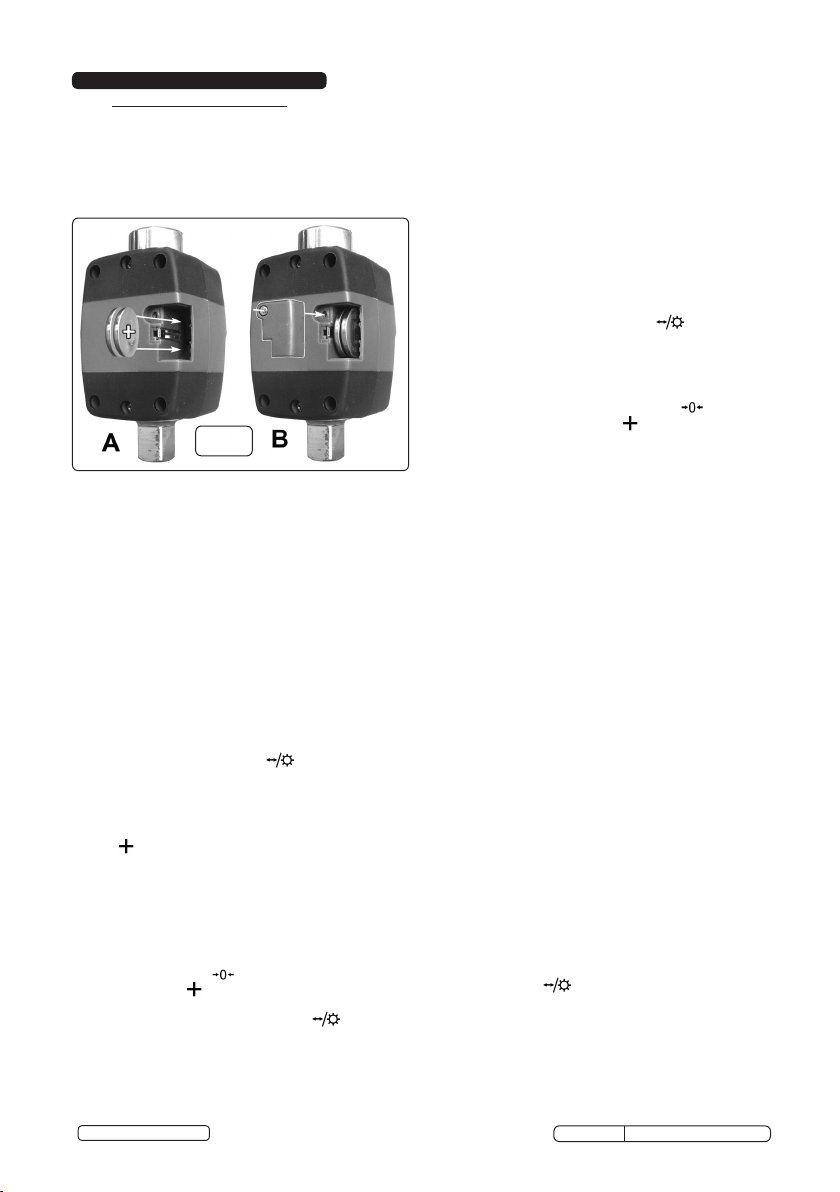

5.1.1 Unscrew the battery cover and install the two batteries

supplied as shown below, ensuring the correct polarity

as indicated in g.1A. Rex the battery cover as shown

in g.1B.

g.1

5.1.2 Press the ON/OFF button once to turn the meter on.

The display will initially show four zeros (“0000”) before

reverting to a “0.0” torque reading.

5.1.3 To select the required unit of measurement, press and

hold the “M/u” button for 4 seconds. As soon as the

display jumps to the next unit of measurement let go of

the button. Repeat this process until the display shows

the unit you require. ( Nm / lb.ft / lb.in ).

5.1.4 Ascertain the correct size and type of socket for the

xing to be tightened and attach it to the square drive

connection (1/2” ) at the base of the adaptor.

5.1.5 Insert the required ratchet wrench/drive bar into the

socket at the top of the adaptor. Do not use a tool that

will allow you to apply excessive force through the

adaptor.

5.2 SELECTING THE TORQUE OR ANGLE

MEASUREMENT MODE:

5.2.1 By default, the adaptor switches on in Torque

Measurement Mode. Press “ “ button to switch

to Angle Measurement Mode or back into Torque

Measurement Mode when required.

5.3 SETTING THE TORQUE OR ANGLE VALUE:

5.3.1 In order to set the torque or angle value, press the

“ “ button for 2 seconds. NOTE: If no buttons are

then pressed, the display will revert to zero after 6

seconds.

5.4 (a) TORQUE setting mode: The display will initially

show “ SET “ for 1 second and then revert to the last

saved torque or “ 000.0 “. The rst digit of this value

( “000.0“ ) will be ashing, indicating that the value can

now be set/altered. ( To zero the last saved torque

setting press the “ “ button ). By repeatedly

pressing the “ “ button, the value of the ashing

digit will be progressively increased. When the

required value is reached, press the “ “ button to

move to the next digit. Repeat this process for all digits

(ones, tens, hundreds etc) until the desired value has

been set.

© Jack Sealey Limited

Original Language Version

5.4.1 This value can then be stored by pressing the “ M/u “

button. Once the value is stored, taking 2 to 3 secs, the

display will revert to “ 000.0 “.

5.4.2 If you attempt to store a torque value that is below the

minimum value or above the maximum value dened in

the specication, the abbreviation “Erro” will be shown

on the display. After 1 second, the torque adaptor will

revert to torque measuring mode. The preset value will

not have been stored, and the warning indicators will

not work until a valid value has been stored.

5.5 (b) ANGLE setting mode:

NOTE: Before setting the angle, the adaptor (with

wrench and socket attached) should be positioned onto

the tting to be tightened so that the adaptor has a

datum starting point against which to set the angle.

5.5.1 To set the angle value, press the “ “ button for 2

seconds. (NOTE: If no buttons are then pressed, the

display will revert to zero after 6 seconds).

5.5.2 The display will initially show “ SET “ for 1 second and

then revert to the last saved angle or “ 0° “. ( To zero

the last saved angle setting press the “ “ button).

By repeatedly pressing the “ “ button, the angle

value will be progressively increased until the required

angle value is reached.

5.5.3 This value can then be stored by pressing the “ M/u “

button. Once the value is stored, taking 2 to 3 secs, the

display will revert to “ 0° “.

5.5.4 When in ANGLE measuring mode the direction of

rotation of the adaptor can be changed from clockwise

(CW) to counterclockwise (CCW) and back again by

pressing the “ M/u “ button

5.6 Mode Select:

5.6.1 The “TRACK” mode is the default when the torque

adaptor is switched on. In “TRACK” mode the display

shows the reading in real time during the torque

process both when the pressure is increased or

released. When the programmed value is reached the

unit signals both audibly and visually whilst the adaptor

is under pressure. As soon as the pressure is released

the display reverts to zero

5.6.2 Press the “M/u” button to shift into “PEAK” mode. The

display shows “peak” in the top left of the display.

5.6.3 In “PEAK” mode the display will always hold the current

value reached, even if the pressure is slightly released.

When the programmed value is achieved, the unit

signals both audibly and visually and the value shown

on the display will begin to ash after approx. one

second. If further pressure is applied after the

programmed value has been reached the unit assumes

that further torque is to be applied up to the current

programmed value and the display again shows torque

ascending from zero. Alternatively, you can zero the

display and apply the programmed torque to another

xing.

5.7 Turning the display illumination on/off.

The display illumination can be turned on prior to or

after programming the torque. In order to do this, press

and hold the “ “ button for 2 Secs.

5.8 OPERATION:

5.8.1 When you approach within +/- 5 Nm of the programmed

torque value the unit will beep intermittently.

5.8.2 When you approach within +/- 2 Nm of the programmed

value the unit will emit a quicker sound sequence.

STW291 Issue No.1 28/06/12

Loading...

Loading...