instructions for

MPORTANT:

PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

screwdriver torque digital 0-20nm

1/4”hex drive

model no: sts104

thank you for purchasing a sealey product. manufactured to a high standard, this product will, if used according to these

instructions, and properly maintained, give you years of trouble free performance.

refer to

instructions

1. safety

warning! ensure that Health & safety, local Authority regulations and general workshop practice regulations are adhered to

when using tools.

8 do not use tools if damaged.

9 maintain tools to ensure that they are in an adequate condition for safe use and optimum performance.

9 Wear suitable clothing to avoid snagging. do not wear jewellery. tie back long hair.

9 When not in use, store in a safe, dry childproof place.

9 Keep children and unauthorised persons away from the work area.

warning! the warnings, conditions and instructions in this manual cannot cover all possible conditions and situations. the

operator/ user must apply caution and common sense (good practical sense).

1.1. for battery use and care

warning! Keep batteries dry at all times.

8 do not combine used batteries with new ones or mix battery types or mix different brands.

9 insert the batteries carefully as indicated on the product.

8 do not use a battery if it is cracked or broken.

8 do not heat or incinerate batteries.

8 do not throw battery into a fire.

1.2. use and care

8 do not exceed the permitted maximum torque value for this meter.

9 Periodic re-calibration is necessary to maintain accuracy.

9 to avoid damaging the torque screwdriver, neVer apply force to the meter when the power is off. Always turn it on before using.

8 do not turn off the torque screwdriver while torque force is applied.

8 do not press, pressure, or damage the lcd display.

8 do not drop or throw this meter. Avoid bumps or shocks to the torque screwdriver.

8 do not leave this meter in any place exposed to excessive heat, humidity, or direct sunlight.

8 do not expose this meter to dust or sand as this could cause serious damage.

warning! do not use on live electrical circuits.

2. introduction

suitable for automotive, workshop and factory use. lcd read-out with led, audible alarm and vibration indicating achieved and target torque

levels. Preset track, peak or desired torque levels using simple push-button menu. clockwise and anti-clockwise operation. selectable read-out

in Nm or lb.ft. Accurate to ±1% of stated capacity. Textured, T-handle for added grip and comfort. Supplied with test certicate.

3. specification

model no. .................................................................. sts104

drive ..........................................................................1/4”Hex

range. ......................................................................0-20nm

length ........................................................................170mm

Battery ......................................................2 x AAA (supplied)

operation

© Jack sealey limited

Original Language Version

sts104 | issue 1 15/05/17

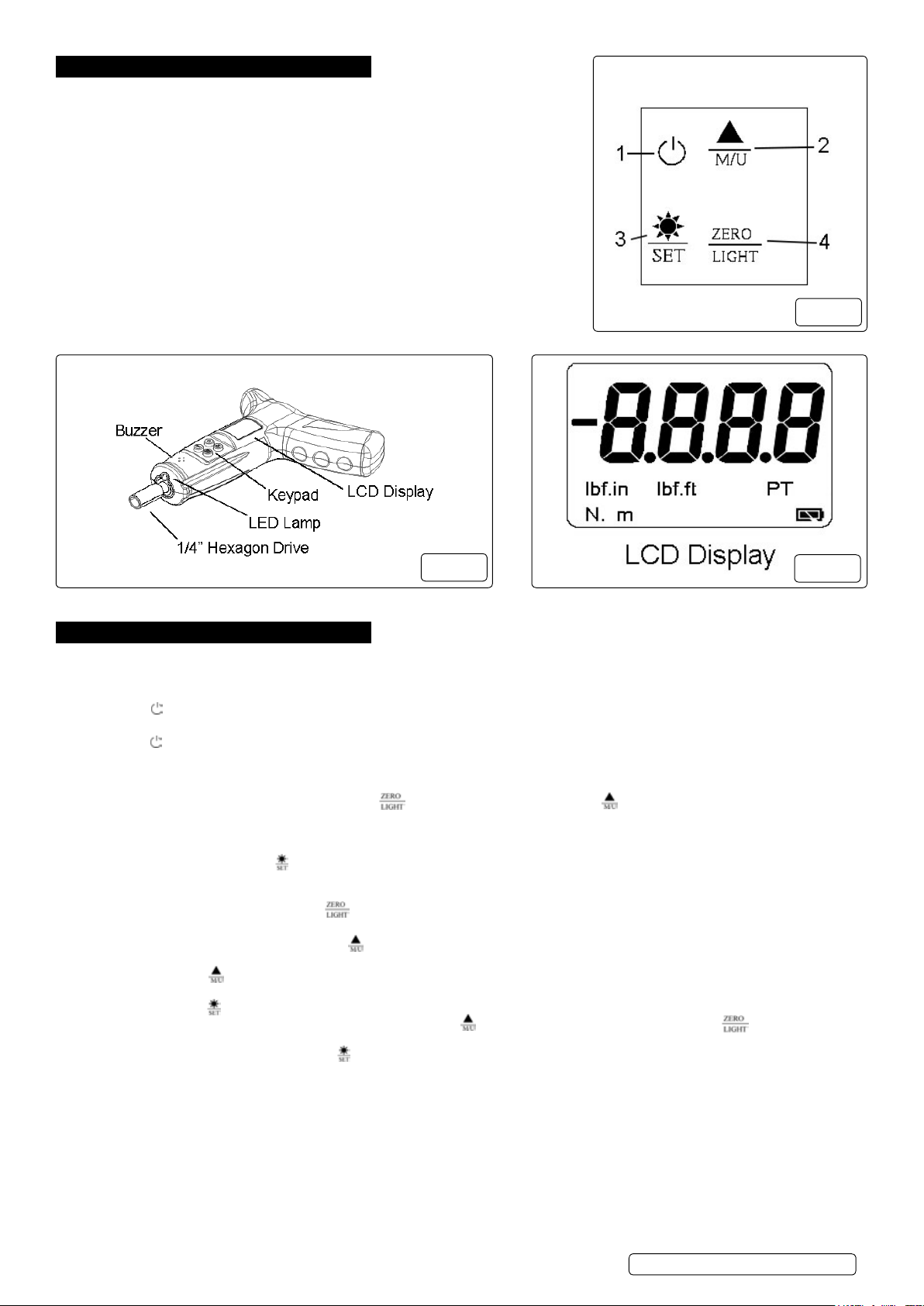

4. function Keys (fig.1.)

1. Press to turn the unit on and off.

2. Press to select the measurement mode between “track” and “peak”. / Press

and hold the button for 2 seconds to select the units. / under setting mode, press

to increase the value to program pre-set torque.

3. under measure status, press to switch on and off the back light. / under

measure status, press and hold the button for 2 seconds to enter the setting

mode. / under setting status, press to memorize the setting value and quit setting

mode.

4. under measure status, press to Zero tare. / under measure status, press

and hold the button for 2 seconds to switch on and off the led lamp which is

at the front of the tool. / under setting mode, press to decrease the value to

program pre-set torque.

g.1

g.2

g.3

5. preparation.

5.1. install the new batteries.

5.1.1. remove battery cover on the side of the screwdriver. Place batteries in battery compartment and replace cover.

5.2. turning the tool on / off.

5.2.1. Press “ ” button to turn on. the buzzer sounds and on the display you can see all readouts at the same time for just a moment. then

wait the display will show “ 0000 ” on the screen.

5.2.2. Press “ “ button again to turn off the electronic system.

5.3. activating the “peak mode”

5.3.1. After turning on the display, the default is in “ tracK “ mode, i.e. the real-time torque reached during operation will be displayed.

5.3.2. during the “ PeAK “ mode, the torque screwdriver will record and display the present maximum value. When the force released, the

maximum value is shown on the display. Press “ “ button to zero the value or press “ “ button switch between trAcK mode

and PeAK mode.

5.4. turning the lcd Back light on/off.

5.4.1. the lcd Back light can be turned on prior to or after programming the torque.

5.4.2. in order to do this, press the “ “ button to turn on or turn off.

5.5. turning the led lamp on/off.

5.5.1. the led lamp, at the front of the tool can be turned on prior to or after programming the torque.

5.5.2. in order to do this, press and hold the “ “ button for 2 seconds to turn on or turn off.

5.6. peak & track mode and units selection

5.6.1. turn the torque screwdriver on and press “ “ button switch between “trAcK“ mode and “PeAK” mode. in “PeAK” mode, the display

shows “peak” on the left side of the screen.

5.6.2. Press and hold “ ” button for 2 seconds to select units between n.m / lbf-ft / lbf-in.

5.7. programming the pre-set torque value

5.7.1. Press and hold “ ” button for 2 seconds to enter the setting mode, the display shows “ set ” on the screen. After 2 seconds, “0.00” or

the last programmed value will be shown on display, press the “ ” button to increase the value, or press the “ ” button to decrease

the value.

5.7.2. once the target torque is select, press “ ” button to memorize and quit setting mode.

warning! if the pre-set torque exceed the 125% maximum torque value (20nm), the value will jump back to Zero. the pre-set has

failed. if the warning indication did not work, reset mode again. the last pre-set torque value will be shown on the screen. if no value

shows, it means the pre-set has failed. Please read the instruction manual again and follow the procedure of “Pre-set torque Value”.

© Jack sealey limited

Original Language Version

sts104 | issue 1 15/05/17

6. operation

6.1. When target torque is reached, the user will hear the buzzer and also feel the vibration at the handle. (note: in PeAK mode,

when you reach the programmed torque, the buzzer will emit a continuous tone. Press “ “ button switch to trAcK mode

or press “ “ button to zero the value and turn off the warning indicator.

6.2. When the force is applied in an anti-clockwise direction, the display will show a minus (-) sign on the left side of screen, the reading

will be positive when the wrench is applied in a clockwise direction. To change ratchet direction see g.4

6.3. the torque screwdriver will automatically switch off if there is inactivity for over 5 mins.

g.4

7. maintenance

8 do not store this product in dusty, sandy, humid areas

8 or near any heat sources.

8 do not leave it in places where it may be subject to high temperatures.

9 Always keep the torque screwdriver dry. Water or other liquid will damage the electronic components inside.

9 if the tool is not used for a long period of time, remove the batteries in order to prevent damage from leakage.

9 Always turn off this product before cleaning. use only a damp cloth for cleaning. never use any type of liquid or aerosol cleaner, or

any type of organic solvent to clean this product.

7.1. recalibration

7.1.1. if the user does not utilize a control procedure, a period of 12 months, or 5000 cycles, whichever occurs first, may be taken as default

values for the interval between calibrations. the interval starts with the first use of the torque tool. shorter intervals between

calibrations may be used if required by the user, their customer or by legislation.

7.1.2. recalibration must take place after any repair, overload, impact or other misuse.

contact a uKAs accredited laboratory for recalibration.

environmental protection

recycle unwanted materials instead of disposing of them as waste. All tools, accessories and packaging should be

sorted, taken to a recycling centre and disposed of in a manner which is compatible with the environment.

When the product becomes completely unserviceable and requires disposal, drain off any fluids (if applicable)

into approved containers and dispose of the product and the fluids according to local regulations.

weee regulations

dispose of this product at the end of its working life in compliance with the eu directive on

Waste electrical and electronic equipment (Weee). When the product is no longer required, it must be disposed

of in an environmentally protective way. contact your local solid waste authority for recycling information.

Battery removal

remove battery cover on side of screwdriver and remove batteries, replace cover.

under the Waste Batteries and Accumulators regulations 2009, Jack sealey ltd are required to inform potential

purchasers of products containing batteries (as dened within these regulations), that they are registered wih Valpak’s

registered compliance scheme. Jack Sealey Ltd’s Batteries Producer Registration Number (BPRN) is BPRN00705.

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specications and component parts without prior notice.

important: no liability is accepted for incorrect use of this product.

warranty: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

© Jack sealey limited

sole uK distributor, sealey Group.

Kempson Way, suffolk Business Park,

Bury st. edmunds, suffolk.

iP32 7Ar

Original Language Version

01284 757500

01284 703534

www.sealey.co.uk

sales@sealey.co.uk

sts104 | issue 1 15/05/17

Loading...

Loading...