Sealey SSC11003 Instructions Manual

INSTRUCTIONS FOR:

SCREW COMPRESSOR 100ltr 3hp

230V LOW NOISE

MODEL No: SSC11003

Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions

and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS AND

CAUTIONS. USE THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY

CAUSE DAMAGE AND/OR PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

SSC11003

1. SAFETY INSTRUCTIONS

1.1. ELECTRICAL SAFETY

Make sure the power supply cable is correctly connected

to the earth. It is the user’s responsibility to read,

understand and comply with the following:

You must check all electrical equipment and appliances to

ensure they are safe before using. You must inspect power

supply leads, plugs and all electrical connections for wear

and damage. You must ensure the risk of electric shock is

minimised by the installation of appropriate safety devices.

An RCCB (Residual Current Circuit Breaker) should be

incorporated in the main distribution board.

You must also read and understand the following instructions

concerning electrical safety.

1.1.1. The Electricity At Work Act 1989 requires all portable

electrical appliances, if used on business premises, to be

tested by a qualified electrician, using a Portable Appliance

Tester (PAT), at least once a year.

1.1.2. The Health & Safety at Work Act 1974 makes owners of

electrical appliances responsible for the safe condition of the

appliance and the safety of the appliance operator. If in any

doubt about electrical safety, contact a qualified

electrician.

1.1.3. Ensure insulation on all cables and the product itself is safe

before connecting to mains power supply.

1.1.4. Ensure that cables are always protected against short circuit

and overload.

© Jack Sealey Limited

Original Language Version

1.1.5. Regularly inspect power supply, leads, plugs and all electrical

connections for wear and damage, especially power

connections, to ensure that none are loose.

1.1.6. Important: The mains voltage must correspond with that

indicated on the electrical data nameplate.

1.1.7. DO NOT pull the powered appliance by the power cable.

1.1.8. DO NOT pull power plugs from sockets by the power cable.

1.1.9. DO NOT use worn or damage leads, plugs or connections.

Immediately replace or have repaired by a qualified electrician.

1.1.10. Products which require more than 13amps are supplied

without a plug. In this case you must contact a qualified

electrician to ensure that a suitably rated supply is available.

We recommend that you discuss the installation of an

industrial round pin plug and socket with your electrician.

1.1.11. If it is necessary to replace a plug on the power supply cable

ensure that the earth wire is connected. All electrical repairs

must be carried out exclusively by a qualified electrical

engineer. Avoid all risks of electric shocks. Never use the

compressor with a damaged electrical mains supply cable.

Regularly check all electrical cables. Never use the

compressor in or near water or near a hazardous area where

electrical shocks may be encountered.

1.1.12. Use only extension cables with a plug and earth connections.

The use of too thin an extension cable would result in a

voltage drop and consequent overheating. An extension cable

with a cross-sectional area of 6mm² is recommended.

SSC11003 Issue: 1 - 03/05/13

1.2. SAFETY (INSTALLATION).

7 DO NOT USE THE COMPRESSOR IF IT IS FAULTY. Ensure

that the compressor is in good condition before use.

If the compressor is noisy or vibrates excessively when

running, stop it immediately. If in any doubt do not use the unit

and contact an electrician/service agent.

3 OPERATE THE COMPRESSOR AT THE RATED VOLTAGE.

Operate the compressor at the voltage specified on the

electric data plate. You could damage or burn-out the motor

and other electric components if the compressor is operated at

a higher or lower voltage than its rated voltage.

3 USE THE COMPRESSOR CORRECTLY. Operate the

compressor in compliance with the instructions provided in this

manual. DO NOT allow children or those who are not familiar

with it to use the compressor.

1.3. SAFETY (OPERATIONAL AREA/ENVIRONMENTAL).

3 OPERATIONAL AREA. Keep the work area clean and remove

any tools or unnecessary items that are not required. Install

the compressor on a firm surface away from any heat sources.

3 USE THE COMPRESSOR IN A WELL VENTILATED AREA.

Ensure there is adequate ventilation space all around the

compressor.

7 DO NOT USE THE COMPRESSOR IN THE PRESENCE OF

FLAMMABLE LIQUIDS OR GAS. The compressor may

produce sparks while running. DO NOT use the compressor

where there may be paints, petrol (gasoline), chemical

compounds, glues or any other flammable or explosive

material.

3 KEEP UNAUTHORISED PERSONS AWAY FROM THE

WORKING AREA. All non-essential persons must be kept at a

safe distance from the operational area. Prevent children or

anyone else from touching the power supply cable of the

compressor.

7 DO NOT use the compressor outdoors. DO NOT

install the compressor in damp or wet locations or in areas

where condensation may form.

7 DO NOT cover the compressor or restrict air flow around the

machine whilst operating.

3 IF THE COMPRESSOR IS USED FOR PAINTING JOBS.

a) DO NOT work in closed rooms or near naked flames.

b) Check that the area selected for spraying is provided with

an air change system or adequate ventilation.

c) Wear face and nose mask.

3

When the compressor is not in use, it should be switched

off, isolated from the mains supply and the air drained

from the tank.

3 STORE THE COMPRESSOR APPROPRIATELY. If the

compressor is not used immediately, it must be stored in a dry

place away from atmospheric agents until it is installed.

1.4. SAFETY (AIR/PRESSURE).

WARNING! THE AIR TANK IS A PRESSURE VESSEL AND

THE FOLLOWING SAFETY MEASURES APPLY:

7 DO NOT tamper with the safety valve and DO NOT modify

or alter the tank in any way. DO NOT strap anything to the

tank.

7 DO NOT subject the tank to impact, vibration or to heat

and DO NOT allow contact with abrasives or corrosives.

7 DO NOT drill, weld or deform the compressed air tank.

7 DO NOT UNSCREW THE OUTLET CONNECTION WHEN

THE TANK IS PRESSURISED. DO NOT unscrew the

connection for any reason whatsoever without first checking if

the tank is discharged.

3 Ensure the air supply valve is turned off before disconnecting

the air supply hose.

PNEUMATIC CIRCUIT.

Use recommended pneumatic hoses. Read the instructions

regarding any accessory used with the compressor. Ensure

the safe working pressure of any air appliance used exceeds

the compressor maximum pressure.

3 Ensure the air hose is not tangled, twisted or pinched.

7 DO NOT operate the compressor without an inlet air filter.

1.5. SAFETY (TRAINING/GOOD PRACTICE).

7 DO NOT allow anyone to operate the compressor unless they

have received full instructions and adequate training.

3 KEEP THESE USE AND MAINTENANCE INSTRUCTIONS

for future reference and make them available to the

compressor operator. The operator must be familiar

with all the controls and compressor characteristics

before starting to work with the machine.

3 AVOID ACCIDENTAL START-UP. Ensure that the main switch

is turned OFF before connecting the compressor to the

electrical power supply. Never move the compressor while it is

connected to the electrical power supply or when the tank is

pressurised.

3 PRECAUTIONS FOR THE POWER SUPPLY CABLE. DO NOT

disconnect the power supply plug by pulling on the cable. Keep

the cable away from heat, oil and sharp edges. DO NOT stand

on the electrical cable or trap it under heavy weights.

3 LOOK AFTER THE COMPRESSOR WITH CARE. Follow the

maintenance instructions. Inspect the power supply cable on a

regular basis and if damaged it must be repaired or replaced

by an authorised service centre. Check the outside

appearance of the compressor, ensuring that all is in order.

Contact your nearest Sealey dealer if necessary.

3 CHECK FOR FAULTY PARTS OR AIR LEAKS. Before each

use, visually inspect the compressor. If a safety guard or other

part is damaged, they must be checked carefully to evaluate

whether they continue to provide the intended protection.

Check the alignment of moving parts, hoses, gauges,

pressure reducers, pneumatic connections and every other part

that may be crucial for the normal operational efficiency of the

compressor. All damaged parts must be properly repaired or

replaced by an authorised service centre or replaced following

the instructions provided in instruction manual.

3 TURN THE COMPRESSOR OFF WHEN IT IS NOT IN USE.

When the compressor is not in use turn the main ON/OFF

switch to the OFF position (“0”).

7 DO NOT DEFACE THE CERTIFICATION PLATE ATTACHED

TO THE END OF THE COMPRESSOR TANK.

1.6. SAFETY (PERSONAL/MECHANICAL).

7 DO NOT USE THE COMPRESSOR WITHOUT THE SAFETY

GUARDS FITTED. Never use the compressor without all the

safety guards properly fitted in their correct place. If these parts

are to be removed for maintenance or servicing purposes,

ensure that they are correctly reinstalled before using the

compressor again.

7 DO NOT PUT OBJECTS OR PARTS OF THE BODY INTO

THE PROTECTION GRILLS. Never put your hands, fingers or

other parts of the body near moving parts of the compressor.

To do so may cause physical injuries and damage to the

compressor.

7 DO NOT TOUCH HOT PARTS OF THE COMPRESSOR.

To avoid burns do not touch the compressor cylinder, cylinder

head, motor or pipe from head to tank as these may be hot and

will remain so for some time after shutdown.

3 ALWAYS WEAR SAFETY GOGGLES or equivalent means of

eye protection. Never direct compressed air towards any part

of your body or that of others.

3 WEAR APPROPRIATE CLOTHING. DO NOT wear unsuitable

clothing, ties or jewellery as these may get caught up in moving

parts. Tie back long hair or wear a cap to cover your hair if

necessary.

3 PROTECT YOURSELF AGAINST ELECTRIC SHOCKS. Avoid

accidentally touching the metal parts of the compressor with

your body, such as pipes, the tank or metal parts connected to

earth. Never use the compressor where there is water or in

damp rooms.

© Jack Sealey Limited

Original Language Version

SSC11003 Issue: 1 - 03/05/13

1.7. SAFETY (MAINTENANCE/PARTS).

WARNING! Compressor must only be serviced by an

authorised agent. DO NOT tamper with, or attempt to

adjust, pressure switch or safety valve.

3 SPARE PARTS. Use only original and identical spare parts to

replace worn or damaged ones. Repairs must be made

exclusively by an authorised service agent.

3 MAINTENANCE. Regular maintenance of the compressor is

essential to ensure a long working life. Follow the maintenance

schedule detailed in these instructions.

7 DO NOT disassemble compressor for any reason. The unit must

be checked by qualified personnel only.

3 DRAIN condensate from tank at least every week, inspect

inside walls for corrosion every three months and have a

detailed tank inspection carried out annually. Tank shell

must not fall below the certified thickness at any point.

3 When not in use, store the compressor carefully in a safe, dry,

childproof location.

3 KEEP THE INTAKE GRILLS CLEAN. Keep the motor

ventilation grills clean. Clean these grills regularly if the work

area is particularly dirty.

7 DO NOT CLEAN PLASTIC PARTS USING SOLVENTS.

Solvents such as petrol (gasoline) and thinners or other

compounds that contain hydrocarbons may damage the plastic

parts. Clean them with a soft cloth and soapy water or other

suitable liquids.

3 USE ORIGINAL SPARE PARTS ONLY. The use of non-original

spare parts will invalidate the warranty and could seriously

damage the compressor. Original spare parts are available

from your local Sealey dealer.

3 MOVING OR MAINTAINING THE COMPRESSOR. Disconnect

the compressor from the electric power supply and completely

discharge the pressure from the tank before moving it or

carrying out any service, inspection, maintenance, cleaning,

replacing or inspection of parts.

WARNING! If an electrical fuse blows, ensure that it is

replaced with one of identical type and rating.

1.8. SAFETY (COMMON SENSE).

WARNING: The warnings, cautions and instructions

discussed in this instruction manual cannot cover all

possible conditions and situations that may occur. It must

be understood that common sense and caution are factors

which cannot be built into this product, but must be

applied by the operator.

3 WARNING. Pay attention to everything you do. Use your

common sense. DO NOT use the compressor if you are tired.

The compressor must never be used if you are under the

influence of alcohol, drugs or intoxicating medicines.

DANGER! DO NOT DIRECT THE JET OF COMPRESSED AIR

DIRECTLY TOWARDS YOUR BODY. To avoid all risks never

direct the jet of air towards other people or animals.

7 DO NOT STOP THE COMPRESSOR BY PULLING ON THE

POWER SUPPLY CABLE (unless in an emergency). Use the

ON/OFF buttons on the control panel to stop the compressor.

7 DO NOT MODIFY THE COMPRESSOR IN ANY WAY.

Contact your local Sealey dealer for all repairs required. Any

unauthorised modification may impair the efficiency of the

compressor and may also cause serious accidents for those

who do not have the technical skill required to make such

modifications.

3 WE RESERVE THE RIGHT TO MAKE MODIFICATIONS

WHERE NECESSARY WITHOUT NOTICE.

2. INTRODUCTION & SPECIFICATIONS

Compact high performance screw compressor providing high volume

and continuous output of air with low running costs. One of the most

economical ways to get compressed air 24/7 with minimal downtime.

Very few moving parts means servicing/maintenance is less frequent

and less expensive compared to equivalent piston compressor.

Features an insulated Class F 3hp motor with IP44 protected control

box and an insulated outer casing to minimise noise (59dB(A) at 1mtr)

and offers protection to inner components. All routine maintenance

functions are easily accessible and there is clear instrumentation

showing tank and line pressures separately. Also tted with drain valve

tap at base of unit to ensure easy function tank drain when required.

Model No:............................. SSC11003

Motor Output: ................................3hp

Voltage/Phase: .........................230V - 1ph

Rated Supply: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15A

Noise Level: ............................. 59dB(A)

Maximum Free Air Delivery: ........10.6cfm (300 ltr/min)

Maximum Pressure: .....................131psi/9bar

Receiver Capacity: ...........................100ltr

Dimensions (W x D x H):...........520 x 920 x1100mm

Weight: ....................................88kg

Plug (not tted):...............................16A

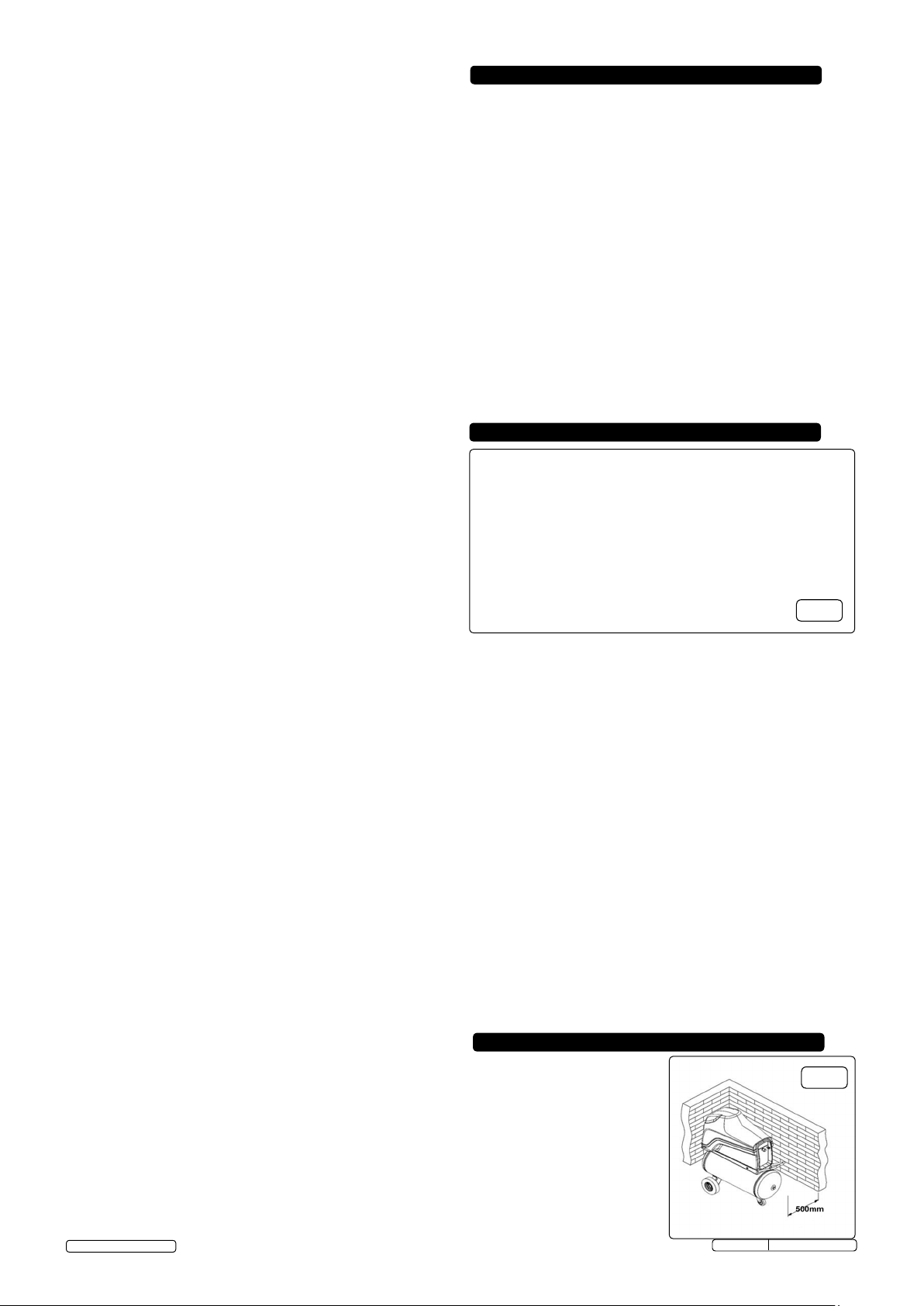

3. PREPARATION

fig.1

3.1 Remove compressor from packaging and inspect for any

shortages or damage. If anything is found to be missing or

damaged contact your supplier.

3.2 Save the packing material for future transportation of the

compressor. We recommend that you store the packing in a

safe location, at least for the period of the guarantee. Then, if

necessary, it will be easier to send the compressor to the

service centre.

3.3 Assemble the two xed wheels and the castor wheel to the

SAC11003 as shown in g.1.

3.4 Confirm that the mains voltage corresponds with the voltage

shown on the compressor data plate.

3.5 Site in a well ventilated place, protected against atmospheric

pollution and not in a place subject to explosion hazard. If the

surface is inclined and smooth, check if the compressor moves

while in operation – if it does, secure the wheels with two

wedges. If the surface is in a raised position, make sure it

cannot fall, securing it in a suitable way.

3.6. STORING THE PACKED AND UNPACKED COMPRESSOR.

. If the compressor is not to be unpacked immediately store it in

a dry place at a temperature between +5°C and +40°C and

sheltered away from the weather. If the compressor is not

used immediately after unpacking it, place sheets over it to

protect it from dust, which may settle on the components.

The oil is to be replaced and the operational efficiency of the

compressor is to be checked if it is not used for long periods.

© Jack Sealey Limited

4. INSTALLATION

4.1. To ensure good ventilation

and efcient cooling, the

compressor's air intake must

be at least 500mm from any

wall (g.2)

Original Language Version

fig.2

SSC11003 Issue: 1 - 03/05/13

Loading...

Loading...