mETAL CUTTING BANDSAW

I

MPORTANT:

PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

mODEL NO: Sm35CE.V4

Thank you for purchasing a Sealey product. manufactured to a high standard, this product will, if used according to these instructions,

and properly maintained, give you years of trouble free performance.

Refer to

instruction

manual

Wear protective

gloves

Wear eye

protection

No reaching in

sharp blade

Indoor use only

1. SAFETY

1.1. ELECTRICAL SAFETY

WARNING! It is the user’s responsibility to check the following:

Check all electrical equipment and appliances to ensure that they are safe before using. Inspect power supply leads, plugs and

all electrical connections for wear and damage. Sealey recommend that an RCD (Residual Current Device) is used with all electrical

products. You may obtain an RCD by contacting your local Sealey stockist.

If the product is used in the course of business duties, it must be maintained in a safe condition and routinely PAT (Portable

Appliance Test) tested.

Electrical safety information, it is important that the following information is read and understood.

Ensure that the insulation on all cables and on the appliance is safe before connecting it to the power supply.

Regularly inspect power supply cables and plugs for wear or damage and check all connections to ensure that they are secure.

Important: Ensure that the voltage rating on the appliance suits the power supply to be used and that the plug is tted with the

correct fuse - see fuse rating in these instructions.

DO NOT pull or carry the appliance by the power cable.

DO NOT pull the plug from the socket by the cable.

DO NOT use worn or damaged cables, plugs or connectors. Ensure that any faulty item is repaired or

is replaced immediately by a qualied electrician.

This product is tted with a BS1363/A 13 Amp 3 pin plug.

If the cable or plug is damaged during use, switch off the electricity supply and remove from use.

Ensure that repairs are carried out by a qualied electrician.

Replace a damaged plug with a BS1363/A 13 Amp 3 pin plug. If in doubt contact a qualied electrician.

a) Connect the GREEN/YELLOW earth wire to the earth terminal ‘E’.

b) Connect the BROWN live wire to the live terminal ‘L’.

c) Connect the BLUE neutral wire to the neutral terminal ‘N’.

Ensure that the cable outer sheath extends inside the cable restraint and that the restraint is tight.

Sealey recommend that repairs are carried out by a qualified electrician.

1.2. GENERAL SAFETY

WARNING! Disconnect the bandsaw from the power source before servicing, changing accessories, or performing any other maintenance.

Familiarise yourself with the applications and limitations of the bandsaw, as well as the potential hazards.

maintain the bandsaw in top condition. Keep it clean and keep blades sharp for best and safest performance.

Use original Sealey spare parts only. Unauthorised parts may be dangerous and will invalidate the warranty.

Keep all guards and fixing screws in place, tight and in working order. Check regularly for damaged parts. A guard or any other part

that is damaged must be repaired or replaced before the saw is used further. Check also for incorrect alignment of moving parts,

loose mountings, or any other condition that could affect the operation of the saw.

Ensure the space allocated for use and maintenance of the machine is adequate, free from unrelated materials and has good lighting.

Wear approved eye and ear protection when operating the machine. If dust is produced, wear an approved face or dust mask.

Keep children and unauthorised persons away from the work area, especially when the saw is in operation.

Remove any adjusting keys and wrenches from the machine before operating.

Ensure that large or oversized workpieces are supported at bed height. Ensure you use a suitable support for any workpiece that

does not have a flat surface. Be cautious when cutting workpieces which are irregular in cross-section as the saw blade could be

pinched before the cut is completed. Any stock such as frame moulding, must lay flat on the table surface and not be allowed to rock.

WARNING! Round bar and tubing have a tendency to roll while being cut and cause the blade to “bite”. DO NOT cut such items

without clamping or blocking the workpiece.

WARNING! Never force the blade through the workpiece.

DO NOT use this bandsaw for anything other than its intended purpose. This bandsaw is designed for light metal cutting work in

engineering workshops, garages, metal fabricators, etc. .

WARNING! The SM35CE.V4 bandsaw must not be used to cut non-metallic materials (including wood). To do so will

invalidate your insurance cover and your warranty and may cause damage and/or personal injury.

DO NOT wear loose or ill-fitting clothing. Remove ties, watches, rings and other jewellery. Tie up, or adequately cover, long hair.

DO NOT start the bandsaw until the workpiece is secure and the blade has been lowered to just above the workpiece.

DO NOT run the bandsaw with the blade in the raised position.

Recommended fuse rating

13 Amp

© Jack Sealey Limited

Original Language Version

SM35CE.V4 | Issue:7 (3) 07/09/18

DO NOT use the bandsaw in areas where fumes from paint, solvents, or flammable liquids pose a potential hazard. Keep all flammable

materials (including wipes or cleaning rags) away from the saw, and dispose of according to local regulations.

DO NOT leave the bandsaw running unattended. Turn power switch ‘Off’ and DO NOT leave area until the blade has come to a complete

stop.

DO NOT use if you are fatigued or under the influence of drugs, alcohol or other intoxicating medication.

DO NOT use the bandsaw with the blade guard or pulley cover removed.

DO NOT use the bandsaw in wet or damp locations.

DO NOT start accidentally. Ensure the switch is off before plugging in the saw.

DO NOT use damaged or deformed bandsaw blades.

Keep correct footing and balance at all times and wear non-slip shoes.

Turn the bandsaw off before raising the blade.

DO NOT stand on the bandsaw.

Always secure the workpiece in the vice.

2. INTRODUCTION

manufactured to comply with Safety of Machinery (Safety) Regulations 1992 (and amendments) and fully CE approved. Saw arm is fitted with

hydraulic damping to prevent the arm being dropped onto the workpiece and to ensure smooth cutting performance. Coolant fluid system and main

power controls are switched on individual circuits. Heavy-duty single phase electric motor.

3. SpECIFICATION

Capacity 90° round .....................................................Ø170mm

Capacity 90° square/rectangular H x W ..............170 x 200mm

Capacity 45° round .......................................................Ø80mm

Capacity 45° square/rectangular H x W ................170 x 80mm

Blade Size .............................................19.0 x 0.81 x 2362mm

Blade Speeds ..........................................34, 41, 59, 98mtr/min

motor Power ....................................................................750W

Power Supply ............................................................230V/1ph

Weight .............................................................................137kg

4. ASSEmBLY

4.1. Remove the unit from packing and check all items. Any transit damage should be reported your supplier immediately.

4.2. Unbolt the saw from the skid and place it on a level surface. (DO NOT attempt to move or lift the machine without the use of proper lifting

equipment).

4.3. Clean those surfaces coated in rust protection with kerosene or diesel oil. DO NOT use cellulose based solvents such as paint or lacquer

thinners as these will damage the paintwork.

4.4. ATTACH WHEELS

4.4.1. Place sound, suitable blocking under both ends of the saw base to support the unit whilst the wheels are being installed. Use proper

lifting equipment to do this and ensure that the saw remains stable whilst supported.

4.4.2. Slide a wheel onto the end of each axle and retain with the circlips provided. Slide the axles through each end of the saw base until they

protrude from the other side. Slide the remaining wheels onto the axles and retain with circlips. Push the red plastic covers provided

onto each wheel moulding as indicated in fig.1J.

4.5. ATTACH DAmpER CYLINDER

4.5.1. Screw the threaded end of the cylinder support rod into the tapped hole in the machine bed (see fig.1C) and tighten it using a 17mm

spanner applied to the hex section. Slide the damper cylinder assembly onto the rod in the correct orientation as shown in fig.1 (with

valve controls upwards) and screw the 14mm retaining nut into position on the end of the rod (fig.1D). Insert the stepped hinge pin

(fig.1E) through the hole in the end of the piston and swing the cylinder upwards towards the cylinder bracket attached to the main arm.

In order to screw the hinge pin into the bracket it may be necessary to depress the piston. Alternatively get a second person to raise

and support the arm until the hinge pin is aligned with the hole in the bracket. Tighten the hinge pin with a 14mm spanner.

4.6. ATTACH STOCK STOp

4.6.1. Insert the threaded end of the Stock Stop Rod (fig.1A) through the hole in the machine bed adjacent to the damper cylinder and retain it

by fixing a bolt and washer on the inside of the bed. Push the stop onto the rod. Retain it by tightening the hex socket set screw (fig.1B).

5. SET Up & ADjUSTmENTS

5.1. COOLANT TANK pREpARATION

5.1.1. The use of a water soluble coolant will increase cutting efficiency and prolong blade life.

5.1.2. Five litres of soluble cutting oil can be ordered under Sealey Part No. SCO5L (follow

instructions on pack regarding use and precautions). The coolant tank is situated in the base

of the machine and can be accessed through an opening in the back of the base.

5.1.3. Disconnect the machine from the power supply before adding/changing coolant.

5.1.4. Pull the coolant return hose from out of the hole in the top of the tank cover.

5.1.5. Slide the tank out of the saw base and lift off the tank cover with pump attached. The cover

must remain next to the machine due to the power cable attached. Fill the tank to

approximately 80% of its capacity and place the lid back onto the tank.

5.1.6. Slide the tank back into the base and push the coolant return hose back through the hole in the

top of the tank.

fig.1

© Jack Sealey Limited

Original Language Version

SM35CE.V4 | Issue:7 (3) 07/09/18

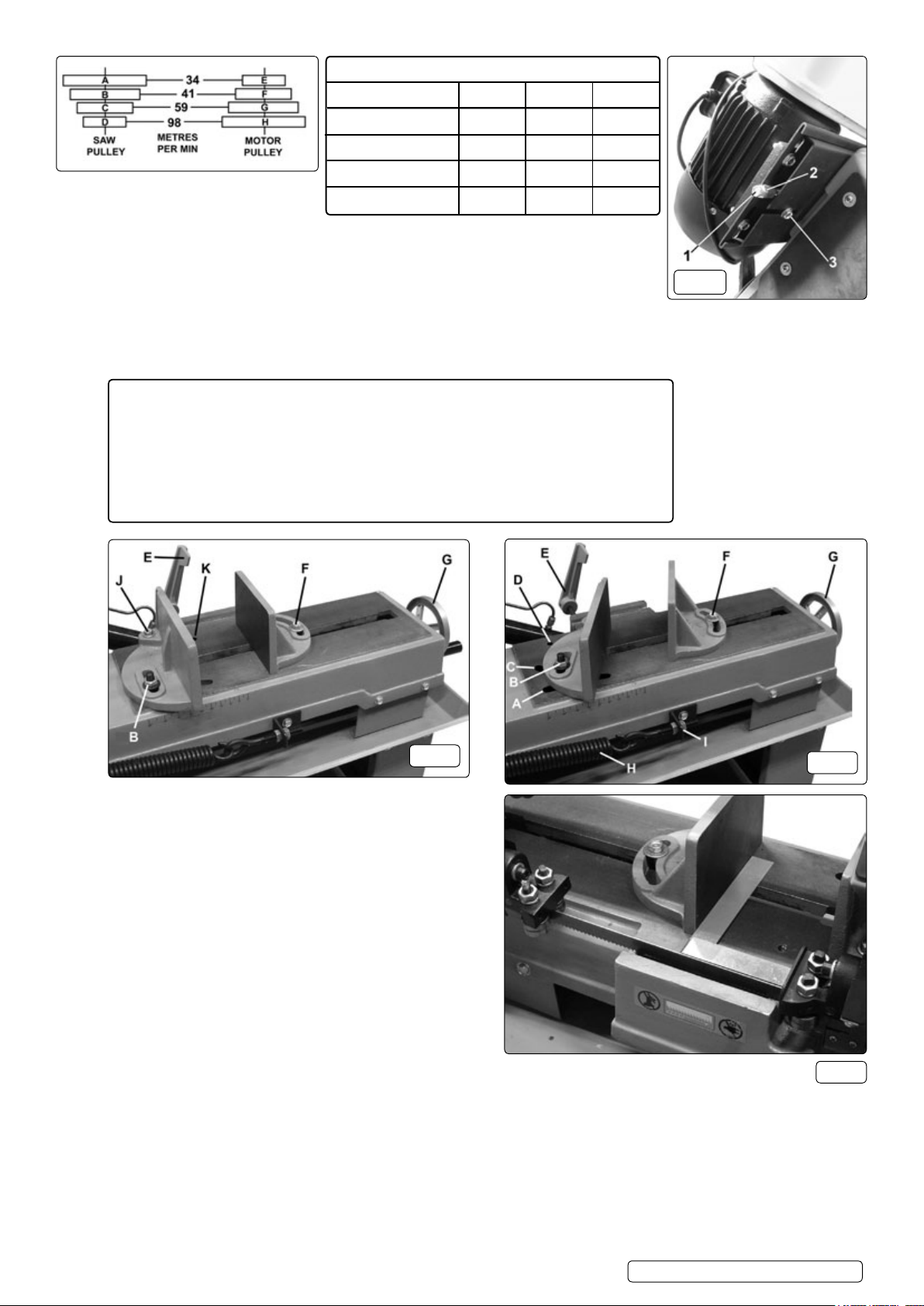

Recommended pulley Selection for Various metals

5.2. CHANGING BLADE SpEED.

material

Tool, stainless or alloy steel.

Bearing bronze.

Low carbon steel.

medium carbon steel.

Aluminium. Copper. Brass.

Saw pulley

(A)

(B)

(C)

(D)

motor pulley

(E)

(F)

(G)

(H)

Blade Speed

34m/min

41m/min

59m/min

98m/min

5.2.1. Disconnect the machine from the power supply.

5.2.2. Remove the pulley cover screw and hinge up the cover to access the pulleys and belt.

5.2.3. Loosen the lock bolt on the rear of the motor plate as shown in fig.2.3.

5.2.4. Loosen the locking nut on the tensioning screw as shown in fig.2.2.

5.2.5. Loosen the tensioning screw itself (see fig.2.1) and slacken it off in order to allow the motor plate

fig.2

to move inwards to shorten the distance between the two pulleys. It may be necessary to tap the

edge of the motor plate with a soft faced hammer to get the plate to move inwards to the point where the belt position can be changed.

Refer to the adjacent diagrams to decide on the best position for the belt for the job in hand.

5.2.6. When the belt is repositioned, retension it ensuring that it is not too tight and tighten the motor plate lock bolt. Close the pulley cover

and replace the cover screw.

Cutting Chart for Flat and Round Bar

Recommended blade teeth per inch (tpi) for nominal cut length

Cut length Under 8mm 4-13mm 6-16mm 8-22mm

Tpi 32 24 18 14

Cut length 10-35mm 17-40mm 25-50mm 38-75mm

Tpi 10 8 6 4

Cut length 50-100mm 75-150mm 114-225mm >200mm

Tpi 3 2 1.25 0.75

fig.3

fig.4

5.3. HYDRAULIC FEED SELECTOR OpERATION.

5.3.1. The rate of descent of the main cutting arm is controlled by the

damping cylinder seen in fig.1. By turning the knob ‘F’ in fig.1

clockwise the rate of descent is slowed down. By turning the knob

anticlockwise the rate of descent is increased. The arm can be locked

in any position by turning the hydraulic flow off using tap ‘G’

in fig.1. When the tap is at 90° to the cylinder the flow is off and the arm

will stop moving.

5.4. VICE SET Up & ADjUSTmENT.

5.4.1. The vice has two adjustment positions. One specifically set at 90°

degrees to the blade (see fig.3) and the other for variable angle

cutting (see fig.4).

5.4.2. For a non angled cut the vice should be set up as shown in fig.3.

Loosen pivot bolt ‘J’ and locking nut ‘B’ and adjust the vice face to be

90° to the blade by laying a set square onto the machine bed

as shown in fig.5. Tighten pivot bolt ‘J’ and locking nut ‘B.

5.4.3. When locking bolt ‘F’ is loosened the distance between the vice faces

can be adjusted by winding handle ‘G’. Adjust the position of the stock stop ‘E’ as required. Lay the material to be cut into the

vice and wind handle ‘G’ until the material is firmly clamped between the vice faces. Tighten locking bolt ‘F’.

fig.5

5.4.4. To change the set up to an angled cut the vice should be configured as shown in fig.4. Remove locking nut ‘B’ and its associated bolt

from straight slot ‘A’ and reassemble them into the curved slot ‘C’. Referring back to fig.3 move the pivot bolt ‘J’ to position ‘K’ on the

bed. The vice face will now pivot around bolt ‘J’. Set the vice face to the desired angle using an adjustable square and lock it at the set

position with nut ‘B’ as shown in fig.4. Lay the material to be cut into the vice and wind handle ‘G’ until the material is firmly clamped

between the vice faces. Tighten locking bolt ‘F’.

5.5. ADjUSTING BOW WEIGHT.

5.5.1. Bow weight is one of the most important adjustments on the saw. Incorrect bow weight can result in poor performance including

crooked cuts, tooth stripping, stalling and the blade coming off the blade wheels. The hydraulic feed rate unit will not compensate for

improper bow weight. Bow weight is factory set and should not normally require adjustment.

© Jack Sealey Limited

Original Language Version

SM35CE.V4 | Issue:7 (3) 07/09/18

5.5.2. If performance problems are encountered the bow weight can be adjusted as follows:

5.5.2.1. The bow weight spring, which acts on the main arm, can be seen in fig.4.H as can the adjuster nuts fig.4.I

5.5.2.2. Disconnect the saw from the power supply.

5.5.2.3. Turn the hydraulic cylinder valve on and place the arm in the horizontal position. Turn the feed rate valve on the cylinder anticlockwise

until it stops.

5.5.2.4. Hook a spring balance under the blade tension handle and lift the saw arm. The scale should read 5-6kg. If this is not the case adjust the

tension until it does.

fig.7

fig.8

fig.6

5.6. ADjUSTING BLADE GUIDES

5.6.1. Disconnect the saw from the power supply.

5.6.2. The two blade guides should be adjusted to be as close as possible to the workpiece without interfering with the cut.

5.6.3. The left hand blade guide can be seen in fig.6 item B. To adjust it, loosen knob A and slide the guide near to the workpiece. Tighten

knob A.

5.6.4. The right hand blade guide can be seen in fig.1 item ’I’. To adjust it, loosen knob H and slide the guide near to the workpiece.

Tighten knob H.

5.7. BLADE TRACKING ADjUSTmENT

WARNING! Blade tracking adjustment requires running the saw with the back cover open.

This adjustment should only be carried out by qualified, experienced personnel. Failure to comply may result in serious injury.

5.7.1. Blade tracking is factory set and should not normally require adjustment. If a blade becomes warped it will not track properly and it

must be replaced. The tracking should be checked whenever a new blade is fitted.

5.7.2. Raise saw arm and lock in place by shutting off the hydraulic cylinder valve.

5.7.3. Conrm that the blade tension is set properly. Adjust if necessary, refer to 5.10.

5.7.4. Open blade cover to check blade-to-wheel relationship. Switch the machine on and observe the running of the blade. The rear edge of

blade should be very close to, but not hard against, the wheel anges. Turn saw off.

5.7.5. If inspection indicates that adjustment is required loosen bolts ‘D’ (g.6) using a 12mm spanner. Start up saw.

5.7.6. Place a 12mm spanner onto the adjuster (g6.E) and rotate it in or out as required whilst observing the position of the blade on the

wheels. Turn the adjuster clockwise to track the blade closer to the wheel anges. Turn the adjuster anti-clockwise to track the blade

away from the wheel anges. When satised with the tracking turn the saw off and close and secure the safety covers. Re-tighten

bolts ‘D’.

5.8. CHANGING THE BLADE.

WARNING! Take care when handling saw blades, blade teeth are very sharp. Wear gloves.

WARNING! BEFORE mAKING ANY ADjUSTmENTS, DISCONNECT SAW FROm pOWER SUppLY

5.8.1. All adjustments that relate to the smooth and safe running of the blade have been set at the factory. However, if you require to replace a

blade due to it being worn out or if you need to change to a blade with a different tooth size it will be necessary to re-adjust the saw.

5.8.2. Raise the main arm to the vertical position and lock it there by turning off the hydraulic feed (the tap should be at 90° to the cylinder).

5.8.3. Remove the two screws that hold the upper blade guard in place (fig.7C) and remove it. Also remove the lower blade guard (fig.7D)

which has a built-in blade brush and is also held in place with two screws.

5.8.4. Loosen the two screws (fig.7B) holding the lower blade wheel cover in place and slide the cover upwards to the full extent of its travel.

This is necessary as the main blade cover will not open fully otherwise. Temporarily tighten the screws to prevent the cover sliding down

again.

5.8.5. Undo and remove the two screws (fig.7A) that hold the main blade cover closed and fully open the cover as shown in fig.8.

5.8.6. Before the blade can be removed release the tension on the blade by turning the blade tension knob (fig.8E) anti-clockwise.

5.8.7. Ease the blade away from the lowest pulley wheel first and support it as you remove it from the upper pulley wheel then carefully remove

the blade from between the guide wheels.

5.8.8. Place the new blade through the guides first and then ease it around the lower pulley wheel. (Ensure that the tooth direction is consistent

with the blade tooth diagram attached to the main bed.) Retain the blade on the lower pulley with one hand and take up the tension at the

top of the blade with the other hand. Then use both hands to ease the blade over the upper pulley.

5.8.9. Reattach the blade guards.

5.9.

© Jack Sealey Limited

Original Language Version

SM35CE.V4 | Issue:7 (3) 07/09/18

fig.10

fig.9

5.10. TENSIONING THE BLADE.

WARNING! DO NOT over tighten the blade as this may cause the blade to stretch and warp.

Note: Blade tension is important for the correct operation of the saw. The correct blade tension is 700 to 900kg as measured on a

blade tension gauge. To set the blade tension without the use of a gauge do the following. Tension the blade slightly to remove any sag in

the blade between the two wheels by turning the knob (fig.8E) clockwise but as you do so make sure that the back edge of the

blade is close to the rim of both pulleys. Check that the blade is seating properly by turning the pulleys by hand until you have observed

a full rotation of the blade.

5.10.1. Once the blade is properly aligned increase the tension by turning the knob one and three quarter to two revolutions clockwise. This

equals approximately 800kg blade tension.

5.10.2. Replace the upper and lower blade guards.

5.10.3. Close the blade protection safety cover and secure it with the two screws.

5.10.4. Loosen the two screws on the lower blade wheel protection cover and slide it downwards so that the lower blade wheel is completely

covered. Tighten the screws.

5.10.5. Reconnect the saw to the power source and run it for two to three minutes to seat the blade.

5.10.6. Disconnect the saw from the mains power supply and open the safety covers again.

5.10.7. Loosen the blade until it just begins to sag.

5.10.8. Tighten blade again until it just becomes straight between the blade wheel with all sag eliminated.

5.10.9. Further tighten the blade by turning the tension knob two full revolutions. The blade is now properly tensioned and ready for use.

5.10.10. Close and secure safety covers.

5.10.11. After fitting a new blade the tracking should be checked as described in section 5.7.

5.11. BLADE GUIDE BEARING ADjUSTmENT

WARNING! This machine is designed and intended for use with blades that are 0.8/0.9mm thick by 19mm wide by 2362mm long.

Use of blades with a different specification may cause inferior performance.

5.11.1. Correct guide bearing adjustment is important so that the blade runs smoothly and evenly without twisting or snagging anywhere along its

path.

5.11.2. Raise arm to vertical position and lock in place by turning off the hydraulic cylinder valve.

5.11.3. For greater visibility and ease of adjustment the protective plate directly over the guide bearings can be temporarily removed.

5.11.4. Loosen the hex socket cap screw (see fig.9C) in order to adjust the position of the back roller bearing (see fig.9E). The bearing should

be 0.08mm to 0.12mm from the back of the blade.

5.11.5. Each of the outer guide bearings is mounted on an adjustable eccentric bushing. Loosen the locknut (see fig.9A) with a 16mm ring

spanner whilst holding the adjuster ‘B’ with an 6mm open ended spanner.

5.11.6. Turn the adjuster to adjust the bearing. The bearing should barely touch the blade (0.001”). This clearance can be measured with a piece

of thin paper which should just fit into the gap between the bearing and the blade. Tighten the lock nut when satisfied with the bearing

adjustment.

5.11.7. Adjust both outer guide bearings. When satisfied that the adjustment is accurate, carefully turn the blade wheels by hand to see if the

blade snags or rubs at any point. Re-adjust bearing(s) if necessary.

5.12. ADjUSTING BLADE TO BE 90° TO THE BED

5.12.1. Disconnect the machine from the power supply.

5.12.2. Place an engineer’s set square onto the bed touching the blade as shown in fig.10.

The blade should make contact with the square across its entire width.

5.12.3. If adjustment is necessary loosen the socket cap screws as shown in fig.10 A&B and rotate both blade guide assemblies slightly in the

same direction until the blade makes contact with the square across its entire width.

5.12.4. Tighten bolts A & B.

5.12.5. Having made this adjustment the blade guide bearing adjustments should be checked again as detailed in section 5.11.

6. OpERATION

WARNING! Before operating the bandsaw ensure that you read, understand and apply the safety instructions in Section 1.

NOTE: Before operating the machine certain checks and adjustments will need to be carried out as detailed in Section 5 ‘Set

Up and Adjustments’. It is very important that these instructions are followed carefully in order that the machine is set up

safely and correctly.

WARNING! The machine is designed for light metal cutting work in engineering workshops, garages, metal fabricators, etc.

The Sm35CE.V4 must not be used to cut any other materials (including wood). To do so will invalidate your insurance cover and

your warranty and may cause damage and/or personal injury.

WARNING! Never operate the saw unless all blade guards are installed and working properly.

© Jack Sealey Limited

Original Language Version

Note: The harder the material being cut, the slower the cutting speed should be. The use of a cutting oil is recommended with the higher

blade speeds.

6.1. OpERATION.

6.1.1. Ensure that the saw is disconnected from the power supply.

6.1.2. Adjust the blade speed to suit the workpiece material (see Section 5.2).

6.1.3. Raise the saw arm to the vertical position.

6.1.4. Adjust the stock stop to the desired length.

6.1.5. Adjust the vice to the desired angle or set up at 90° to the bed as required.

6.1.6. Open vice, insert the workpiece and clamp it securely.

6.1.7. Adjust the two blade guides so that they are close to the workpiece but will not foul it.

6.1.8. Adjust the rate of descent of the arm as described in Section 5.3 so that it is creeping slowly down towards the workpiece. Shut off the

hydraulic cylinder when the blade gets close to the workpiece.

DO NOT start cutting on a sharp edge. File it off first.

DO NOT turn on machine until workpiece is secured and blade has been lowered to just above workpiece.

6.1.9. If using coolant, position the nozzle over the workpiece and turn on the pump. Direct the flow to the cutting area.

6.1.10. Start the saw.

6.1.11. To bring the blade into contact with the workpiece open the valve on the hydraulic cylinder. If the blade jams, immediately switch off

the power. Refer to the ‘Troubleshooting’ section for common problems.

6.1.12. When the cut is completed switch off the coolant pump and disconnect the saw from the power supply, raise blade and remove

workpiece.

WARNING! Never raise blade when machine is running .

WARNING! Wear gloves when handling sawn metal parts as the cutting process will have made them hot to touch and the

cut edges will be sharp.

7. LUBRICATIONn

WARNING! Disconnect the bandsaw from the power source before performing any maintenance.

7.1. The bearings on the blade guide assemblies and the blade wheels are permanently sealed and require no lubrication. Lubricate vice

lead screw as necessary.

7.1.1. Change the gearbox oil after the first 90 days of operation and thereafter every 6 months.

7.1.2. To change the gearbox oil first disconnect the machine from the power supply.

7.1.3. Place the saw arm in the horizontal position.

7.1.4. Remove the screws from the four corners of the gearbox cover and remove the gearbox cover and gasket.

7.1.5. Place an oil container under right hand lower corner of gearbox and then carefully raise saw arm fully to drain oil.

7.1.6. Lower saw arm, remove any remaining oil from gearbox with clean cloths and then refill with 0.3litres of SAE90 gear oil. Replace cover

and gasket.

8. mAINTENANCE

WARNING! Disconnect the bandsaw from the power source before servicing, changing accessories, or performing any other

maintenance.

8.1. mAINTENANCE

8.1.1. Keep all surfaces clean and free from rust, slag, chips and coolant build-up.

DO NOT use compressed air to clean bandsaw. Compressed air may force chips into the guide bearings and other critical areas of the saw.

8.1.2. Use a small paint brush or parts cleaning brush to remove metal particles.

8.1.3. Wipe saw down with a clean dry cloth and oil all unpainted surfaces with light machine oil.

8.1.4. Keep blade guides clean and free from metal chips.

8.1.5. Check guide bearings frequently to make sure they are properly adjusted and running freely.

8.2. BLADE CLEANING BRUSH.

8.2.1. It is important that the blade cleaning brush be properly adjusted and kept in good working order. (The brush is built into the blade guard

attached to the right hand blade guide). Blade life will be shortened severely if the brush is allowed to go out of adjustment, becomes

worn or damaged. Replace the brush if it becomes worn or damaged.

WARNING! DO NOT attempt to to adjust the blade brush with the machine running. Adjust only when the machine is

disconnected from the power source.

© Jack Sealey Limited

Original Language Version

SM35CE.V4 | Issue:7 (3) 07/09/18

9. TROUBLESHOOTING

Problem Cause Solution

Excessive blade

breakage and/or

teeth ripping from

the blade.

Premature blade

Dulling.

Unusual wear on

side or back of

blade.

Bad, crooked or

Rough cuts.

Blade is twisting. 1. Blade is binding in the cut.

1. Workpiece is loose in the vice.

2. Incorrect speed or feed.

3. Blade is too coarse.

4. Workpiece material is too coarse.

5. Incorrect blade tension.

6. Blade is in contact with workpiece before saw

is started.

7. Blade is rubbing on the wheel flange.

8. Blade guides are misaligned.

9. Blade is too thick.

10. Bad weld on blade

1. Blade tpi is too high.

2. Incorrect speed - too fast.

3. Inadequate feed pressure.

4. Hard spots or scale on the workpiece.

5. Blade installed backwards.

6. Insufficient blade tension.

7. Work hardened material especially stainless

1. Blade guides are worn.

2. Blade guides not properly adjusted.

3. Blade guide brackets are loose.

1. Feed pressure too great.

2. Blade guide bearings not properly adjusted.

3. Inadequate blade tension.

4. Blade is dull.

5. Incorrect speed.

6. Blade guides are spaced out too far.

7. Blade guide assembly is loose.

8. Blade is too coarse.

2. Blade tension is too high.

1. Clamp the workpiece securely.

2. Check machinist’s handbook.

3. Check machinist’s handbook for recommended blade type.

4. Use the saw at slower speed and use a smaller tpi blade.

5. Adjust blade tension so that it does not slip on the wheel.

6. Place blade in contact with the workpiece only after the saw has

started.

7. Adjust blade tracking.

8. Adjust blade guide alignment.

9. Use correct thickness blade.

10. Re-weld or replace blade.

1. Replace with a smaller tpi blade.

2. Reduce speed.

3. Increase feed pressure by unscrewing tension bar. This will

decrease the spring tension on the arm.

4. Reduce speed, increase feed pressure.

5. Remove blade, twist inside out and reinstall.

6. Increase blade tension.

7. Increase feed pressure by reducing spring pressure.

1. Replace blade guides.

2. Adjust as described in manual.

3. Tighten blade guide brackets.

1. Reduce feed pressure by increasing the spring tension on the

arm.

2. Adjust blade guide bearing in accordance with manual.

3. Increase blade tension a little at a time.

4. Replace the blade.

5. Check manual for recommended speed.

6. Move guides closer to workpiece.

7. Tighten the guide assembly.

8. Use a finer blade.

1. Decrease feed pressure.

2. Decrease blade tension.

WEEE REGULATIONS

Dispose of this product at the end of its working life in compliance with the EU Directive on Waste Electrical and Electronic Equipment

(WEEE). When the product is no longer required, it must be disposed of in an environmentally protective way. Contact your local solid

waste authority for recycling information.

ENVIRONmENT pROTECTION

Recycle unwanted materials instead of disposing of them as waste. All tools, accessories and packaging should be sorted, taken to

a recycling centre and disposed of in a manner which is compatible with the environment. When the product becomes completely

unserviceable and requires disposal, drain any fluids (if applicable) into approved containers and dispose of the product and fluids

according to local regulations.

Note: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior

notice.

Important: No Liability is accepted for incorrect use of this product.

Warranty: Guarantee is 12 months from purchase date, proof of which is required for any claim.

Sealey Group, Kempson Way, Suffolk Business park, Bury St Edmunds, Suffolk. Ip32 7AR

01284 757500 01284 703534 sales@sealey.co.uk www.sealey.co.uk

© Jack Sealey Limited

Original Language Version

SM35CE.V4 | Issue:7 (3) 07/09/18

Loading...

Loading...