Sealey SM35CE Instructions Manual

INSTRUCTIONS FOR:

12 HORIZONTAL BANDSAW

Model:

Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions

and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS.

USE THE PRODUCT CORRECTL

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

Y AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DA MAGE OR

SM35CE

1. SAFETY INSTRUCTIONS

pp

1.1. ELECTRICAL SAFETY.

You must check all electrical equipment and appliances to ensure they are safe before using. You must inspect power supply leads, plugs and

all electrical connections for wear or damage. You must ensure the risk of electric shock is minimised by the installation of appropriate safety

devices. An RCCB (Residual Current Circuit Breaker) should be incorporated in the main distribution board. We also recommend that an RCD

(Residual Current Device) is used with all electrical products. It is particularly important to use an RCD with portable products that are plugged

into an electrical supply not protected by an RCCB. If in doubt consult a qualified electrician. You may obtain a Residual Current Device by

contacting your Sealey dealer. You must also read and understand the following instructions concerning electrical safety.

1.1.1. The Electricity At Work Act 1989 requires all portable electrical appliances, if used on business premises, to be tested by

a qualified electrician, using a Portable Appliance Tester (PAT), at least once a year.

1.1.2. The Health & Safety at Work Act 1974 makes owners of electrical appliances responsible for the safe condition of those appliances,

and the safety of appliance operators. If in any doubt about electrical safety, contact a qualified electrician.

1.1.3. Ensure the insulation on all cables and the product itself is safe before connecting to the mains power supply.

See 1.1.1. & 1.1.2. above and use a Portable Appliance Tester (PAT).

1.1.4. Ensure that cables are always protected against short circuit and overload.

1. 1. 5. Regularly inspect power supply leads and plugs for wear or damage and connections to ensure that none is loos e.

1.1.6. Important: Ensure the voltage marked on the product is the same as the electrical power supply

to be used, and check that plugs are fitted with the correct capacity fuse. A 13 amp plug may require

a fuse smaller than 13 amps for certain products - see fuse rating at right.

1.1.7. DO NOT pull or carry the powered appliance by its power supply lead.

1.1.8. DO NOT pull power plugs from sockets by the power cable.

1.1.9. DO NOT use worn or damage leads, plugs or connections. Immediately replace or have repaired by

a qualified electrician. Where a U.K. 3 pin plug with ASTA/BS approval is fitted, in case of damage, cut off

and fit a new plug according to the following instructions (discard old plug safely).

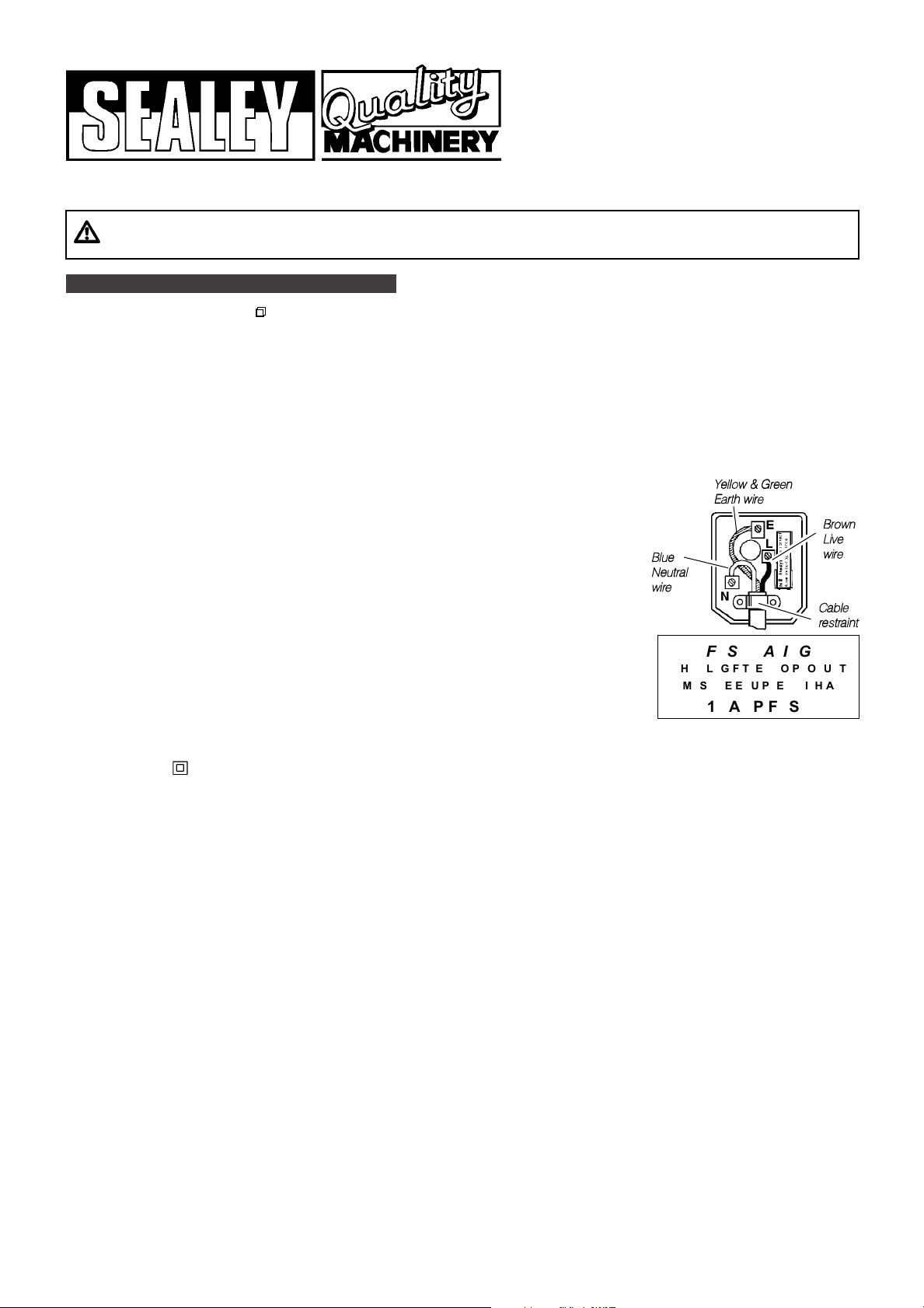

(UK only - see diagram at right). Ensure the unit is correctly earthed via a three-pin plug.

a) Connect the GREEN/YELLOW earth wire to the earth terminal E.

b) Connect the BROWN live wire to the live terminal L.

c) Connect the BLUE neutral wire to the neutral terminal N.

d) After wiring, check there are no bare wires, that all wires have been correctly

connected, that the cable outer insulation extends past the cable restraint and that the cable restraint is tight.

Double insulated products are often fitted with live (BROWN) and neutral (BLUE) wires only. Double insulated products are always marked with

this symbol . To re-wire, connect the brown & blue wires as indicated above. DO NOT connect the brown or blue wires to the earth terminal.

1.1.10. NOTE: If this product requires more than a 13 amp electrical supply, then NO plug is fitted. You must therefore contact a qualified electrician to

ensure a 30 amp fused supply is available. W

1.1.11. Cable extension reels. When a cable extension reel is used it should be fully unwound before connection. A cable reel with an RCD

fitted is recommended since any product which is plugged into the cable reel will be protected. The section of the cores in the cable

is important and should be at least 1.5mm

for others that may be used in the other output sockets, the use of 2.5mm

WARNING! It is the users responsibility to read, understand and comply with the following:

YYeellllooww && GGrreeeenn

EEaarrtthh wwiirree

BBrroowwn

LLiivvee

BBlluue

e

NNeeuuttrraall

wwiirre

e

wwiirre

CCaabbllee

rreessttrraaiinnt

FUSE RATING

THE PLUG FITTED TO PRODUCT

MUST BE EQUIPPED WITH A

13 AMP FUSE

e recommend you discuss the installation of a industrial round pin plug and socket with your electrician.

2

, but to be absolutely sure that the capacity of the cable reel is suitable for this product and

2

section is recommended.

n

e

t

1.2 GENERAL SAFETY

3 Familiarise yourself with the application and limitations of the saw

p WARNING! Ensure all Health and Safety, local authority, and general workshop practice regulations are strictly adhered to.

p WARNING! Keep all guards and holding screws in place, tight and in good working order. Check regularly for damaged parts.

A guard, or any other part, that is damaged must be repaired or replaced before next use of the saw. The safety guards are mandatory

when the bandsaw is used in premises covered by the Health & Safety at W

p WARNING! Disconnect bandsaw from the mains power supply before changing accessories, making repairs or adjustments.

p WARNING! Wear approved safety eye protection, ear defenders, gloves and, if dust is generated, respiratory protection.

p

WARNING! Evaluate your working area before using the bandsaw and always give your work your undivided attention.

p

WARNING! Replace warning labels if they become obscured or removed.

p

WARNING! Always provide adequate support for long and heavy material.

p WARNING! Never operate the bandsaw unless all blade guards are installed and in proper working order

p WARNING! Never operate the bandsaw with the blade in the raised position.

p WARNING! Do not turn bandsaw on until workpiece is secured in vice and the blade has been positioned just above the workpiece.

p

WARNING! Do not over tighten blade as it will stretch and warp.

p

WARNING! Take care lifting the bandsaw arm as it is heavy, and could, if not correctly lifted, affect the whole balance of the machine.

3

Locate the bandsaw in a suitable area, keep area clean and uncluttered and ensure there is adequate lighting.

3 Maintain the machine and keep in good condition (use an authorised service agent).

3 Ensure the machine is situated on a solid surface, adequate for supporting the weight of the machine and the workpiece.

3 Check the alignment of moving parts regularly, for safest performance keep the machine clean at all times.

3 Turn off the machine before raising the blade.

p

, as well as the specific potential hazards.

ork Act.

.

SM35CE - 0016 - (4) - 140301

3 Avoid unintentional starting.

3 Regularly remove, clean and inspect the blade brush.

3 Remove any adjusting keys and wrenches from the bandsaw before turning it on.

3 Replace or repair damaged parts. Use recommended parts only. Non-authorised parts may be dangerous and will invalidate the warranty.

3 Keep hands and body clear of the work table when operating the bandsaw.

3 Maintain correct balance and footing, ensure the floor is not slippery and wear non-slip rubber soled footwear.

3 Remove ill fitting clothing, ties and loose jewellery, and tie back long hair.

3 Ensure there are no flammable or combustible materials near the work area.

7 DO NOT leave the machine running unattended.

7 DO NOT operate the machine if any parts are damaged or missing as this may cause failure and/or personal injury.

7 DO NOT use the bandsaw for a task it is not designed to perform.

7 DO NOT use bandsaw near to flammable liquids, solids or gases, such as paint solvents and including waste wiping or cleaning rags.

7 DO NOT use damaged or deformed bandsaw blades.

7 DO NOT remove the safety guard whilst in use.

7 DO NOT hold the workpiece by hand.

7 DO NOT touch the workpiece immediately after cutting, it may be very hot.

7 DO NOT operate the machine when you are tired, under the influence of alcohol, drugs or intoxicating medication.

7 DO NOT allow children or untrained persons to operate the machine. Keep them away from the work area.

3 When not in use unplug from the mains supply and make every effort to make the machine childproof.

2. INTRODUCTION & SPECIFICATION

The SM35CE is designed for light/medium metal cutting work in engineering workshops, garages and metal fabricators, etc., in a horizontal

position only. It is not to be used for cutting any other material, or used in a vertical position. The bandsaw is not suitable for cutting wood

and, if used for this purpose, the insurer will not provide coverage.

The saw arm is fitted with hydraulic damping to prevent it being dropped onto the workpiece and to ensure smooth cutting performance and

the blade guards are redesigned for improved safety. The heavy duty single phase electric motor has an over-current sensor to cut the power in

the event of blade jamming.

The saw is manufactured to comply with Supply of Machinery (Safety) Regulations 1992 (S.I.3073) and is fully CE approved.

Cutting Capacities: Specification:

90° - Round . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Ø170mm Blade Size . . . . . . . . . . . . . . . . . . . . . . . . . .19 x 0.032 x 2360mm

90° - Sq/Rect., H x W . . . . . . . . . . . . . . . . . .170 x 210mm Blade Speeds . . . . . . . . . . . . . . . . . . . . . . . .22, 34, 45, 66 m/min

90° - Bar, H x W . . . . . . . . . . . . . . . . . . . . . . .50 x 300mm Motor Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.75kW (1HP)

45° - Round . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Ø110mm Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .230V/1ph

45° - Sq/Rect., H x W . . . . . . . . . . . . . . . . . .170 x 110mm Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115kg

Cutting Chart for Flat and Round Bar

Recommended Pulley Selection for Various Metals

Recommended blade teeth per inch (tpi) for nominal cut length

Cut length <13mm 6-16mm 8-22mm 17-40mm >38mm

Tpi 24 18 14 8 4

A

B

C

Motor Pulley

D

E

F

Saw Pulley

Medium to high carbon steel.

Hard brass or bronze. Cast iron.

Low to medium carbon steel.

Material Motor Pulley Saw Pulley Blade Speed

Tool, stainless or alloy steel.

Bearing bronze.

Soft brass.

Aluminium. Copper. Brass. Large (C) Small (F) 66m/min

3. ASSEMBLY

3.1. Unpacking

3.1.1. Unpack the bandsaw and inspect all parts. If any parts are damaged contact your distributor.

3.1.2. Unbolt from the transport skid and place on a firm, level surface.

3.1. 3. Clean all rust protected surfaces with kerosene, diesel oil, or a mild solvent. Do not use cellulose based

solvents as these will damage painted surfaces.

3.2. Assembly

3.2.1. Place blocks under each end of the saw base to allow for wheel installation.

sure the saw is completely supported.

3.2.2. Insert both wheel axles through the holes in the base.

3.2.3. Attach wheels onto both axles and fasten with washers and split pins provided.

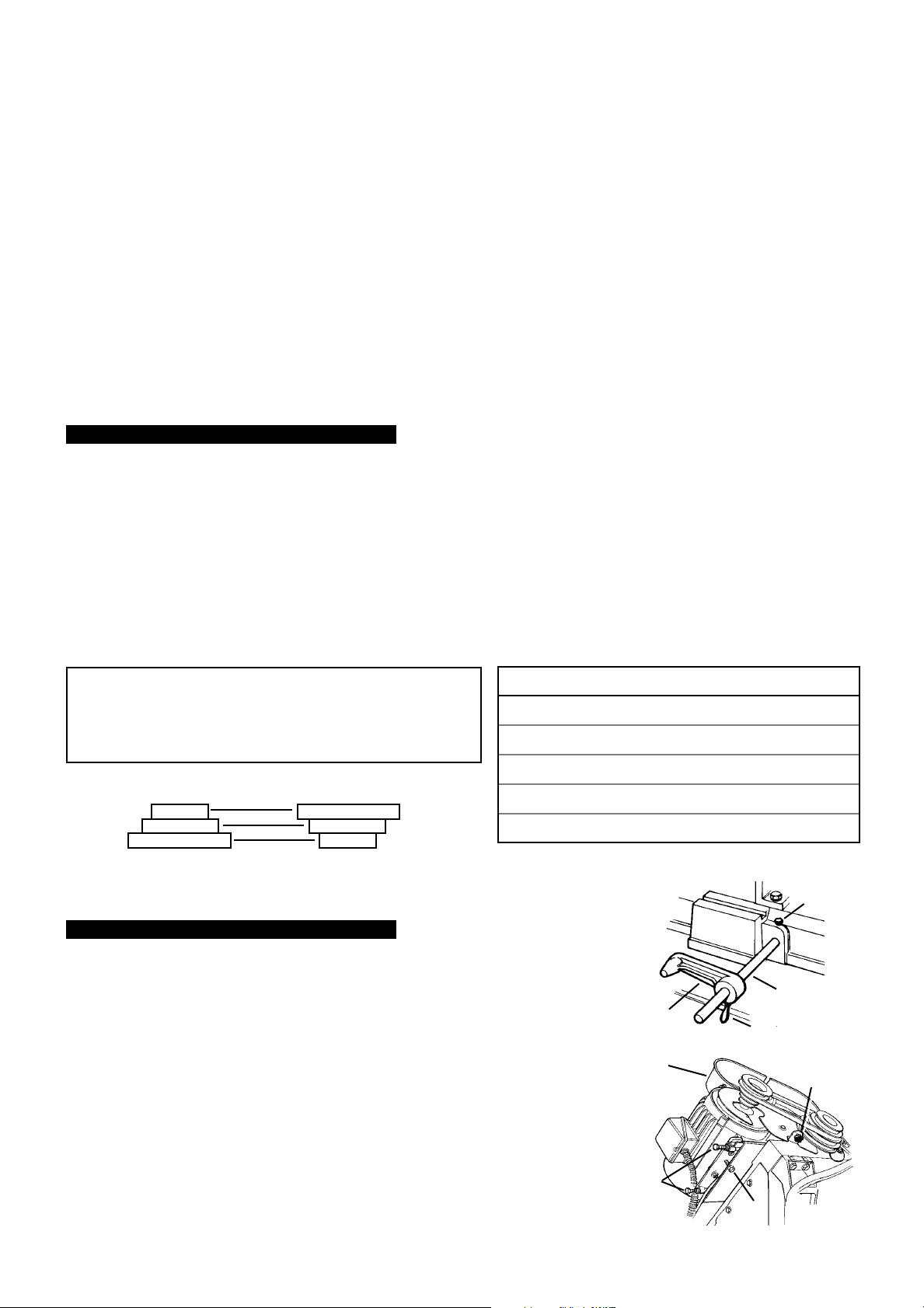

3.2.4. Insert the stop rod (fig.1.A) into the cutting base and tighten screw (B).

3.2.5. Locate the material stop (C) onto stop rod and secure it by tightening the thumb screw (D).

3.2.6. Attach the pulley cover (fig.2.1) with the screws and washers provided. Close when attached

and secure with thumb screw (fig.2.2).

3.2.7. Remove the transportation strap and save for later use should the saw need to be moved see label on bottom left of blade arm. Adjust arm stop so that toothed edge of blade is just

below level of table. Adjust cut-off switch actuation screw

, to the right of arm stop, so that

motor is cut-off at this point but switch is not supporting weight of blade arm.

Caution: Make

Small (A) Large (D) 22 m/min

Medium (B) Large (D) 34m/min

Medium (B) Medium (E) 45m/min

B

A

C

D

fig. 1

1

2

B

A

fig. 2

SM35CE - 0016 - (4) - 140301

Loading...

Loading...