Sealey SM1304.V2 Instructions Manual

INSTRUCTIONS FOR

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

PROFESSIONAL BANDSAW 10”

MODEL NO: SM1304.V2

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these

instructions, and properly maintained, give you years of trouble free performance.

Refer to

instructions

Wear eye

protection

Wear protective

gloves

Wear safety

footwear

Wear protective

clothing

Wear ear

protection

Wear a

mask

1. SAFETY

1.1. Electrical Safety

WARNING! It is the user’s responsibility to check the following:

Check all electrical equipment and appliances to ensure that they are safe before using. Inspect power supply leads, plugs and

all electrical connections for wear and damage. Sealey recommend that an RCD (Residual Current Device) is used with all

electrical products. You may obtain an RCD by contacting your local Sealey dealer. If used in the course of business duties, it must

be maintained in a safe condition and routinely PAT (Portable Appliance Test) tested.

Electrical safety information, it is important that the following information is read and understood.

9 Ensure that the insulation on all cables and on the appliance is safe before connecting it to the power supply.

9 regularly inspect power supply cables and plugs for wear or damage and check all connections to ensure that they are secure.

9 Ensure that the voltage rating on the appliance suits the power supply to be used and that the plug is tted with the correct fuse

- see fuse rating in these instructions.

8 DO NOT pull or carry the appliance by the power cable.

8 DO NOT pull the plug from the socket by the cable.

8 DO NOT use worn or damaged cables, plugs or connectors. Ensure that any faulty item is repaired or

replaced immediately by a qualied electrician.

9 This product is tted with a BS1363/A 13 Amp 3 pin plug.

If the cable or plug is damaged during use, switch the electricity supply and remove from use.

Ensure that repairs are carried out by a qualied electrician.

Replace a damaged plug with a BS1363/A 13 Amp 3 pin plug. If in doubt contact a qualied electrician.

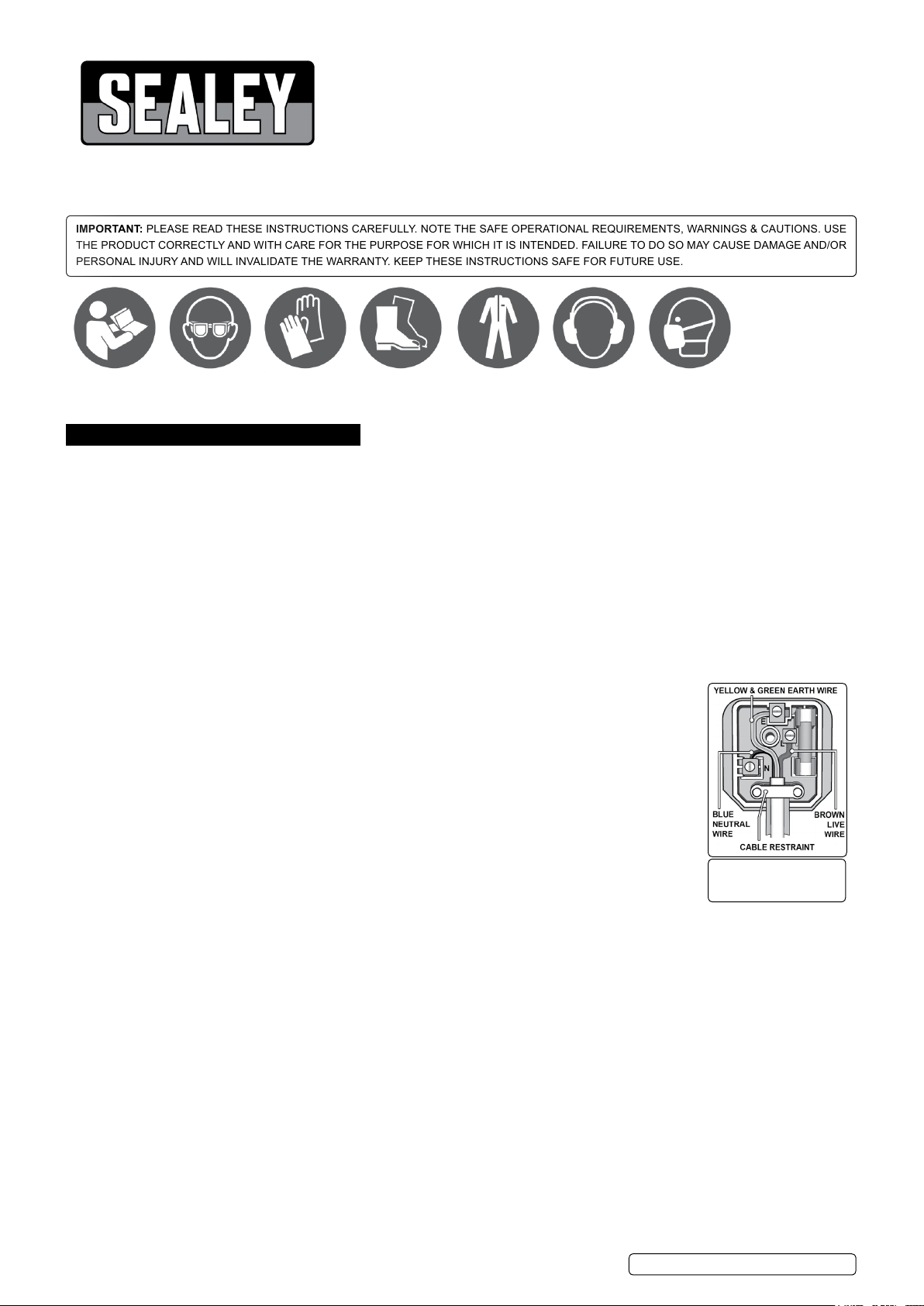

a) Connect the GREEN/YELLOW earth wire to the earth terminal ‘E’.

b) Connect the BROWN live wire to the live terminal ‘L’.

c) Connect the BLUE neutral wire to the neutral terminal ‘N’.

Ensure that the cable outer sheath extends inside the cable restraint and that the restraint is tight.

Sealey recommend that repairs are carried out by a qualied electrician.

1.2. General Safety

WARNING! Disconnect the saw from the mains power before changing saw blades and accessories,

servicing or performing maintenance.

9 Mount the saw to a secure surface such as a workbench.

9 Keep area clean and tidy and free from unrelated materials and ensure there is adequate lighting.

9 Maintain the saw in good condition (use authorised service agent only).

9 Replace or repair damaged parts. Use recommended parts only. Unauthorised parts may be dangerous and will invalidate the

warranty.

9 Keep the machine clean and the blade sharp for best and safest performance. Check moving parts alignment regularly.

9 Before each use check saw blade condition. If worn or damaged replace immediately.

9 Place the blade guide to within 3mm of the material being cut.

WARNING! Keep all safety guards and holding screws in place, tight and in good working order. Check regularly for damaged parts.

A guard or any other part that is damaged should be repaired or replaced before the saw is next used. The safety guard is a

mandatory fitting.

9 Remove adjusting keys and wrenches from the saw before turning it on.

9 Wear approved safety eye protection, ear defenders, safety gloves and, if dust is generated, respiratory protection.

9 Remove ill fitting clothing. Remove ties, watches, rings, and other loose jewellery, and contain long hair.

9 Maintain correct balance and footing. Ensure the floor is not slippery and wear non-slip shoes.

9 Keep children and unauthorised persons away from the working area.

9 Secure unstable work piece with a clamp, vice or other adequate holding device.

9 Avoid unintentional starting.

9 Keep hands and fingers at a safe distance from the saw blade, especially at the end of a cut. Guide the work with a piece of

wood or push rod rather than your fingers when cutting small pieces.

9 Disconnect the saw from the power supply before removing wood chips or dust.

9 Use a workpiece support when sawing material which extends beyond the saw table.

8 DO NOT operate the machine if damaged.

© Jack Sealey Limited

Original Language Version

SM1304.V2 | Issue 1 20/09/16

Recommended fuse rating

5 Amp

8 DO NOT operate the machine if any parts are missing as this may cause failure and/or personal injury.

8 DO NOT use saw blades which are damaged or deformed. Use only Sealey blades and spare parts. Non-standard blades can be

dangerous.

8 DO NOT get the saw wet or use in damp or wet locations or areas where there is condensation.

8 DO NOT expose the saw housing to flame or high temperature.

8 DO NOT allow untrained persons to operate the saw.

8 DO NOT use saw where there are flammable liquids, solids or gases such as paint solvents and including waste wipers or cleaning rags etc

8 DO NOT leave the saw operating unattended.

8 DO NOT operate the saw if either of the blade covers is open or if the blade guard is not fitted.

8 DO NOT operate the saw when you are tired or under the influence of alcohol, drugs or intoxicating medication.

8 DO NOT use the saw for a task it is not designed to perform.

9 When not in use switch off the saw and unplug from the mains power.

2. INTRODUCTION

Steel chassis with locking blade wheel covers. Smooth operation by bearing mounted blade wheels and belt drive induction motors. Micro

switches prevent operation when either blade wheel cover is open. No-volt release switches prevent uncontrolled blade re-start after power

interuption. Suitable for cutting wood and plastics. Fitted with tilting table for cutting compound mitres. Supplied with metal stand. Fully

adjustable blade tracking and tensioning for precise cutting action. Features quick adjusting rip fence, mitre guage, dust extraction port, blade

wheel brushes and push sticks

3. SPECIFICATION

Model No ...................................................................SM1304

Throat Depth .............................................................. 245mm

Maximum Cutting Height ............................................ 100mm

Table Size ...........................................................340x335mm

Table tilt ......................................................................... 0-45°

Blade Length ............................................................ 1712mm

Blade Speed ................................................. 400/730mtr/min

Motor Power ..................................................................370W

Supply ............................................................................230V

Dust Extraction Ø ......................................................... 40mm

A Blade tension adjustment knob

B Blade cover screw

C Blade guard height adjuster

D Blade guard

E Fence

F No Volt On/Off switch

G Fence lock handle

H Table side guide

I Mitre guide

J Saw Blade

K Extraction outlet

L Tracking adjustment knob

M Worktable

4. ASSEMBLE

Unpack the product and check contents for damage. Should there be any

damaged or missing parts contact your supplier immediately.

4.1. Saw Assembly

An assistant may be required to help.

4.1.1. To install the worktable:

SM1304: Carefully place worktable (fig.1.M) onto its supporting base, whilst

sliding saw blade through the slot in the table. Fix to base with four bolts and

washers supplied. Before finally tightening these, check that the table blade slot

and sawblade are in line, set correctly and then tighten all bolts.

Using a square backed up to the saw blade, check that the worktable is square

to the saw blade, if any adjustment is needed slacken the four bolts holding the

supporting bracket to the main frame of the saw.

Set table to correct angle, tighten all fixings. Attach the table side guide (fig.1.H)

to worktable using four bolts and washers.

4.1.2. Fit the fence (fig.1E) by sliding onto the worktable from either the front or the back

as required. Push down handle (fig.1G) to lock when fence is in required

position.

4.1.3. Important! The saw must be placed on a firm, stable work surface capable of

supporting the saw and any workpiece.

Using four pre-drilled holes in base, fix to the work surface with appropriate fixings.

8 DO NOT attempt to use the saw if it is not on a stable surface as it may topple over

during use and cause damage and/or personal injury.

4.1.4. Connect extraction port (Ø60mm) (fig.2a k) to dust extractor system (if available).

g.1

g.2

© Jack Sealey Limited

Original Language Version

g.2a

SM1304.V2 | Issue 1 20/09/16

Loading...

Loading...