Sealey SA93,SA94 Instructions Manual

INSTRUCTIONS FOR:

RETRACTABLE AIR HOSE REEL

15MTR/20MTR

MODEL NO'S: SA93/SA94

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these

instructions, and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE THE

PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY

Refer to

instruction manual

Familiarise yourself with the application and limitations of the air hose reel, as well as the specific hazards.

WARNING!Disconnect the air hose reel from the air supply before servicing or performing any maintenance.

Maintain the air hose reel in good condition (use an authorised service agent).

Replace or repair damaged parts. Use recommended parts only. Unauthorised parts may be dangerous and will invalidate the

warranty.

Locate and fix the air hose reel in a suitable working area, ensure that the correct fixings are used to secure the unit to the wall.

DO NOT position the hose in direct sun light, or in areas of extreme heat or cold.

DO NOT mount inside spray booth/oven.

Ensure that there is adequate lighting.

WARNING! Ensure maximum air pressure is not exceeded.

WARNING! DO NOT over extend the hose as this will cause the mechanism to malfunction, preventing the hose from retracting.

Keep extended air hose away from heat, oil and sharp edges.

Check hose for wear before each use and ensure all connections are secure.

Keep the unwound air hose away from wet, damp, oily surfaces.

WARNING! Always wear approved eye protection when operating the air hose reel.

Maintain correct balance and footing. Ensure the floor is not slippery and wear non-slip shoes.

Remove ill fitting clothing. Remove ties, watches, rings, other loose jewellery and contain and/or tie back long hair.

Keep children and unauthorised persons away from the working area.

DO NOT operate the air hose reel if any parts are damaged or missing as this may cause failure and/or personal injury.

DO NOT use the air hose reel for any purpose other than that for which it is designed.

DO NOT operate the air hose reel when you are tired or under the influence of alcohol, drugs or intoxicating medication.

DO NOT direct air from the air hose at yourself or others.

When not in use, ensure the air supply is turned off and tools disconnected. Disconnect from the air supply and retract the hose into

case.

WARNING! DO NOT dismantle the hose reel casing. To do so may result in damage to the appliance and/or personal injury and will

invalidate the warranty. Internal maintenance, which will require the opening of the casing, must only be undertaken by an authorised

service agent.

Wear eye

protection

2. INTRODUCTION

Tough, durable design suitable for the professional workshops. Features a solid brass internal spindle for added strength and durability. Auto

rewind mechanism with self layering system provides tangle free operation. Positive latching at every full revolution of inner drum for hose length

control. Fitted with reinforced PVC braided hose. Supplied with heavy-duty swivel mounted wall bracket and 2mtr inlet hose.

3. SPECIFICATION

Model No: ..................SA93 .................... SA94

Hose Length: ................20mtr .................... 15mtr

Hose Size (ID/OD):.........10/16mm .............. 12.5/18.5mm

Maximum Pressure: ..........300psi ....................300psi

Hose Type: ...Reinforced Braded PVC ..... Reinforced Braided PVC

Inlet/Outlet: ...............3/8"BSPT .................1/2"BSPT

© Jack Sealey Limited

Original Language Version

SA93, SA94 Issue: 1 - 22/10/14

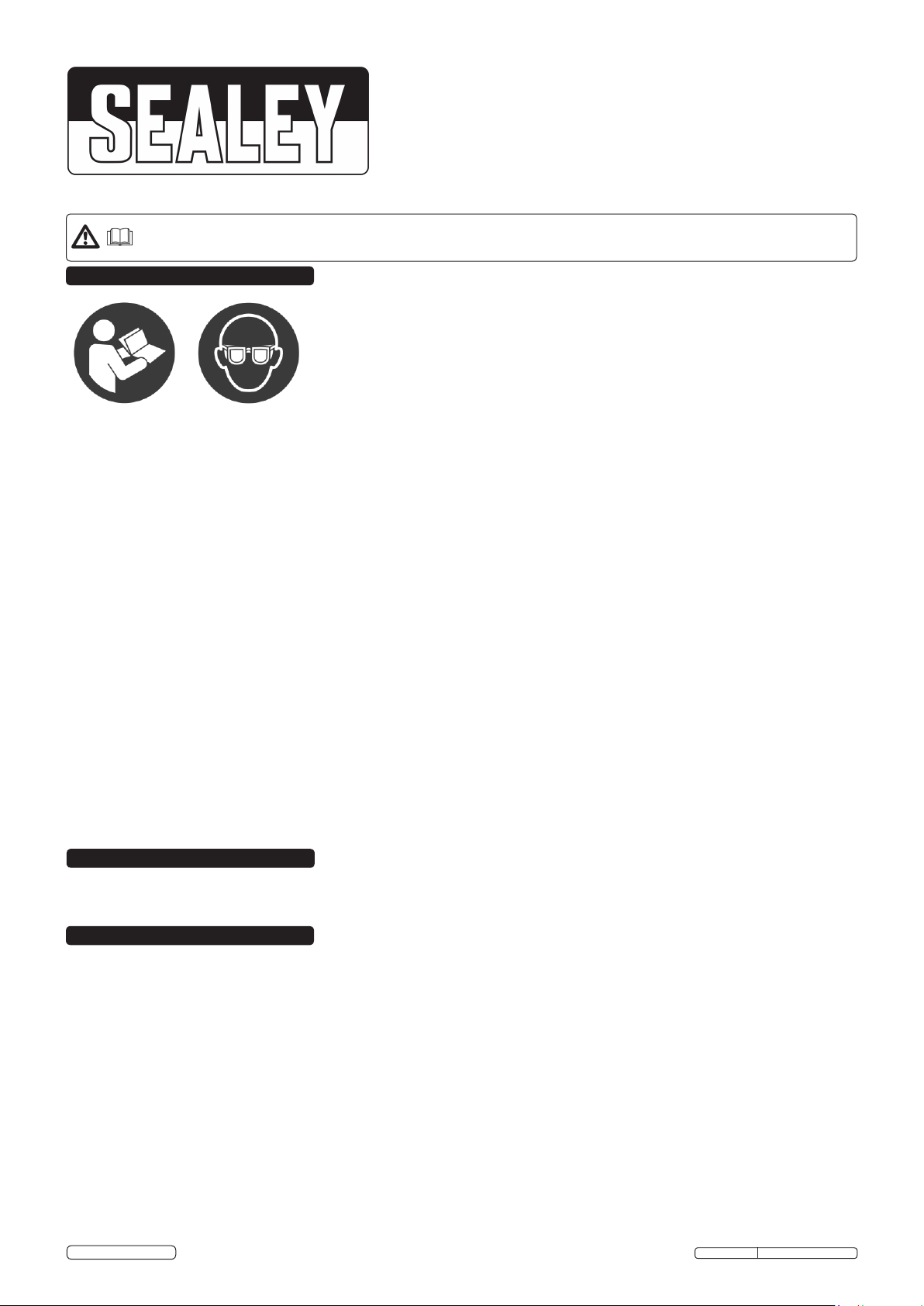

4. MOUNTING

4.1. The mounting bracket MUST be installed on a flat surface. It is

recommended that the mounting bracket is installed a minimum of 0.8

metres above the floor level.

4.2. This reel can be mounted in a vertical or horizontal position. If mounting

the reel over 1.8 metres it is advised that the reel is mounted vertically.

4.3. If mounting vertically, ensure there is adequate clearance underneath to

prevent injury or damage.

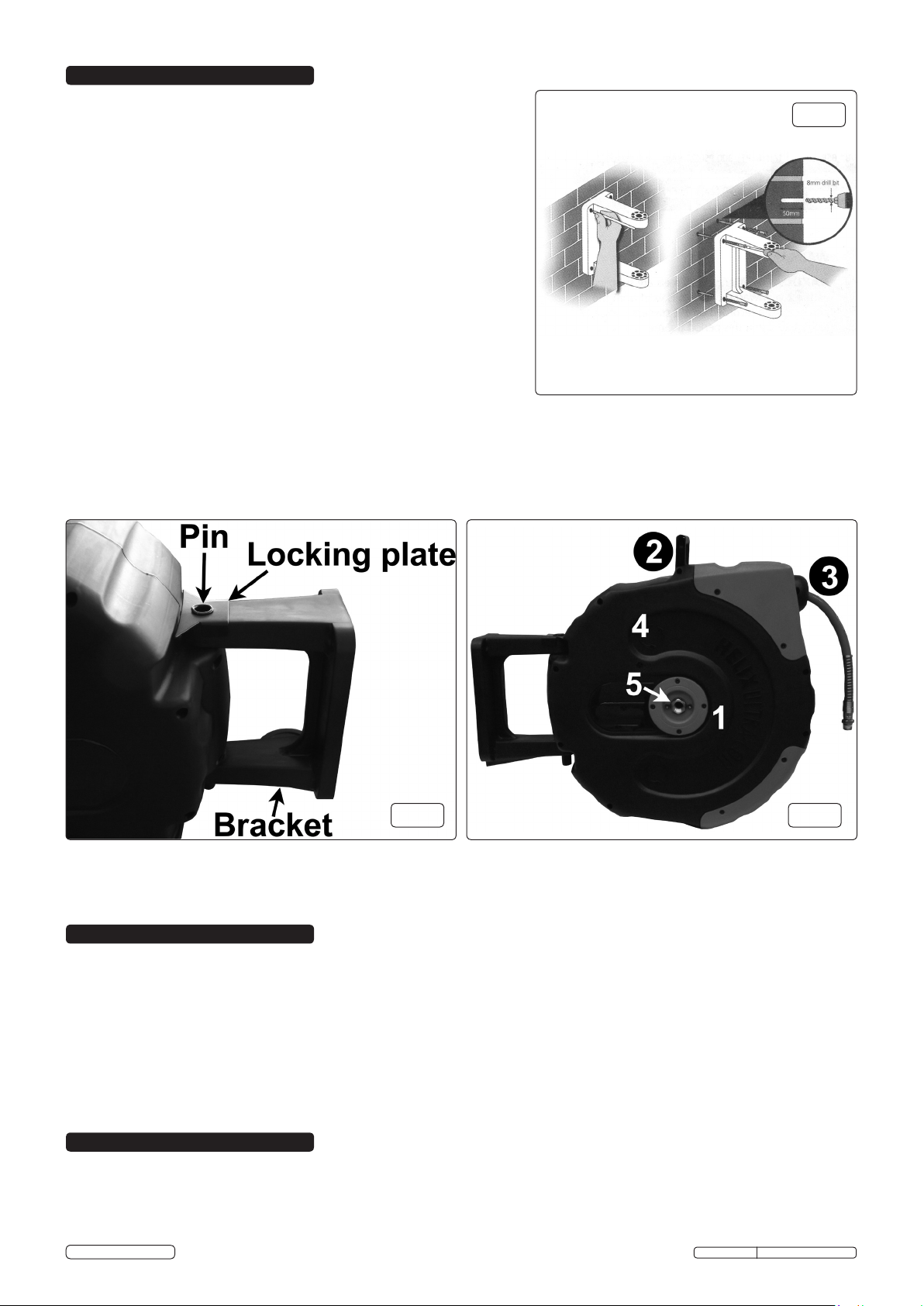

4.4. The reel should be able to swing through 180° unless the locking plate

has been installed, see fig.2.

4.5. Mounting the Bracket (Refer to fig.1)

4.5.1. Choose a location that is close to the compressed air source. For large

areas place the reel in the centre of the work space.

4.5.2. Measure the position of the bracket 0.8 metres from the floor (minimum)

and mark the bracket position through the screw holes, onto the wall.

4.5.3. Using a spirit level lined up with the top two markings, make sure the

bracket will be level.

4.5.4. Drill four holes to match the holes located on the mounting bracket. Holes

need to be 8mm wide and 50mm deep.

4.5.5. Insert the wall plugs and screw the bracket into place. You must use wall

plugs and screws appropriate to the installation surface.

4.6. Fitting the Connecting Hose (Refer to fig.3)

4.6.1. Lay the reel on a soft surface with the inlet side facing up.

4.6.2. Attach the 90° brass elbow to the reel inlet and brass swivel female to the supply, see fig.3.5.

4.7. Installing the Reel

4.7.1. Lift the reel onto the bracket and line up the holes in the bracket with those on the reel.

4.7.2. Push the pivot pin through the top hole and down through the bottom hole in the bracket, which will secure the reel in place and allow

it to move through 180°.

NOTE: If the reel is required to be static, place the locking plate onto the mounting bracket prior to inserting the pin, see fig.2.

g.1

g.2 g.3

1 - Solid brass internal spindle

2 - Carry handle

3 - Hose with adjustable stopper

4 - Fully enclosed case

5 - Inlet connector

5. OPERATION

WARNING! DO NOT attempt to open the inner drum assembly.

WARNING! DO NOT let go of the hose while rewinding. Always walk the hose back to the reel holding the hose.

WARNING! DO NOT place fingers or objects in the hose case at any time.

WARNING! DO NOT attempt to fix the product if damaged, return to Sealey service agent.

WARNING! If the hose becomes tangled and will not retract, slowly pull out the hose past the tangled section and then allow the hose

to slowly retract while guiding the hose back into the hose reel. Always ensure the hose is clean and not twisted.

5.1. Slowly pull out the hose to the required length. A clicking noise will be heard every revolution of the inner drum. To lock the reel, allow

the hose to retract slowly after hearing the second or third click.

5.2. To release the hose, pull out the hose until the clicking noise stops, then allow the hose to slowly retract while guiding the hose back

into the hose reel. The self-layering mechanism will coil the hose back onto the inner drum.

5.3. To avoid injury and damage always hold the hose while it is retracting.

5.4. Always retract the hose when not in use.

6. MAINTENANCE

6.1. Always keep the hose clean.

6.2. If the hose becomes dirty, clean it with a damp cloth whilst retracting the hose.

6.3. DO NOT twist the hose whilst in use.

6.4. DO NOT allow the hose to contact any corrosive chemicals or fluids.

© Jack Sealey Limited

Original Language Version

SA93, SA94 Issue: 1 - 22/10/14

Loading...

Loading...