INSTRUCTIONS FOR:

AIR STAPLE GUN 13-32MM CAPACITY

MODEL NO: SA789.V2

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these

instructions, and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE THE PRODUCT

CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR PERSONAL INJURY AND WILL

INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY

Refer to

instruction

manual

WARNING! DO NOT use the nail gun if damaged, has missing parts or is thought to be faulty. Contact your Service Agent.

WARNING! Never engage in horseplay with the tool.

WARNING! Always wear approved eye, face and hand protection when operating the nail gun. Wear a full face shield if stapling produces

metal filings or wood chips.

WARNING! Check correct air pressure is maintained and not exceeded. We recommend 60 to 100psi.

WARNING! Keep hands, face, feet and all parts of the body away from the firing head at all times.

DO NOT use the nail gun for a task it is not designed to perform.

DO NOT operate the nail gun near flammable substances or flammable containers.

DO NOT use the nail gun unless you have been instructed in its use by a qualified person.

DO NOT carry the nail gun by the air hose, or pull the hose from the air supply.

DO NOT operate the nail gun if you are tired or under the influence of alcohol, drugs or intoxicating medication.

DO NOT carry the nail gun with your hand on the power trigger in order to avoid unintentional firing.

DO NOT direct the nail gun or the air from the air hose at yourself or others.

DO NOT load bent or damaged staples into the magazine.

DO NOT overreach. Keep proper footing and balance at all times. Ensure the floor is not slippery and wear non-slip shoes.

DO NOT drive staples into thin boards or near the corners of the workpiece.

▲ DANGER!When putting the nail gun down, ensure that the trigger safety slide is not fouled, risking accidental firing.

Avoid unintentional firing. Keep fingers away from the trigger when not driving staples. Disconnect from the air supply especially

when loading staples,when carrying the tool, handing the tool to another person, leaving the work area, making adjustments to the tool,

clearing a jam or whenever it is left unattended.

Check the safety mechanism before use. Never use the stapler unless the safety is operating properly, otherwise the stapler could

drive a staple unexpectedly.

Place the tool properly on the workpiece. DO NOT drive staples one on top of another or with the tool at too steep an angle. The

staples could ricochet.

Keep the work area clean and well lit.

Keep people away from the work area.

Maintain the nail gun in good condition and replace any damaged or worn parts. Use genuine parts only. Unauthorised parts may

be dangerous and will invalidate the warranty.

Keep the air hose away from heat, oil and sharp edges. Check the air hose for wear before each use and ensure that all

connections are secure.

Follow all workshop safety rules, regulations, and conditions when using the nail gun.

Keep children and non essential persons away from the working area.

When not in use, disconnect from the air supply, remove the staples from the magazine and store cased in a safe, dry, childproof

location.

WARNING! The warnings, cautions and instructions in this manual cannot cover all possible conditions and situations that

may occur. It must be understood by the operator that common sense and caution are factors which cannot be built into

this product, but must be applied by the operator.

Wear ear

protection

Wear eye

protection

Wear

protective

gloves

2. INTRODUCTION

Professional air stapler with lightweight aluminium body and rubber grip handle. Safety trigger device to prevent accidental firing of staples.

Supplied in carry-case with oiler and starter pack of staples.

3. SPECIFICATION

Model No: .................SA789.V2

Staple Capacity:. ......13-32mm 18SWG

Maximum Pressure:.. ............100psi

Air Inlet Size:................. 1/4"BSP

Gun Weight: . . . . . . . . . . . . . . . . . . .1.05kg

Noise Power: .................95dB(A)

Noise Pressure: ...............82dB(A)

Vibration: ...................3.05m/s²

Uncertainty: ................1.525m/s²

© Jack Sealey Limited

Original Language Version

SA789.V2 Issue: 1 - 27/02/15

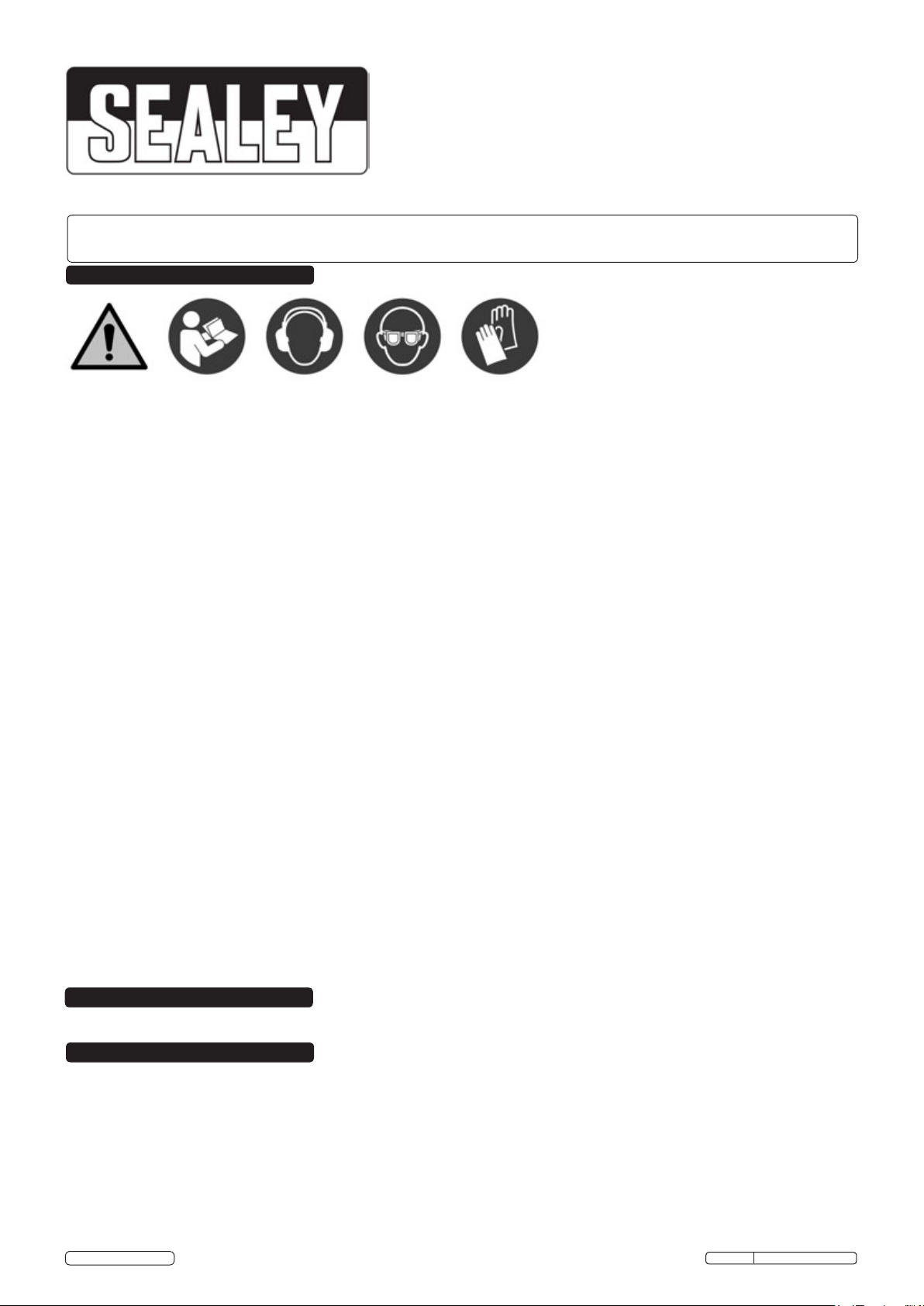

g.1

4. PREPARATION

WARNING! Ensure the air supply is clean, dry and between 60 - 100psi while operating the nail gun. Too high an air pressure and/or

unclean air will shorten the product life due to excessive wear, and may be dangerous causing damage and/or personal injury.

4.1. AIR SUPPLY (From a compressor not a gas bottle)

4.1.1 Ensure the nail gun trigger release slide is not depressed when connecting to the air supply.

4.1.2 You will require an air pressure of between 60 - 100psi, and an air flow according to specification.

4.1.3 Drain your compressor air tank of water daily. Water in the air line will damage the nail gun.

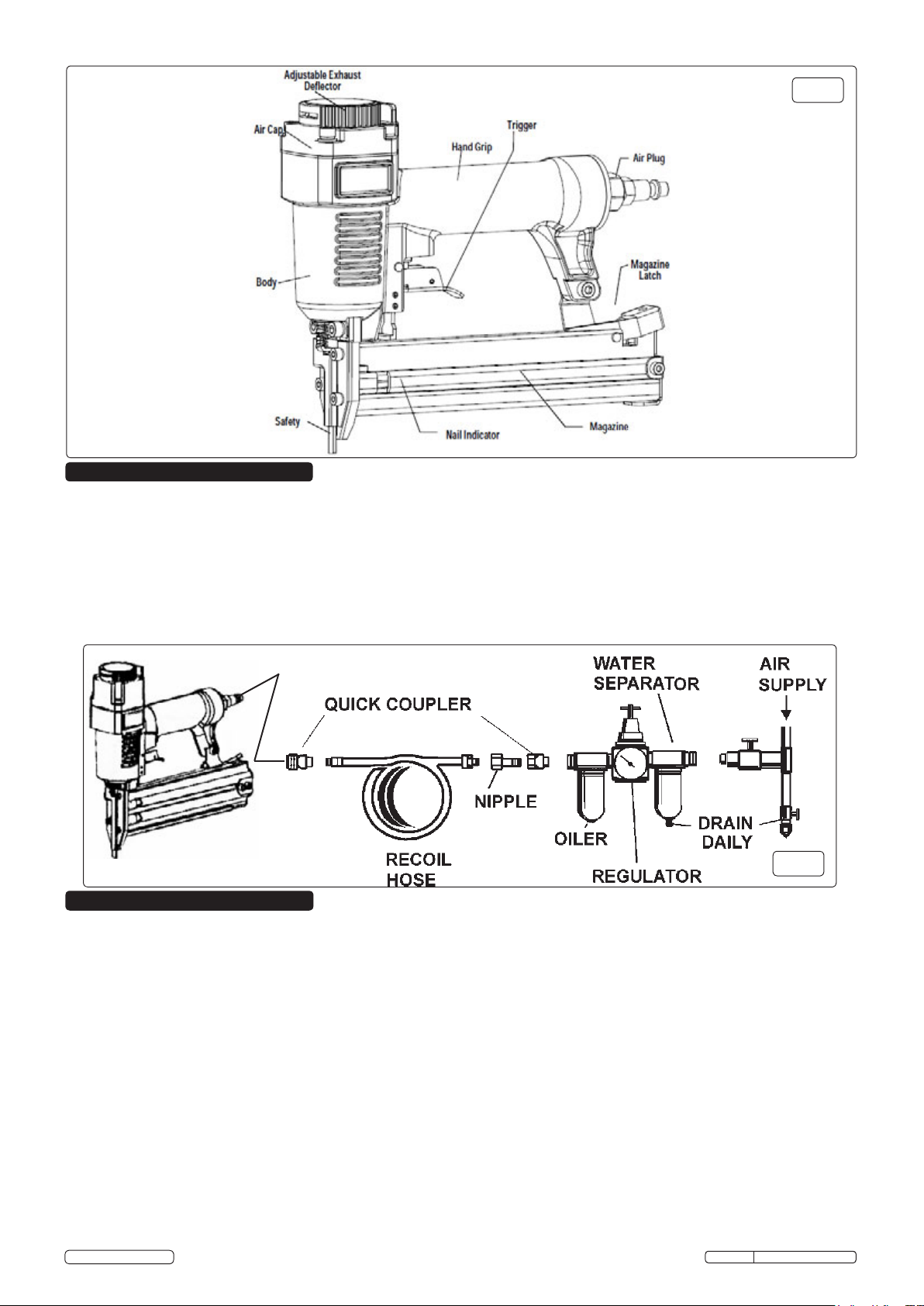

4.1.4 Clean the compressor air inlet filter weekly. Recommended hook-up procedure is shown in fig.2.

4.1.5 Line pressure should be increased to compensate for unusually long air hoses (over 8 metres). The minimum hose diameter should be

1/4” I.D. and fittings must have the same inside dimensions.

4.1.6 Keep the hose away from heat, oil and sharp edges. Check hose for wear, and make certain that all connections are secure.

g.2

5. OPERATION

WARNING! Never use non relieving couplers and/or female quick disconnect couplings on the tool. Non relieving couplings

and female couplings will trap high pressure air in the tool when the air line is disconnected. This will leave the tool charged with

enoughairafterithasbeendisconnectedtodriveastaple.OnlyMALEpneumatictypeairconnectorsshouldbettedtothetool,so

that high pressure air in the tool is vented to atmosphere as soon as the air line is disconnected.

5.1. Adjusting air pressure

5.1.1. Set the regulator at the air delivery system to a PSI that falls within the tool's operating range of 60-100PSI.

5.1.2. The correct pressure is the lowest pressure that will do the job.This depends on the length of the nails and the hardness of the wood.

5.2. Connecting air supply

5.2.1. Snap the air hose onto the quick connector. Check for air leakage. If leakage is noted, stop using the tool immediately and seek repair

5.2.2. Be sure the air pressure gauge is operating properly and check it at least twice a day.

© Jack Sealey Limited

byqualiedpersonnel.

Original Language Version

SA789.V2 Issue: 1 - 27/02/15

Loading...

Loading...