Sealey SA633,SA632 Instruction Manual

Thank you for purchasing a Sealey Product. Manufactured to a high standard this product will, if used according to these

instructions and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL

REQUIREMENTS, WARNINGS AND CAUTIONS. USE THIS PRODUCT CORRECTLY AND WITH CARE FOR THE

PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR PERSONAL

INJURY AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY INSTRUCTIONS

Follow all workshop safety rules, regulations, and conditions when using wrench.

WARNING!Disconnect from air supply before changing accessories or servicing.

Maintain the wrench in good condition and replace any damaged or worn parts. Use

genuine parts only. Un-authorised parts may be dangerous and will invalidate the warranty.

WARNING! Check correct air pressure is maintained and not exceeded. We recommend 90psi.

Keep air hose away from heat, oil and sharp edges. Check air hose for wear before each

use and ensure that all connections are secure.

Wear approved safety eye/face shield, ear defenders and hand protection.

Maintain correct balance and footing. Ensure the floor is not slippery and wear non-slip shoes.

Keep children and non essential persons away from the working area.

DO NOT use the wrench for a task it is not designed to perform.

WARNING! DO NOT use wrench if damaged or thought to be faulty. Contact Service Agent.

DO NOT use wrench unless you have been instructed in its use by a qualified person.

DO NOT carry the wrench by the air hose, or yank the hose from the air supply.

DO NOT operate wrench if you are tired or under the influence of alcohol, drugs or intoxicating

medication.

DO NOT carry wrench with your hand on power trigger, in order to avoid unintentional starting.

DO NOT direct air from the air hose at yourself or others.

When not in use disconnect from air supply and store in a safe, dry, childproof location.

INSTRUCTION MANUAL:

SUPER STUBBY AIR RATCHET WRENCHES

MODEL No:

SA632 & SA633

2. INTRODUCTION & SPECIFICATIONS

Ultra-compact air ratchet wrenches fit in the palm of the hand. Perfect for working around

tightly-packed engine compartments. Ratchet yoke designed and manufactured to provide

additional strength. Rear exhaust with baffle to reduce noise.

IMPORTANT WARRANTY INFORMATION

This product is covered by a 1 year parts and labour warranty, except for the ratchet head. This does not

affect your statutory rights. DO NOT operate with external leverage, hence exceeding rated torque.

DO NOT drop the tool after task completion, always place down to prevent ratchet head damage.

MODEL: ....................SA632 ...............SA633

Drive Size: ................. 1/4”Sq ............... 3/8”Sq

Max Torque: ..........33.9Nm(25lb.ft) ........ 33.9Nm(25lb.ft)

Air Consumption: ............ 2.4cfm ............... 2.4cfm

Operating Pressure: ............90psi ................ 90psi

Air Inlet Size: .............. 1/4”BSP ..............1/4”BSP

Noise Power: ...........101.49dB(A) ...........101.49dB(A)

Noise Pressure: ..........91.33dB(A) ............91.33dB(A)

Weight: ......................0.5kg ................ 0.5kg

Original Language Version

© Jack Sealey Limited 2013

SA632, SA633 Issue: 3 (SP) - 29/08/13

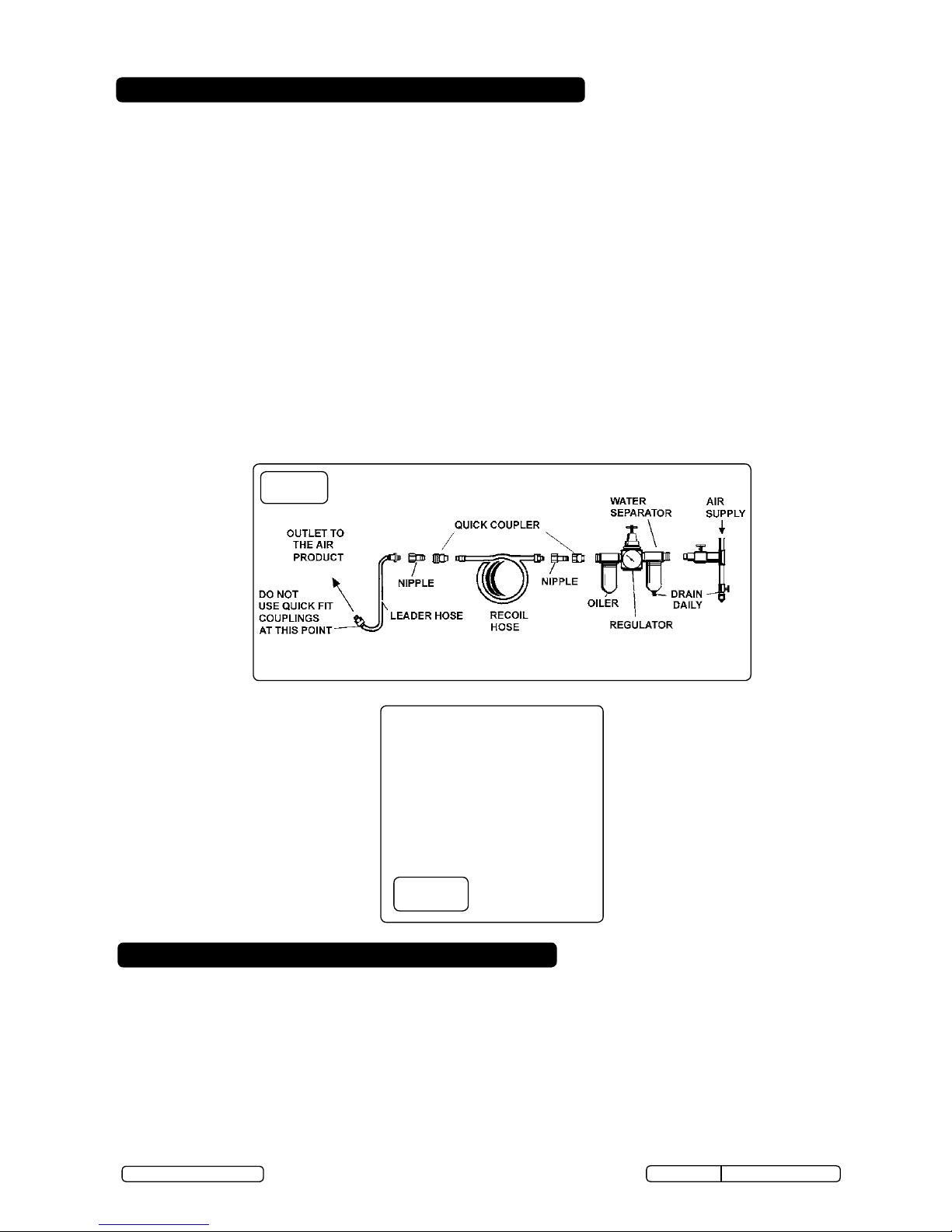

3.1. Air Supply. (Recommended hook-up procedure is shown in fig 1.)

3.1.1. Ensure wrench air valve (or trigger) is in the "off" position before connecting to the air supply.

3.1.2. You will require an air pressure of 90psi, and an air flow according to specification.

3.1.3. WARNING! Ensure the air supply is clean and does not exceed 90 psi while operating

the wrench. Too high an air pressure and or/unclean air will shorten the product life due to

excessive wear, and may be dangerous causing damage and/or personal injury.

3.1.4. Drain the

compressor air tank daily. Water in the air line will damage the wrench.

3.1.5. Clean compressor air inlet filter weekly.

3.1.6. Line pressure should be increased to compensate for unusually long air hoses (over 8

metres). The minimum hose diameter should be 1/4” I.D. and fittings must have the same

inside dimensions.

3.1.7. Keep hose away from heat, oil and sharp edges. Check hose for wear, and make certain

that all connections are secure.

3.2. Couplings.

Vibration may cause failure if a quick change coupling is connected directly to the wrench.

To overcome this, connect a leader hose to the wrench. A quick change coupling may then

be used to connect the leader hose to the air line recoil hose. See fig 1 & 2.

3. PREPARING WRENCH FOR USE

4. OPERATING INSTRUCTIONS

fig 1

WARNING! Ensure you read, understand and apply safety instructions before use.

4.1. Fit the required socket to the wrench.

4.2. Connect the wrench to the air hose as indicated in section 3.

4.4. Place the socket over the subject nut and depress the trigger to operate the wrench.

4.5. To change wrench direction turn the switch on the head of the wrench (see fig.3).

DO NOT use any additional force upon the wrench in order to remove a nut, it is possible to

break the head by using exessive hand force. Use penetrating oil and a spanner to

crack the fixing.

DO NOT

allow wrench to free run for an extended period of time as this will reduce bearing life.

fig 2

Original Language Version

© Jack Sealey Limited 2013

SA632, SA633 Issue: 3 (SP) - 29/08/13

Loading...

Loading...