INSTRUCTIONS FOR:

AIR SHEARS

MODEL No: SA53.V3

Thank you for purchasing a Sealey Product. Manufactured to a high standard this product will, if used according to these instructions

and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS,

WARNINGS AND CAUTIONS. USE THIS PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH

IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR PERSONAL INJURY AND WILL INVALIDATE

THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY INSTRUCTIONS

p WARNING! Ensure health & safety, local authority, and general workshop practice regulations are adhered to

when using this equipment.

p WARNING!Disconnect from air supply before changing accessories or servicing.

3 Maintain the tool in good condition and replace any damaged or worn parts. Use genuine parts only.

Unauthorised parts may be dangerous and will invalidate the warranty.

p WARNING! Check correct air pressure is maintained and not exceeded. We recommend 90psi.

3 Keep air hose away from heat, oil and sharp edges. Check air hose for wear before each use and ensure that

all connections are secure.

3 Wear approved safety eye/face shield, ear defenders, and hand protection.

3 Maintain correct balance and footing. Ensure the floor is not slippery and wear non-slip shoes.

3 Keep children and non essential persons away from the working area.

7 DO NOT use the tool for a task it is not designed to perform.

p WARNING! DO NOT use tool if damaged or thought to be faulty. (Contact Sealey service agent).

7 DO NOT use tool unless you have been instructed in its use by a qualified person.

7 DO NOT carry the tool by the air hose, or yank the hose from the air supply.

7 DO NOT operate tool if you are tired or under the influence of alcohol, drugs or intoxicating medication.

7 DO NOT carry tool with your hand on the power trigger in order to avoid unintentional starting.

7 DO NOT direct air from the air hose at yourself or others.

3 When not in use disconnect from air supply and store in a safe, dry, childproof location.

2. INTRODUCTION & SPECIFICATIONS

Suitable for cutting straight lines in metal sheet. Palm throttle control and alloy head and housing. Blades are

consumable items and are not covered by warranty.

Maximum cutting capacity ........1.2mm(Steel)

Air consumption .......................4cfm

Operating pressure....................90psi

Air inlet size ...................... 1/4” BSP

Weight .............................1.0kg

Noise Power........................85dB.A

Replacement Blade - Right ........SA53.V3-30

Replacement Blade - Left..........SA53.V3-31

Replacement Blade - Centre .......SA53.V3-32

3. PREPARING TOOL FOR USE

3.1. Air Supply

3.1.1. Ensure tool valve (or trigger) is in the "off" position before connecting to the air supply.

3.1.2. You will require an air pressure of 90psi, and an air flow according to specification.

3.1.3. p WARNING! Ensure the air supply is clean and does not exceed 90 psi while operating the tool.

Too high an air pressure and unclean air will shorten the product life due to excessive wear, and may be

dangerous causing damage and/or personal injury.

3.1.4. Drain the air tank daily. Water in the air line will damage the tool.

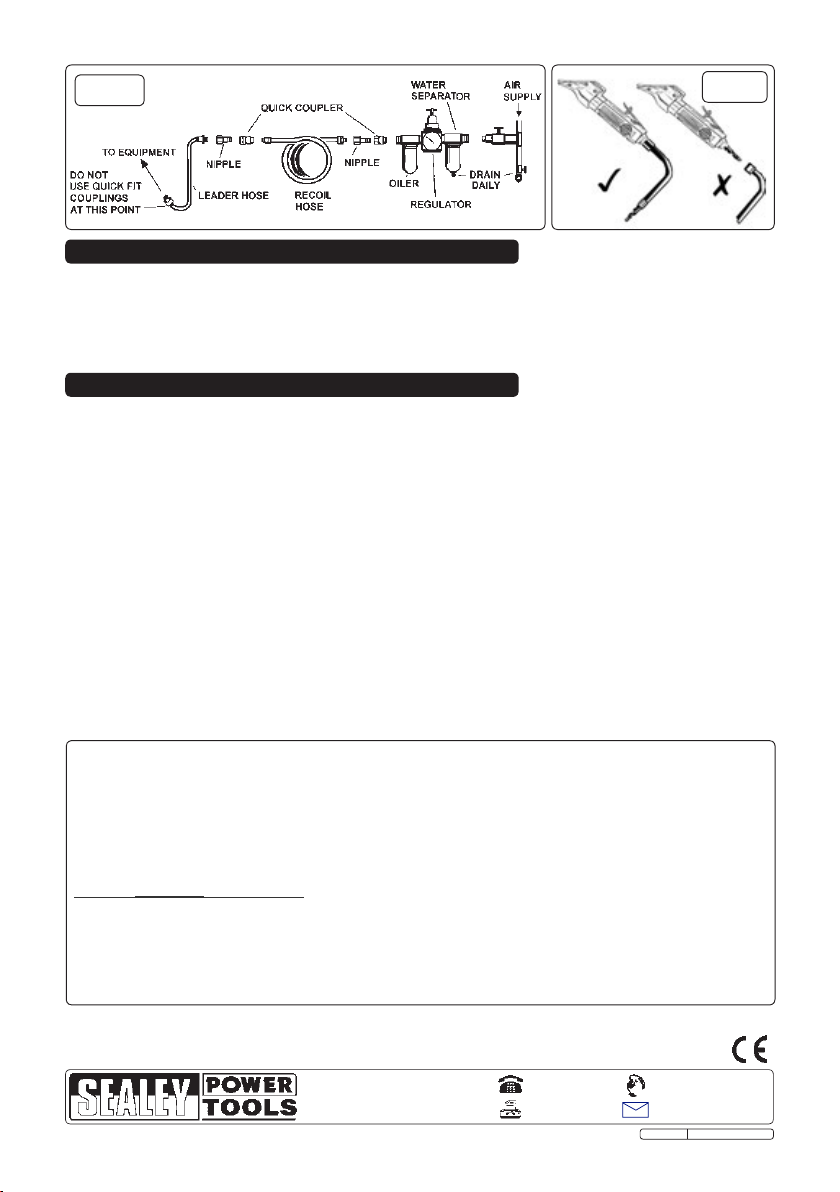

3.1.5. Clean air inlet filter weekly. Recommended hook-up procedure is shown in fig 1.

3.1.6. Line pressure should be increased to compensate for unusually long air hoses (over 8 metres).

The minimum hose diameter should be 1/4” I.D. and fittings must have the same inside dimensions.

3.1.7. Keep hose away from heat, oil and sharp edges. Check hose for wear, and make certain that all

connections are secure.

3.2. Couplings.

Vibration may cause failure if a quick change coupling is connected directly to the tool. To overcome this,

connect a leader hose to the tool. A quick change coupling may then be used to connect the leader hose to the

air line recoil hose. See fig 1 & 2.

Original Language Version

SA53.V3 Issue: 1 -

16/08/11

fig.1

fig.2

4. OPERATING INSTRUCTIONS

p WARNING! Ensure you read, understand and apply safety instructions before use.

4.1. Remove the shears from the package. The tool should be assembled and ready to use.

4.2. Connect the shears to the air hose as in chapter 3.

4.3. To start the shears, depress the throttle lever.

DO NOT allow the shears to free run for an extended period of time as this will shorten their life.

5. MAINTENANCE

p WARNING!Disconnect tool from air supply before changing accessories, servicing or performing

maintenance.Replace or repair damaged parts. Use genuine parts only.

Unauthorised parts may be dangerous and will invalidate the warranty.

Note: Numbers in brackets refer to item numbers in the parts diagram.

5.1. To replace the blades (30, 31 and 32), unscrew the three lock screws (29) and slide the cutter housing

(28) off the motor housing (1). Remove the two lock screws (33 ) that secure the blades (30, 31 and 32)

and remove the blades. Fit new blades, ensuring the spacer (34) is correctly positioned and refit the lock

screws. Slide the cutter housing onto the motor housing and secure using the lock screw. Tighten all

three lock screws.

5.2. Lubricate the tool daily with a few drops of Sealey air tool oil dripped into the air inlet.

5.3. Clean the tool after use.

5.4. Loss of power or erratic action may be due to the following:

a) Excessive drain on the air line. Moisture or restriction in the air pipe. Incorrect size or type of hose

connectors. To remedy check the air supply and follow instructions in chapter 3.

b) Grit or gum deposits in the tool may also reduce performance. Flush the tool out with gum solvent oil

or an equal mixture of SAE No 10 oil and paraffin.

Allow to dry before use.

5.5. For a full service contact your local Sealey service agent.

5.6. When not in use, disconnect from air supply, clean tool and store in a safe, dry, childproof location.

Air Shears Model No. SA53.V3, when operated in accordance with these instructions and tested in accordance

Risk of Hand Arm Vibration Injury.

with BS EN 28662-1:1993, ISO 8662-1:1988 and BS EN ISO 28927-7:2009 results in the following vibration

emission declared in accordance with BS EN12096:1996.

Measured vibration emission value: 2.5m/s² Uncertainty: 1m/s²

These values are suitable for comparison with emission levels of other tools that have been subject to the

same test.

This tool may cause hand-arm vibration syndrome if its use is inadequately managed.

This is a ‘NO LOAD’ vibration figure.

A competent person should carry out a risk assessment following HSE guidelines.

Measurement results can be highly variable, depending on many factors, including the operator's technique,

the condition of the work equipment, the material being processed and the measurement method.

Recommended Measures to reduce risk of hand-arm vibration syndrome:

We recommend appropriate safety equipment is utilised and regular breaks for the operator are employed to

reduce any residual risk of fatigue or repetitive strain injury.

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of this product.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

INFORMATION: For a copy of our latest catalogue and promotions call us on 01284 757525 and leave your full name and address, including postcode.

Sole UK Distributor, Sealey Group,

Kempson Way, Suffolk Business Park,

Bury St. Edmunds, Suffolk,

IP32 7AR

Original Language Version

01284 757500

01284 703534

www.sealey.co.uk

Web

sales@sealey.co.uk

email

SA53.V3 Issue: 1 - 16/08/11

Loading...

Loading...