AIR RIVETER 1/4” STEEL ALUMINIUM, ALLOY

I

MPORTANT:

PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

& STAINLESS STEEL RIVETS

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these instructions,

and properly maintained, give you years of trouble free performance.

Refer to

instruction

manual

Wear eye

protection

Wear ear

protection

Wear protective

gloves

1. SAFETY

WARNING! Ensure health & safety, local authority, and general workshop practice regulations are adhered to when using this

equipment.

9 Familiarise yourself with this products application and limitations, as well as the specific potential hazards peculiar to the riveter.

WARNING! Disconnect the riveter from the air supply before changing accessories, servicing or performing any maintenance.

9 Maintain the riveter in good condition (use an authorised service agent).

9 Replace or repair damaged parts. Use genuine parts only. Unauthorised parts may be dangerous and will invalidate the warranty.

9 Use in a suitable work area. Keep area free from unrelated materials and ensure that there is adequate lighting.

9 Keep the riveter clean for best and safest performance.

WARNING! Always wear approved eye (or face) and hand protection when operating the riveter.

9 Maintain correct balance and footing. DO NOT over reach, ensure the floor is not slippery, wear non slip shoes.

9 Remove ill fitting clothing. Remove ties, watches, rings, and other loose jewellery, and contain and/ or tie back long hair.

9 Wear appropriate protective clothing and keep hands and body clear or working parts.

9 Keep the riveter away from your body and at a safe distance from others.

9 Keep children and unauthorised persons away from the working area.

9 Secure non stable work piece with a clamp, vice or other adequate holding device.

9 Ensure that spent rivet stems are disposed of correctly and DO NOT cause a hazard.

WARNING! Ensure correct air pressure is maintained and not exceeded. Recommended pressure 90psi.

9 Keep air hose away from heat, oil and sharp edges. Check air hose for wear before each use, and ensure that all connections are

secure.

8 DO NOT use the riveter for a task it is not designed to perform.

8 DO NOT operate the riveter if any parts are damaged or missing as this may cause failure and/or personal injury.

9 Ensure the safety cap is correctly fitted.

8 DO NOT carry the by the hose, or yank the hose from the air supply.

8 DO NOT get the riveter wet or use in damp or wet locations or areas where there is condensation.

8 DO NOT allow untrained persons to operate the riveter.

8 DO NOT operate the riveter when you are tired, under the influence of alcohol, drugs or intoxicating medication.

8 DO NOT direct air from the air hose at yourself or others.

9 When not in use disconnect from the air supply and store in a safe, dry, child proof location.

9 Avoid unintentional starting.

MODEL NO: SA314.V4

2. INTRODUCTIONi

Suitable for aluminium, steel and stainless steel up to 3/16”. Supplied with four riveting nozzles and two spanners. Trigger operated riveter with

hardened jaw assembly and rivet shaft safety cap. Will handle heavy assembly work.

3. SPECIFICATION

Model no: .................................................................... SA314

Nozzle sizes:

.............................. 3/32” (2.4mm), 1/8” 3.2mm, 5/32” (4mm),

.................................................. 3/16” (4.8mm), 1/4” (6.4mm)

Air consumption: .......................................................3.46cfm

Operating pressure: ...................................................... 90psi

Air inlet size:..............................................................1/4”BSP

Weight: ..........................................................................1.6kg

Blind rivet type: ....................aluminium, steel, stainless steel

Noise power/pressure: .........................................81/70dB(A)

Vibration: ..................................................................10.9m/s²

Uncertainty: ..............................................................4.36m/s²

© Jack Sealey Limited

Original Language Version

SA314.V4 Issue: 2(H,F) 01/06/18

4. AIR SUPPLY

4.1. AIR SUPPLY

WARNING! Ensure the air supply is clean and does not exceed 90 psi while operating the riveter. Too high an air pressure and

unclean air will cause excessive wear, and may be dangerous, causing damage and/or personal injury.

4.1.1. Ensure the riveter air valve (or trigger) is not depressed before connecting to the air supply.

4.1.2. You will require an air pressure between 70-90psi, and an air flow according to the specification above.

4.1.3. Drain the air tank daily. Water in the air line will damage the riveter and invalidate your warranty.

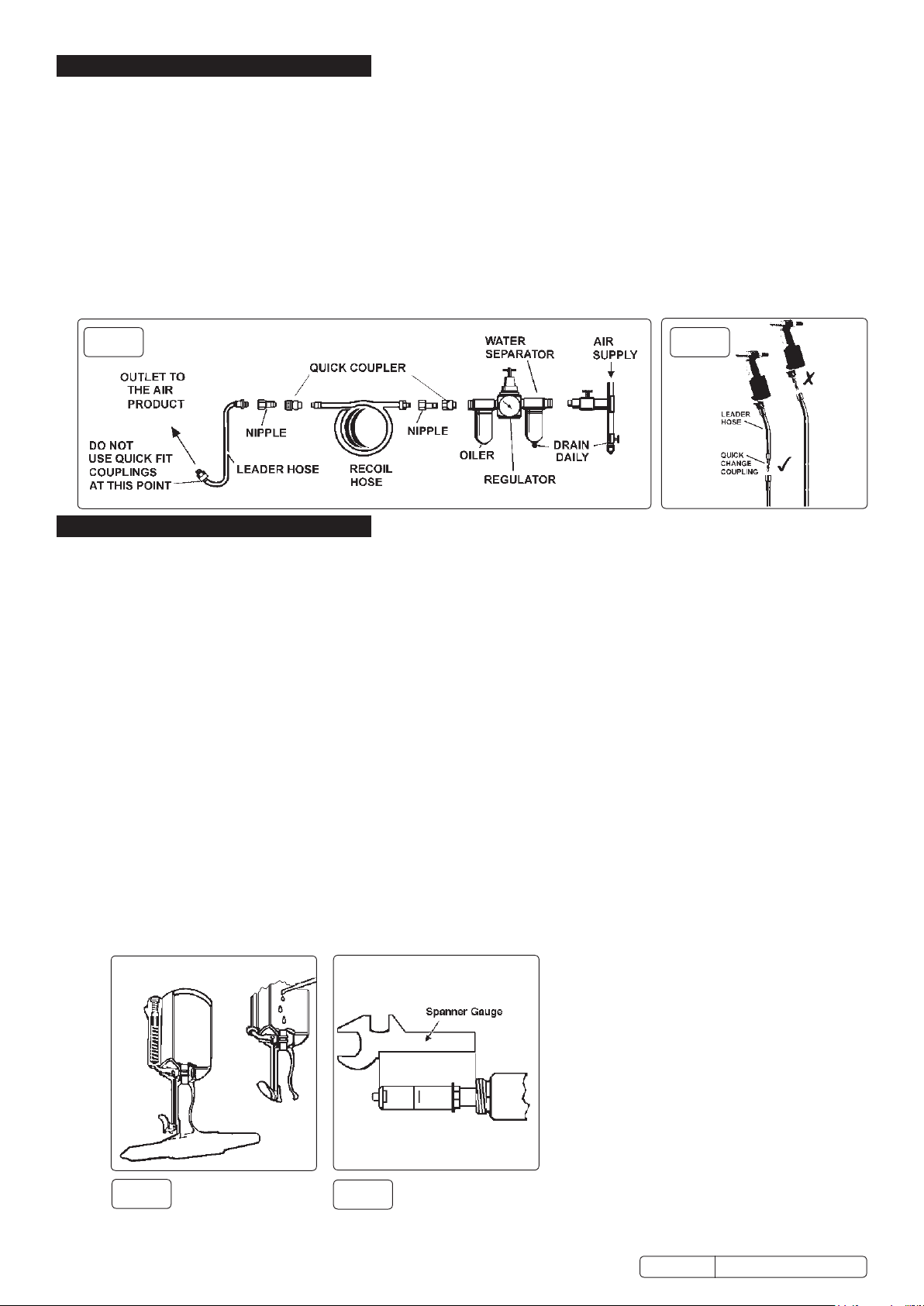

4.1.4. Clean air inlet filter weekly. Recommended hook-up procedure is shown in fig 1.

4.1.5. Line pressure should be increased to compensate for unusually long air hoses (over 8 metres).

4.1.6. The minimum hose diameter should be 1/4” I.D. and fittings must have the same inside dimensions.

4.1.7. Keep hose away from heat, oil and sharp edges. Check hoses for wear, and make certain that all connections are secure.

4.2. COUPLINGS

4.2.1. Vibration may cause failure if a quick change coupling is connected directly to the air drill. To overcome this, connect a leader hose -

Sealey model number AH2R or AH2R/38 - to the riveter. A quick change coupling may then be used to connect the leader hose to the

airlinerecoilhose.Seegs.1&2.

fig.

1

fig.

2

5. OPERATION

WARNING! Ensure you have read, understood and apply the safety instructions. This Tool is designed for riveting metal, primarily in

workshops and garages. We do not recommend any other use.

5.1. FILLING WITH HYDRAULIC OIL (Check each time before use).

5.1.1. Disconnect the tool from the air line.

5.1.2. Hold the tool upside-down and remove the air cylinder cap with a spanner.

5.1.3. Remove piston set.

5.1.4. Pump hydraulic oil into hydraulic cylinder until it overflows from the cylinder neck, (fig 3) and wipe any excess oil away with a dry cloth.

5.1.5. Insert hydraulic plunger into cylinder and press it in slightly.

5.1.6. Reverse above procedure to reassemble. Slightly lubricate the inside wall of the air cylinder.

5.2. ADJUSTING THE STROKE

5.2.1. Check that the hydraulic level is at its maximum (see 4.1).

5.2.2. Check the jaw stroke by using the supplied wrench/gauge as in figure 4, and adjust if necessary (there is a 5mm tolerance).

5.2.3. Hold the jaw case in place with a spanner and loosen the lock nut with the spanner gauge supplied. Adjust the distance between them

as required.

5.2.4. Tighten the lock nut when adjustment is complete.

5.3. CHANGING JAWS

5.3.1. Disconnect the tool from the air line.

5.3.2. Use a spanner to remove the frame head.

5.3.3. Use both spanners to unscrew the jaw case.

5.3.4. Remove the jaws and clean with solvent or a brush. If the teeth are blunted, replace with new jaws. Use genuine Sealey jaws only.

5.3.5. Reverse the above procedure to reassemble.

5.4. OPERATION

5.4.1. Be sure to select the correct nosepiece and rivet for the job.

5.4.2. Insert the rivet into the nosepiece.

5.4.3. Direct the nosepiece at the pre-drilled hole and squeeze the trigger.

3

fig.

© Jack Sealey Limited

Note: Wrench/gauge design may differ from

above. See spare parts diagram.

4

fig.

Original Language Version

SA314.V4 Issue: 2(H,F) 01/06/18

6. MAINTENANCE

WARNING! Ensure you disconnect the tool from the air supply system before attempting any service or maintenance.

6.1. Maintain the tool with care. Keep it oiled for optimum performance.

6.2. Lubricate the air tool daily with a high quality air tool oil, (Sealey model no. ATO/500 or ATO/1000).

6.3. Store the tool in a safe, dry, secure environment.

6.4. Factors that may inhibit performance:

Loss of power or erratic action may be caused by reduced compressor output, an excessive drain on the air line, moisture or

restrictions in air pipes or the use of hose connections of improper size. Grit or gum deposits in the tool may cut power and can

be corrected by cleaning the air strainer and flushing out the tool with gum solvent oil or an equivalent de-greaser. If all outside

conditions are in order, disconnect the tool from the air supply, disassemble and replace any worn or damaged parts with

Sealey original parts. Clean all parts, reassemble the tool and lubricate as described above. Alternatively, take the tool to your nearest

authorised service agent.

WARNING! – Risk of Hand Arm Vibration Injury.

This tool may cause Hand Arm Vibration Syndrome if its use is not managed adequately.

This tool is to be operated in accordance with these instructions.

Measured vibration emission value (a): 10.9m/s²

Uncertainty value (k): 4.36m/s²

Please note that the application of the tool to a sole specialist task may produce a different average vibration emission. We recommend that a

specific evaluation of the vibration emission is conducted prior to commencing with a specialist task.

A health and safety assessment by the user (or employer) will need to be carried out to determine the suitable duration of use for each tool.

NB: Stated Vibration Emission values are type-test values and are intended to be typical.

Whilst in use, the actual value will vary considerably from and depend on many factors.

Such factors include; the operator, the task and the inserted tool or consumable.

NB: ensure that the length of leader hoses is sufficient to allow unrestricted use, as this also helps to reduce vibration.

The state of maintenance of the tool itself is also an important factor, a poorly maintained tool will also increase the risk of Hand Arm Vibration

Syndrome.

ENVIRONMENT PROTECTION

Recycle unwanted materials instead of disposing of them as waste. All tools, accessories and packaging should be sorted, taken to

a recycling centre and disposed of in a manner which is compatible with the environment. When the product becomes completely

unserviceable and requires disposal, drain any fluids (if applicable) into approved containers and dispose of the product and fluids

according to local regulations.

Note: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior

notice.

Important: No Liability is accepted for incorrect use of this product.

Warranty: Guarantee is 12 months from purchase date, proof of which is required for any claim.

Sealey Group, Kempson Way, Suffolk Business Park, Bury St Edmunds, Suffolk. IP32 7AR

01284 757500 01284 703534 sales@sealey.co.uk www.sealey.co.uk

© Jack Sealey Limited

Original Language Version

SA314.V4 Issue: 2(H,F) 01/06/18

Loading...

Loading...